Patents

Literature

62results about How to "Synchronous cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic part polishing and burnishing method

InactiveCN108032223AAvoid problems that damage workpiece accuracyAvoid deformationRevolution surface grinding machinesGrinding drivesEngineeringMachining

The invention relates to the field of machining of car plastic parts and particularly discloses a plastic part polishing and burnishing method. The plastic part polishing and burnishing method comprises the following steps that firstly, plastic part polishing and burnishing equipment needing to be used is prepared; secondly, mounting is conducted, specifically, the plastic part polishing and burnishing equipment is mounted according to demands; thirdly, a plastic part is clamped; fourthly, the plastic part is polished and burnished; fifthly, plastic part polishing blocks are cooled; and sixthly, residues are removed after the plastic part is polished. According to the plastic part polishing and burnishing method, cleaning work of chippings after polishing can be conducted directly, and theproblem that the precision of a workpiece is damaged due to uneven manual polishing is avoided.

Owner:宁波鑫神泽汽车零部件有限公司

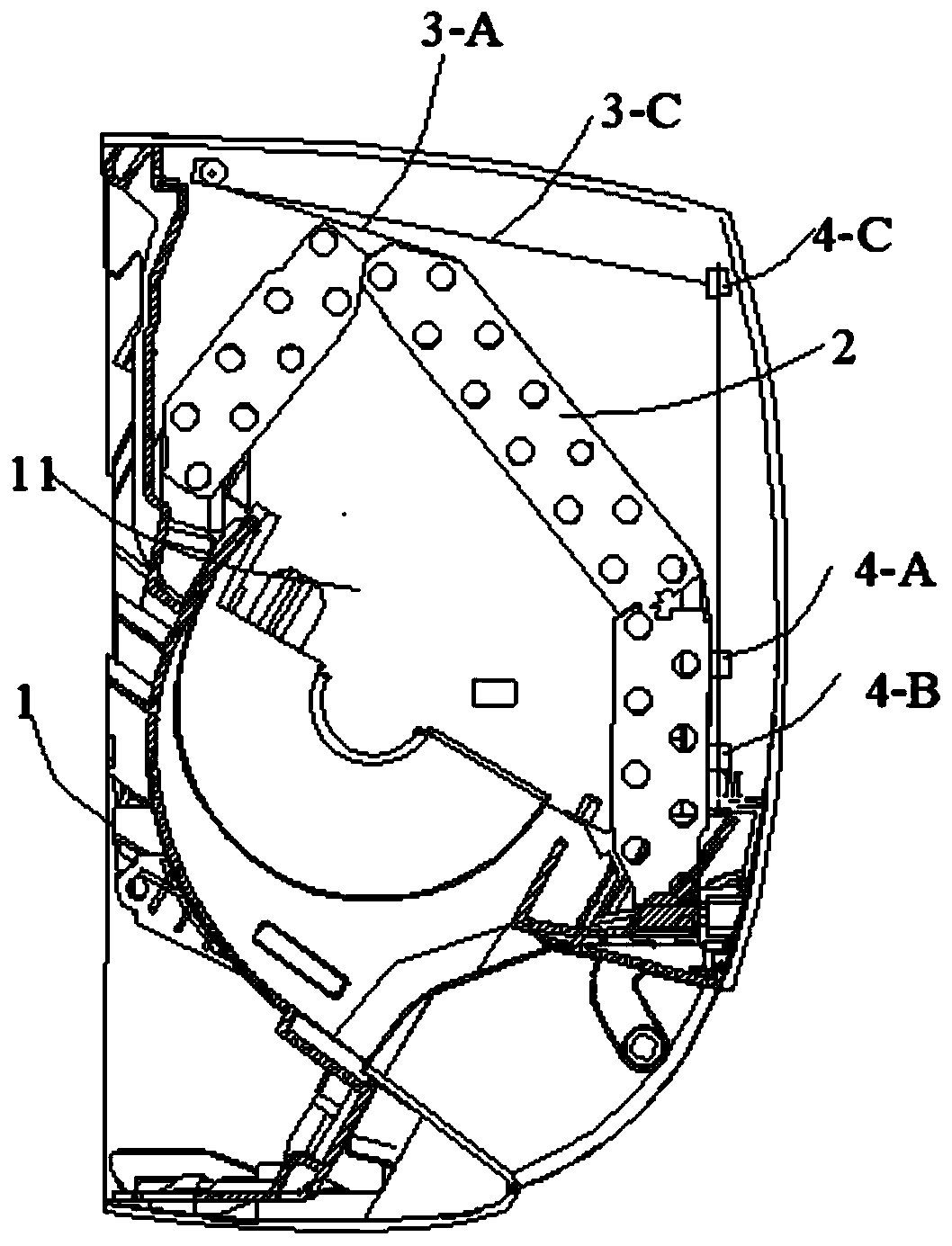

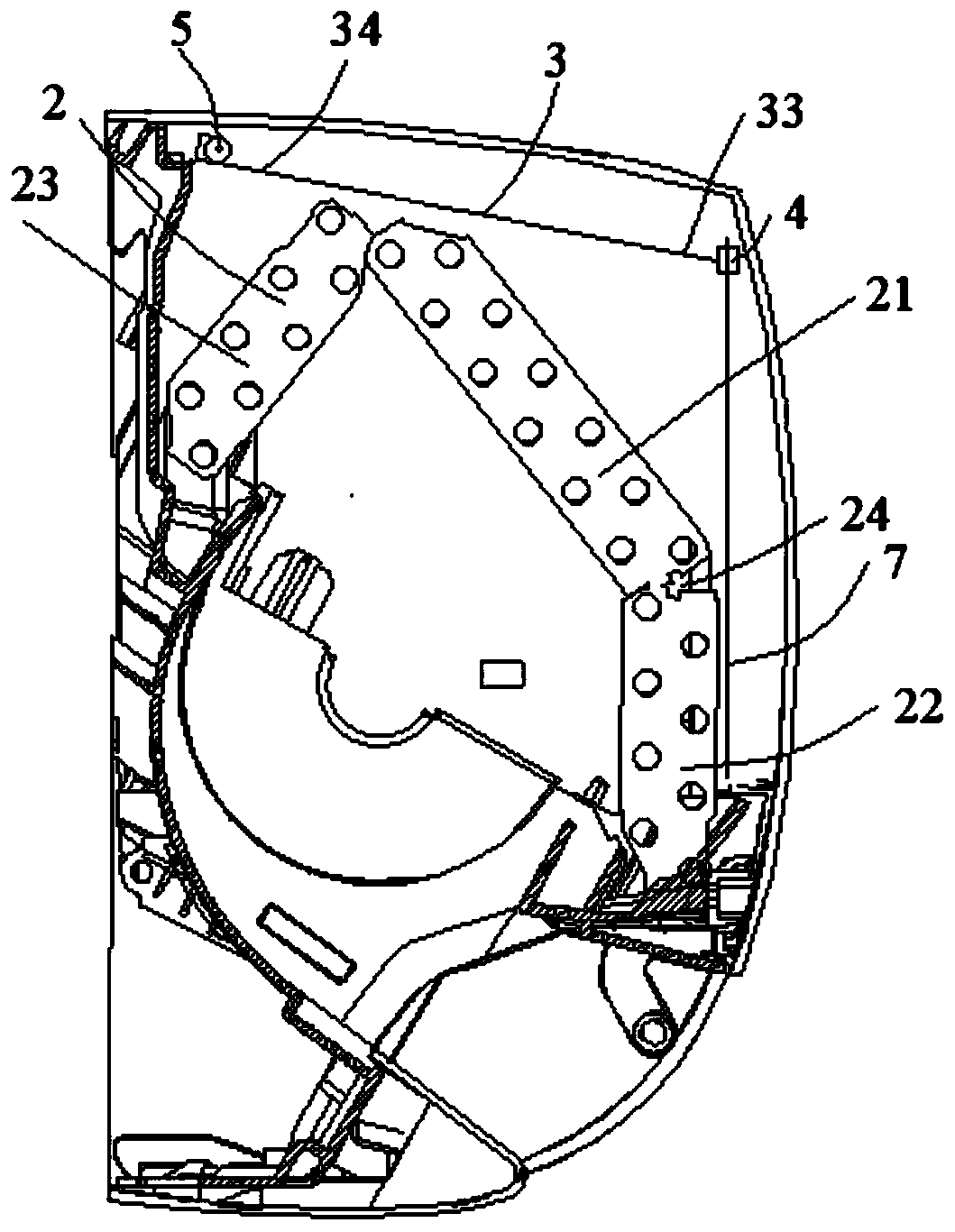

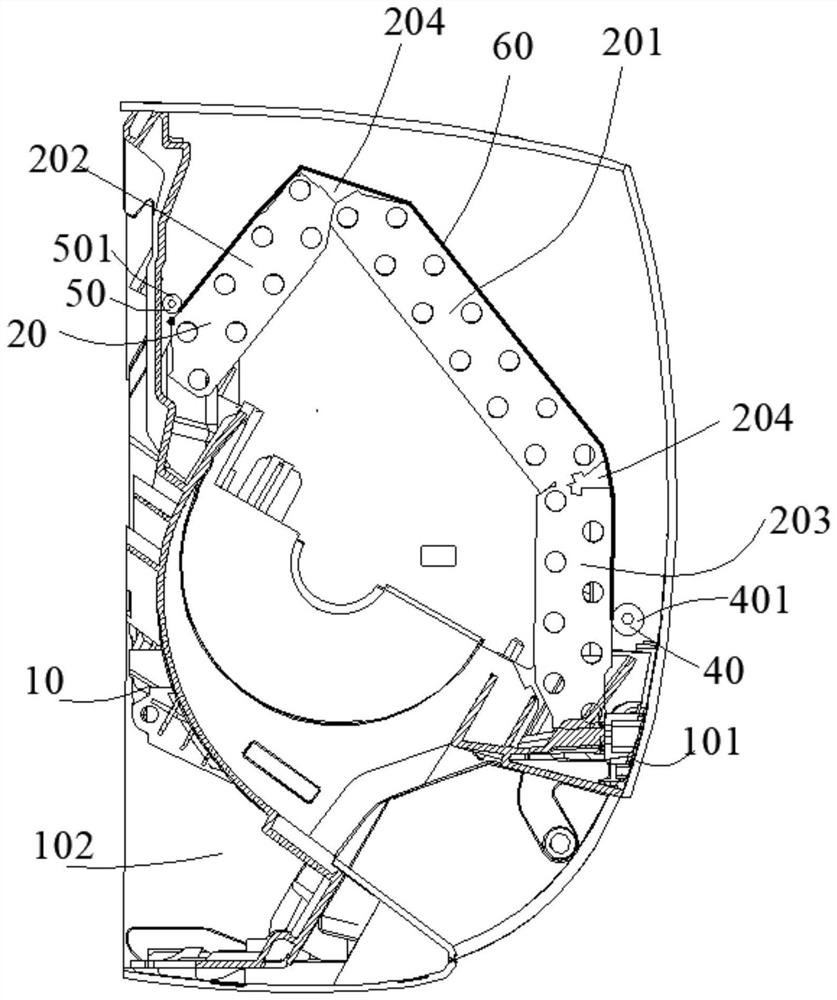

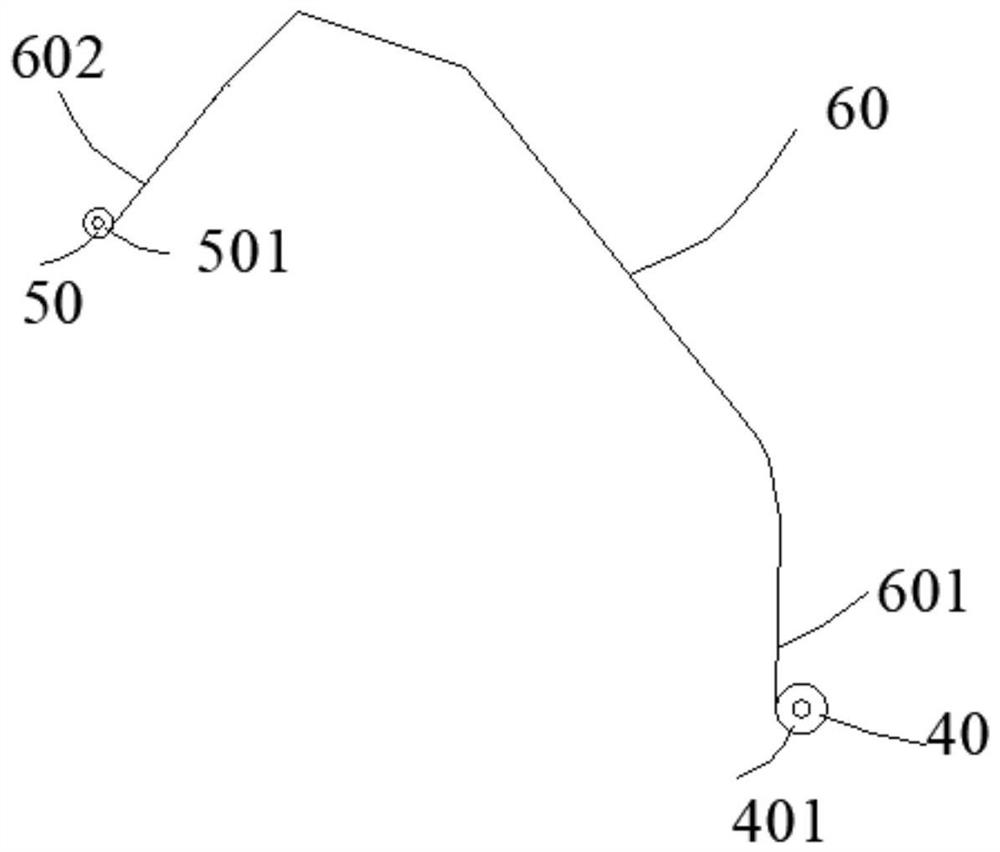

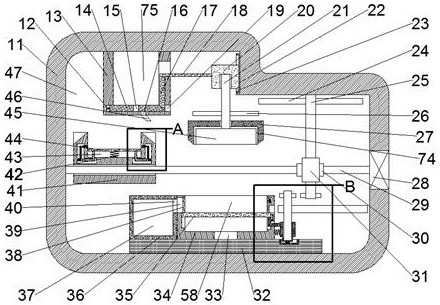

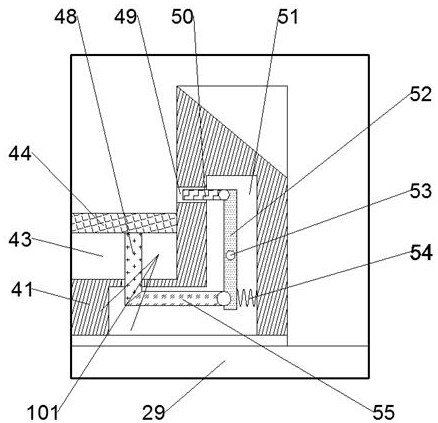

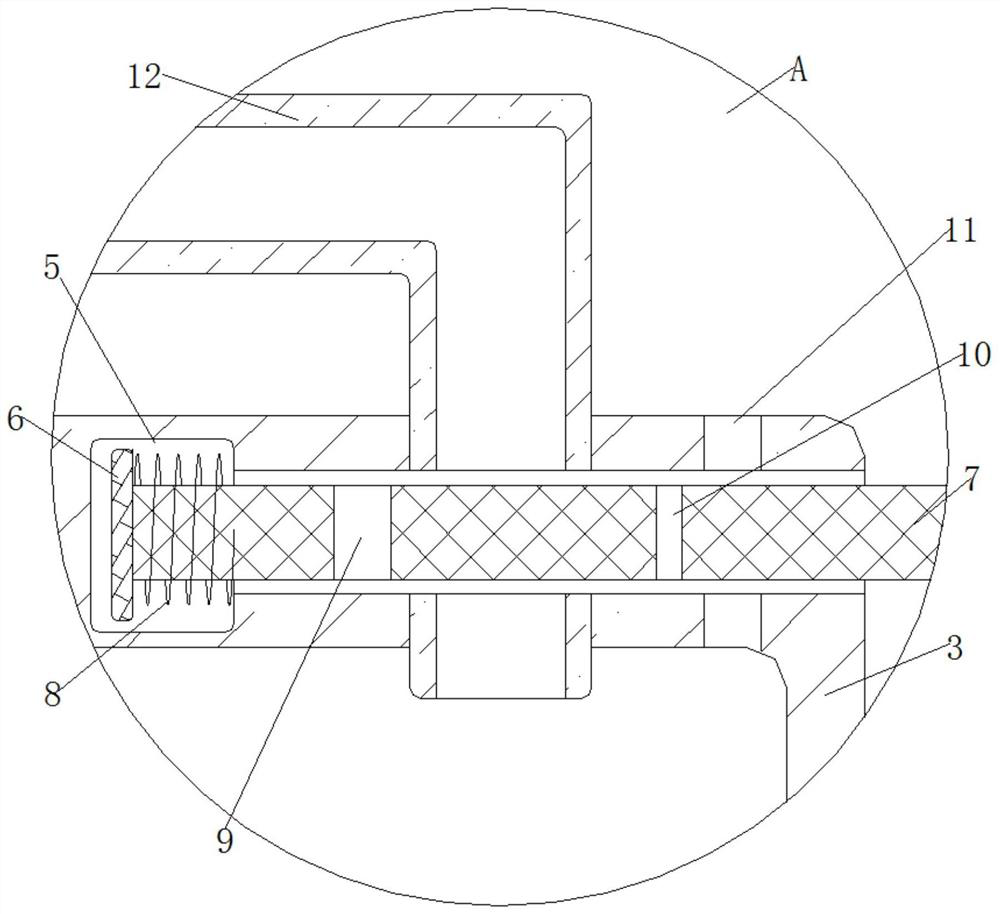

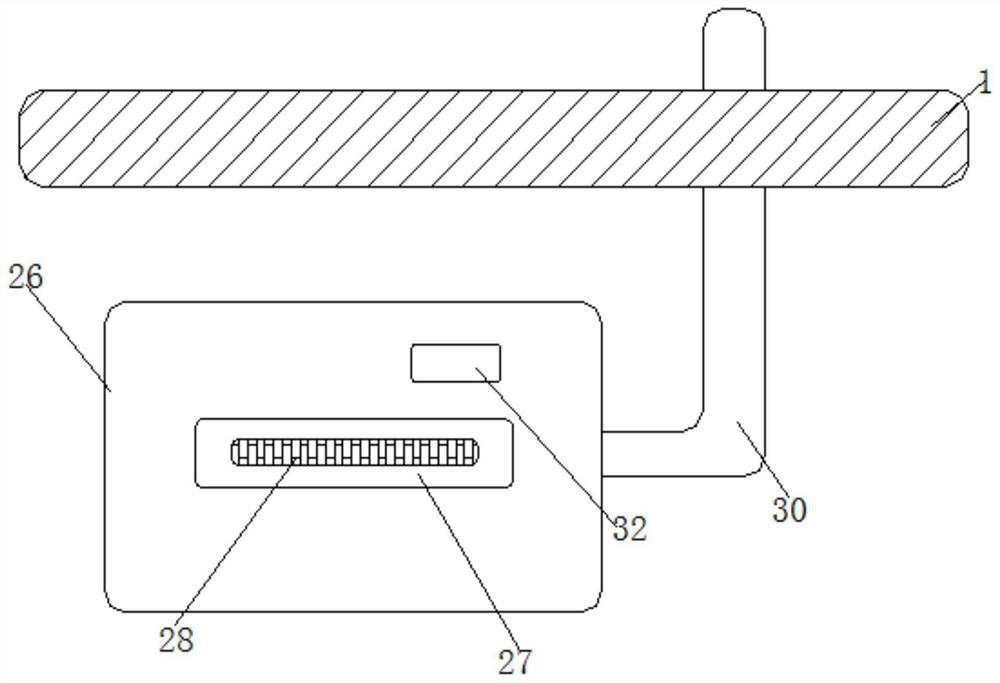

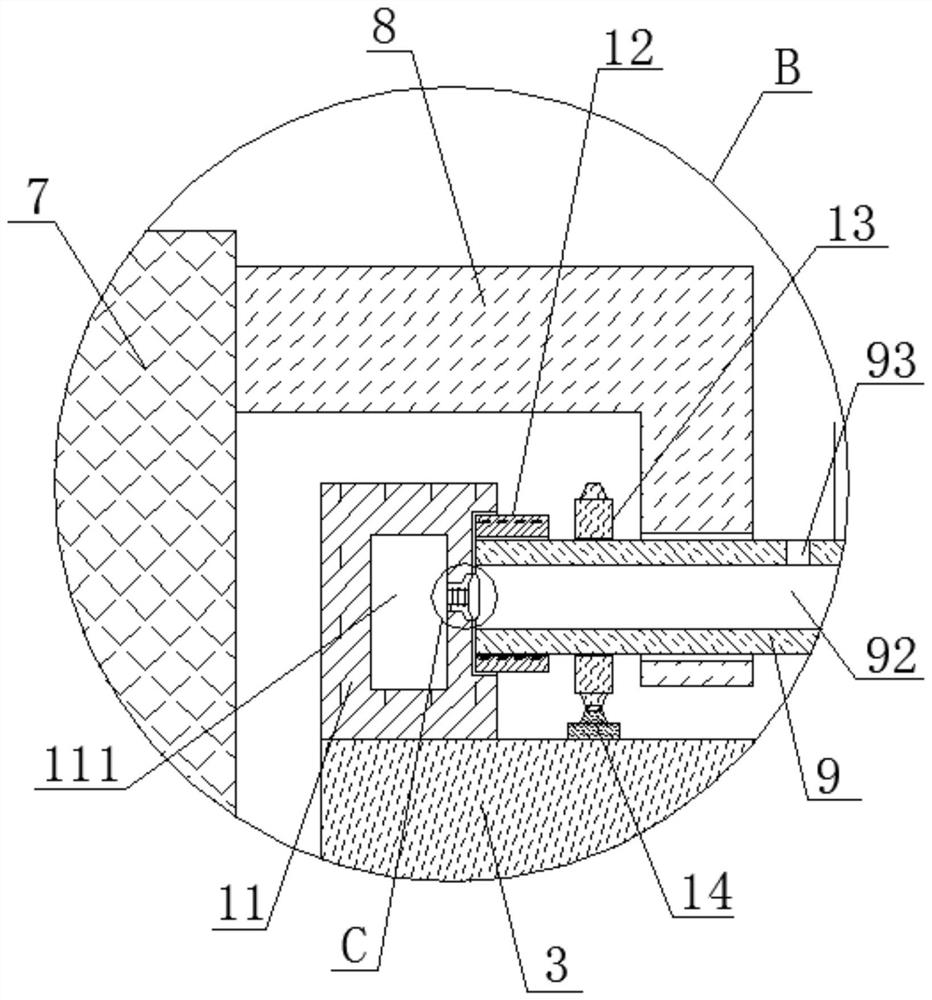

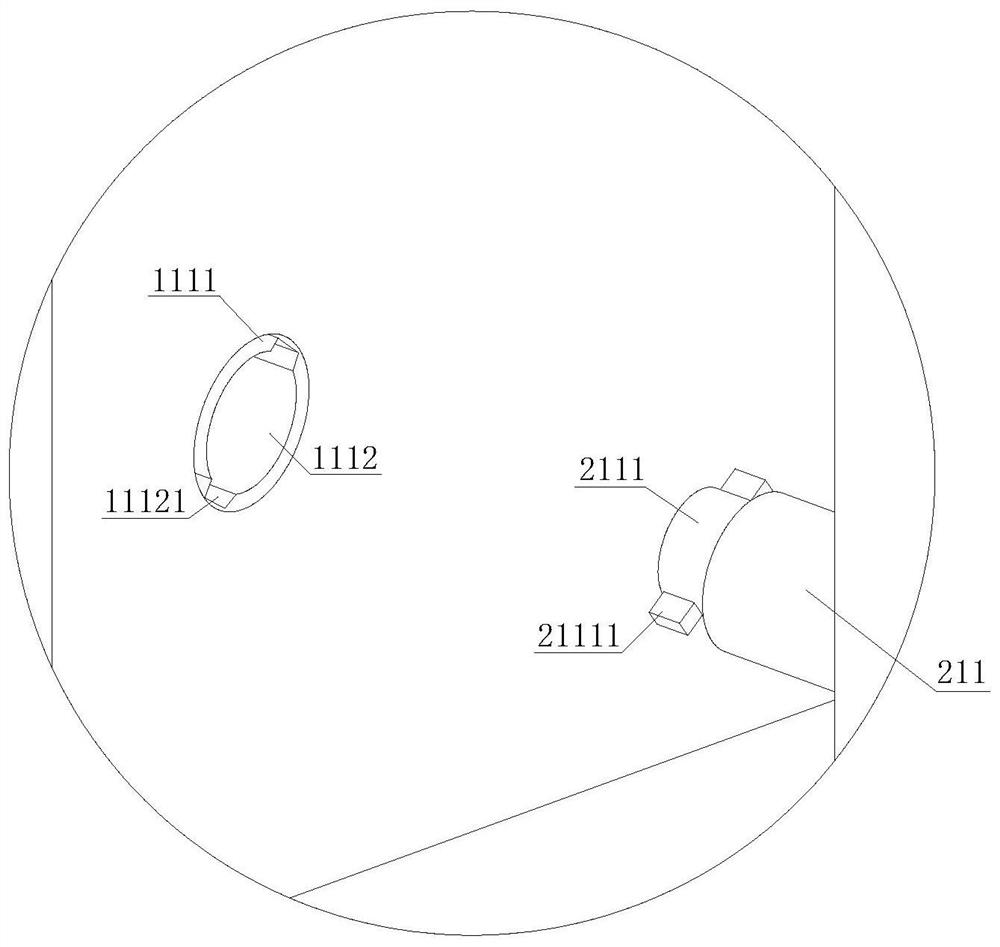

Safety protection intelligent door lock for smart home

ActiveCN109003379ARealize dustproofAchieve protectionIndividual entry/exit registersDaily operationFingerprint

The invention relates to the technical field of door locks, in particular to a safety protection intelligent door lock for a smart home. The door lock comprises a lock body, a fingerprint identifier main body, a cleaning mechanism, a driving mechanism and a control mechanism; an operation surface of fingerprint identification can be embedded into the lock body, so that the dustproof and waterproofprotection for a fingerprint identification probe is realized; when a finger of a user has water, the finger can be dragged obliquely and downwards along a sponge column, so that the water on the finger is absorbed by a top area of the sponge column; when the sponge column rotates around an installation plate, a bottom area of the sponge column also rotates, the water on the fingerprint identification probe is absorbed away and dust is wiped off, so that synchronous cleaning of the finger and the probe is realized, and the finger can be rapidly wiped to be dry and the fingerprint identification is performed under the condition that the finger has the water; and the cleaning mechanism can be quickly reset under the pushing of a spring, so that daily operation is not affected.

Owner:嘉兴管通机电科技有限公司

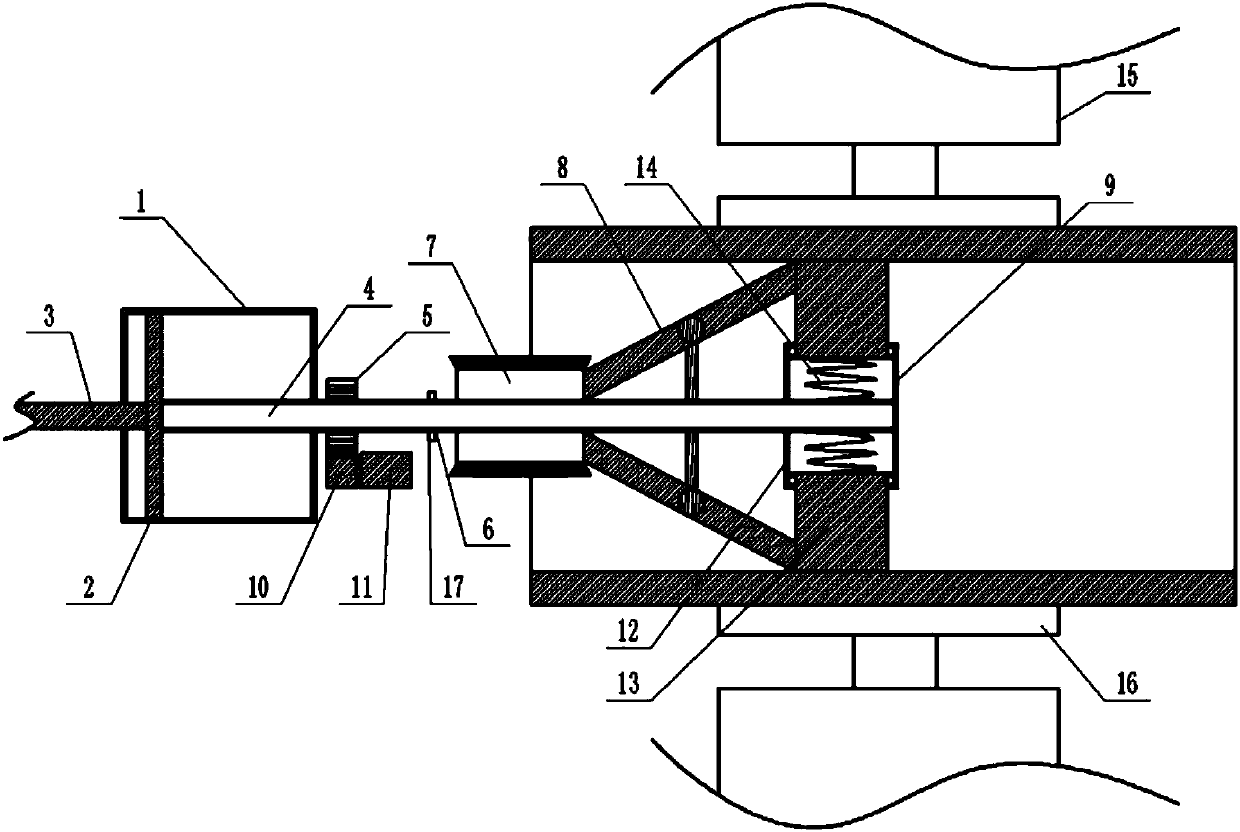

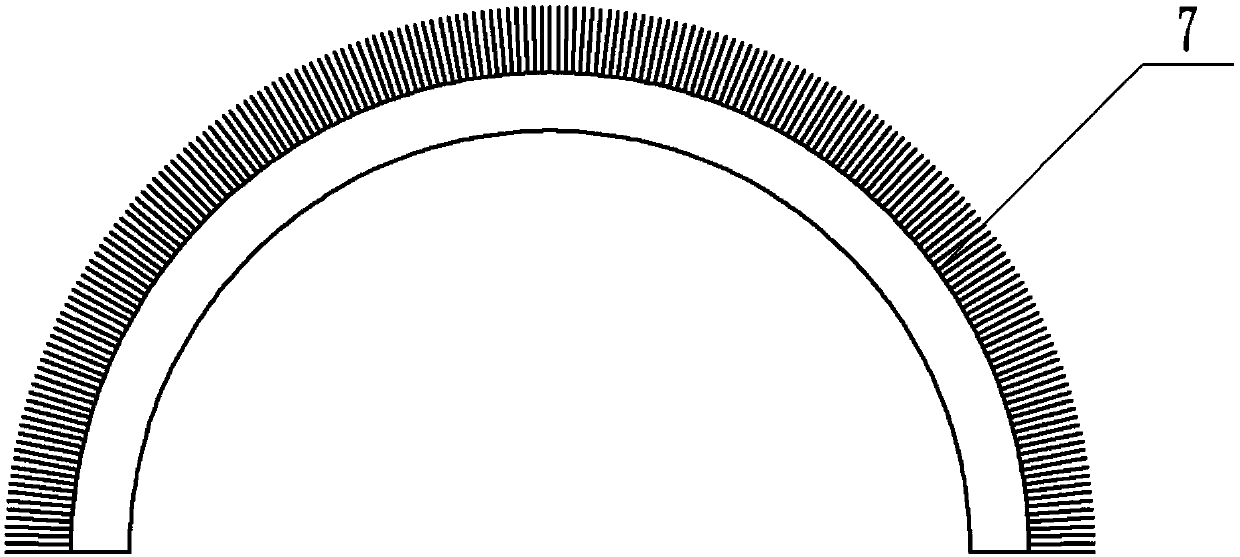

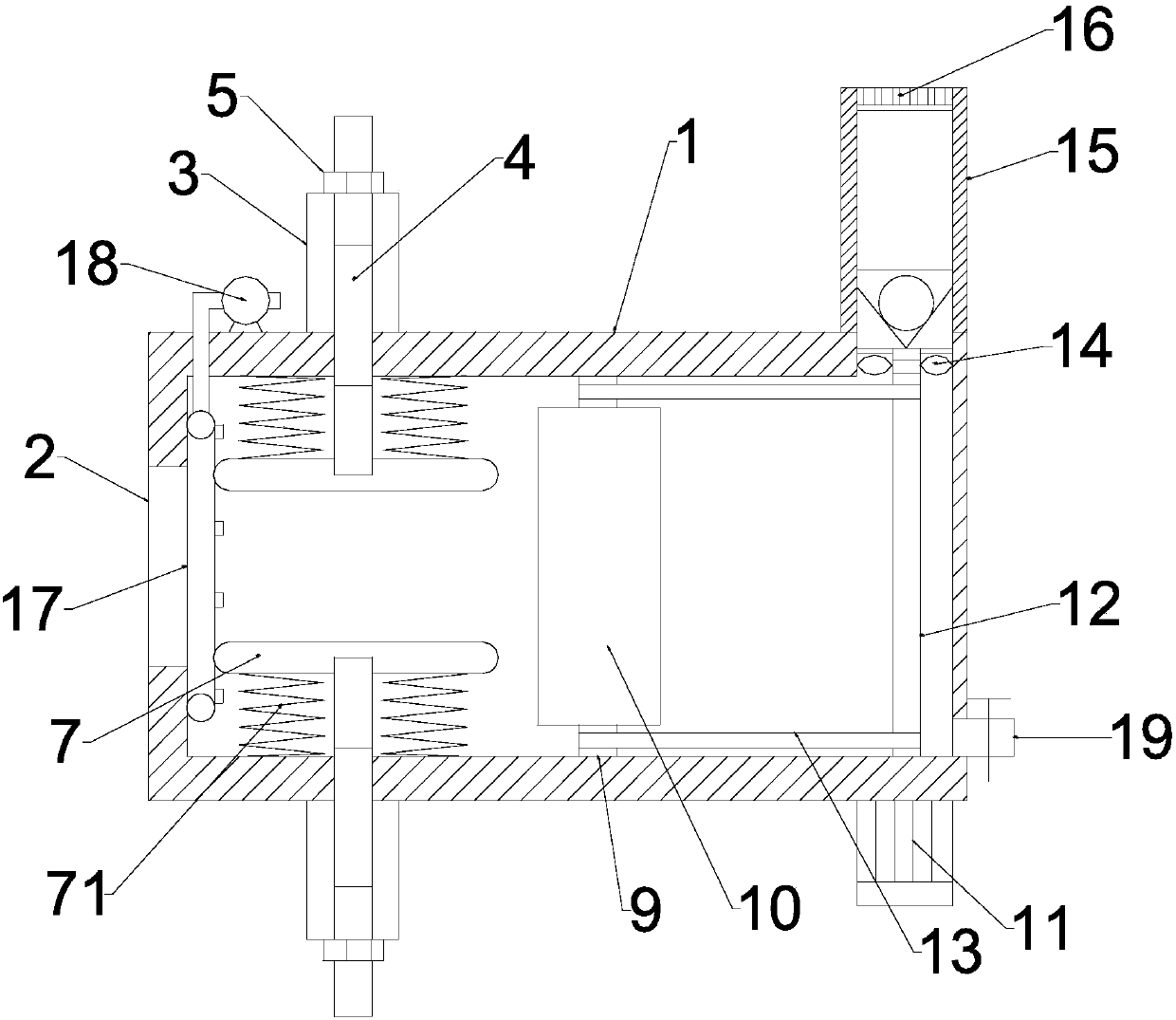

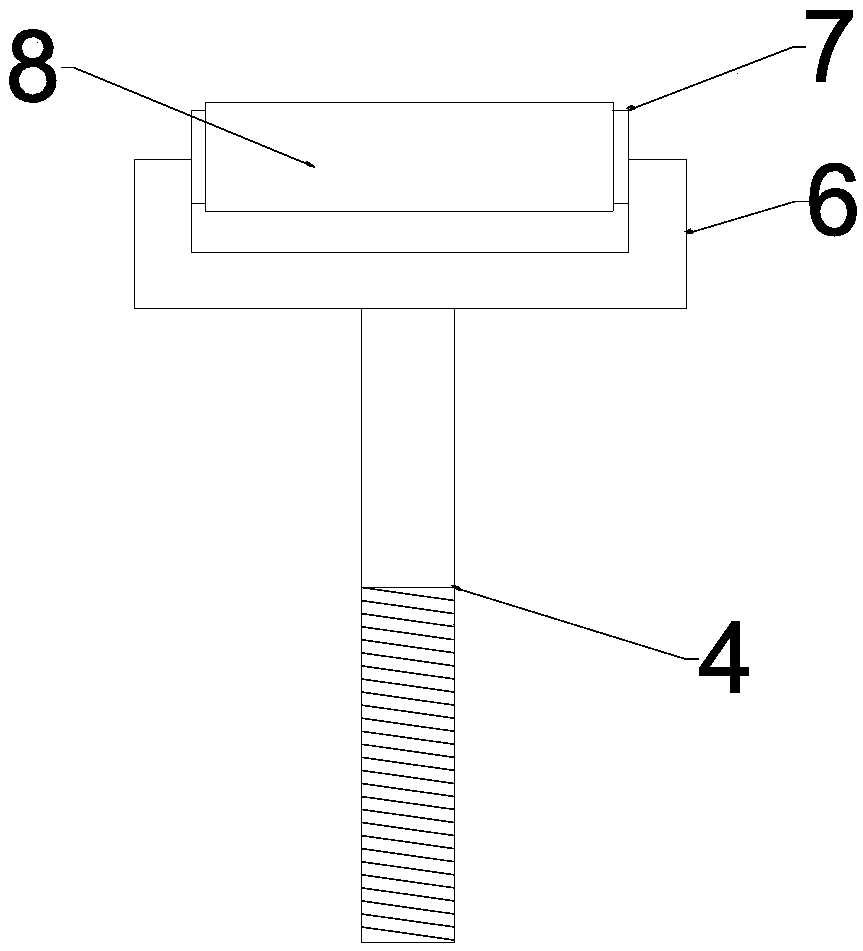

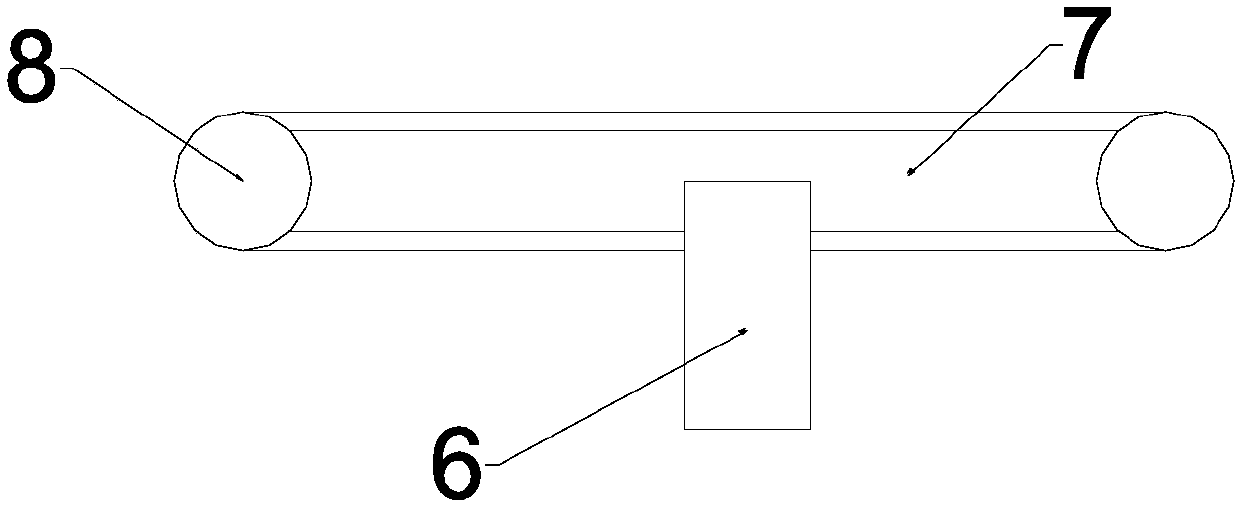

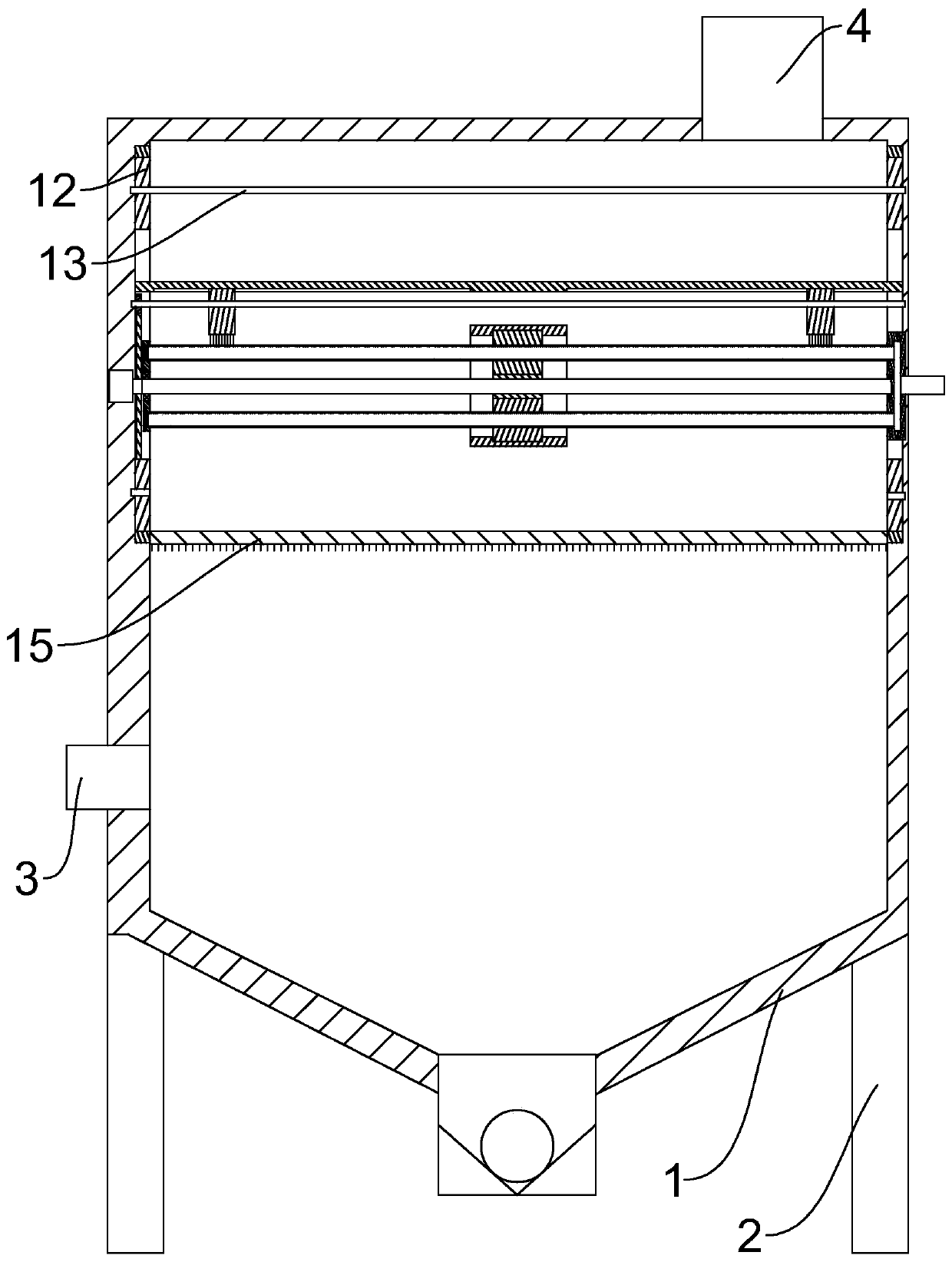

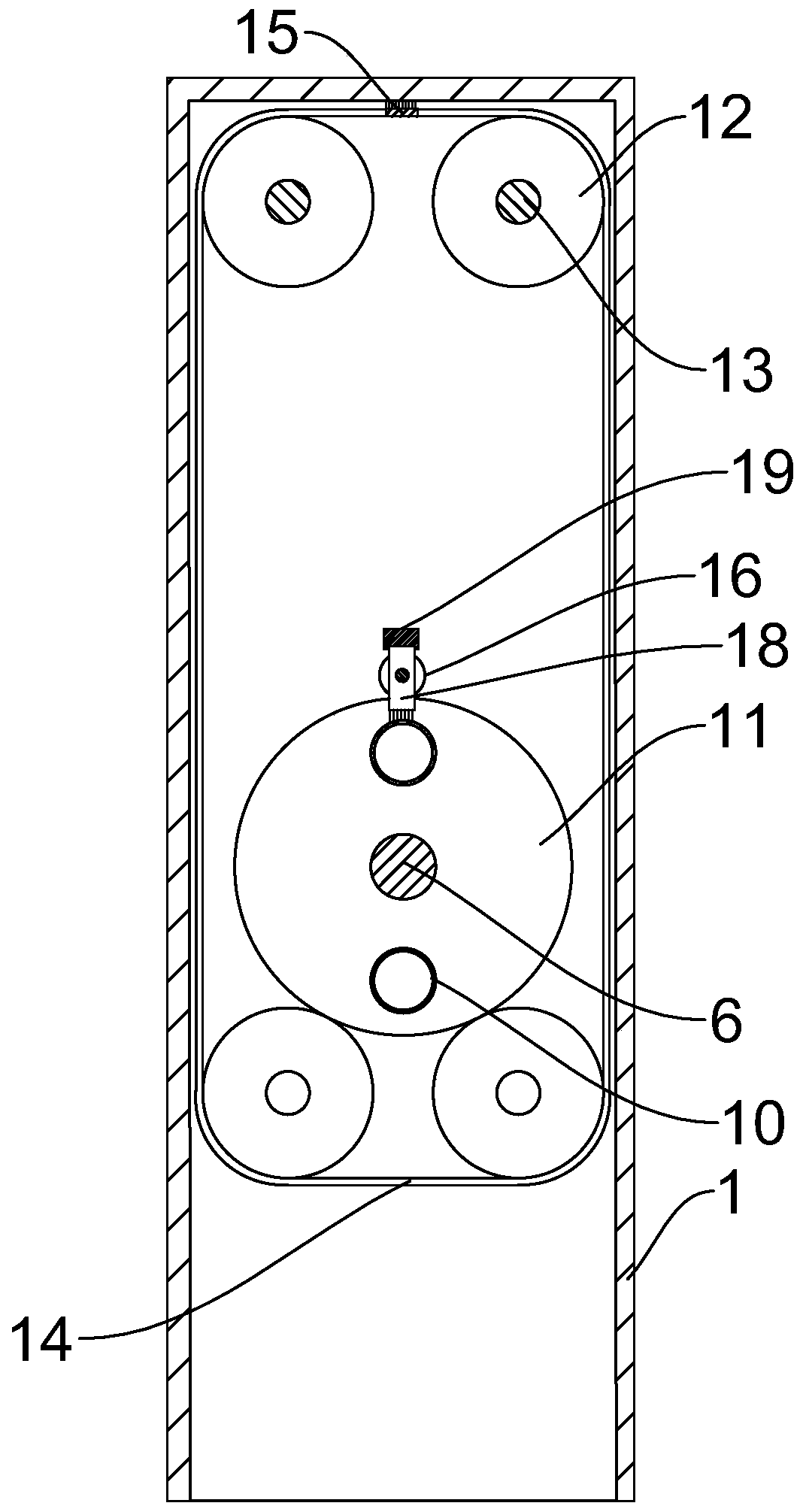

Pipe end face polishing device

InactiveCN107900812AWith damping effectSynchronous cleaningPlane surface grinding machinesGrinding/polishing safety devicesDrive shaftAir pump

The invention discloses a pipe end face polishing device which comprises a shell. A pipe feeding opening is formed in the left end of the shell. The left portion of the upper end and the left portionof the lower end of the shell are provided with pipe sleeves, thread rods, control nuts, U-shaped supporting plates, horizontal supporting plates, supporting springs and wheel axles. A rotating shaftand a polishing wheel axle are arranged on the middle portion of the inner wall of the shell. The right portion of the lower side of the shell is provided with a motor. A transmission shaft is arranged at the output end of the motor. A transmission belt is arranged between the periphery of the transmission shaft and the rotating shaft. The upper wall of the shell is provided with a dust collectingcylinder. Ventilating fan vanes are arranged at the upper end of the periphery of the transmission shaft. The dust collecting cylinder is provided with an air output cover. The left wall of the shellis provided with an air injecting pipe. An air pump is arranged on the left side of the upper end of the shell. The pipe end face polishing device can be pushed into a pipeline stably and machine theend face flexibly, and meanwhile impurities and tail gas can be cleaned fast and synchronously.

Owner:季元吉

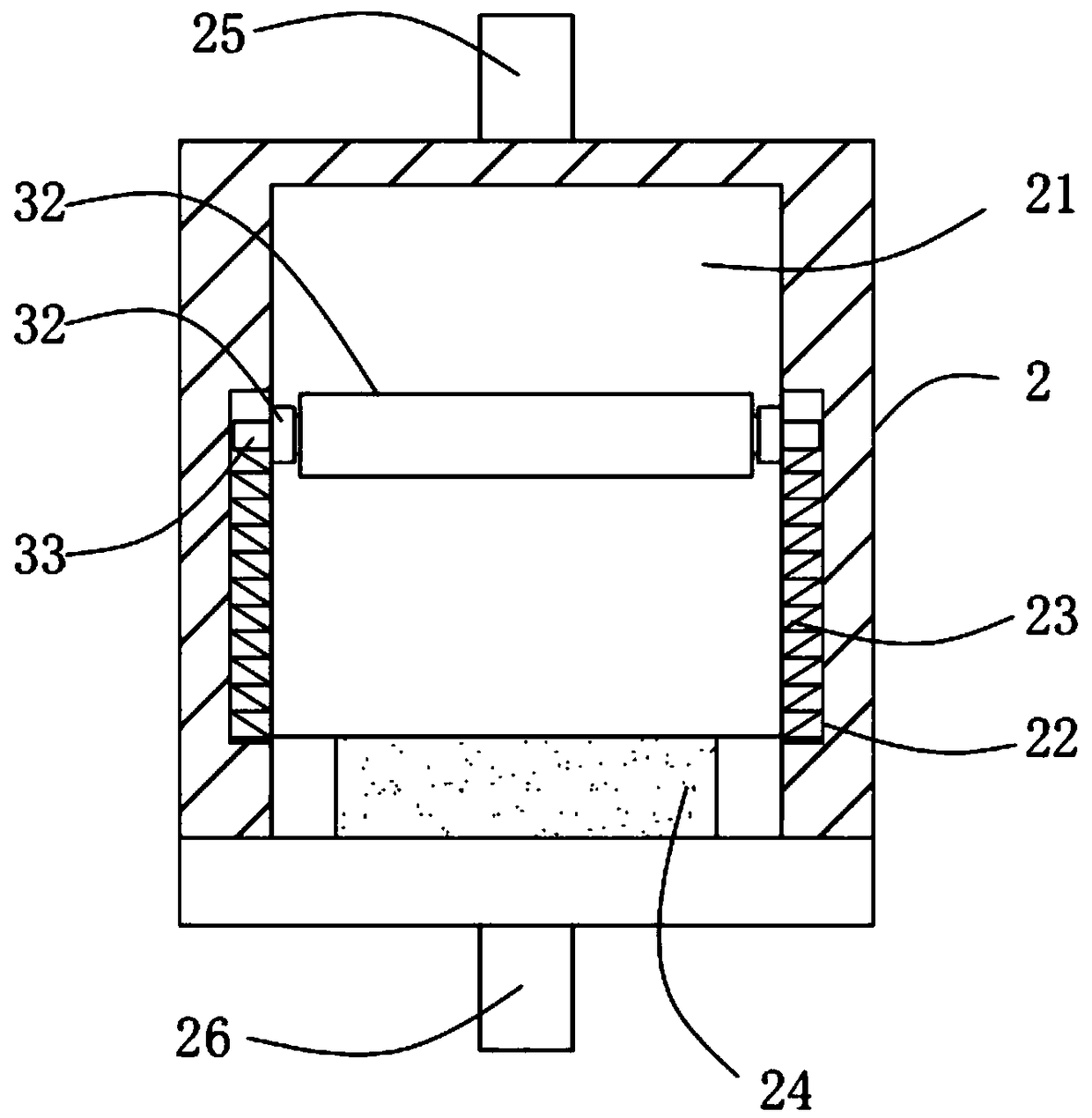

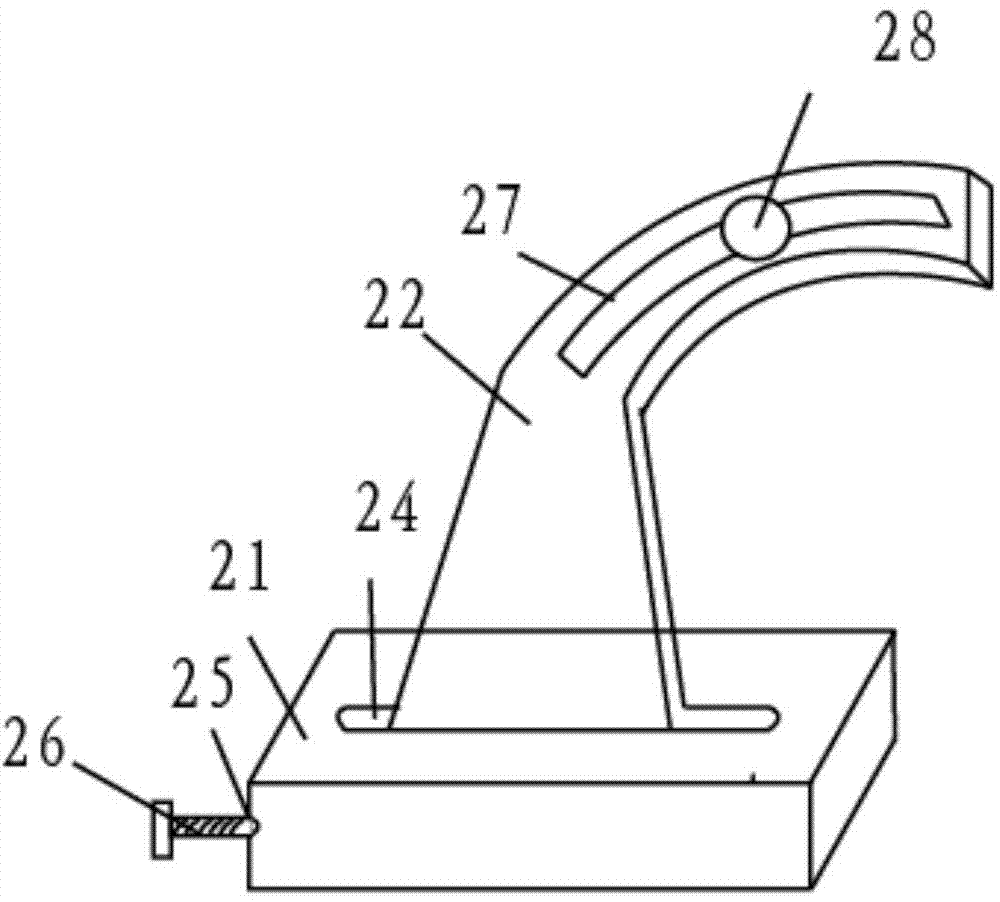

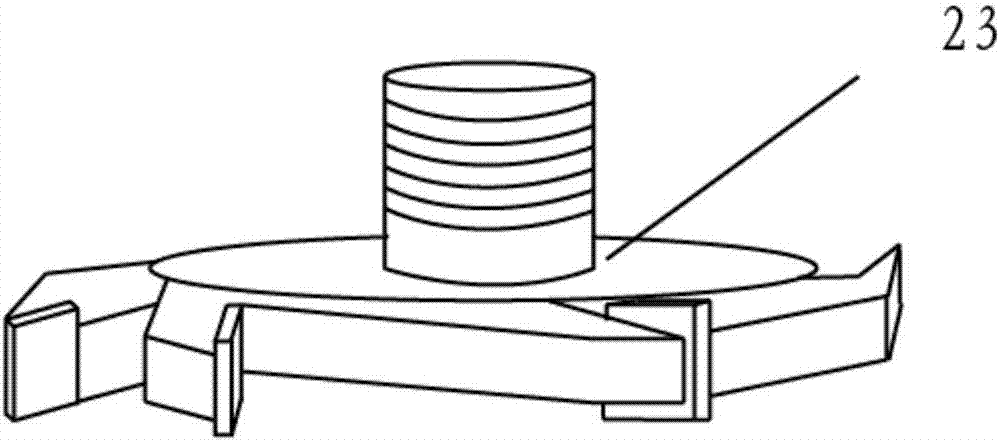

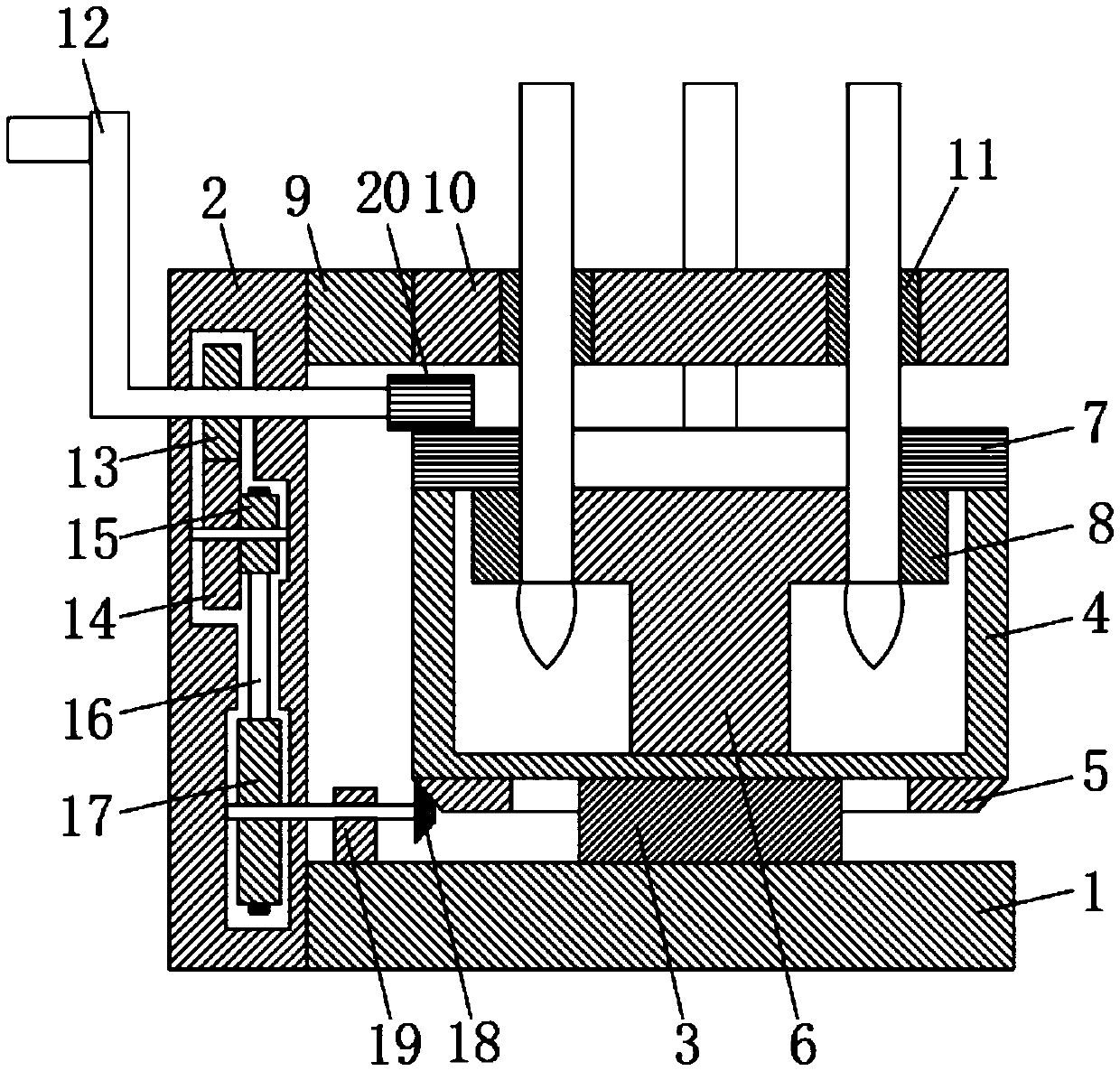

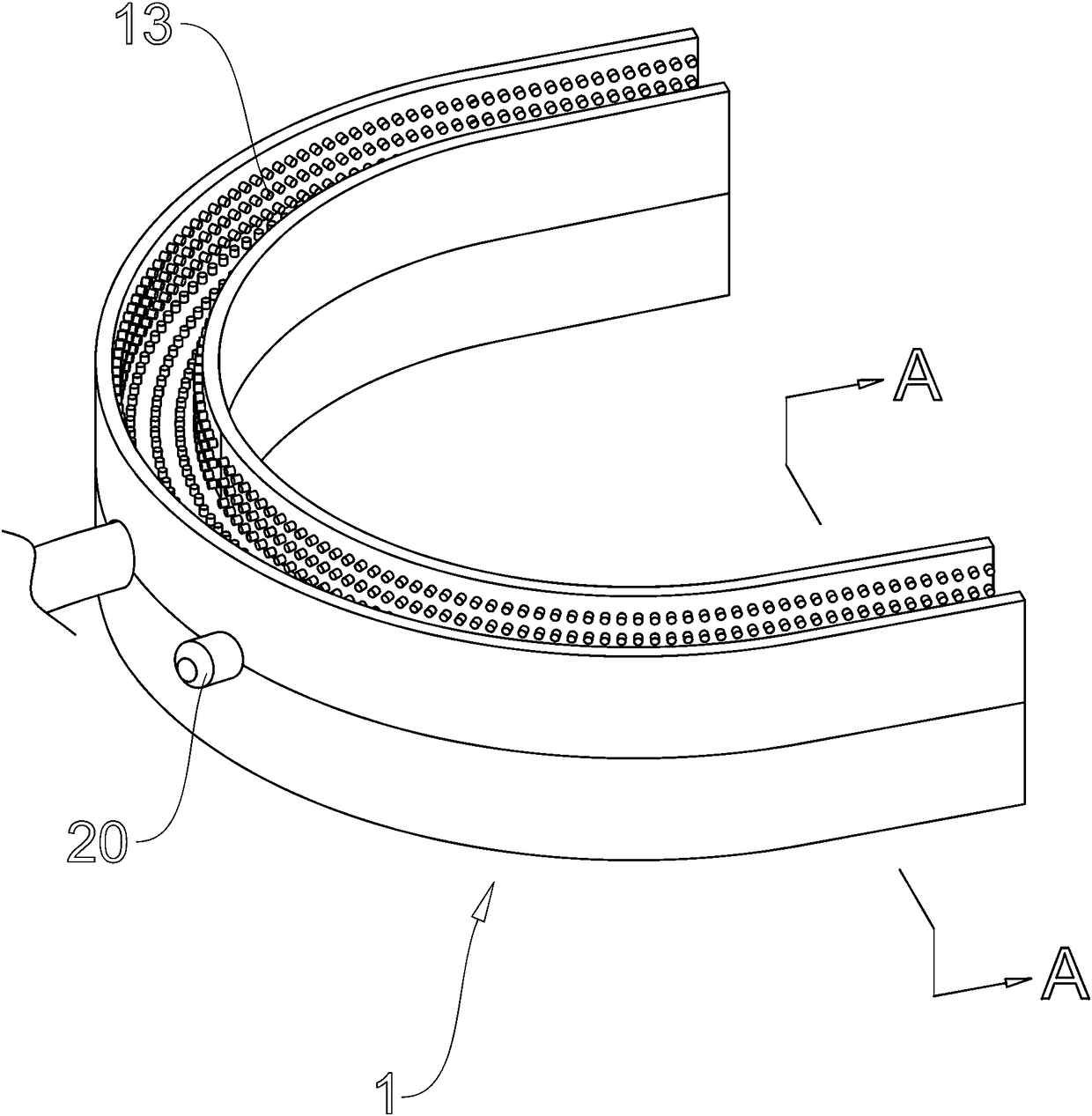

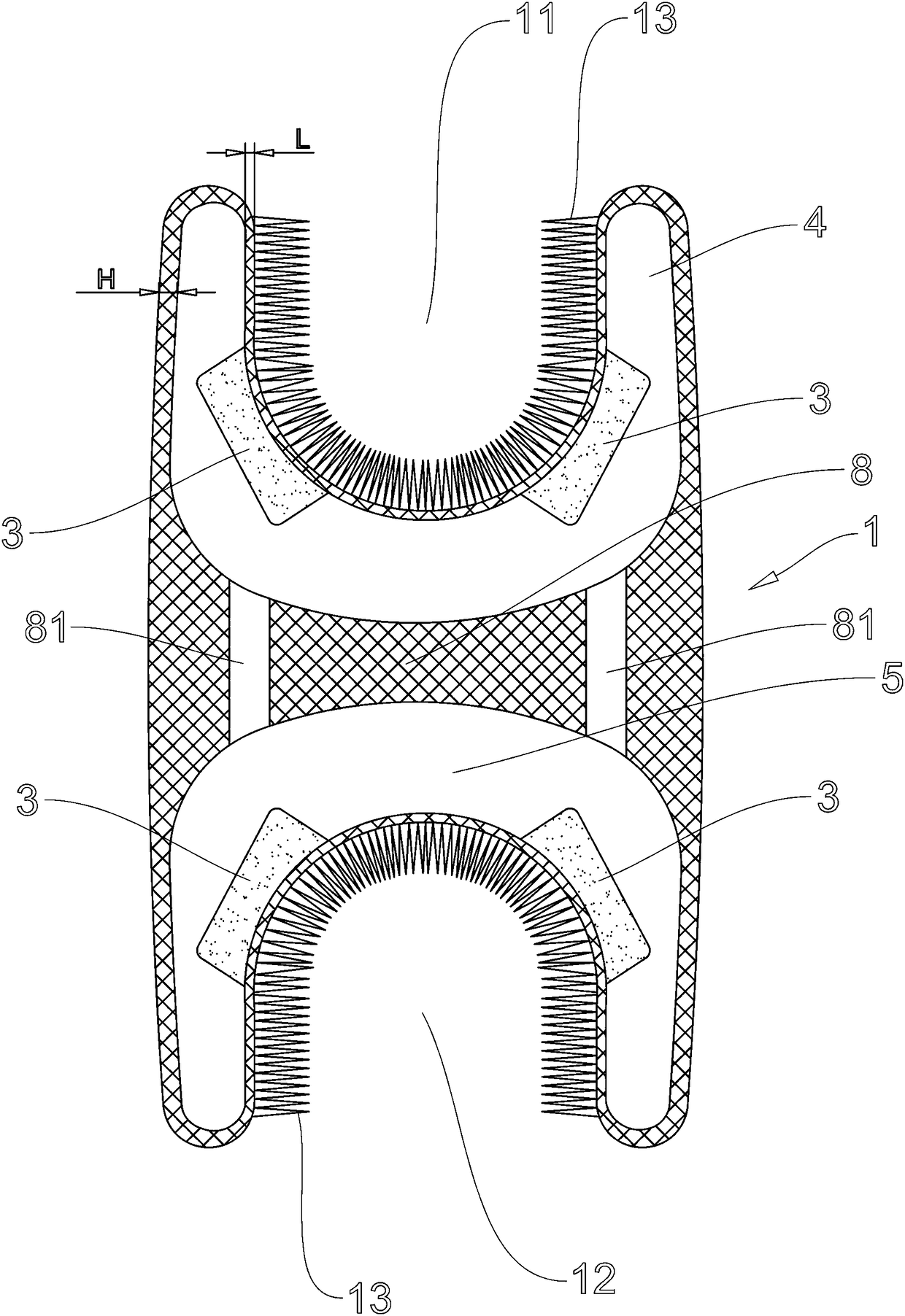

Slot wedge one-time forming device

ActiveCN104759671AReduce driftPlay a clamping effectLarge fixed membersMilling equipment detailsMilling cutterEngineering

The invention provides a slot wedge one-time forming device. The slot wedge one-time forming device comprises a polishing device, a milling device, a conveying device and a pressing holder. The conveying device comprises a plurality of pairs of paired rollers and a guide rail which are arranged on a conveying path of a slot wedge strip. The paired rollers include driving rollers and driven rollers, wherein the driven rollers are arranged above the driving rollers. The milling device comprises two milling machines arranged on the two sides of the conveying device respectively, and it is guaranteed that the two milling machines are staggered. Each milling machine comprises a base, an arc-shaped support and a third milling cutter. The pressing holder is used for clamping the slot wedge strip at the conveyed state. The slot wedge one-time forming device has the advantages that the automation degree is high, deviation of the slot wedge strip in the conveying process and sparks produced in the machining process are prevented, safety is improved, and timeliness of scrap cleaning is improved.

Owner:安徽省盛鑫绝缘材料有限公司

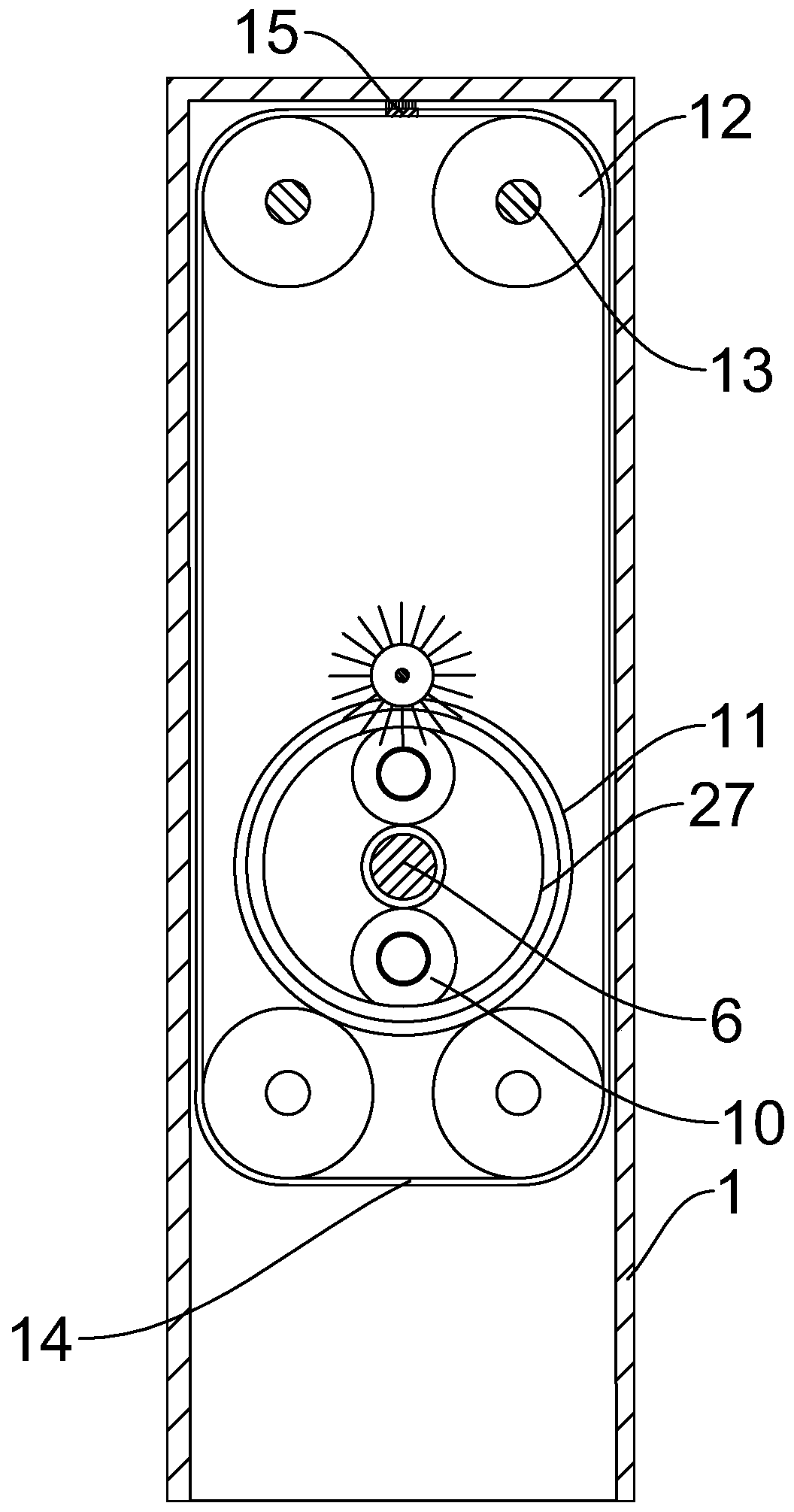

Relative rotating type writing brush holder and hair cleaning device and use method thereof

InactiveCN109649040ASynchronous operationSynchronous cleaningNib removersEngineeringElectrical and Electronics engineering

The invention discloses a relative rotating type writing brush holder and hair cleaning device and a use method thereof. The cleaning device comprises a rack, a cleaning pond rotatably arranged on therack, a brush holder cleaning mechanism directly or indirectly rotatably arranged on the cleaning pond, a first transmission mechanism for driving the brush holder cleaning mechanism to rotate, a second transmission mechanism for driving the cleaning pond to rotate and a driving mechanism for driving the first transmission mechanism and the second transmission mechanism to synchronously operate,the first transmission mechanism is directly or indirectly arranged on the cleaning pond, the second transmission mechanism is directly or indirectly arranged on the rack, and the driving mechanism isrotatably arranged on the rack. A brush holder and brush hair of a writing brush can be synchronously cleaned efficiently and portably, the two transmission mechanisms synchronously operate under theeffect of one driving mechanism, and the device is ingenious and convenient.

Owner:潘艾欣

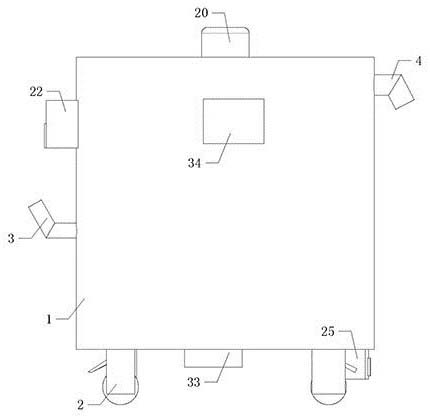

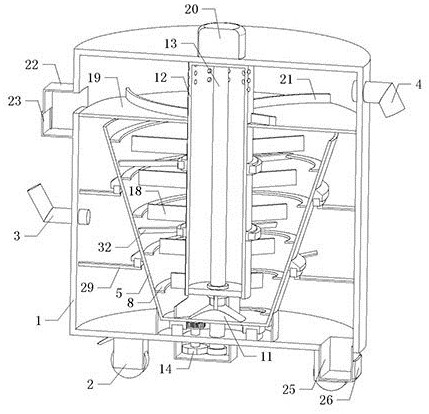

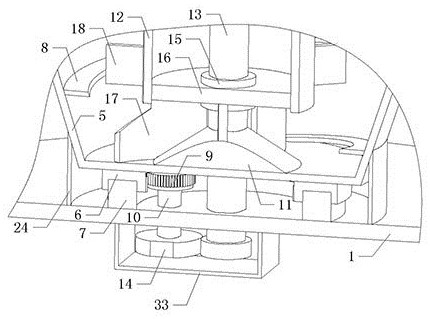

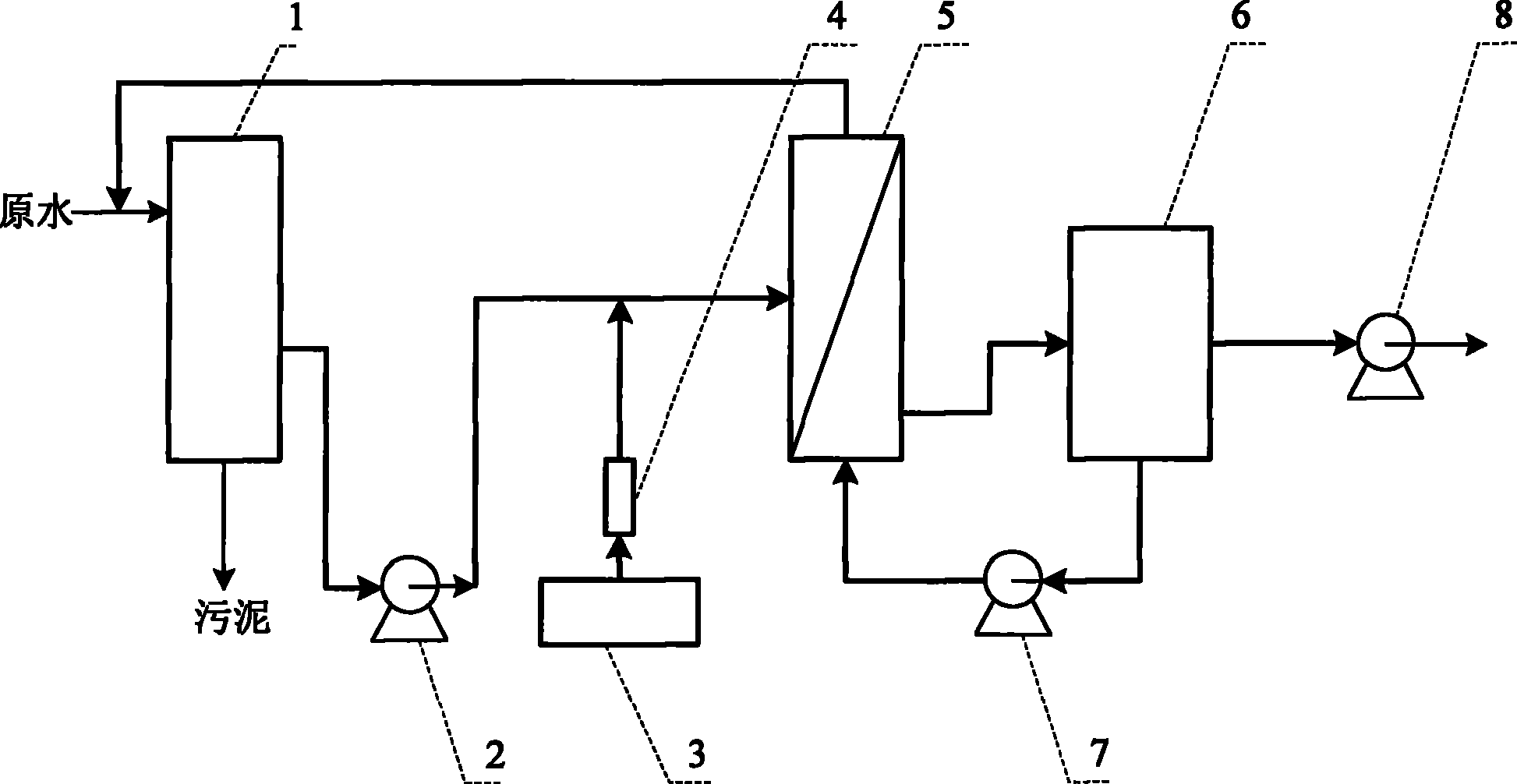

Movable small wastewater treatment equipment

ActiveCN111924996AEasy to cleanSynchronous cleaningWater/sewage treatment by centrifugal separationSpecific water treatment objectivesSewageWater treatment

The invention relates to the technical field of environmental protection equipment. The invention relates to wastewater treatment equipment, in particular to movable small wastewater treatment equipment. Sewage is subjected to purification treatment, particle impurities in sewage can be conveniently and effectively separated, the particle impurities in the sewage are prevented from blocking equipment, normal operation of the equipment is guaranteed, meanwhile, the particle impurities in the sewage are subjected to multi-section purification treatment, the particle impurities can be effectivelyprevented from causing overstock damage to the equipment, the equipment is conveniently protected, and practicability and reliability are improved. The equipment comprises a treatment bin, four groups of self-locking universal wheels, a water inlet pipe, an overflow pipe, a centrifugal hopper and a first annular chute, the four sets of self-locking universal wheels are evenly installed at the bottom of the treatment bin, the water inlet pipe is installed on the left side of the treatment bin, the overflow pipe is installed on the upper right side of the treatment bin, the centrifugal hopper is located on the lower side in the treatment bin, the bottom of the centrifugal hopper is sealed, and the first annular sliding groove is formed in the bottom of the centrifugal hopper.

Owner:海普欧环保集团有限公司

Structure for automatically cleaning filter screen of air conditioner, and air conditioner

ActiveCN111578386AEasy to cleanAvoid the disadvantages of concentrating on the dust box and then manually dismantling and washing the dust boxDispersed particle filtrationLighting and heating apparatusEngineeringMechanical engineering

The invention relates to the technical field of air conditioners, and discloses a structure for automatically cleaning a filter screen of an air conditioner. The structure comprises the filter screen,a driving device and a length adjusting device, wherein the filter screen comprises a first end part and a second end part; the driving device is in driving connection with the first end part, is configured to drive the filter screen to move towards the direction close to a heat exchanger of the air conditioner and can move to a first cleaning position and a second cleaning position, in the firstcleaning position, a first area of the filter screen abuts against the heat exchanger, in the second cleaning position, a second area of the filter screen abuts against the heat exchanger, and the first area and the second area are at least partially not overlapped; and the length adjusting device is connected with the second end part and configured to adjust an uncontained length of the filter screen so that the filter screen can be moved to the first cleaning position and the second cleaning position. The invention also discloses the air conditioner.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

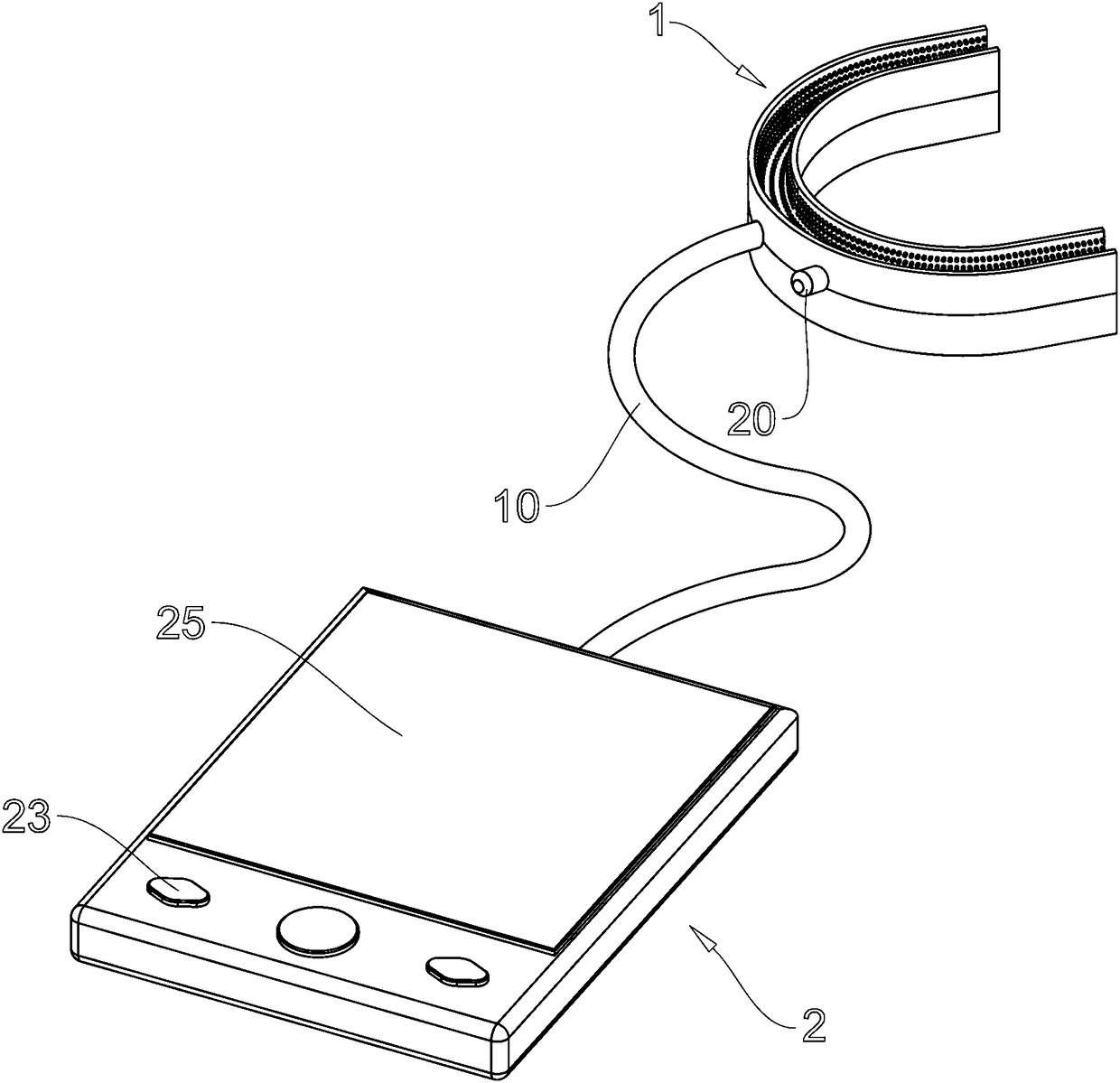

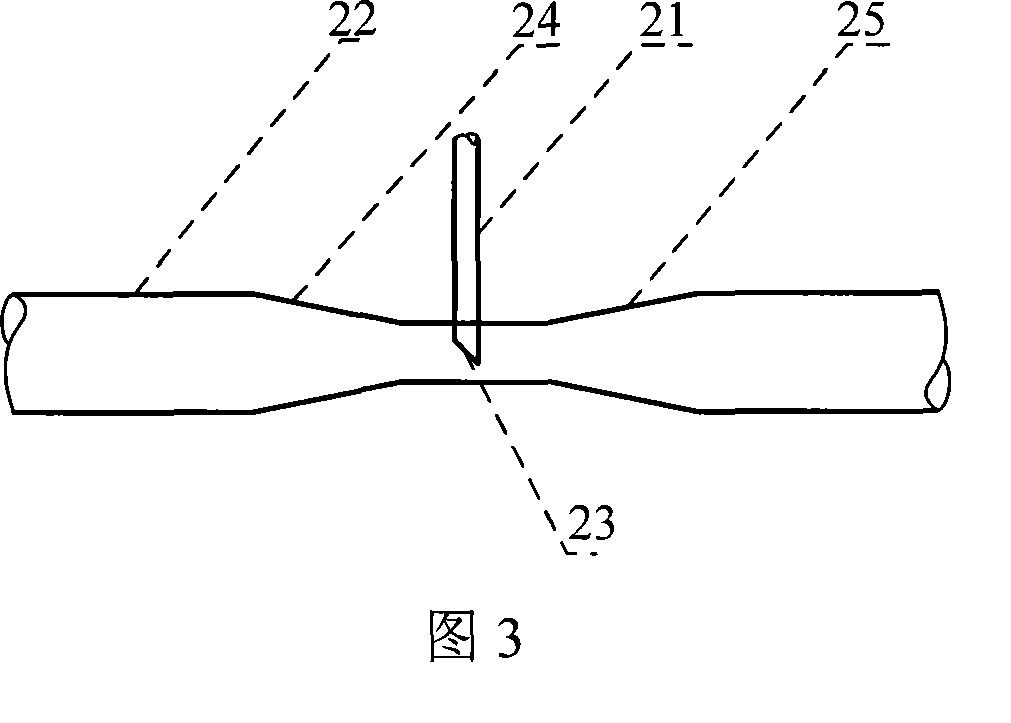

Ultrasonic dental scaler for brush bulged after being inflated

ActiveCN108354689AMaintain healthPromote blood circulationBristleCleaning using liquidsDental ScalerEngineering

The invention relates to an ultrasonic dental scaler for a brush bulged after being inflated. The ultrasonic dental scaler comprises a U-shaped tooth cleaning head with an upper tooth slot and a lowertooth slot, a main machine, and a micro ultrasonic transducer, wherein a brush is arranged in the tooth slots; a U-shaped inner chamber is further arranged in the U-shaped tooth cleaning head; at least one micro ultrasonic transducer is further arranged in the U-shaped inner chamber; the outer side surface of the U-shaped tooth cleaning head is further connected with an electric wire; the electric wire is electrically connected with the micro ultrasonic transducer; a pipeline is further connected on the outer side surface of the U-shaped tooth cleaning head; the pipeline is communicated withthe U-shaped inner chamber; and the main machine comprises a PLC circuit board, a micro air pump, a control button module and the like. A way of bulging the brush by inflating is adopted, and ultrasonic waves are utilized for performing high-frequency vibration on the bulged brush, so that inner and outer surfaces of teeth and tooth gaps of inner and outer surfaces are comprehensively and synchronously cleaned without a dead corner in an all-around mode through the brush in the tooth slots, and therefore, the problem that the teeth are damaged as a result of excessive cleaning is avoided, andthe problem of the cleaning is incomplete and is not thoroughly is avoided.

Owner:彭志军

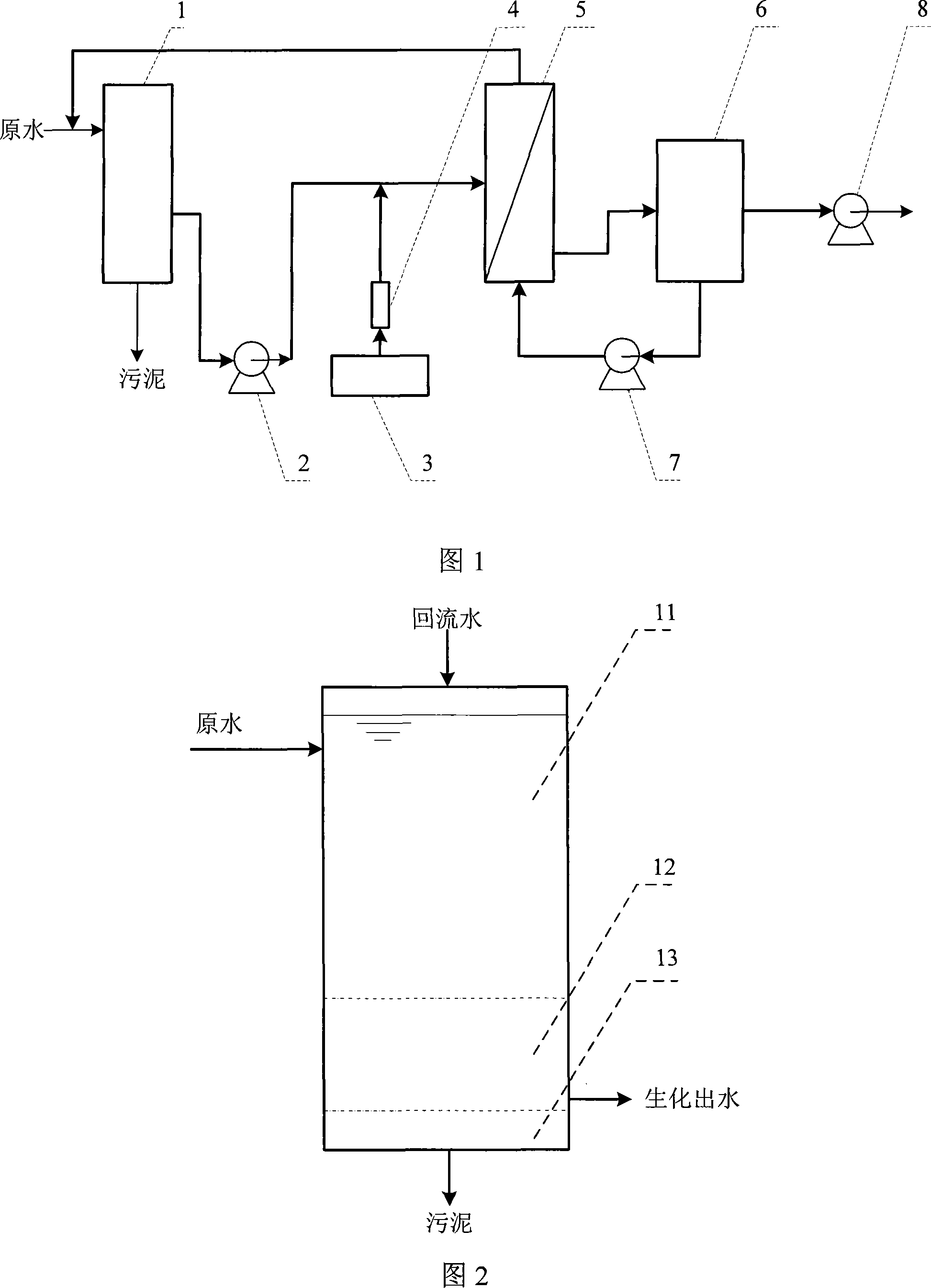

Membrane bioreactor and use thereof in wastewater treatment

ActiveCN101434444BEasy loadingIncrease concentrationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentMembrane surfaceMembrane bioreactor

The invention discloses a membrane bioreactor and an application method thereof in wastewater treatment. The membrane bioreactor comprises a biochemical reaction unit which adopts a particle biofilm medium, a pulse type air supply unit and a membrane filtering unit, wherein, a pulse airflow transforms wastewater entering the membrane filtering unit into pulse aerated flow, the particle biofilm medium in the wastewater is fluidized and rubbed and scraped with a membrane component, and fouling sedimentary on the membrane surface is removed. The membrane bioreactor and the application method have the advantages that the biochemical treatment of the particle biofilm medium has good effect, and the effect of rubbing and cleaning the membrane component is good; combined with the disturbing strengthening cleaning effect of the pulse aerated flow, synergistic effect is played, thus improving the membrane pollution preventing effect of an MBR unit, reducing the running cost of the unit, and being applicable to various wastewater treatment occasions.

Owner:CHINA PETROLEUM & CHEM CORP +1

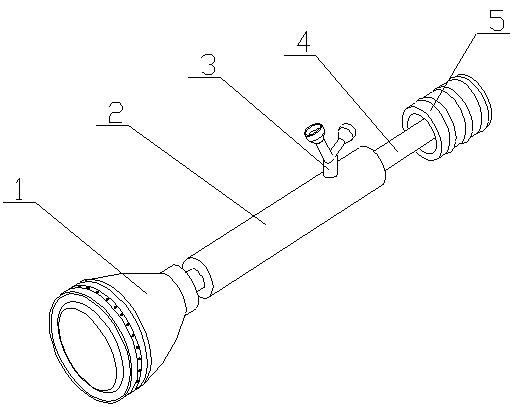

Hydraulic cylinder inner wall cleaner

ActiveCN109604284ASynchronous cleaningSimple structureRotary stirring mixersTransportation and packagingHydraulic cylinderEngineering

The invention relates to a hydraulic cylinder inner wall cleaner, and discloses a cleaner which is capable of extending in a cylinder body, conducting cleaning liquid preparation during cleaning, andwashing the inner wall of the cylinder with spraying holes formed in a circumferential mode. Impurities in the cleaning liquid can be filtered before washing. The hydraulic cylinder inner wall cleaneris characterized in that a connecting pipe is connected to the middle of one end of a hollow pipe and communicates with the hollow pipe; a cleaning shell is located on the connecting pipe and communicates with the connecting pipe; the diameter of the cleaning shell gradually increases from one end to the other end; a filtering plug is located on the inner side of the cleaning shell and corresponds to the connecting pipe; a supporting column is located on the filtering plug and is located in the cleaning shell; one end of the supporting column extends to an opening of the other end of the cleaning shell; the diameter of the supporting column gradually increases from the other end to the end; a plurality of flow distributing blocks are arranged outside the supporting column an equal angles;a distance is formed between the outer lateral surface of the flow distributing blocks and the inner wall of the cleaning shell; and a end cover is arranged on the outer wall of the other end of thecleaning shell in a sleeving mode.

Owner:钱俊

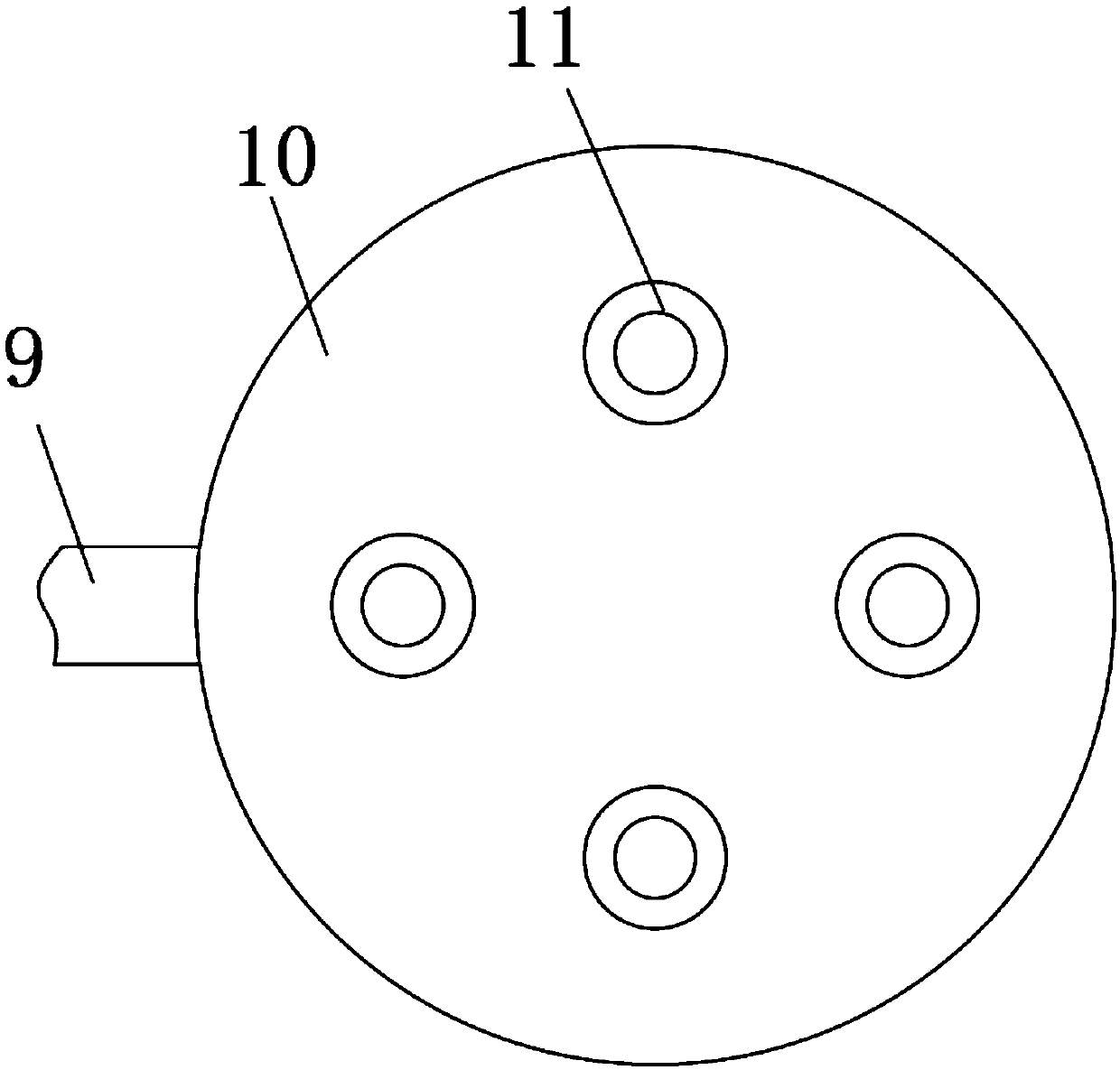

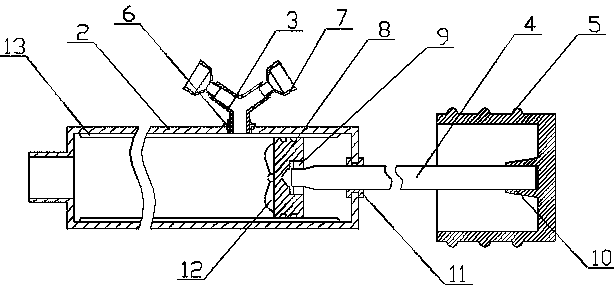

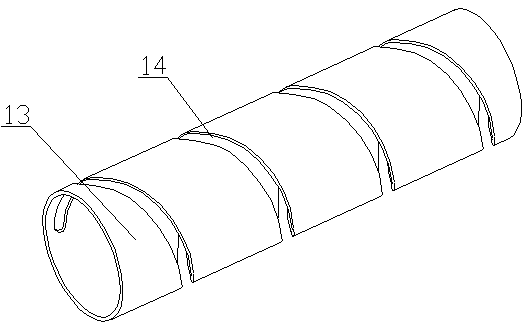

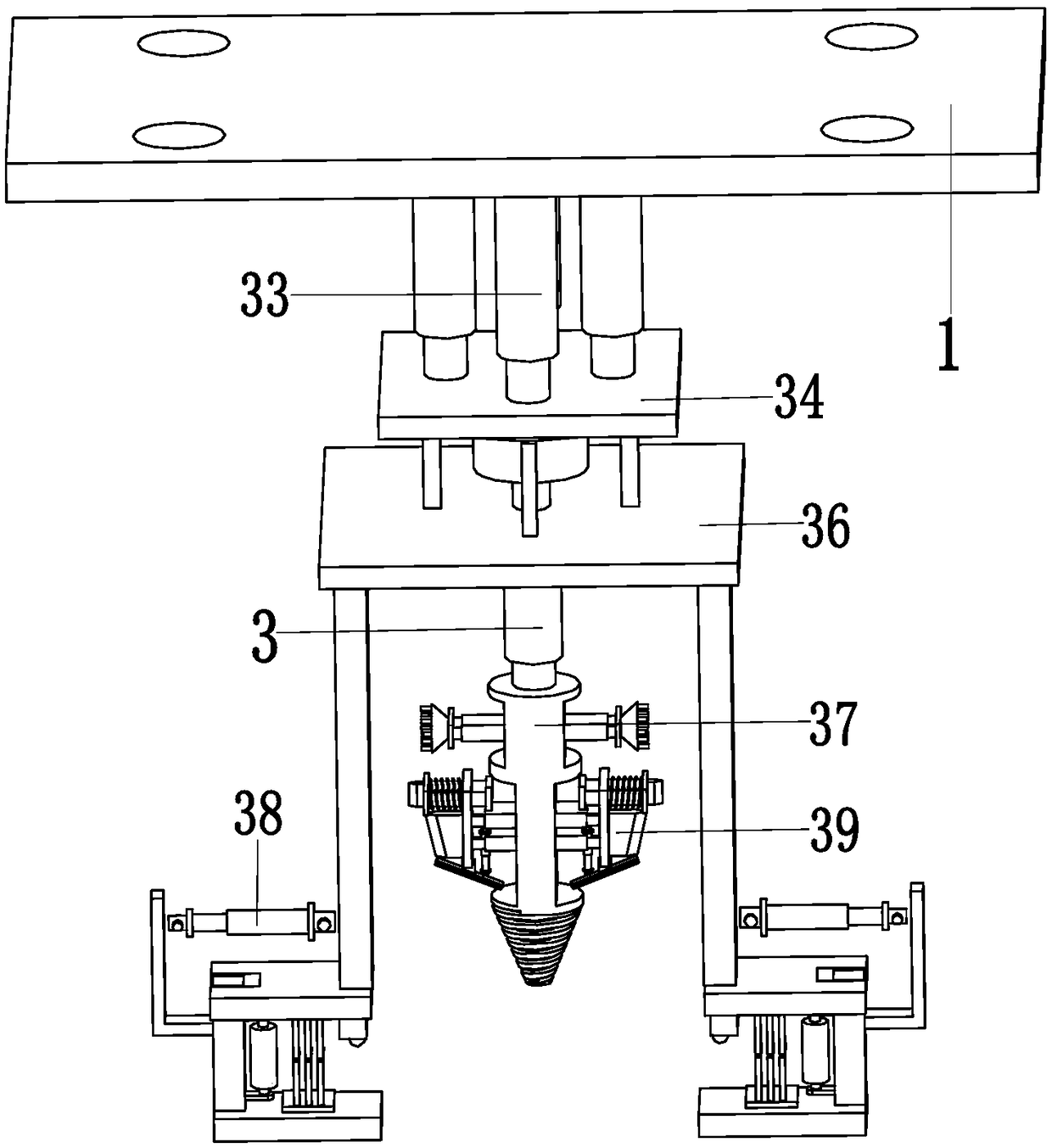

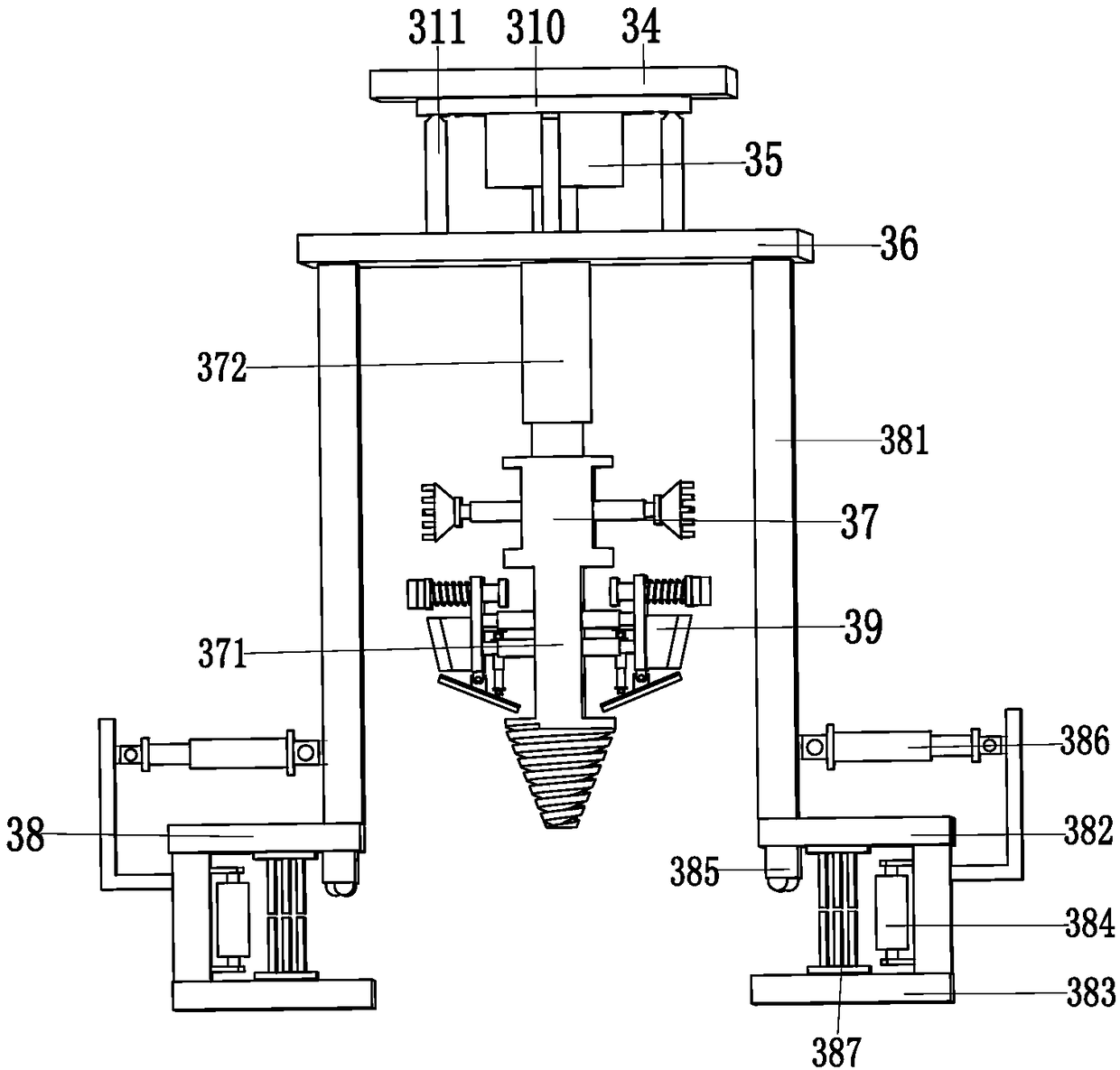

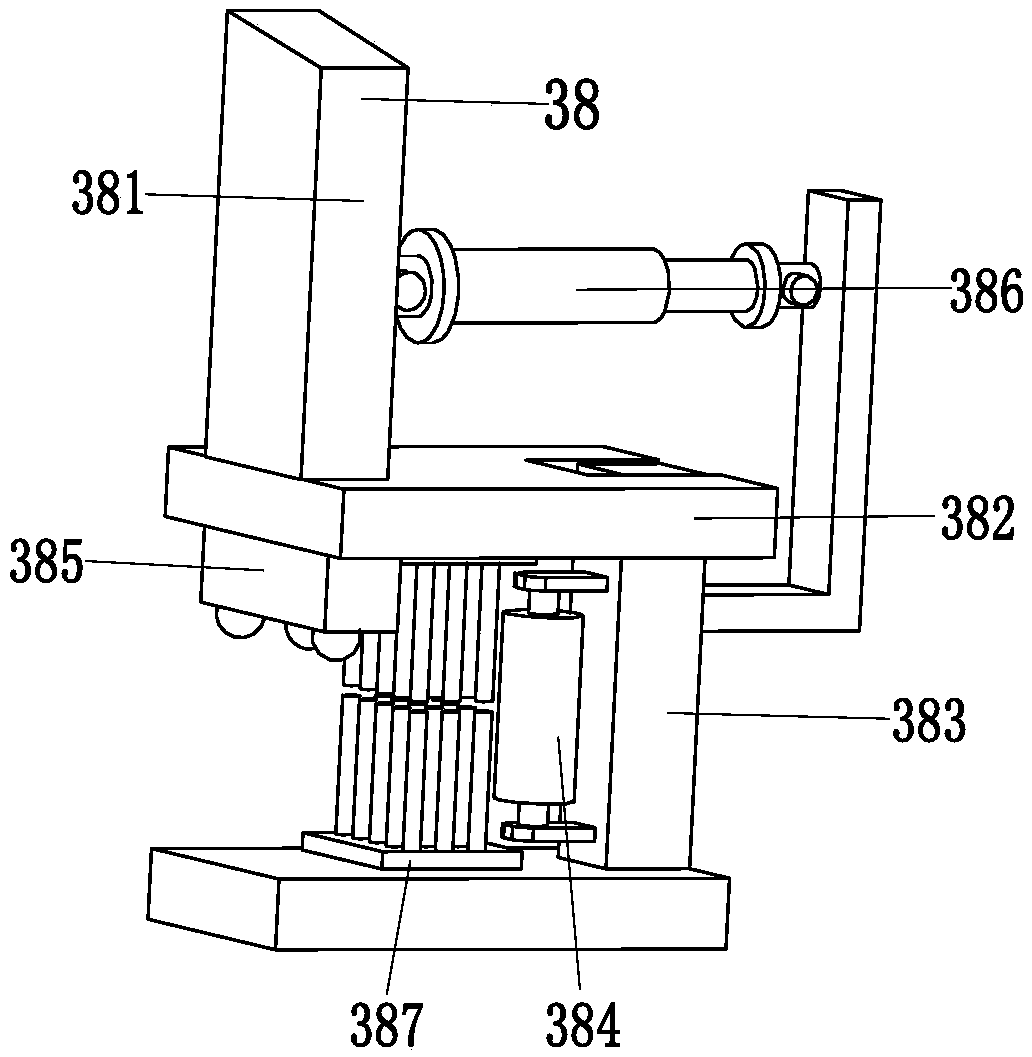

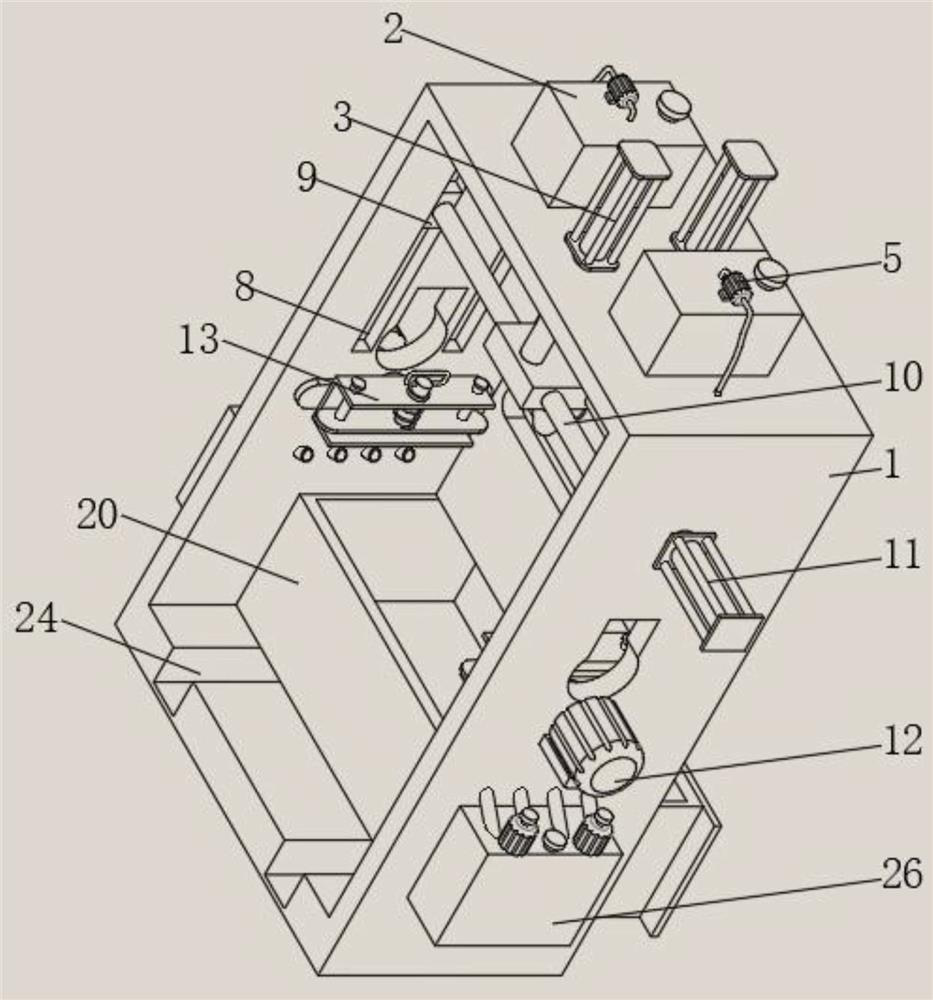

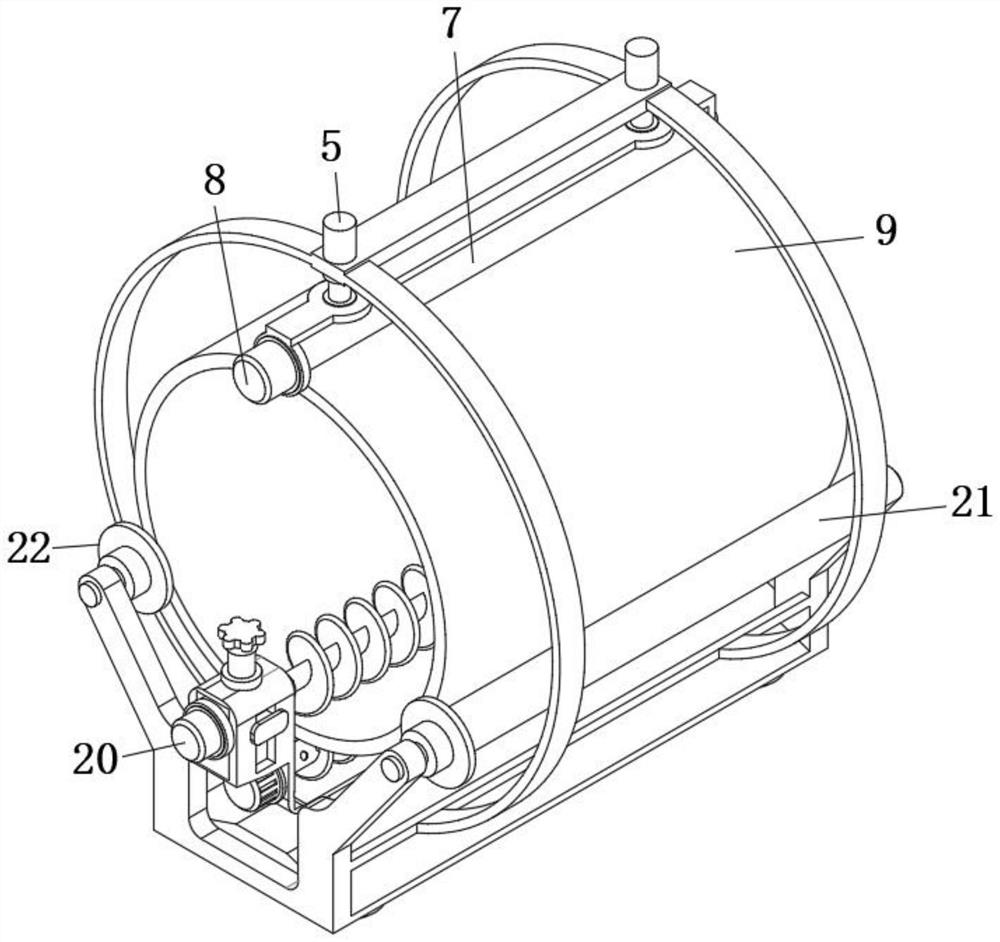

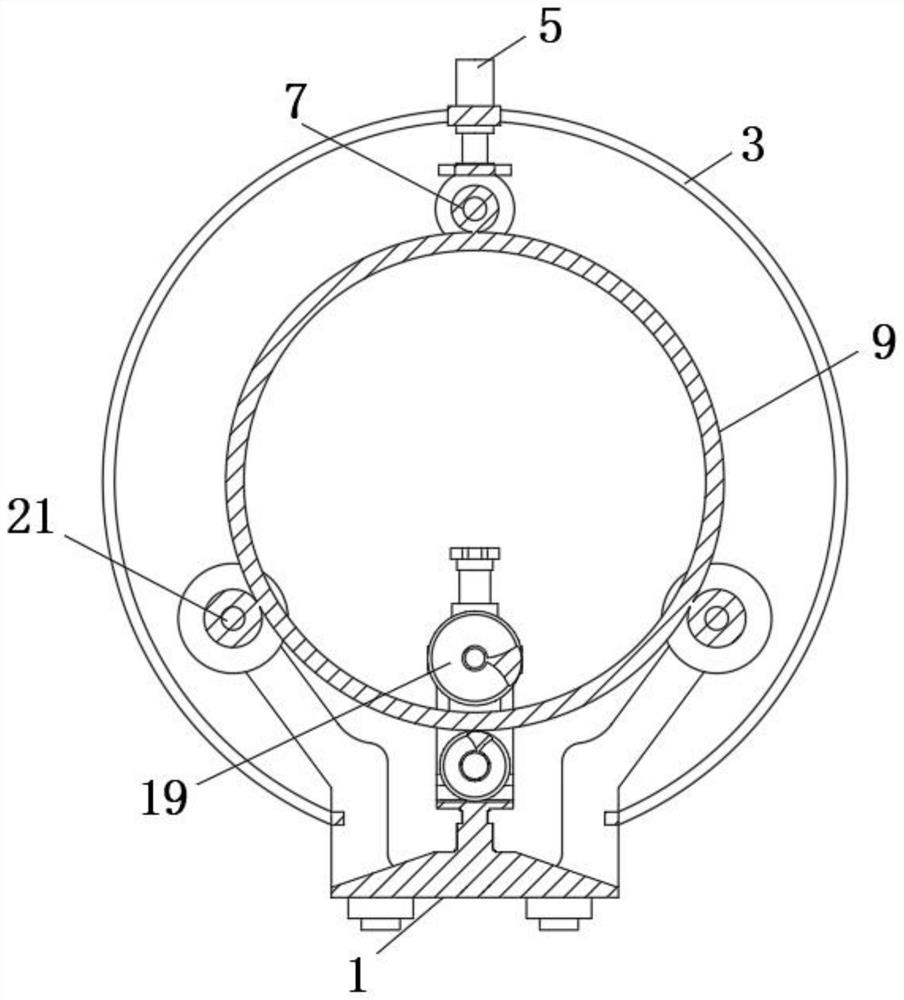

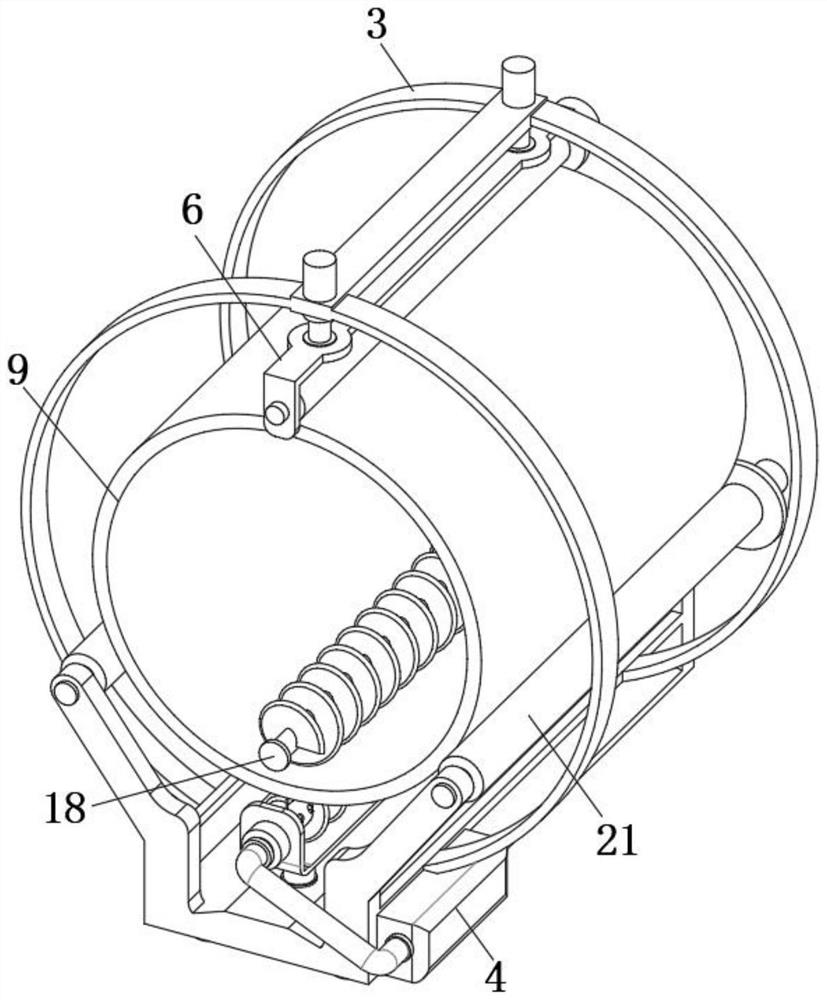

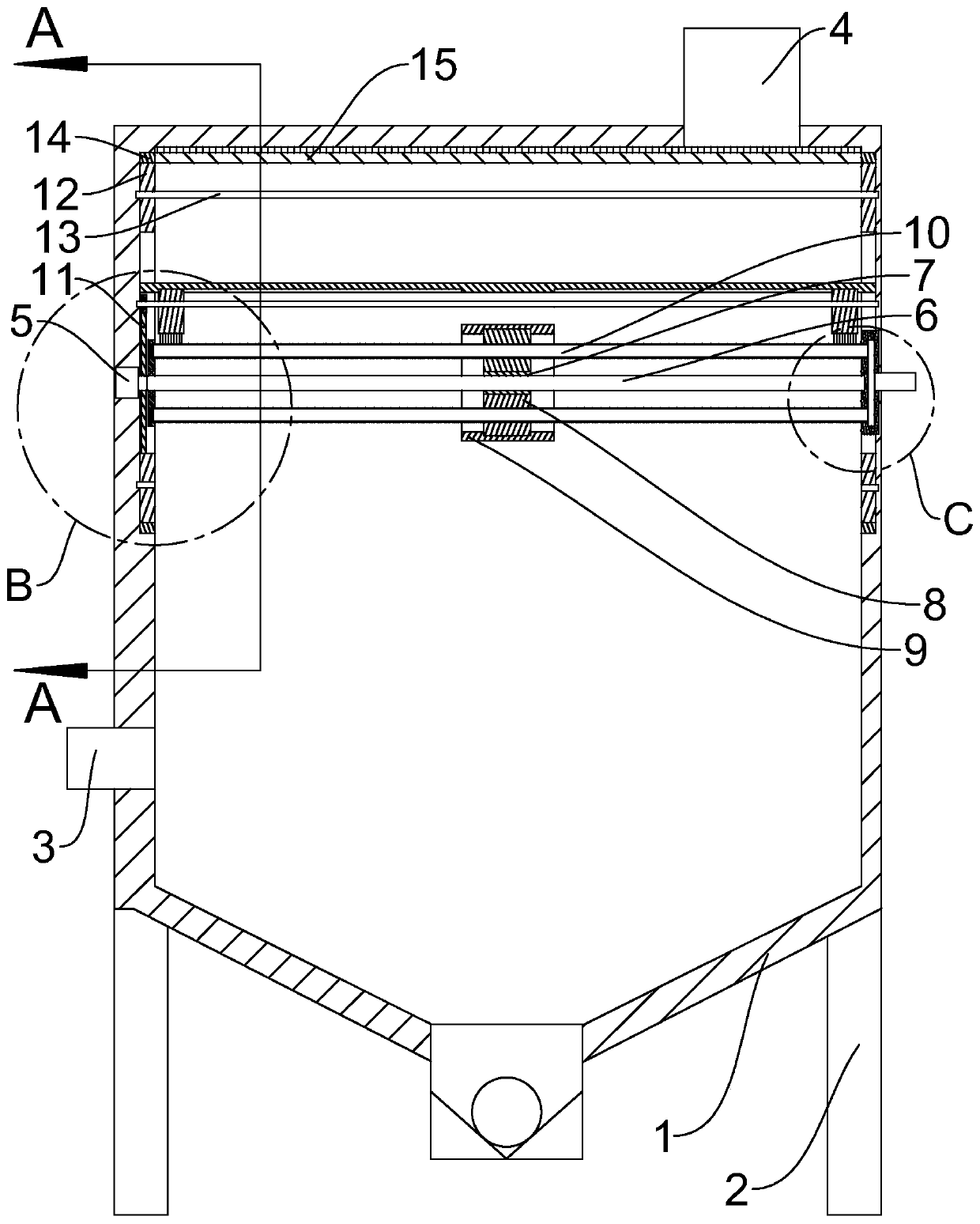

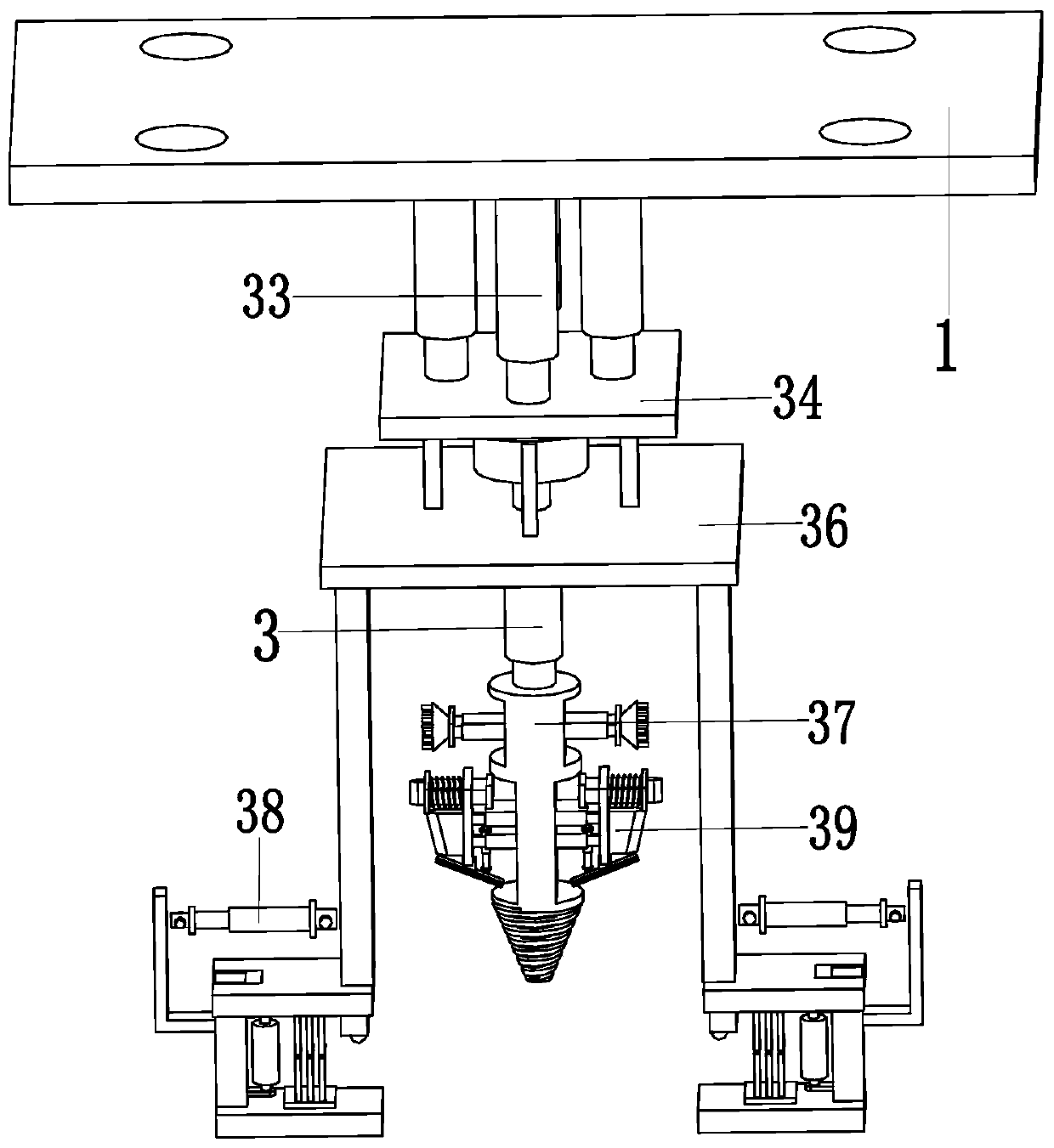

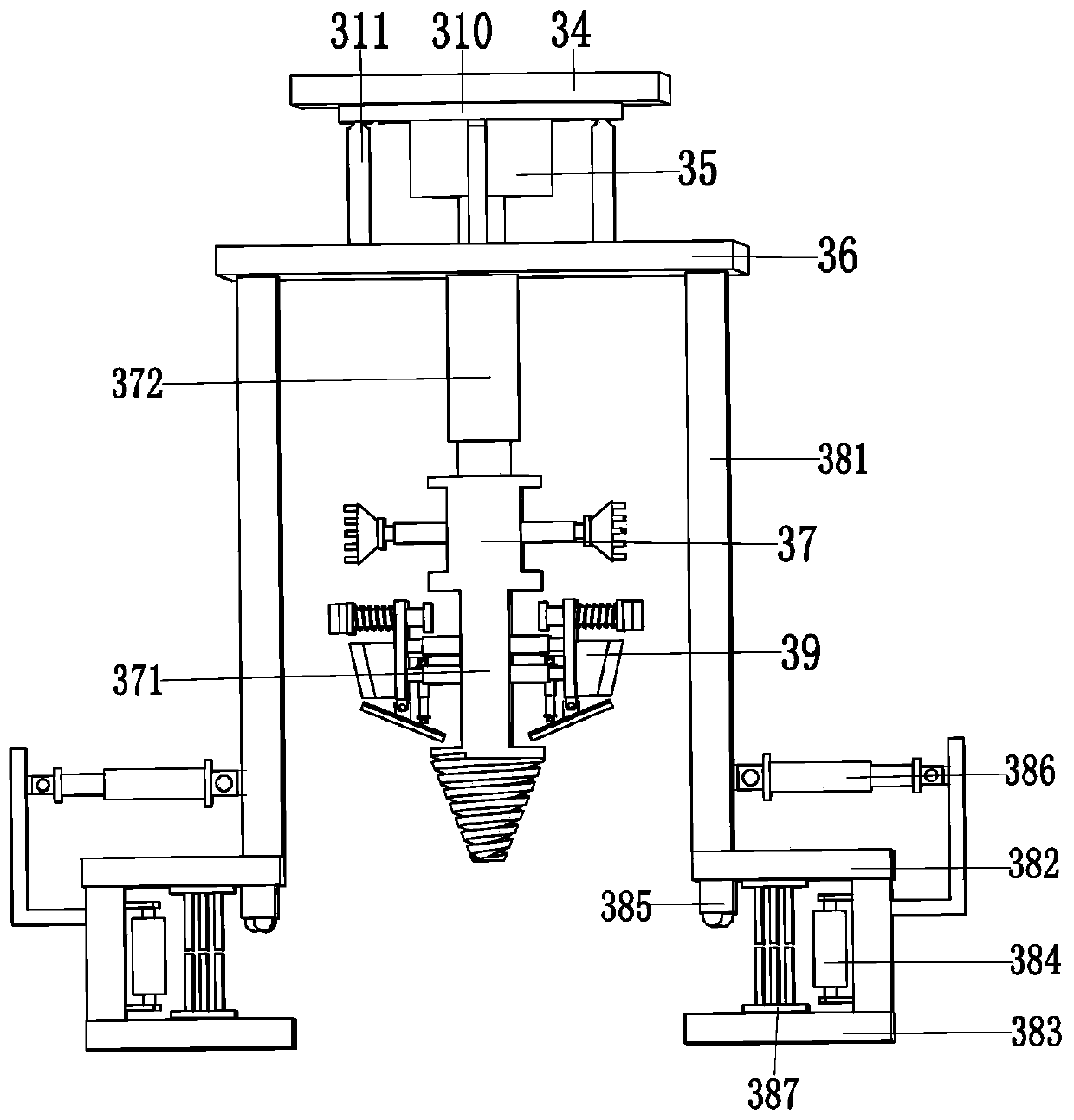

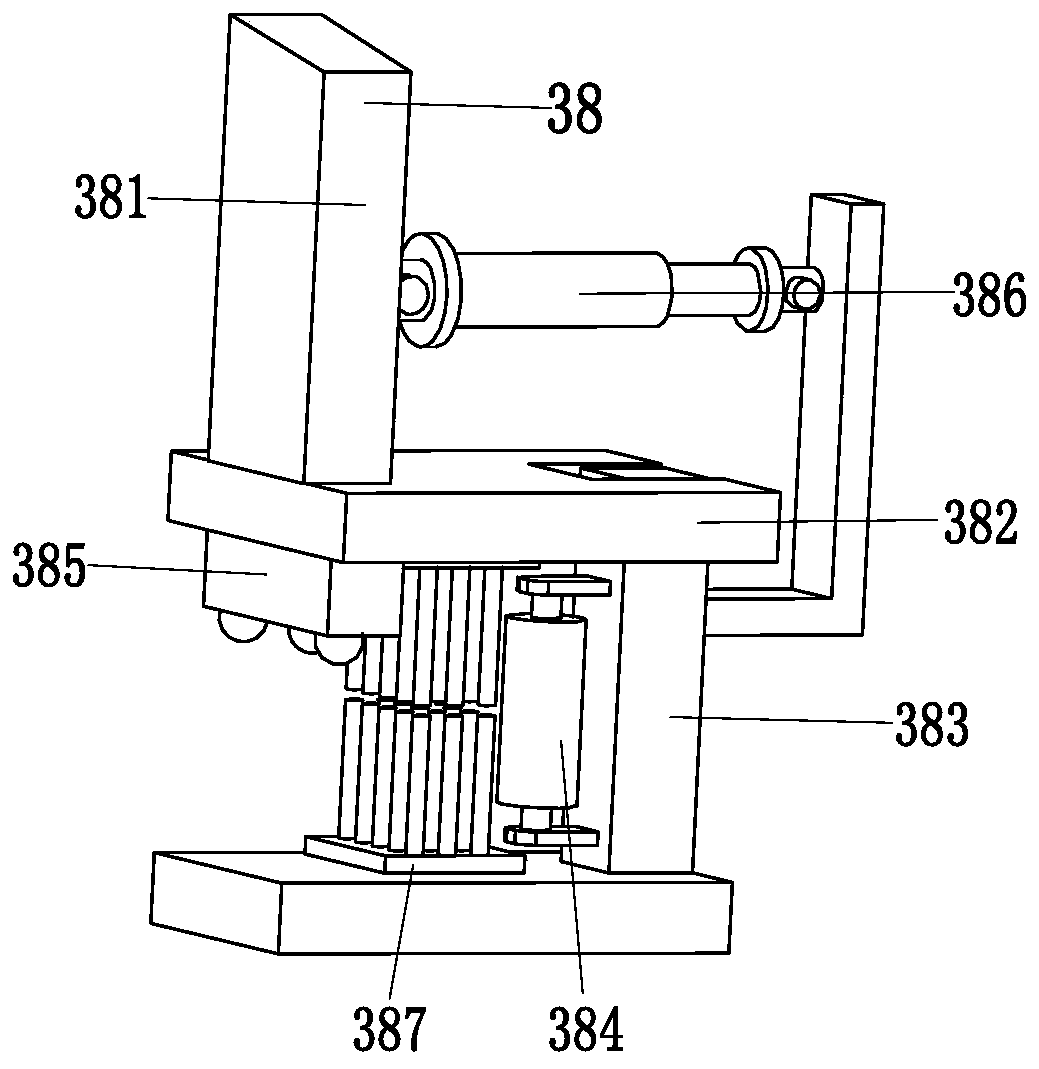

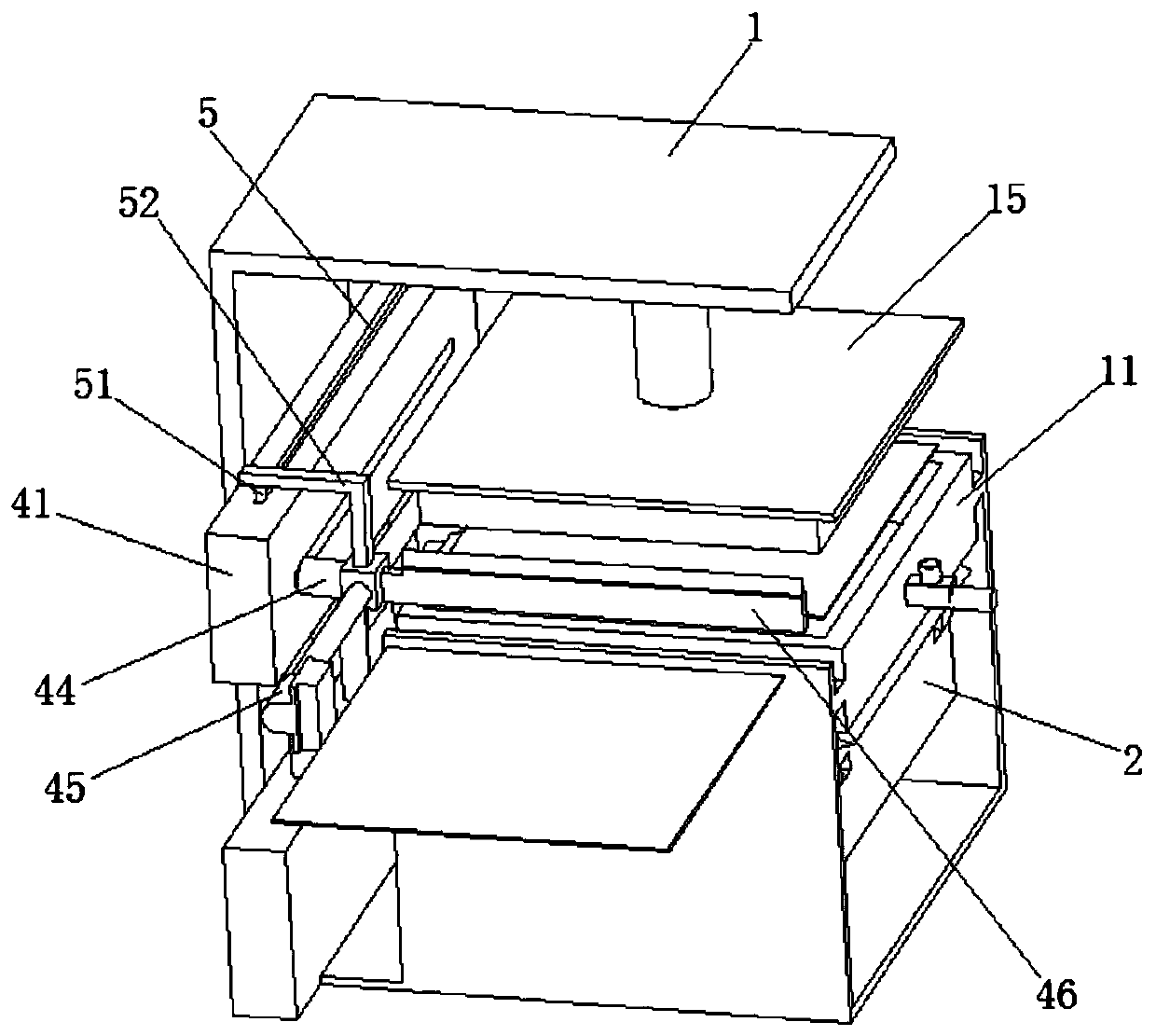

Automatic cleaning equipment for cast flange pipe

The invention relates to automatic cleaning equipment for a cast flange pipe. The automatic cleaning equipment comprises a supporting top plate and a cleaning device, wherein the supporting top plateis uniformly provided with mounting holes. The cleaning device is installed on the lower end surface of the middle portion of the supporting top plate. The cleaning device comprises cleaning push rods, a cleaning expansion plate, a cleaning motor, a cleaning supporting plate, a cleaning mechanism, flange cleaning mechanisms, scraping mechanisms, a cleaning sliding groove and cleaning sliding rods.The flange cleaning mechanisms comprise flange connecting columns, flange supporting plates, flange rotating frames, flange rollers, flange supporting blocks, rotating frame rotating push rods and cleaning brushes. The automatic cleaning equipment for the cast flange pipe can solve the problems that the manual labor intensity is high when an existing flange pipe performs in-pipe sand cleaning, asteel pipe needs to be manually cleaned, the steel pipe cleaning effect is poor, and the inner wall of the steel pipe and the flange cannot be simultaneously cleaned.

Owner:LIANGSHANTONGYA EAVY IND MASCH CO LTD

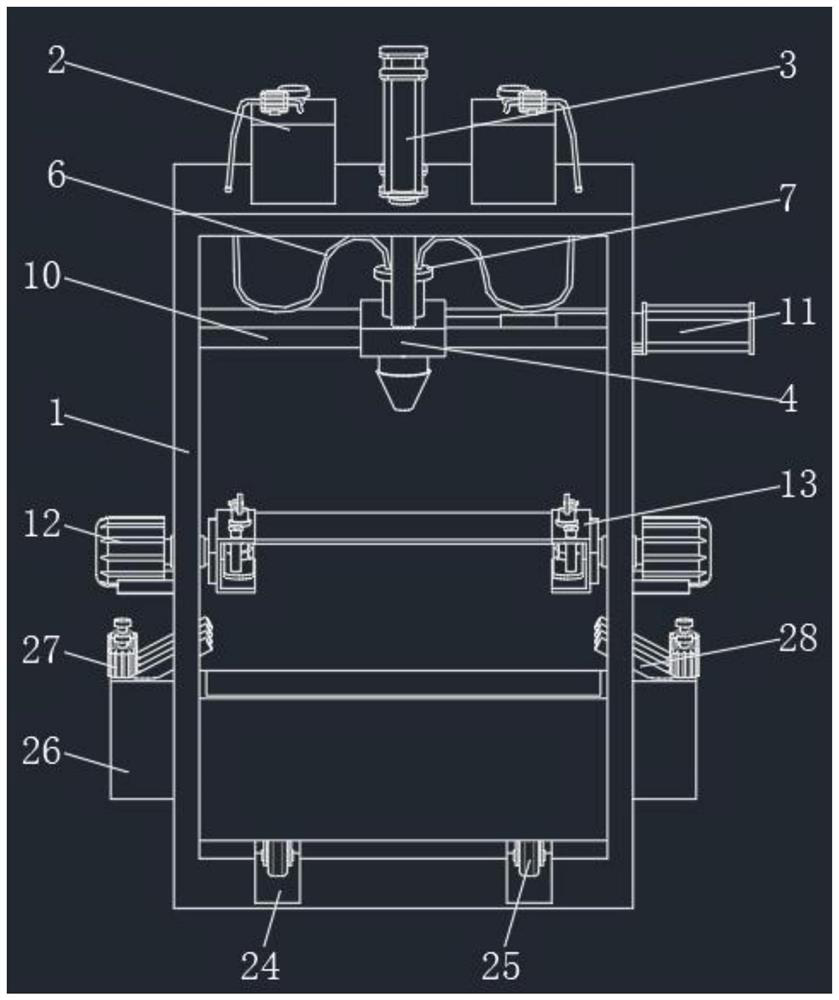

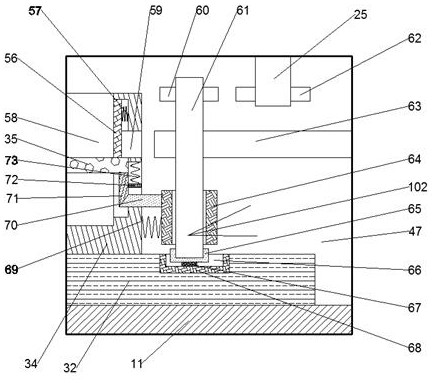

Inner wall polishing rust-proof device for steel pipes

PendingCN112676943AGood rotary transportImprove the efficiency of conveying and grindingRevolution surface grinding machinesGrinding drivesPolishingEngineering

The invention discloses an inner wall polishing rust-proof device for steel pipes, and relates to the technical field of steel pipe machining polishing. The inner wall polishing rust-proof device comprises a base table, a conveying mechanism is fixedly installed on the left side of the upper surface of the base table, and a material pushing mechanism is fixedly installed on the middle portion of the upper surface of the base table. A linkage mechanism, a polishing mechanism, a cleaning mechanism and a paint spraying mechanism are fixedly installed on the right side of the upper surface of the base table. According to the inner wall polishing rust-proof device for the steel pipes, the short steel pipes are horizontally placed in a discharging frame, the short steel pipe at the bottom end falls into a top groove of a bearing base, the telescopic end of a first electric push rod stretches out to push a push column to move towards the left side, and the polishing mechanism, a cleaning mechanism and a paint spraying mechanism are driven to synchronously move through stretch-out and draw-back of the first electric push rod. When the steel pipe on the bearing base is pushed to be fed to the left side, the steel pipe which rotates by a circle and is polished, cleaned and subjected to paint spraying is ejected to the left side, the short steel pipe is guided out through guiding of a discharging groove, and the effect of synchronous polishing, cleaning, paint spraying and material returning is achieved in the conveying process.

Owner:李萍

Desulfurization tower for efficiently treating flue gas

InactiveCN109821387ASpread area expandedAdequate responseDispersed particle separationEngineeringFlue gas

The invention discloses a desulfurization tower for efficiently treating flue gas. The tower comprises a support and a tower body fixed at the upper end of the support; the left end, the top end and the right end of the tower body are provided with a flue gas inlet, a flue gas outlet and an absorption mist inlet respectively; a stepping motor is arranged inside the left end of the tower body, a desulfurization cavity is formed in the tower body, and a spraying mechanism connected with an output shaft of the stepping motor is arranged in the desulfurization cavity; the spraying mechanism is matched with the absorption mist inlet, the output shaft of the stepping motor is in key connection with a second driving gear, and the upper end of the second driving gear is meshed with a second drivengear. The desulfurization tower has the advantages that a mist tube can revolve and rotate around a rotating shaft, so that the expanding range of sprayed absorption mist is expanded, the absorptionmist is distributed uniform and fully reacts with the flue gas, and bristles on a brush roller are used for carrying out synchronous cleaning on spraying holes.

Owner:沙丽萍

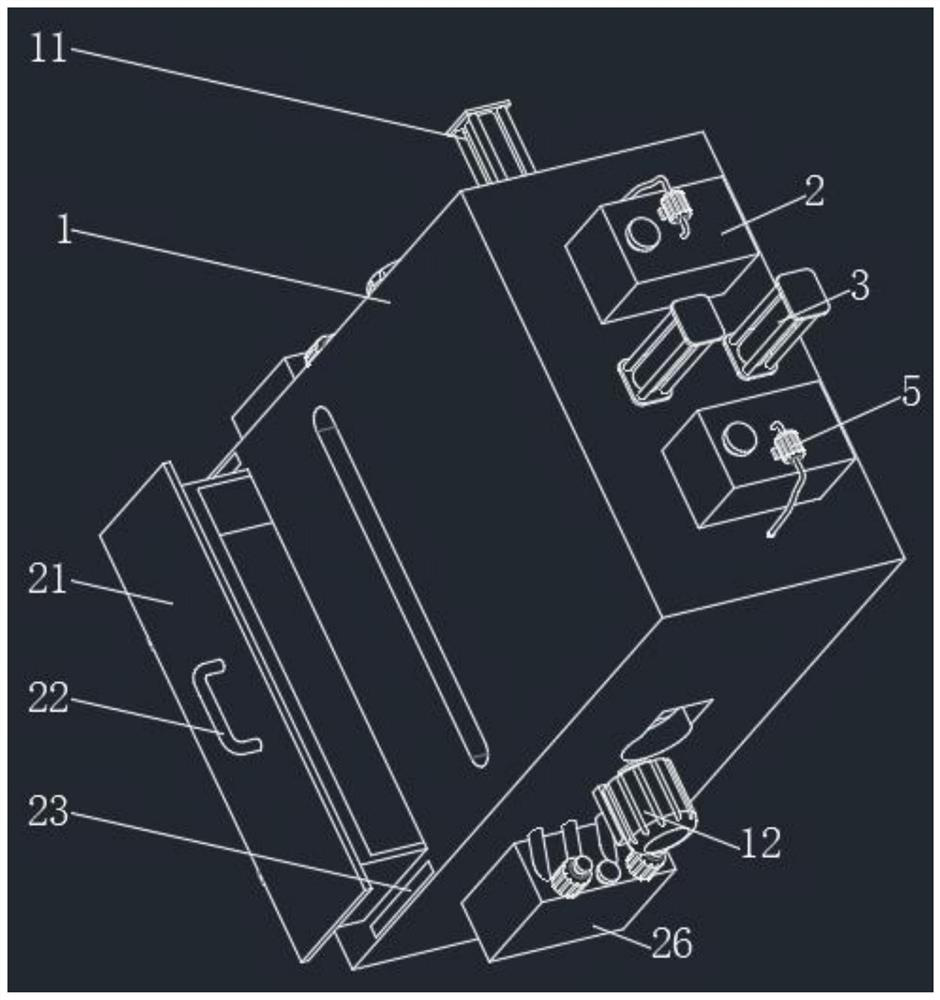

Aluminum profile surface etching device and method

InactiveCN114369827AGood etchingEtched thoroughlyCleaning using liquidsElectric machineryEngineering

The invention relates to an aluminum profile surface etching device and method. Belongs to the technical field of etching equipment. In order to solve the problems that an aluminum profile cannot be subjected to clamping treatment before etching, etching liquid is wasted and etching is excessive, the following technical scheme is provided, the aluminum profile etching device comprises an etching box body, an etching liquid box, a liquid guide hose and an etching gun, a guide assembly is connected to the interior of the etching box body, a water pump is connected to the upper portion of the etching liquid box, and the liquid guide hose is connected to the lower portion of the etching liquid box. One end of the water pump is connected with one end of the liquid guide hose, a clamping mechanism is connected to the middle of the etching box body, driving motors are connected to the surfaces of the two sides of the etching box body, and the driving ends of the driving motors are connected with the clamping mechanism. By arranging the clamping and fixing mechanism and the driving motor, the aluminum profile can be better fixed before being etched, so that later etching is facilitated, in addition, after one face is etched, the aluminum profile can be turned over rapidly, and etching of the aluminum profile is more thorough.

Owner:上海秋阳金属科技(集团)有限公司

Air conditioner

ActiveCN111720893AEasy to cleanClean thoroughlyLighting and heating apparatusSpace heating and ventilation detailsEngineeringRefrigeration

The invention relates to the technical field of refrigeration equipment, and discloses an air conditioner. The air conditioner comprises an air conditioner main body, a filter screen and a driving device, wherein the air conditioner main body comprises a heat exchanger; the filter screen is arranged on one side of the heat exchanger, and at least part of the filter screen abuts against the heat exchanger in an attached mode; and the driving device is in driving connection with the filter screen and is configured to drive the filter screen to move between a first position and a second positionrelative to the heat exchanger, in the first position, a first area of the filter screen abuts against the heat exchanger in an attached mode, and in the second position, a second area of the filter screen abuts against the heat exchanger in an attached mode. The first area and the second area are at least partially not overlapped so that different positions of the filter screen can be cleaned atthe first position and the second position, the cleaning effect on the filter screen is improved, and a cleaning blind area on the filter screen is avoided.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

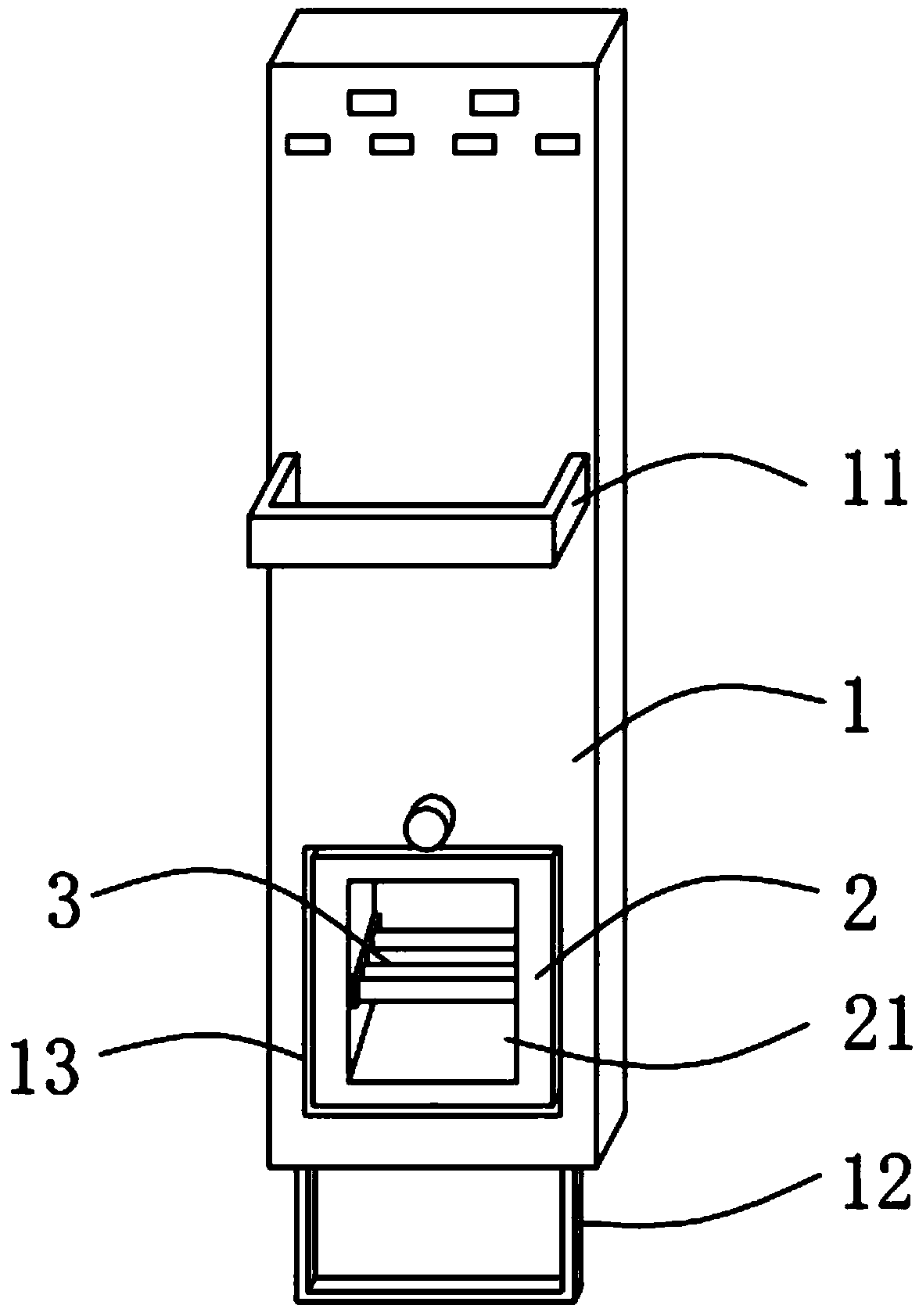

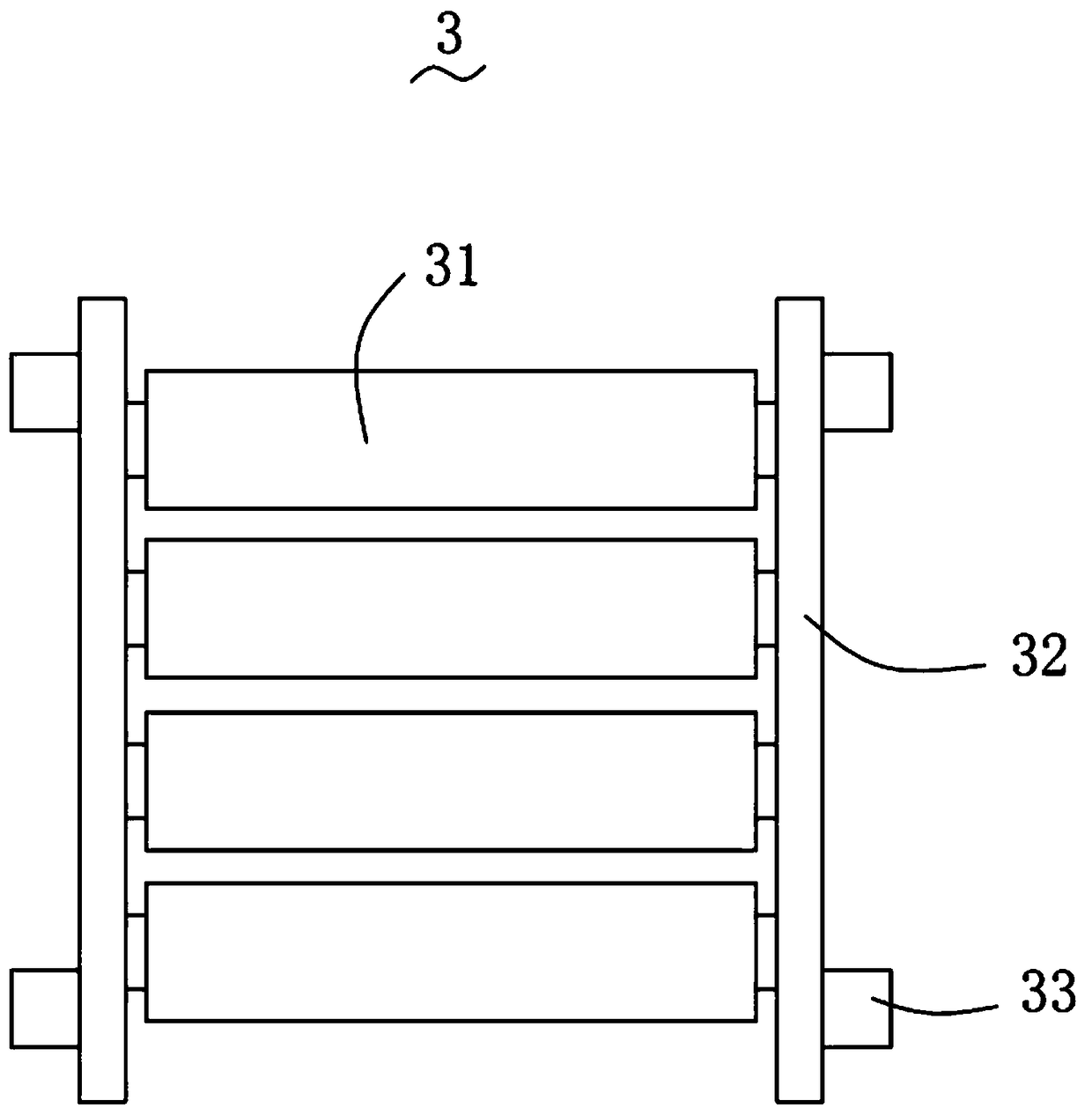

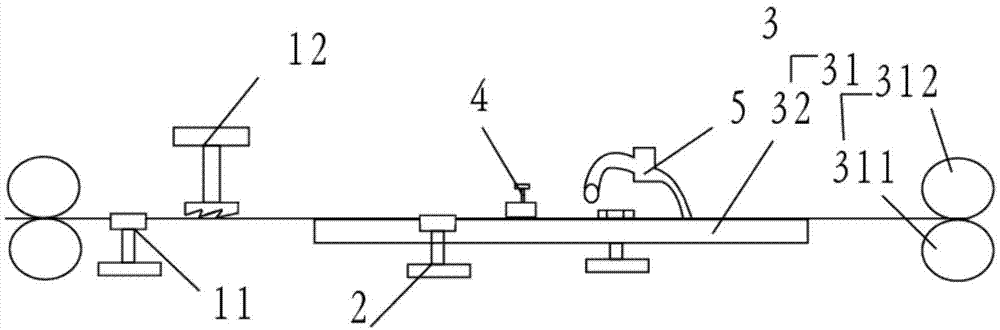

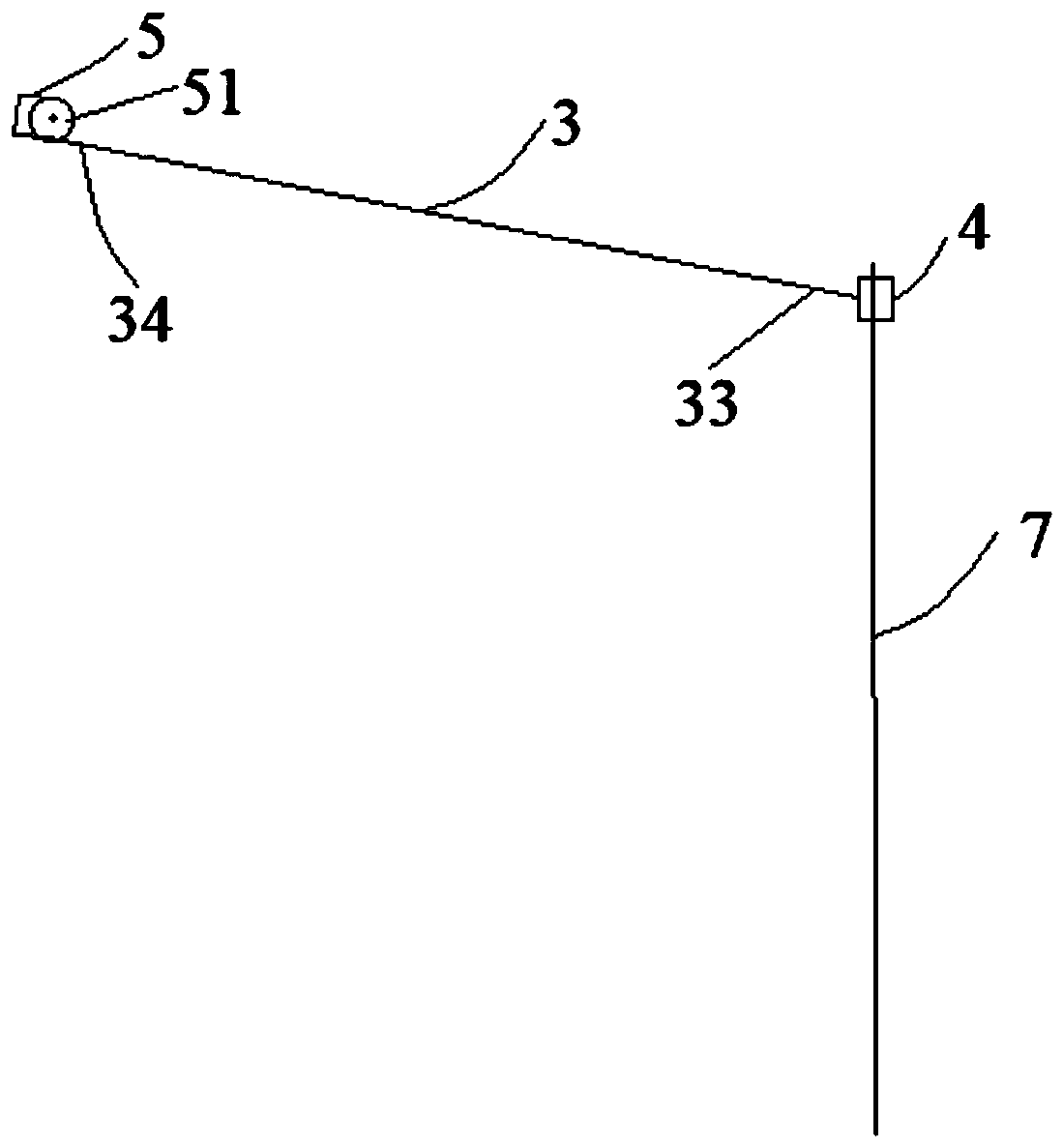

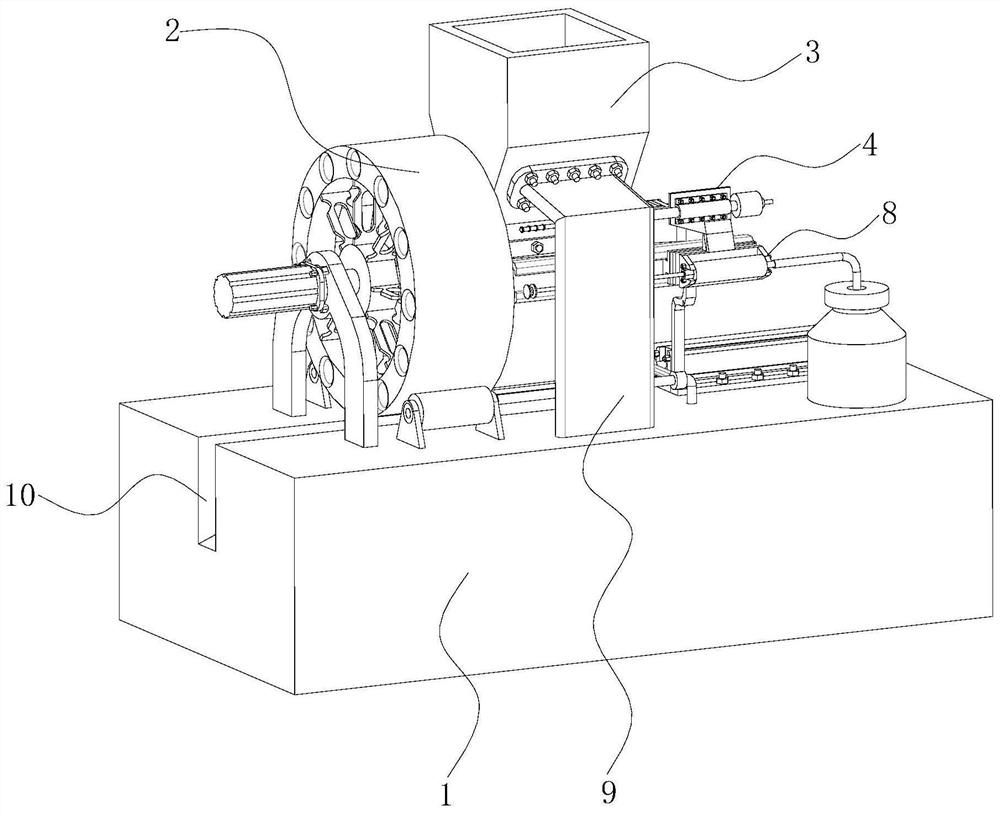

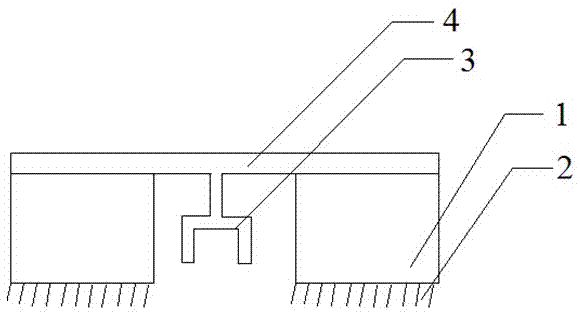

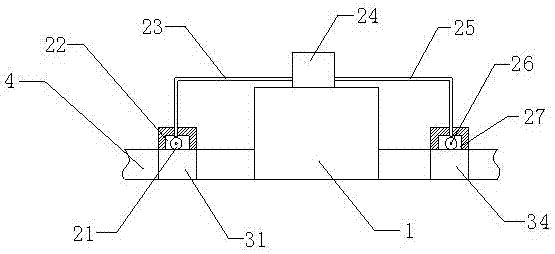

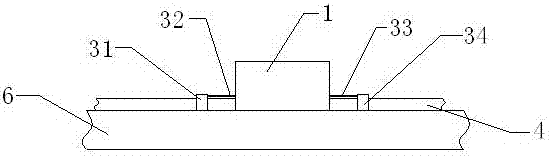

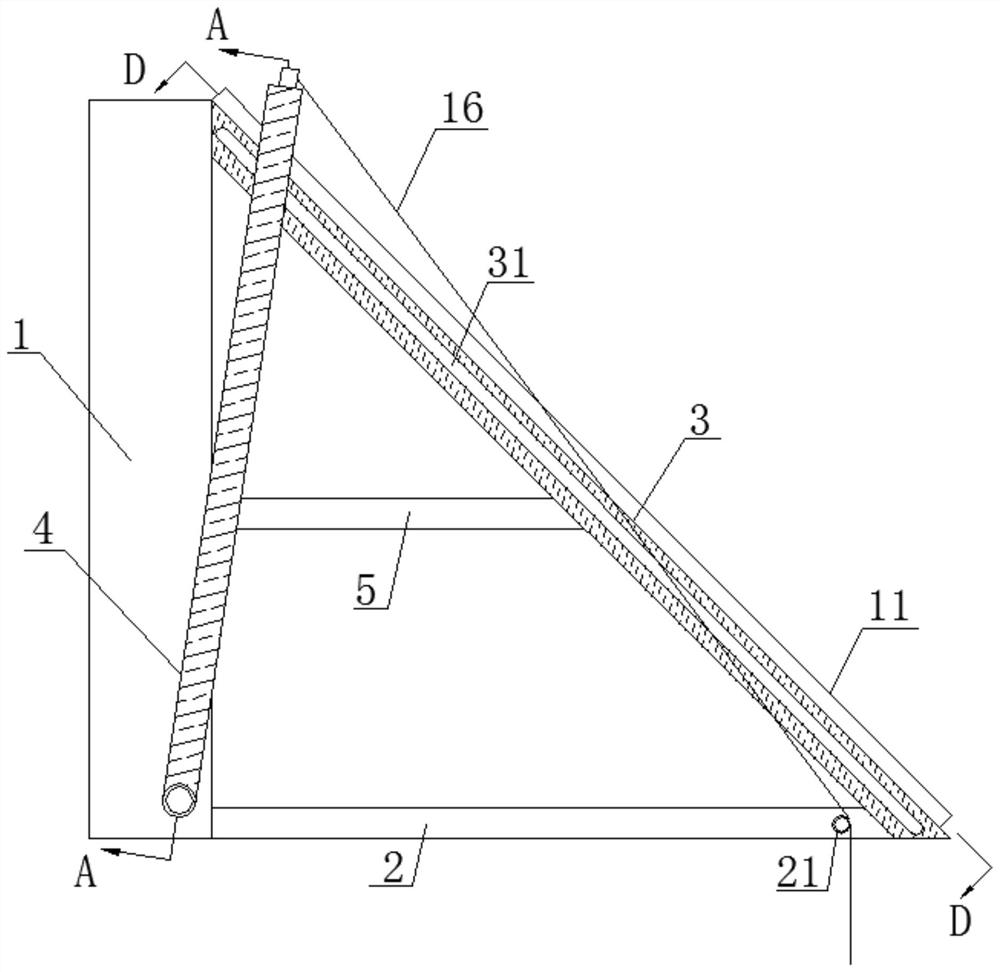

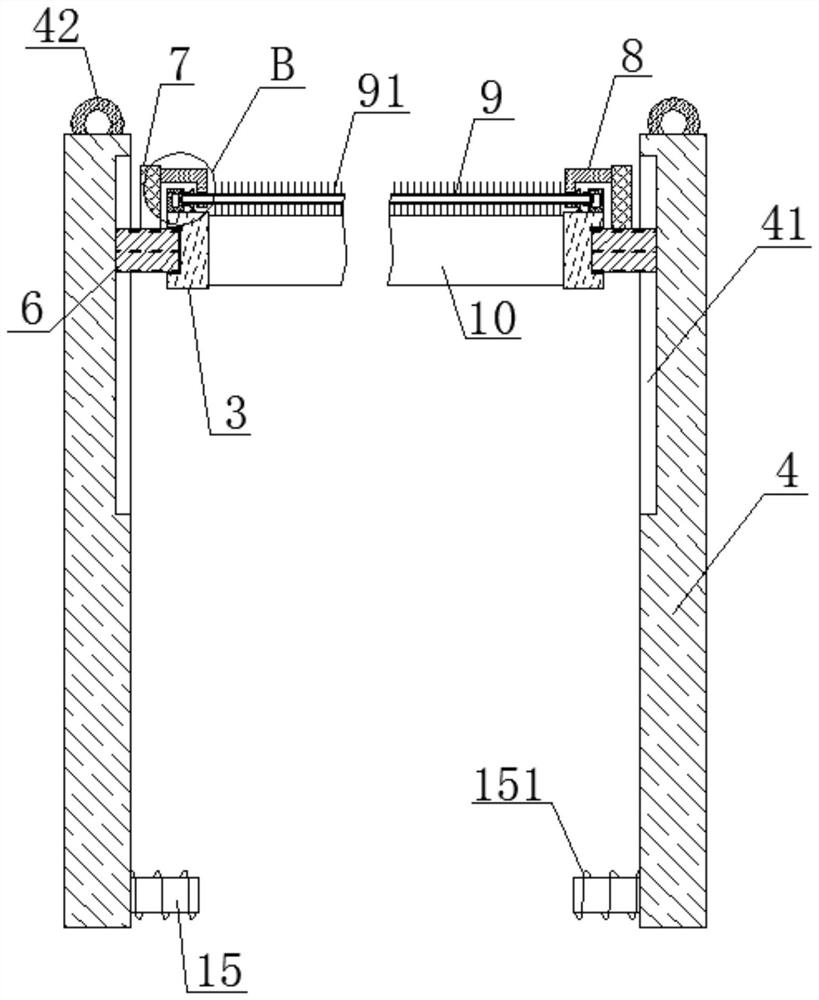

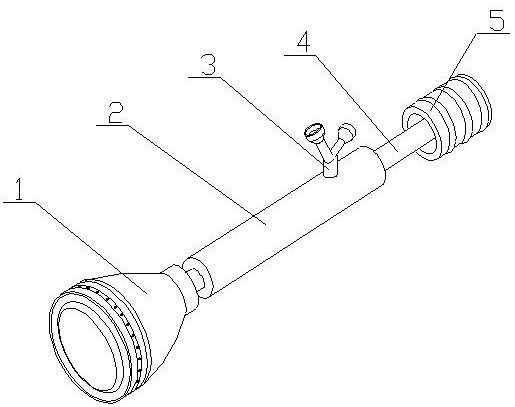

Automatic cleaning equipment for painting line

InactiveCN105436106ASynchronous cleaningIncrease productivityCleaning using toolsCleaning using liquidsProduction lineAutomatic test equipment

The invention discloses automatic cleaning equipment for a painting line. The automatic cleaning equipment for the painting line comprises bodies (1), brushes (2), a liquid spraying device (3) and a connecting pipe (4). The brushes (2) are connected to the bottoms of the bodies (1). The two bodies (1) are connected to the two ends of the connecting pipe (4) respectively. The liquid spraying device (3) is connected to the middle of the connecting pipe (4) and is in an inverted-Y shape. The liquid spraying device (3) is hollow. According to the automatic cleaning equipment for the painting line, synchronous cleaning of the painting production line can be achieved rapidly and effectively, and periodical maintenance after production halts in the prior art does not need to be adopted; the working time is shortened, and the production efficiency of the painting production line is improved. The automatic cleaning equipment for the painting line has high promotional value in the technical field of brush assemblies.

Owner:WUXI PRITEN TRANSMISSION MACHINERY

Pre-clearing machine for corrosion protection of outer wall of oil pipe

InactiveCN111744894AFor automatic dischargeSynchronous cleaningHollow article cleaningPretreated surfacesPipe fittingAir pump

The invention discloses a pre-clearing machine for corrosion protection of an outer wall of an oil pipe, and relates to the technical field of pipe clearing. The machine comprises a base, wherein a clearing mechanism and a rack are fixedly mounted on the top surface of the base, a high-pressure air pump is fixedly connected to the side surface of the base, one end of an air outlet of the high-pressure air pump is matched with the clearing mechanism, a group of first electric push rods are fixedly connected to the top surface of the rack, pressing seats are fixedly connected to the lower ends of the group of first electric push rods, and a limiting driving roller is rotationally connected between the inner surfaces of the pressing seats through bearings. According the machine, through design of the clearing mechanism, the machine can quickly realize synchronous clearing of the inner and outer walls of a pipe in an automated manner, during clearing, cleared impurities can be automatically discharged through spiral structure design of a clearing brush, and through matching design of the high-pressure air pump, on one hand, cleared dust can be timely blown out of the surface of the pipe, and on the other hand, the self-clearing property of the clearing brush can be conveniently ensured.

Owner:安徽彩色云环保科技有限公司

Desulfurization tower for preventing spray hole blockage

InactiveCN109876632ASynchronous cleaningSpread area expandedDispersed particle separationBristleEngineering

The invention discloses a desulfurization tower for preventing spray hole blockage. The desulfurization tower comprises a support frame and a tower body fixed to the upper end of the support frame, wherein a smoke gas inlet, a smoke gas outlet and a suction fog inlet are respectively formed in the left end, the top end and the right end of the tower body; a step motor is arranged inside the left end of the tower body; a desulfurization cavity is arranged inside the tower body; a spraying mechanism connected with an output shaft of the step motor is arranged in the desulfurization cavity; the spraying mechanism is matched with the absorption fog inlet; a second driving gear is connected onto the output shaft of the step motor through keys; the upper end of the second driving gear is engagedwith a second driven gear; a guide rail fixed onto the left and right ends of the desulfurization cavity is horizontally arranged above the second driven gear. The desulfurization tower has the advantages that a fog pipe can do autoroatation and can also do revolution around the rotating shaft, so that the scattering range of the sprayed absorption fog is expanded and is uniform; the reaction with the smoke gas is sufficient; bristles on a square screw nut is used for performing synchronous cleaning and brushing on a spray hole.

Owner:沙丽萍

Stone milling machine capable of controlling milling positions according to stone thickness

InactiveCN111941175ASynchronous cleaningPrevent milling effectsGrinding drivesGrinding work supportsParticulatesMilling cutter

The invention discloses a stone milling machine capable of controlling milling positions according to the stone thickness. The stone milling machine comprises a machining machine body, a moving cavityis formed in the machining machine body, and a large motor is fixedly embedded in the right wall of the moving cavity. The stone milling machine is mainly applied to being used for the surface milling procedure during stone machining. In the milling process, stone is clamped by a clamping block under the action of a sliding clamping mechanism, and then the situation that milling is influenced bystone moving is avoided; meanwhile, rotating of a milling cutter and moving of the stone can be achieved to a certain position to achieve automatic milling through abutting connection of a threaded sliding block and a cutter shell; meanwhile, water injection milling can be achieved on the surface of the stone through a water outlet pipeline; and particulate matter left after milling is synchronously cleaned through an engaging and jacking mechanism, a driven gear and a driving gear are engaged while a filter plate is stressed to move downwards, then an eccentric wheel is driven to move, and then the particulate matter is cleaned.

Owner:福州袋书吧电子科技有限公司

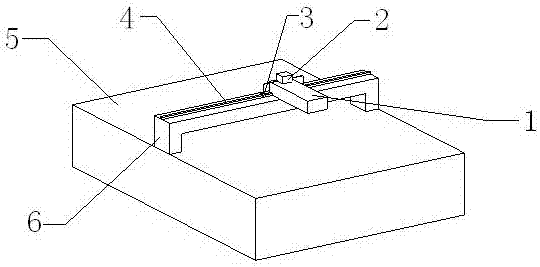

Linear module right angle coordinate automatic laser cutter

InactiveCN107378284AReal-time lubricationImprove the lubrication effectLaser beam welding apparatusBristleFuel tank

The invention provides a linear module Cartesian coordinate automatic laser cutting machine, which includes a hair roller one, a groove one, a left oil pipe, a lubricating oil tank, a right oil pipe, a hair roller two, a groove two, a left cleaning frame, a connecting rod one, a connecting rod Rod 2 and the right cleaning frame, the wool roller 1 is assembled in groove 1, the wool roller 2 is assembled in groove 2, the lubricating oil tank is assembled on the upper end surface of the laser head, and the right end of the left oil pipe is connected to the lubricating oil tank , the left end of the right oil pipe is connected to the lubricating oil tank. This design realizes the purpose of lubricating the track in real time in the present invention. The left end of the connecting rod is connected to the left cleaning frame, and the right end of the connecting rod is installed on the left end face of the laser head. The right end of the connecting rod two is connected to the right cleaning frame, and the left end of the connecting rod two is installed on the right end face of the laser head. This design realizes the purpose of synchronous cleaning of dust in the present invention. The present invention cleans dust in real time, has good lubricating effect, good stability and reliability high.

Owner:夏新河

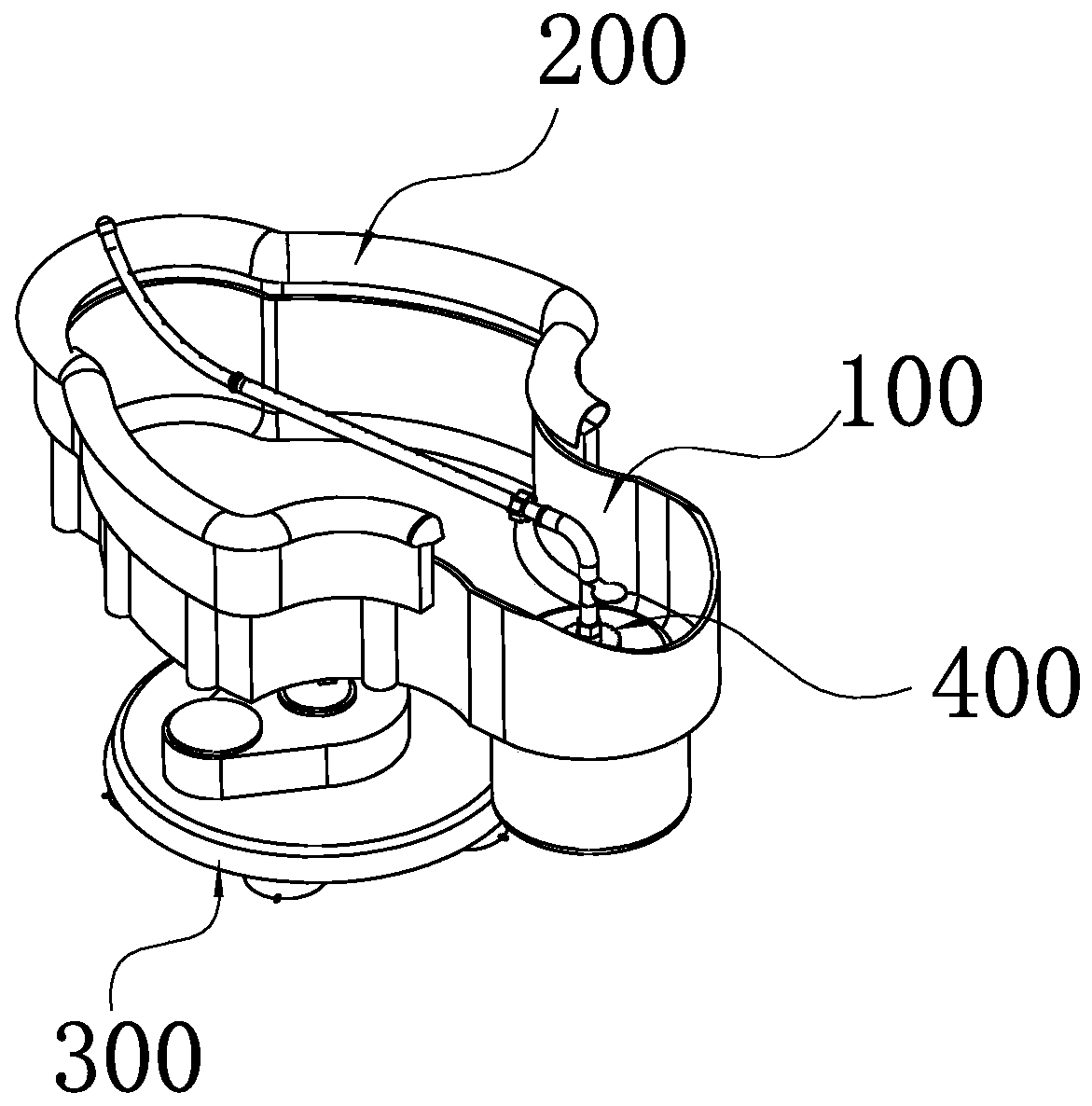

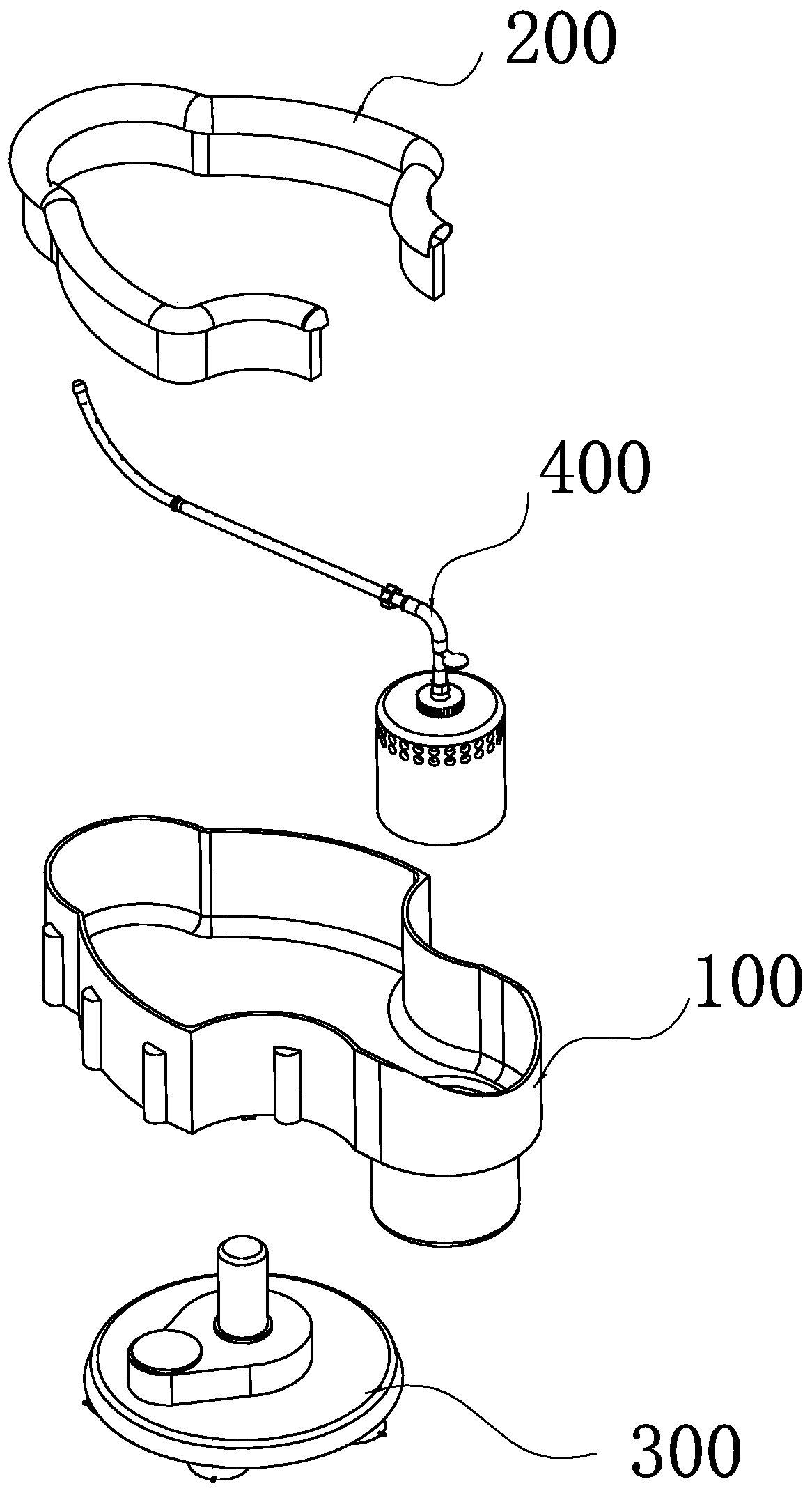

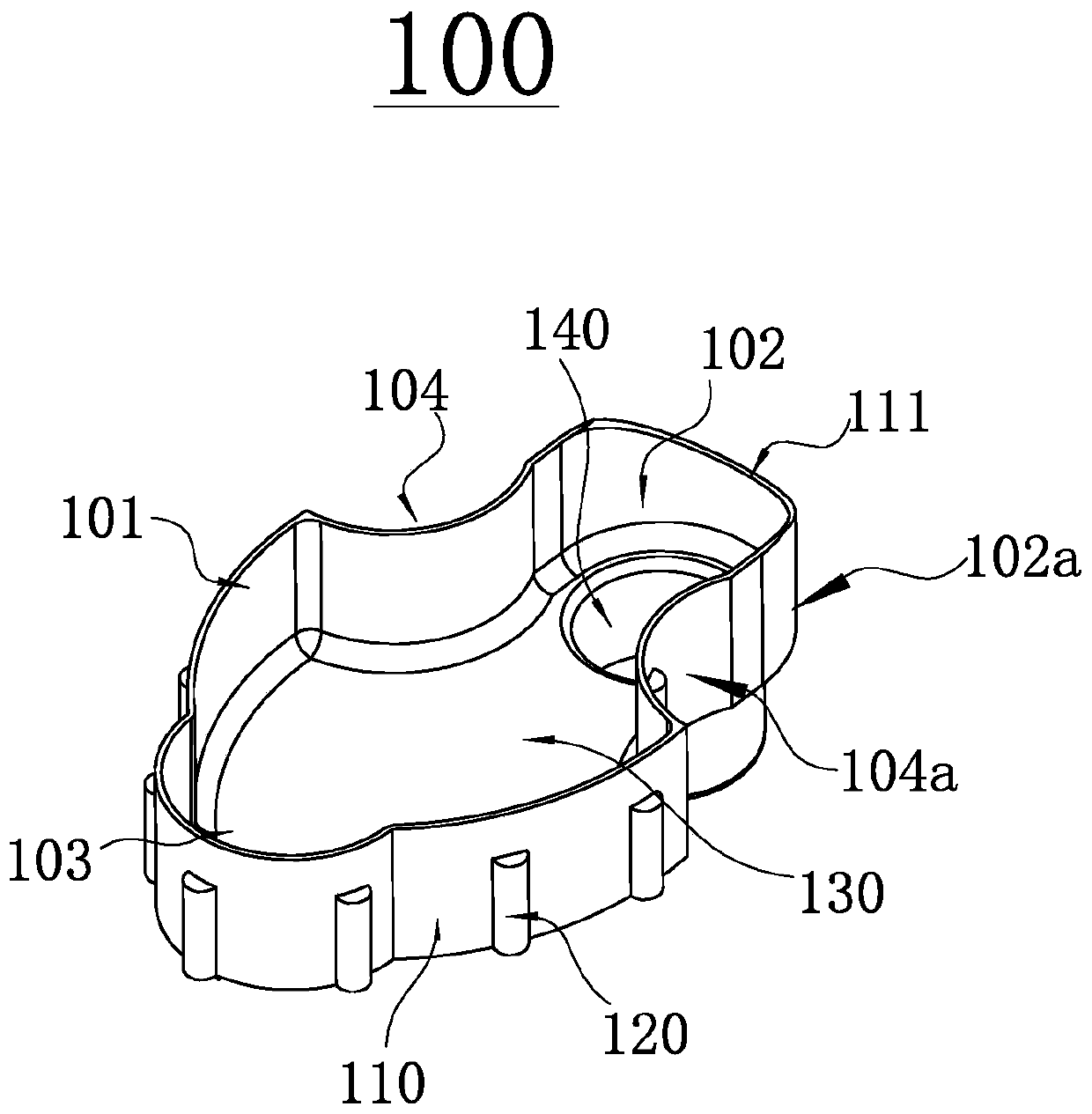

An anus and genital cleaning device

InactiveCN109024819BAvoid cross infectionSynchronous cleaningLavatory sanitoryCross infectionsCushion

The invention provides a device for cleaning the anus and the pudenda. The device includes a seat basin, a spray device assembly, a base and a cushion, wherein the spray device assembly is installed in the seat basin, the base is installed on the bottom of the seat basin, and the cushion is installed on the edge of the top of the seat basin. By independently arranging the spray device assembly andthe base used for helping adjusting the height, the requirements of patients different in height and shape can be met when the patients squat, a handle is used for adjusting a straight spray pipe anda bent spray pipe left and right, flushing of the anus and the pudenda at all angles is thus achieved, the purpose of synchronous cleaning is achieved, and meanwhile cross infection of the anus and the pudenda is avoided.

Owner:山东省第二人民医院(山东省耳鼻喉医院、山东省耳鼻喉研究所)

Energy-saving and environment-friendly automatic cleaning device for oil accumulating groove of range hood

InactiveCN112032786AOil pumping effect is goodAvoid blockingDomestic stoves or rangesLighting and heating apparatusProcess engineeringOil water

The invention relates to the technical field of household appliances, and discloses an energy-saving and environment-friendly automatic cleaning device for an oil accumulating groove of a range hood.The device comprises a wall, wherein a cross beam is fixedly connected to the middle of the right end of the wall, a cleaning tank is fixedly connected to the upper end of the cross beam, an exhaust pipe is fixedly inserted into the cleaning tank, a circular groove is formed in the inner wall of the upper end of the cleaning tank, a limiting block is movably inserted into the circular groove, a first movable rod is fixedly connected to the right end of the limiting block, and a first spring is movably connected to the outer side of the first movable rod in a sleeving mode and located in the circular groove. According to the device, a second movable rod is driven by a pull rod to move leftwards, the second movable rod pushes a piston to move leftwards along a cylinder groove, hot cleaning liquid in the cylinder groove surges to a first guide pipe after being extruded by the piston and then is jetted towards the inner wall of an oil pumping tank at a nozzle, residual dirty oil in the oilpumping tank is cleared up, an oil-water mixture obtained after clearing flows into a cleaning groove through a second guide pipe and then is discharged through a drainage channel, and therefore theeffect of synchronously removing oil stains in the range hood while cleaning the oil groove is achieved.

Owner:王搏思

A solar panel cleaning device

ActiveCN112427358BGood effectClean up thoroughlyPhotovoltaicsCleaning using toolsMechanical equipmentPhysics

Owner:广东大粤新能源科技股份有限公司

A kind of automatic cleaning equipment for cast flange pipe

The invention relates to automatic cleaning equipment for a cast flange pipe. The automatic cleaning equipment comprises a supporting top plate and a cleaning device, wherein the supporting top plateis uniformly provided with mounting holes. The cleaning device is installed on the lower end surface of the middle portion of the supporting top plate. The cleaning device comprises cleaning push rods, a cleaning expansion plate, a cleaning motor, a cleaning supporting plate, a cleaning mechanism, flange cleaning mechanisms, scraping mechanisms, a cleaning sliding groove and cleaning sliding rods.The flange cleaning mechanisms comprise flange connecting columns, flange supporting plates, flange rotating frames, flange rollers, flange supporting blocks, rotating frame rotating push rods and cleaning brushes. The automatic cleaning equipment for the cast flange pipe can solve the problems that the manual labor intensity is high when an existing flange pipe performs in-pipe sand cleaning, asteel pipe needs to be manually cleaned, the steel pipe cleaning effect is poor, and the inner wall of the steel pipe and the flange cannot be simultaneously cleaned.

Owner:LIANGSHANTONGYA EAVY IND MASCH CO LTD

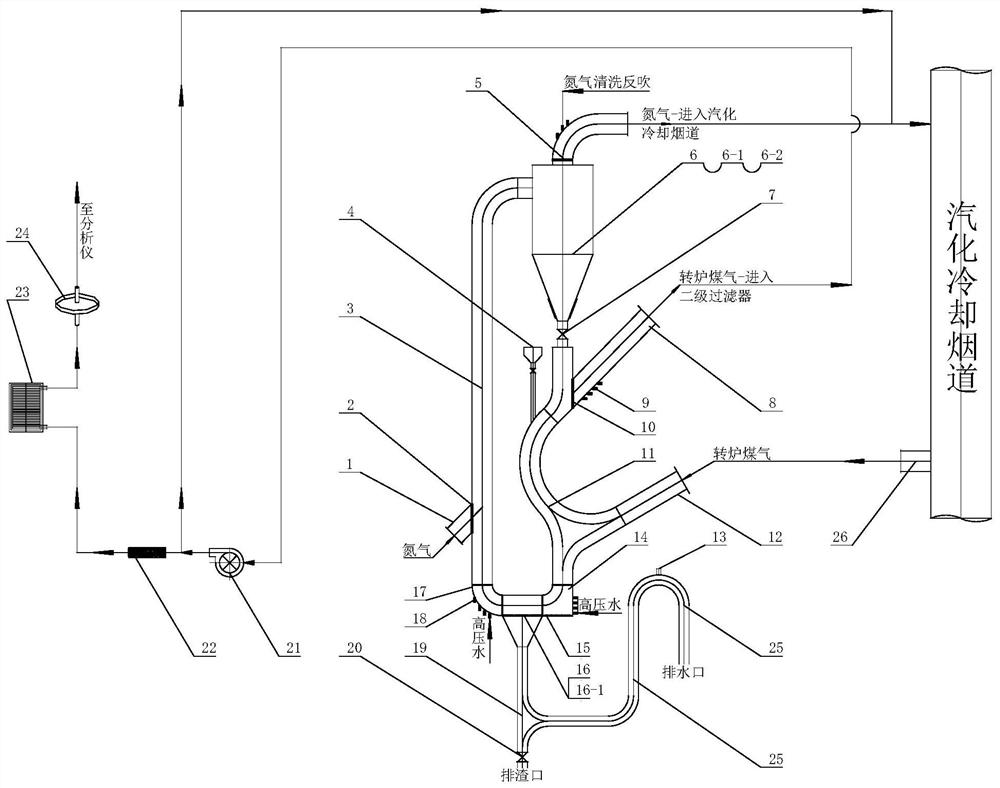

Converter flue gas sample gas dry pretreatment method based on thermal-state sampling

ActiveCN114480778ARestrict normal smooth operationGuaranteed uptimeMaterial analysis by electric/magnetic meansMaterial analysis by optical meansParticulatesPretreatment method

The invention discloses a converter flue gas sample gas dry pretreatment method based on thermal-state sampling, which solves the problems of sampling head damage, blockage and the like in the existing sampling process, and adopts the technical scheme that high-temperature converter flue gas is led out from a converter evaporation cooling flue through a flue gas sampling port and enters a sample gas pretreatment unit to be subjected to pretreatment such as cooling and purification; the high-temperature converter flue gas is fed into a mass spectrometer or an infrared analyzer for flue gas analysis for flue gas composition analysis, and the high-temperature converter flue gas is in reverse direct contact with the solid particle medium packed bed in the sample gas pretreatment unit for heat exchange, and is filtered and intercepted by a solid particle medium layer of the solid particle medium packed bed to obtain the high-temperature converter flue gas. And most smoke dust particles carried by the high-temperature converter smoke are captured. The method provided by the invention has the advantages of maintenance-free system, compact structure and high cooling efficiency, and can realize continuous and stable operation of the sampling process.

Owner:江苏集萃冶金技术研究院有限公司 +1

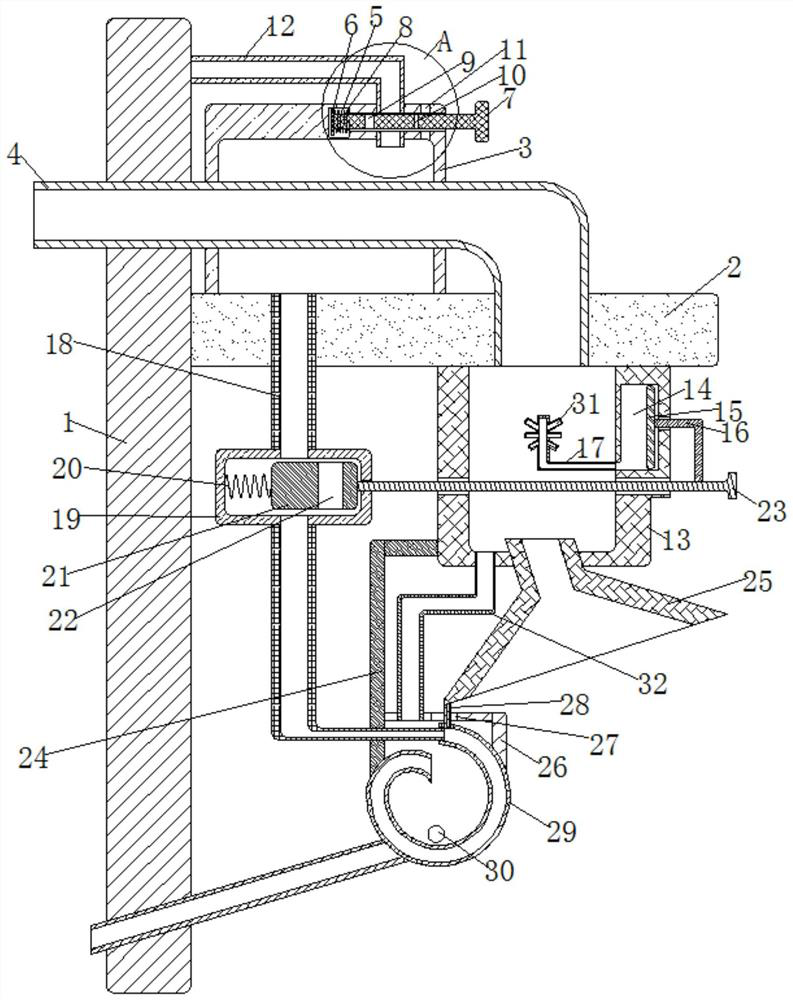

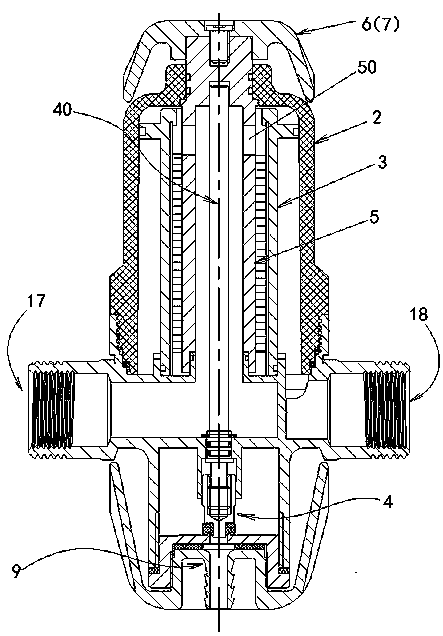

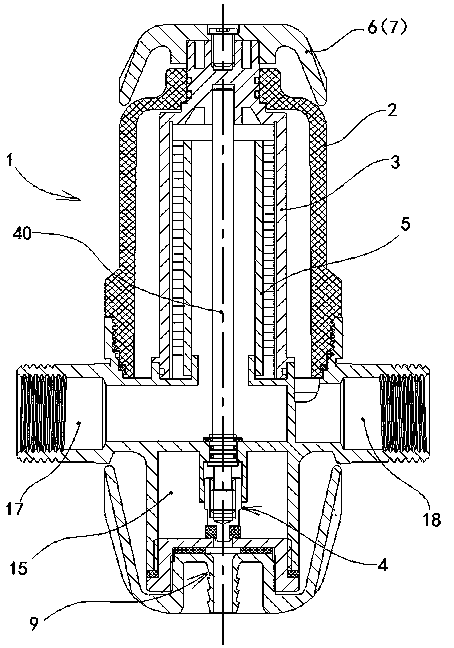

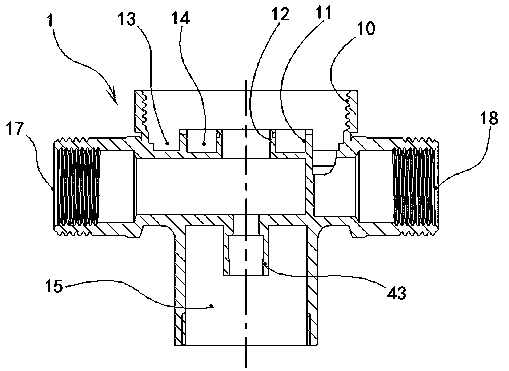

Inversion type pre-filter

InactiveCN108837578AImprove convenienceExtended service lifeStationary filtering element filtersEngineeringBlowing down

The invention relates to the technical field of water treatment, in particular to an inversion type pre-filter. The invention provides a novel technology for combining a novel built-in blow-down valvestructure and a flexible scraping brush decontamination device. The methods that the conventional pre-filter generally adopts a technological approach of decontamination by an external ball valve andthe cylinder, the filter cartridge and the like of the pre-filter are generally arranged at the lower end of a connecting part structurally are completely changed. Compared with the traditional pre-filter, the inversion type pre-filter disclosed in the invention has an inverted structure.

Owner:李渊

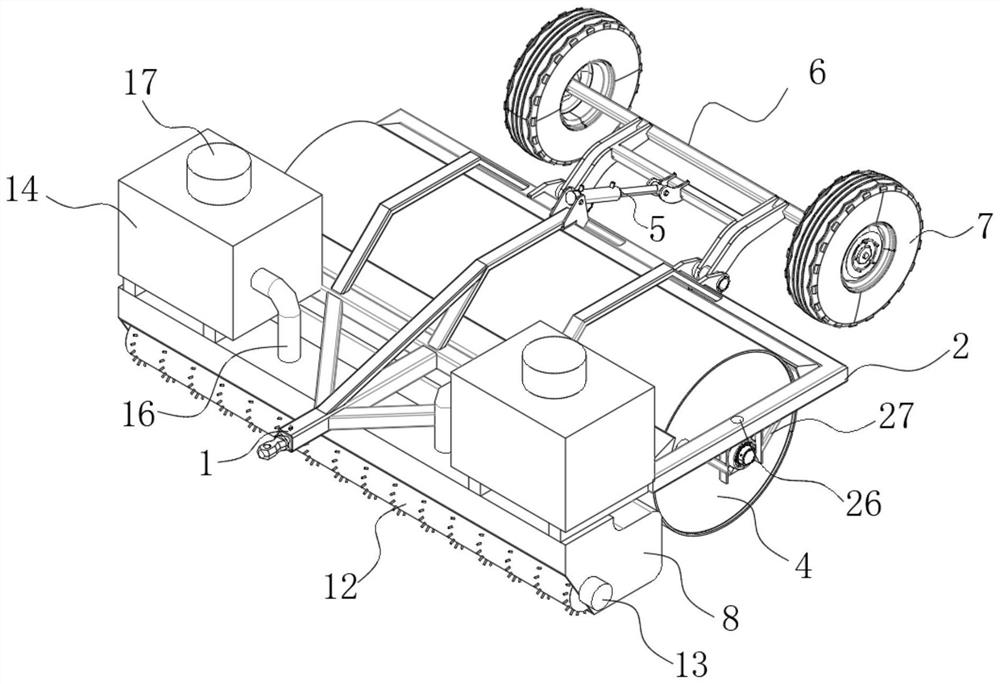

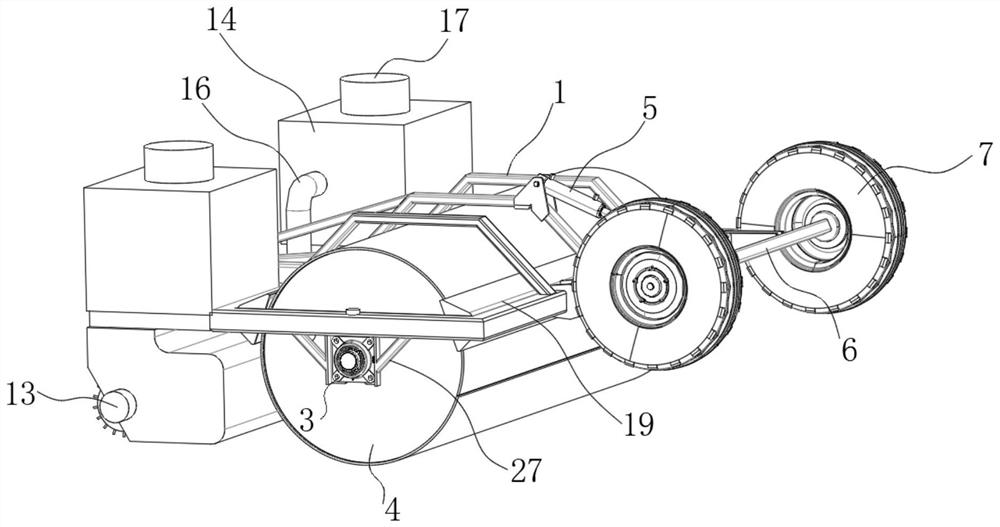

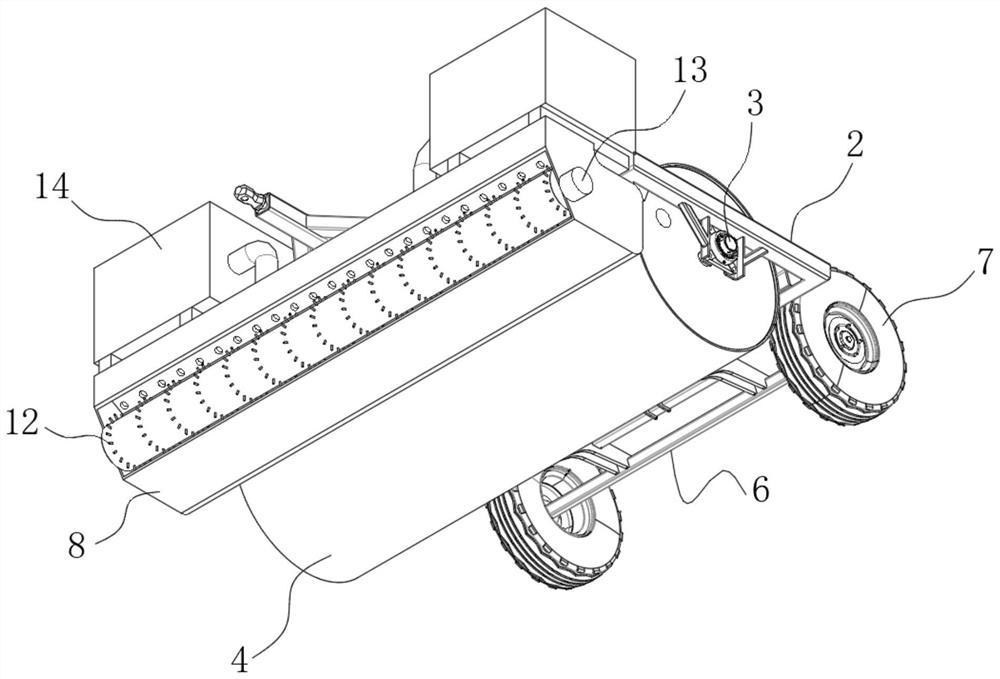

Asphalt pavement rolling device based on municipal road engineering

PendingCN114753213APlay a guiding roleImprove accuracyRoad cleaningRoads maintainenceRoad engineeringArchitectural engineering

The embodiment of the invention discloses an asphalt pavement rolling device based on municipal road engineering, and belongs to the technical field of municipal road engineering equipment.The asphalt pavement rolling device comprises a reinforced triangular arch cage frame installed on a road roller, a self-cleaning road rolling assembly is arranged on one side of the reinforced triangular arch cage frame, and a cleaning assembly is arranged on the self-cleaning road rolling assembly; a supporting assembly is arranged on one side of the self-cleaning road rolling assembly. Through corresponding cooperative use of all the structures, gravel impurities on a road surface can be collected and cleaned firstly during road rolling, damage to the road surface caused by gravel can be effectively avoided, dust generated during road rolling is further prevented from polluting the surrounding environment, and the device is convenient to use and high in practicability. And meanwhile, dust on the road surface can be cleaned synchronously, the situation that soil pollutes other road sections during follow-up road rolling can be avoided, road rolling and cleaning are conducted synchronously, manpower and material consumption can be effectively reduced, and good practicability is achieved.

Owner:衡阳润鹏道路工程有限公司

A hydraulic cylinder inner wall cleaner

ActiveCN109604284BSynchronous cleaningSimple structureRotary stirring mixersTransportation and packagingHydraulic cylinderStructural engineering

The invention discloses a cleaner for the inner wall of a hydraulic cylinder, which can extend into the cylinder, prepare cleaning liquid while cleaning, and wash the inner wall of the cylinder through spray holes distributed around the circle. It can filter out the impurities in the cleaning solution before flushing. It is characterized in that a connecting pipe is arranged in the middle of one end of the hollow pipe and communicates with the hollow pipe, the cleaning shell is placed on the connecting pipe and communicates with the connecting pipe, the diameter of the cleaning shell is from one end to the other One end gradually increases, the filter plug is placed inside the cleaning housing, and corresponds to the connecting pipe, the support column is placed on the filter plug, and is located in the cleaning housing, and one end of the support column extends to the other port of the cleaning housing, The diameter of the support column gradually increases from the other end to one end, and a plurality of diverter blocks are placed on the outside of the support column at equal angles. On the outer wall of the other end of the housing.

Owner:钱俊

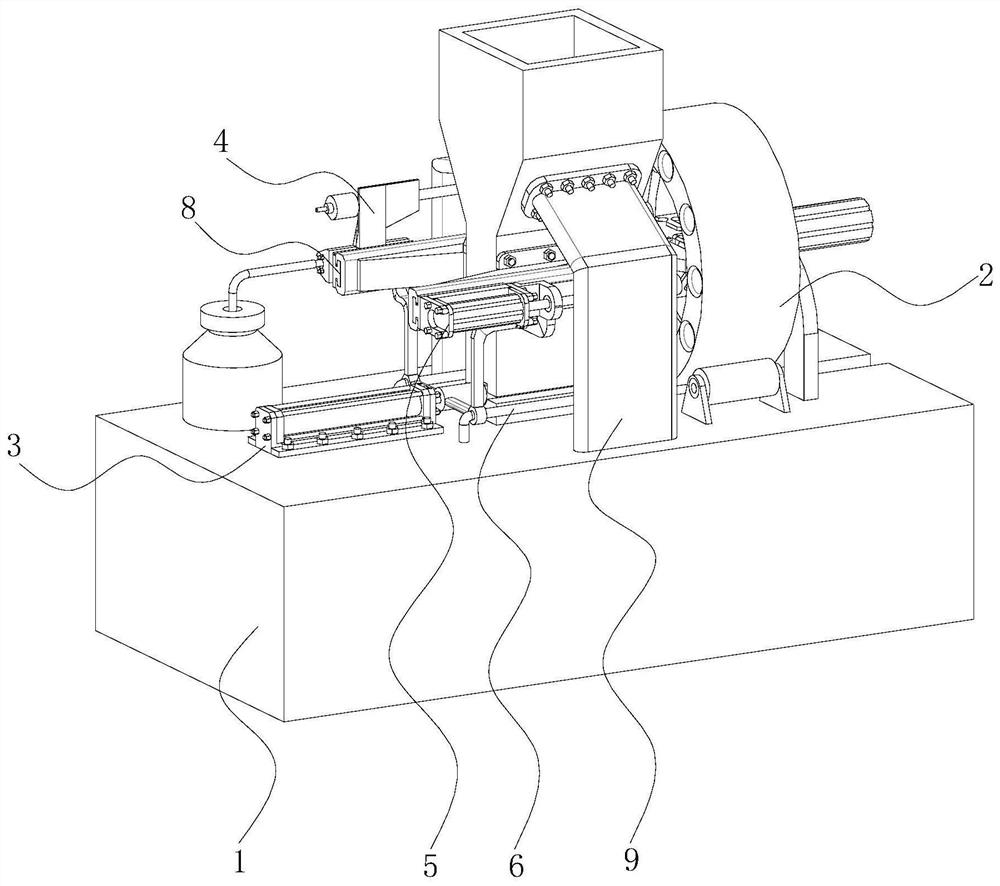

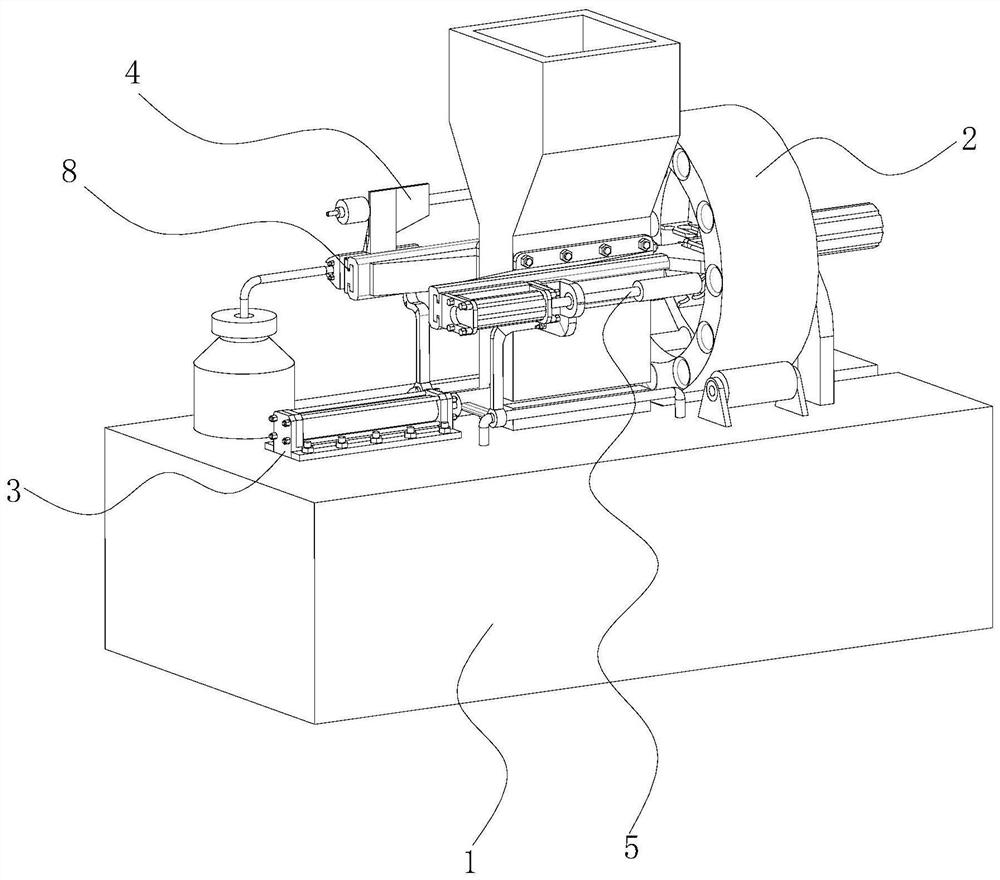

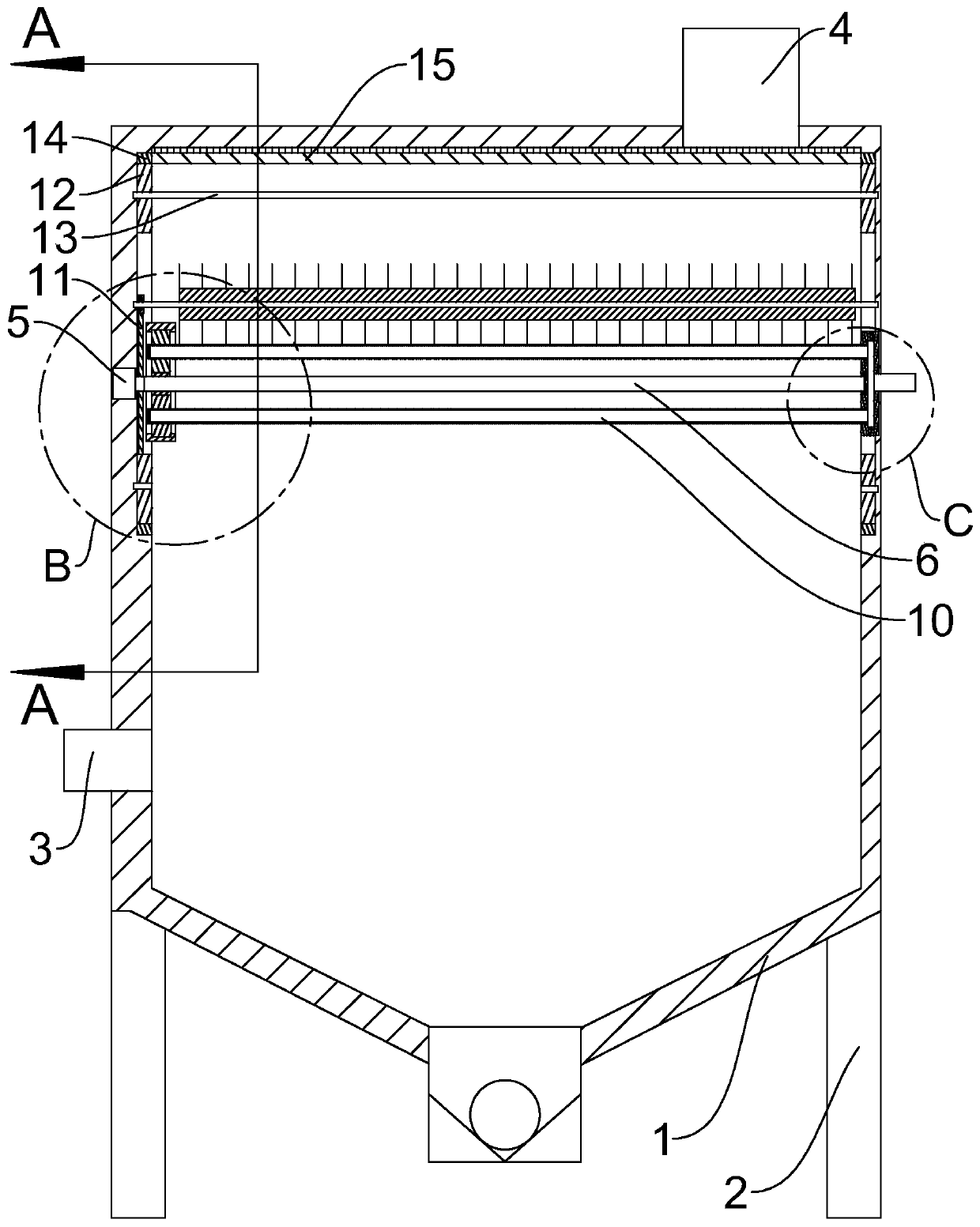

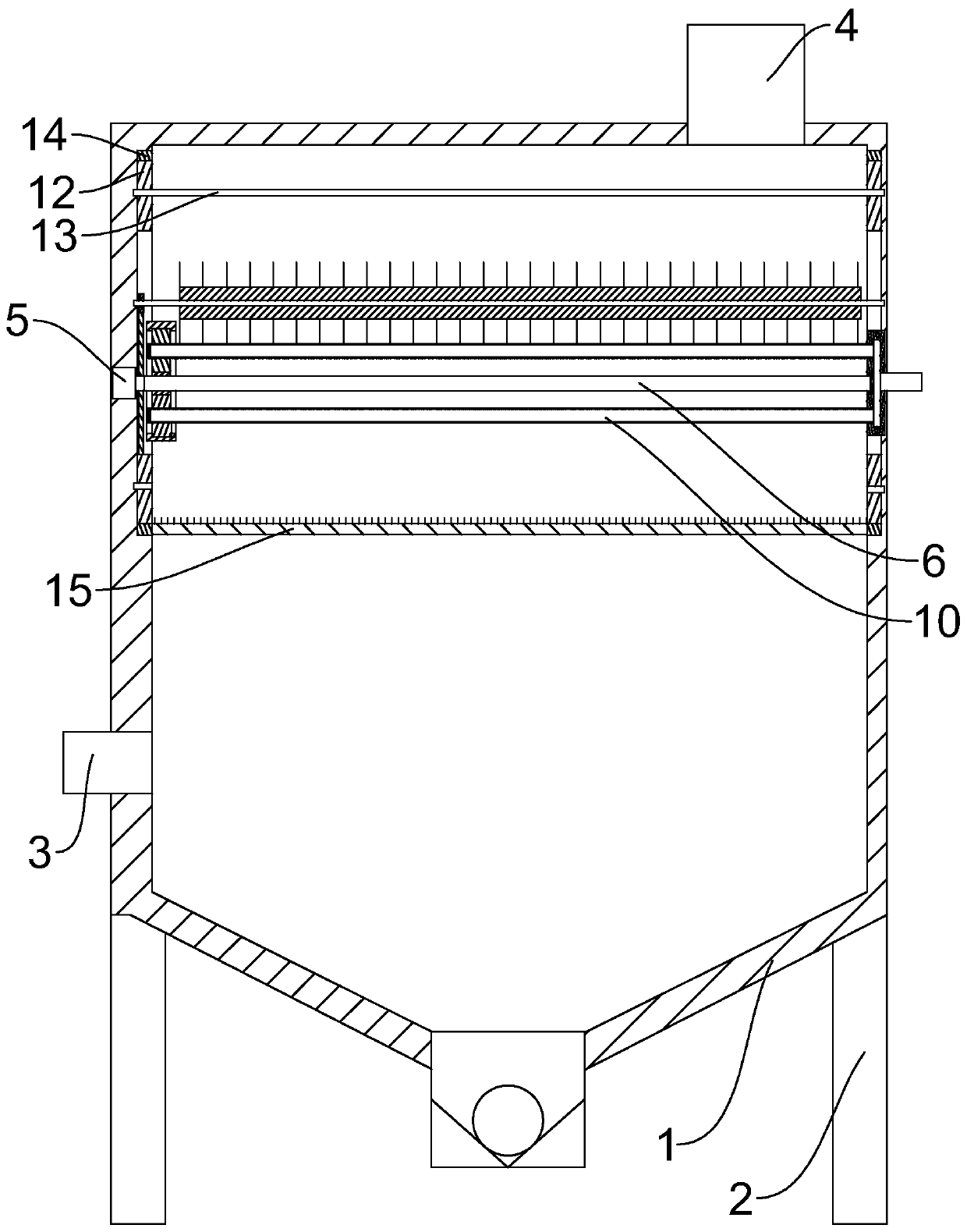

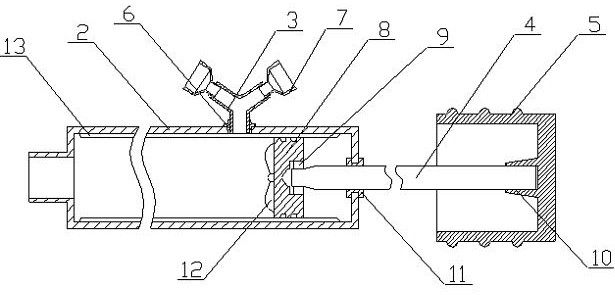

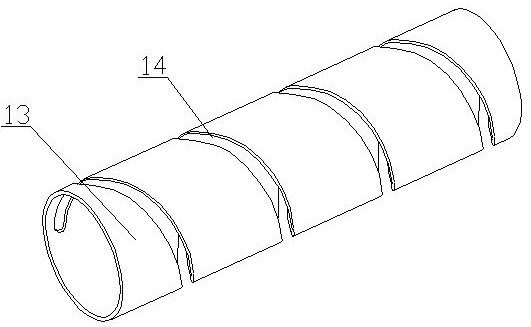

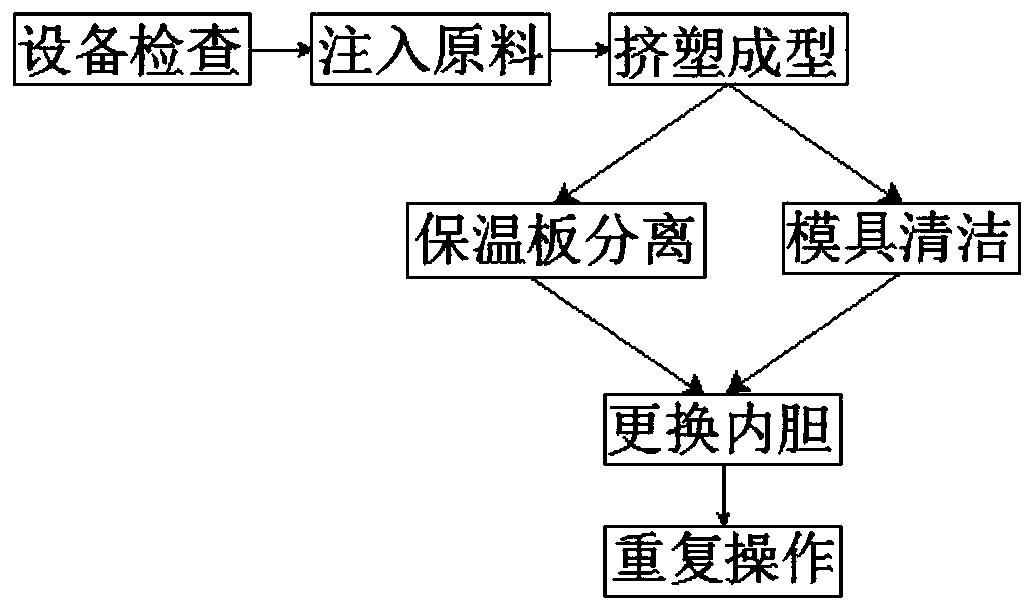

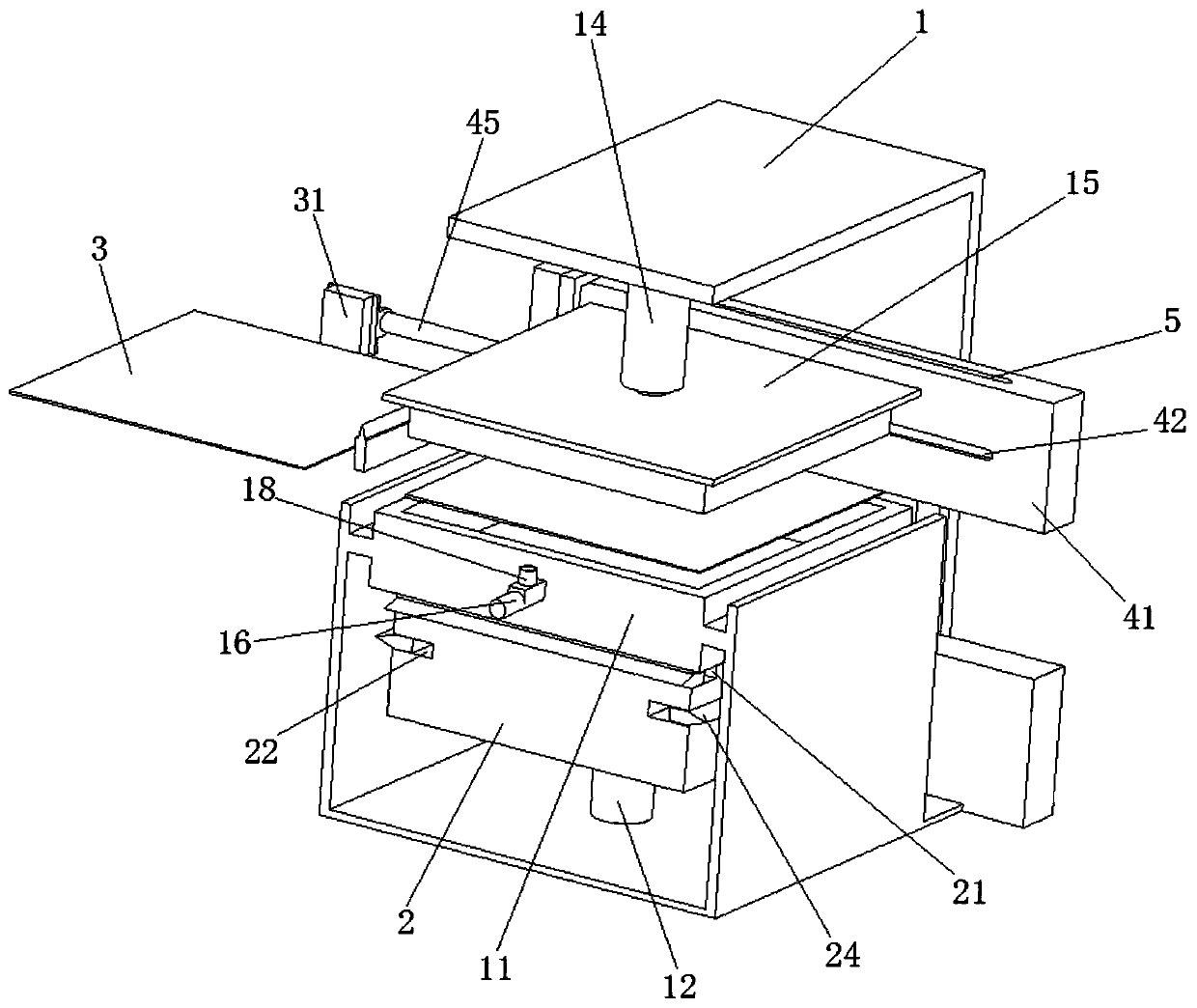

Production process of extruded insulation board

The invention relates to the field of production and processing, and particularly relates to a production process of an extruded insulation board. An extrusion mold is used and comprises a main frame,an extrusion module and an inner container, wherein a limiting frame with a square hollow structure is fixedly connected to the top of the main frame; a first hydraulic cylinder is fixedly connectedto the position, positioned below the limiting frame, in the main frame; the extrusion module is fixedly connected to the top of the first hydraulic cylinder; the top of the extrusion module is inserted into the limiting frame; first grooves are symmetrically formed in the two sides of the extrusion module; second grooves are symmetrically formed in the positions, positioned below the first grooves, of the two ends of the extrusion module; spring telescopic rods are fixedly connected in the first grooves and the second grooves; and one of the ends of the spring telescopic rods is fixedly connected with telescopic clamping strips. The production process has the advantages of being simple in structure, convenient to operate, capable of greatly improving the production efficiency of the extruded insulation board and suitable for popularization.

Owner:Jiangsu Jiunuo Architectural Materials Technology Co Ltd

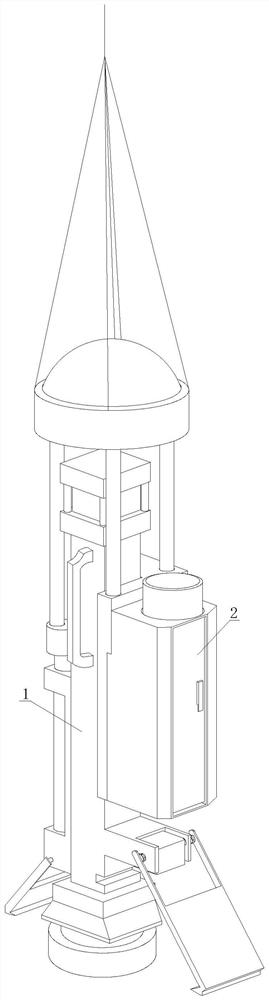

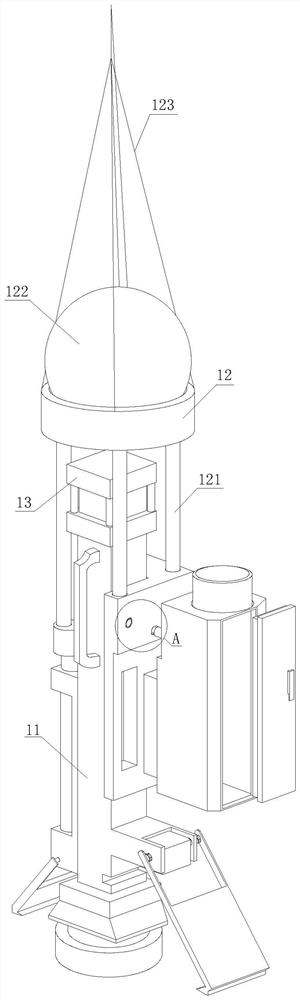

Deep sea mineral mining device

The invention discloses a deep sea mineral mining device. The deep sea mineral mining device comprises a lower mining mechanism and a mineral collection mechanism, wherein the mineral collection mechanism is fixedly installed on one side of the lower mining mechanism. According to the device, waterproof rubber gaskets are respectively arranged on the two sides of a sealing piston column, so that when the device goes deep into a seabed, a hydraulic push rod can be driven by a hydraulic oil cylinder to drive the sealing piston column to descend to the position near a feeding pipe for sealing, and a large amount of water flow is prevented from rushing into a working feeding cavity; additionally, when a delivery pump is used for feeding, the sealing piston column can be lifted to the position above a through groove, so that feeding is facilitated; and after mining feeding is completed, the hydraulic push rod is driven again to enable the sealing piston column to move downwards, so that redundant water and mineral aggregates can be squeezed out, and in the downward movement process of the sealing piston column, mineral aggregates which remain on the inner wall of the working feeding cavity can be scraped away through the waterproof rubber gaskets on the two sides of the sealing piston column, so that the synchronous cleaning purpose is achieved, and the use for the next time is also facilitated.

Owner:吴高庭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com