Convenient pipeline connection inspection well

An inspection well and convenient technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems of time-consuming, labor-intensive, difficult to replace, and high replacement cost, and achieve simple pipeline connection and convenient operation. , The effect of convenient maintenance and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

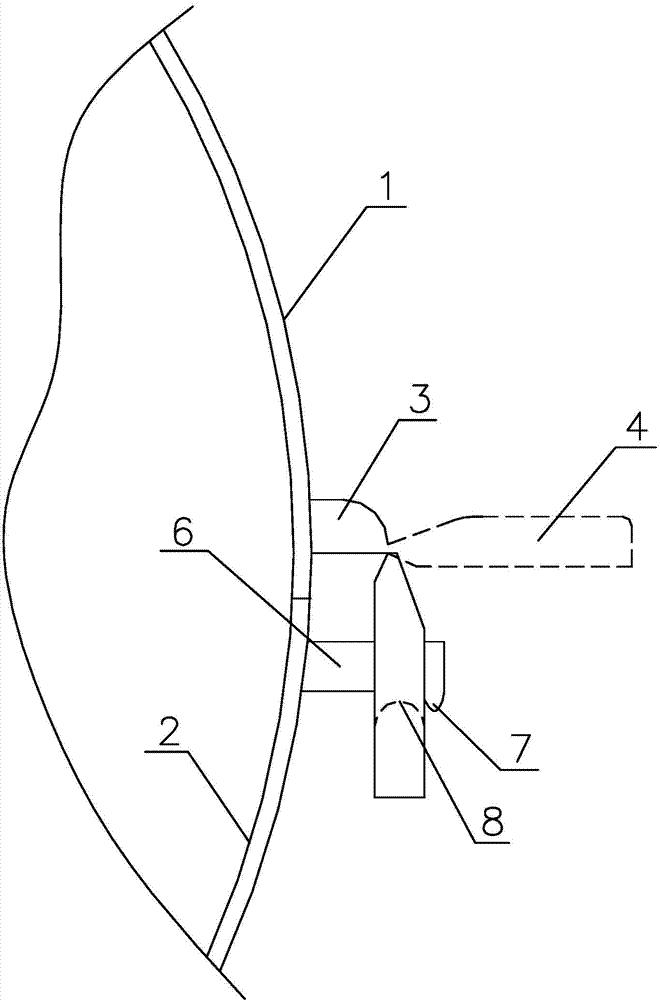

[0017] Such as figure 1 with 2 , Including upper socket 1 and lower socket 2, the outer wall of the upper socket 1 has a number of buckles evenly distributed in the circumferential direction, and the outer wall of the lower socket 2 has fasteners corresponding to the buckles. The mouth 1 and the lower socket 2 are hermetically connected by the closure of the buckle and the fastener.

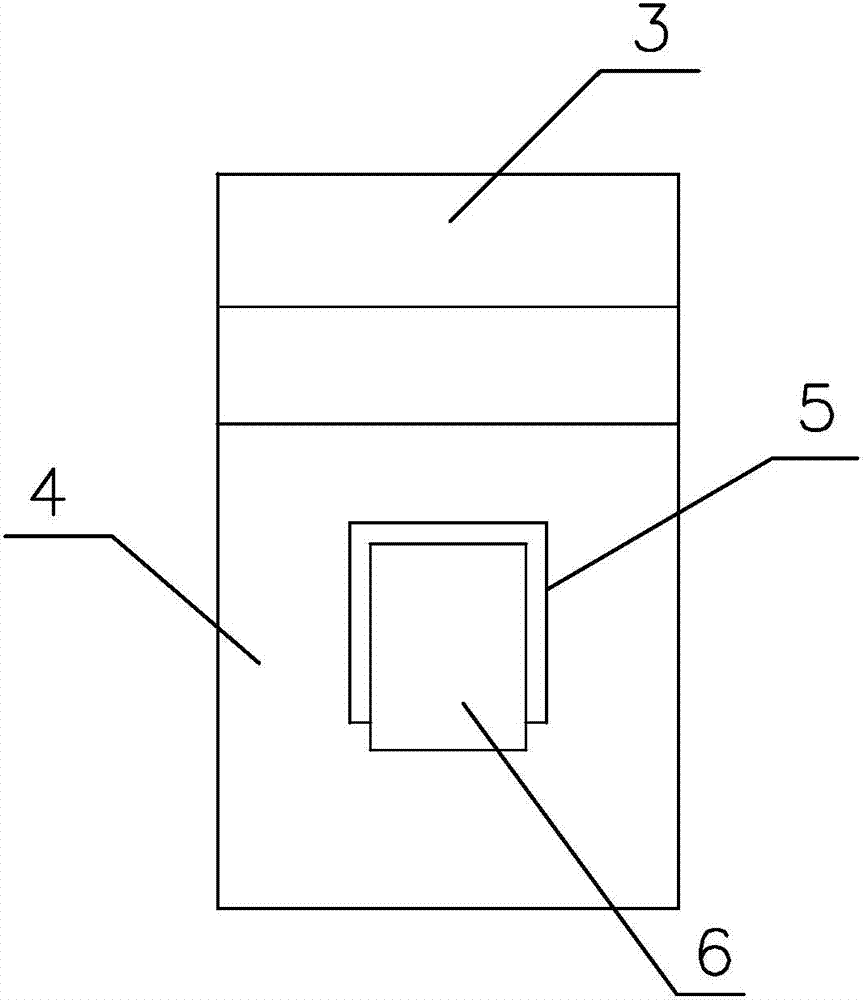

[0018] The buckle includes a fixing plate 3 fixed to the upper socket 1 and a flap 4 rotatably connected to the fixing plate 3. A window hole 5 is opened in the middle of the flap 4, and the fastener includes a protrusion fixed to the lower socket 2. 6. A hook 7 is provided on the surface of the head of the protrusion 6 away from the mouth of the lower socket 2. The bottom of the window hole 5 has a connecting portion 8 with a semicircular cross section. When the flap 4 is turned down, the protrusion 6 passes through The window hole 5 and the hook portion 7 of the protrusion 6 are buckled with the c...

Embodiment 2

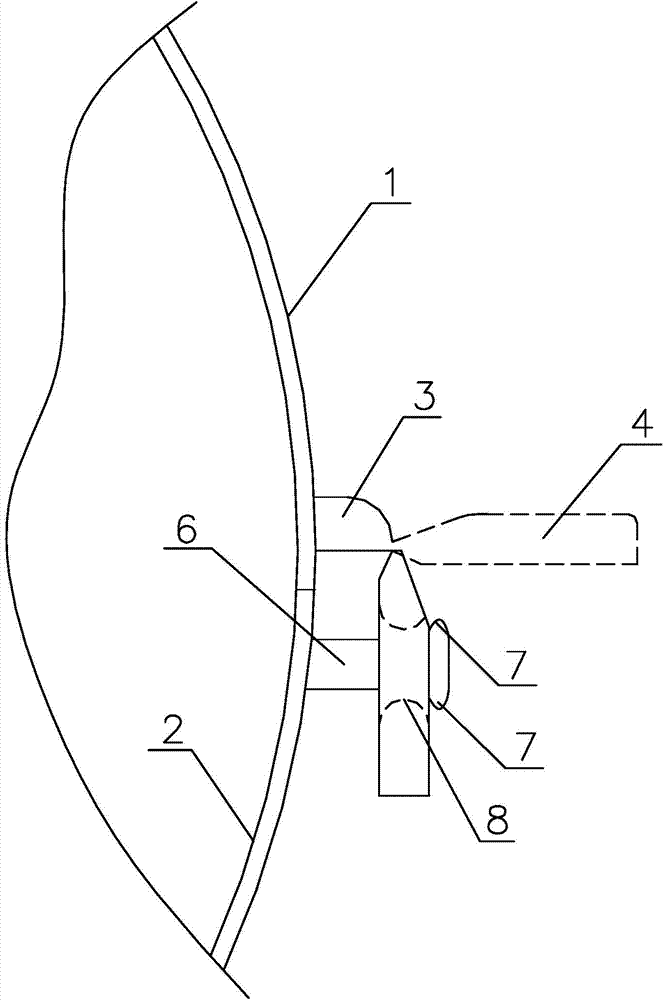

[0020] Such as image 3 with 4 The difference from embodiment 1 is that: the top of the window hole 5 also has a connecting portion 8 with a semicircular cross-section, a hook 7 is also provided on the surface of the head of the protrusion 6 near the mouth of the lower socket 2, and a flap 4 When turning down, the hooks 7 at the upper and lower positions of the protrusion 6 and the connecting parts at the upper and lower positions of the window hole 5 are buckled with each other.

[0021] When the two pipes are connected, the flap 4 is turned down, and the protrusion 6 at the lower socket 2 will pass through the window hole 5. Since the connecting portion 8 of the window hole 5 is semicircular, then it is connected to the hook 7 The connection will be smooth without interference, the whole connection process has no technical difficulty, the operation is simple, and the installation and maintenance are very convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com