Converter flue gas sample gas dry pretreatment method based on thermal-state sampling

A converter flue gas and pretreatment technology, applied in the direction of manufacturing converters, instruments, and analytical materials, can solve the problems of reducing oxygen supply intensity, furnace material quality, composition, cooling capacity error, and high O content, so as to solve the problem of sampling unit blockage , clean cooling medium, less control variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

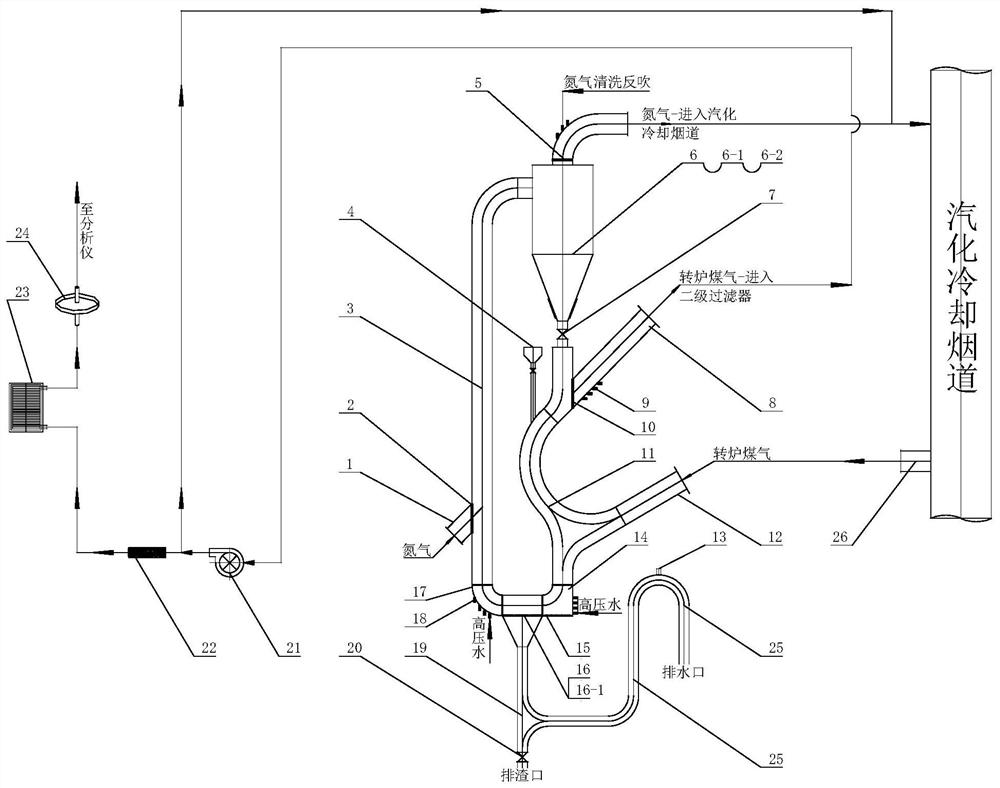

[0110] see figure 1 , on the inclined vaporization cooling flue near the upper part of the converter hood, more than two flue gas sampling ports 26 are evenly arranged along the circumference of the vaporization cooling flue. Under the suction of the sampling fan 21, the high temperature converter flue gas is sampled from the flue gas Port 26, enter the flue gas cooler 11 through the converter flue gas sampling pipe 12 with jacket water cooling, and flow through the gap of the stainless steel ball bed with a particle size of 1 to 3 mm filled in the flue gas cooler 11 , and directly contact with stainless steel balls for heat exchange, at the same time, the condensable components in the flue gas are condensed and attached to the surface of the steel balls, and the soot particles brought in with the flue gas are also intercepted and captured by most of the steel ball bed .

[0111] After being cooled, intercepted and filtered by the bed of stainless steel balls, the concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com