Electro-hydraulic co-rotating joint

A technology of rotating joints and common bodies, which is applied in the direction of rotating current collectors, circuits, current collectors, etc., can solve the problems of large volume, difficulty in realizing rotating joints, and difficulty in ensuring rotation accuracy, etc., and achieves small size, reduced quantity and volume , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

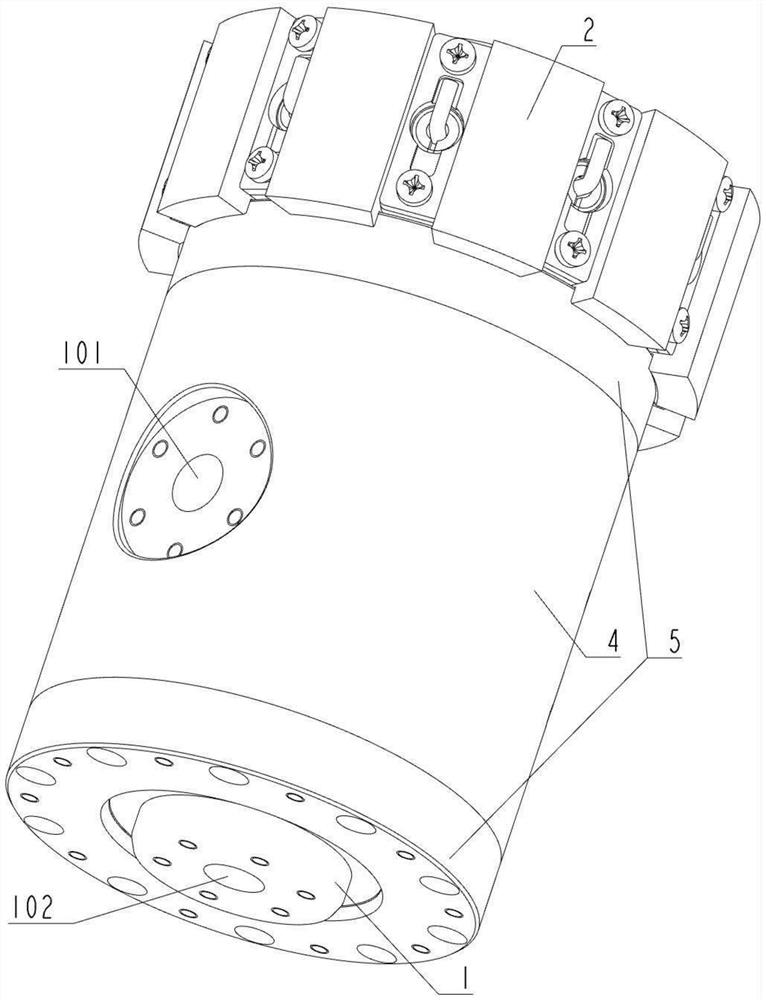

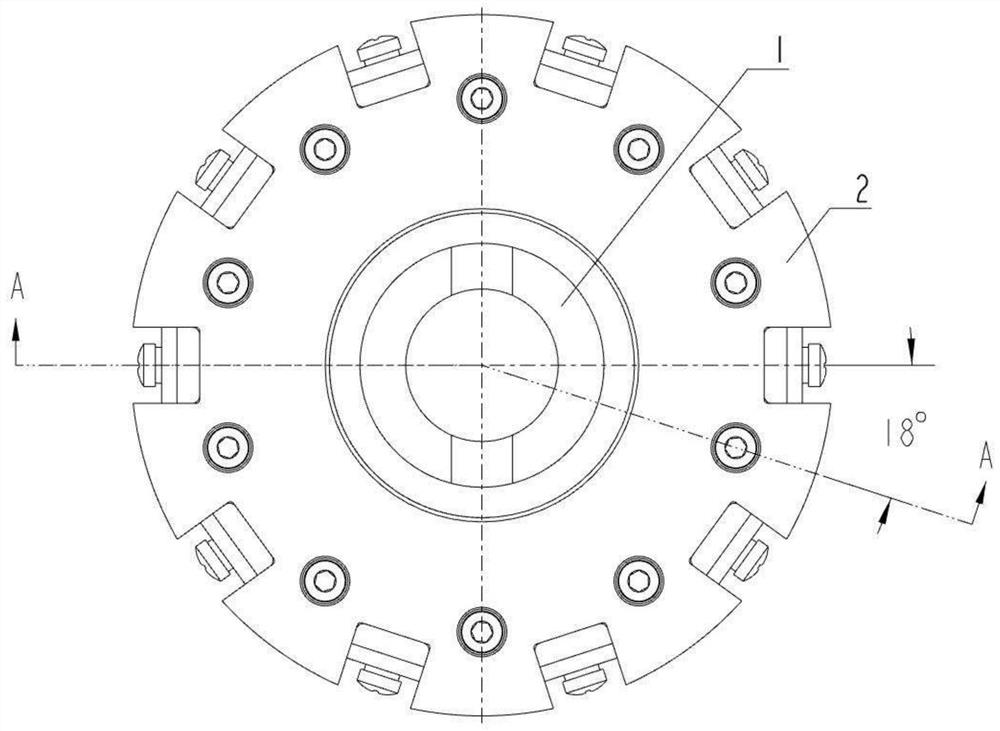

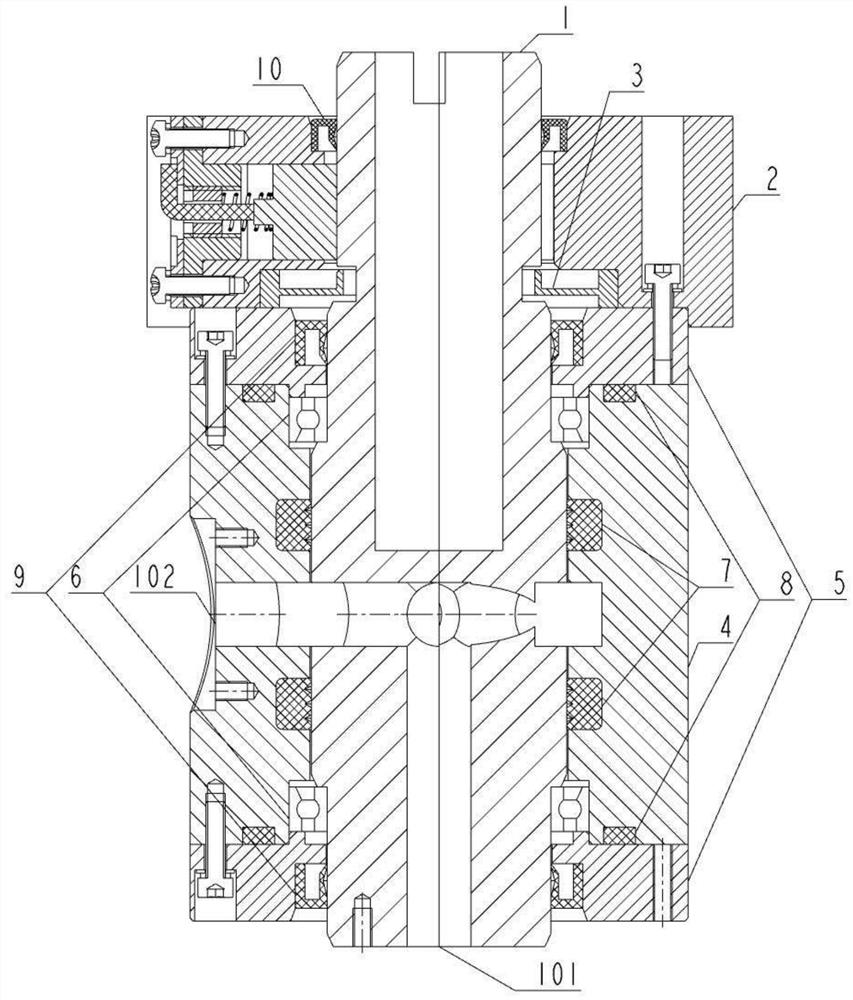

[0023] Such as Figure 1 to Figure 5 as shown, figure 1 It is a three-dimensional structure diagram of the electro-hydraulic body rotary joint; figure 2 It is a top view of the structure of the electro-hydraulic body rotary joint; image 3 for figure 2 The cross-sectional view of A-A in the middle; Figure 4 It is a three-dimensional structure diagram of the brush assembly;

[0024] Figure 5 It is a cross-sectional view of the brush assembly. The electro-hydraulic integrated rotary joint of the present invention includes an inner ring 1 and an outer ring arranged on the outer surface of the inner ring 1 , and the inner ring 1 and the outer ring can rotate relative to each other.

[0025] The outer ring includes a brush assembly 2, a powder receiving tray 3, a sealing housing 4 and a bearing retai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com