Patents

Literature

65results about How to "Play a clamping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

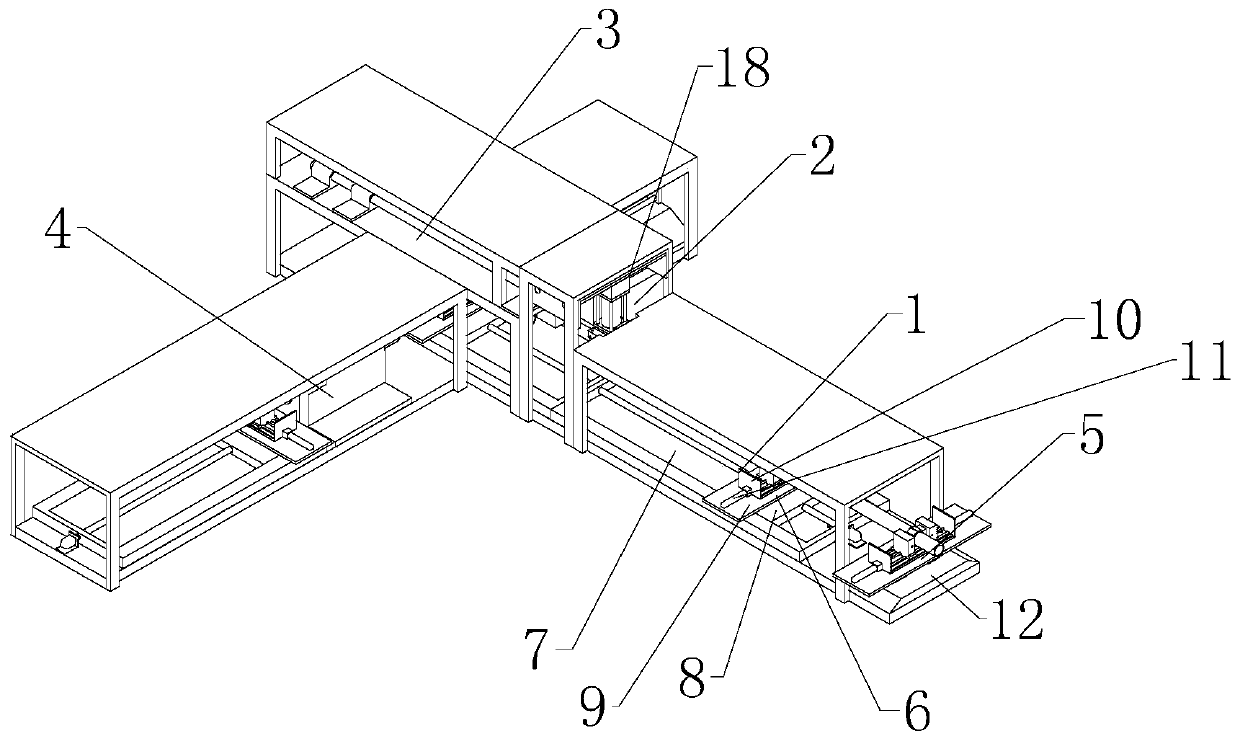

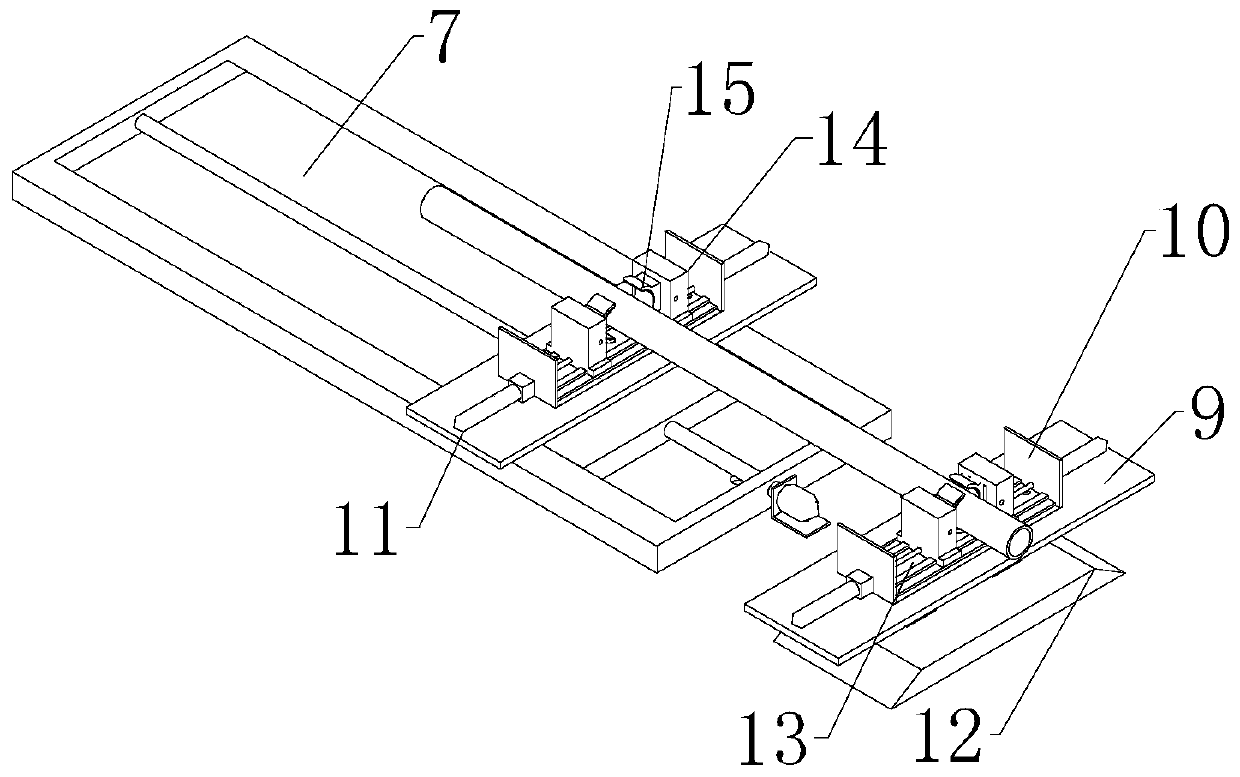

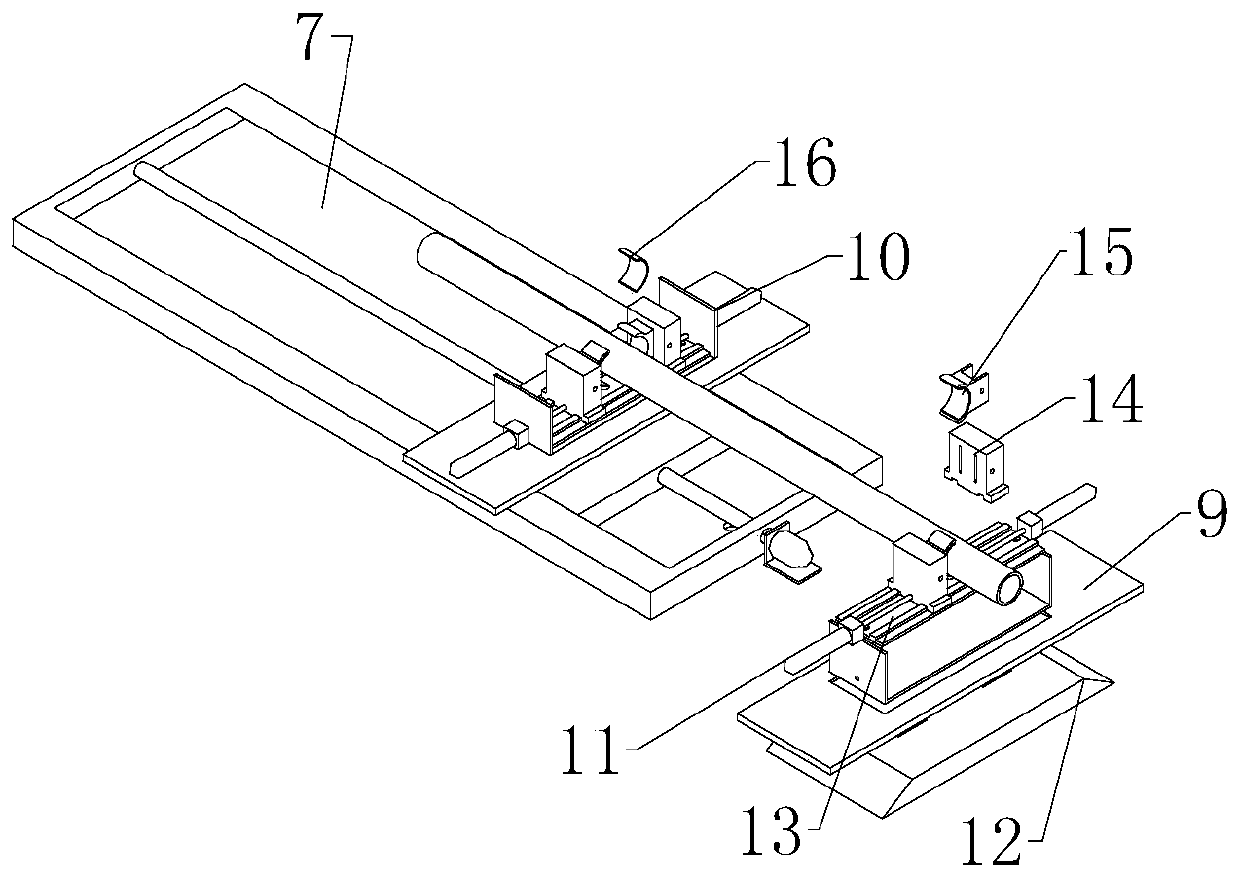

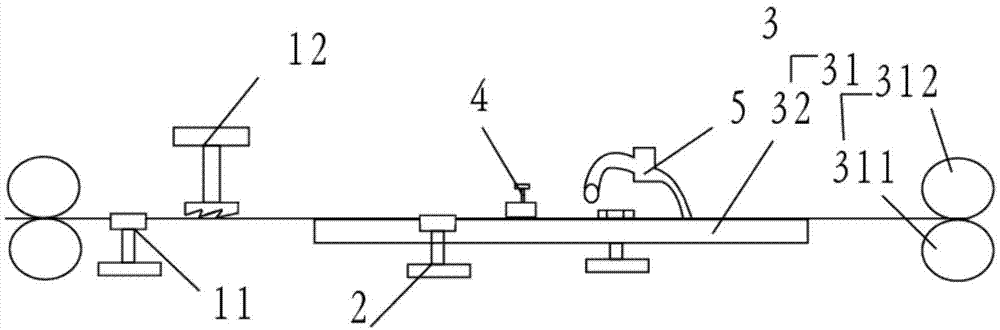

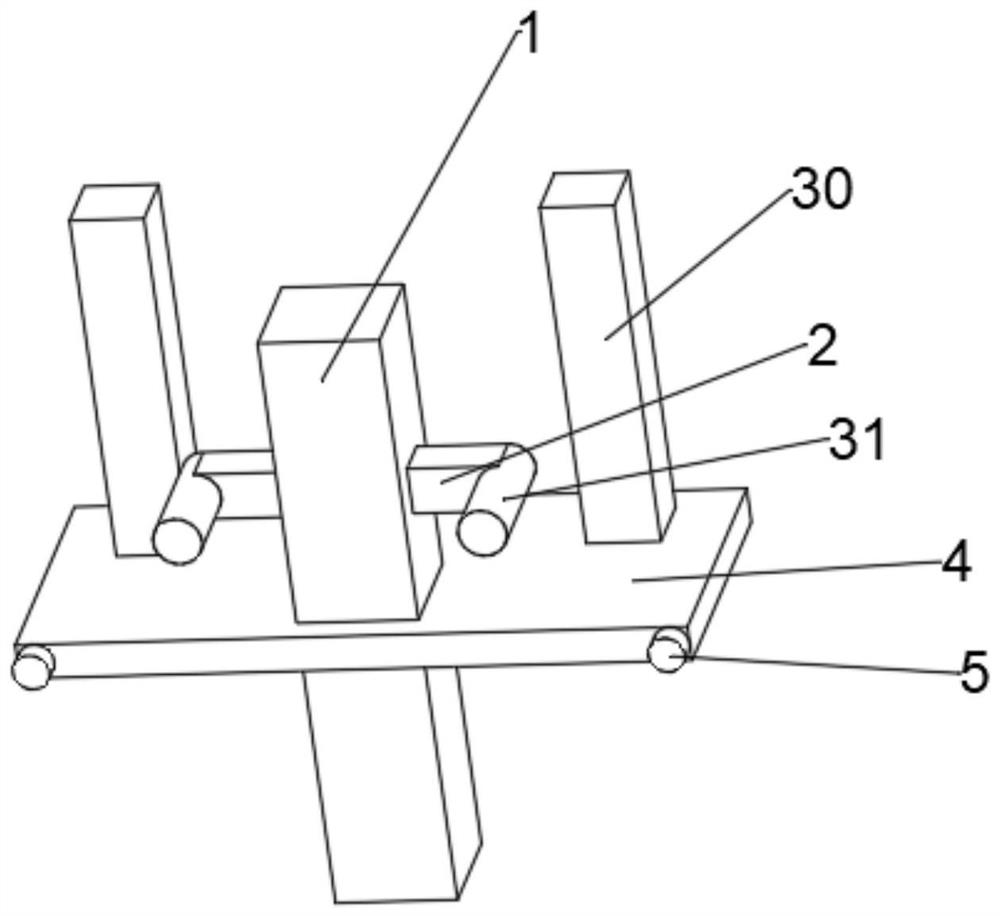

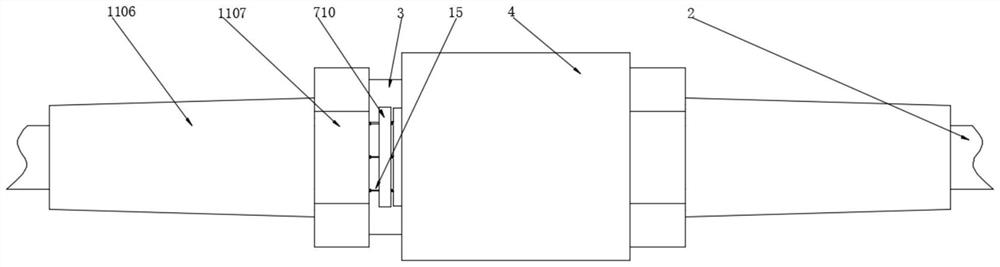

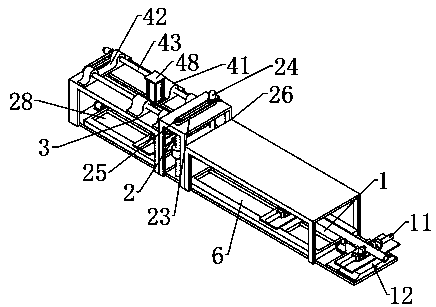

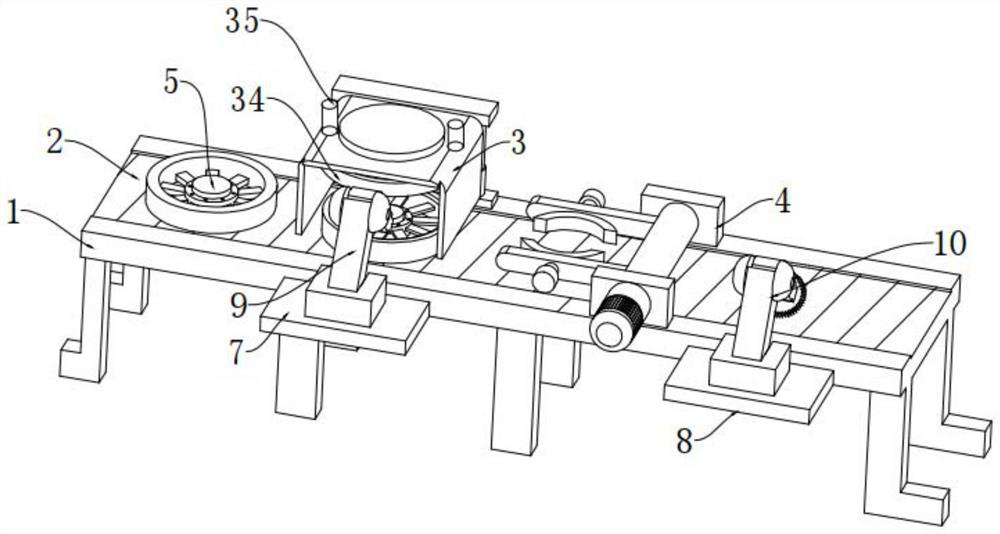

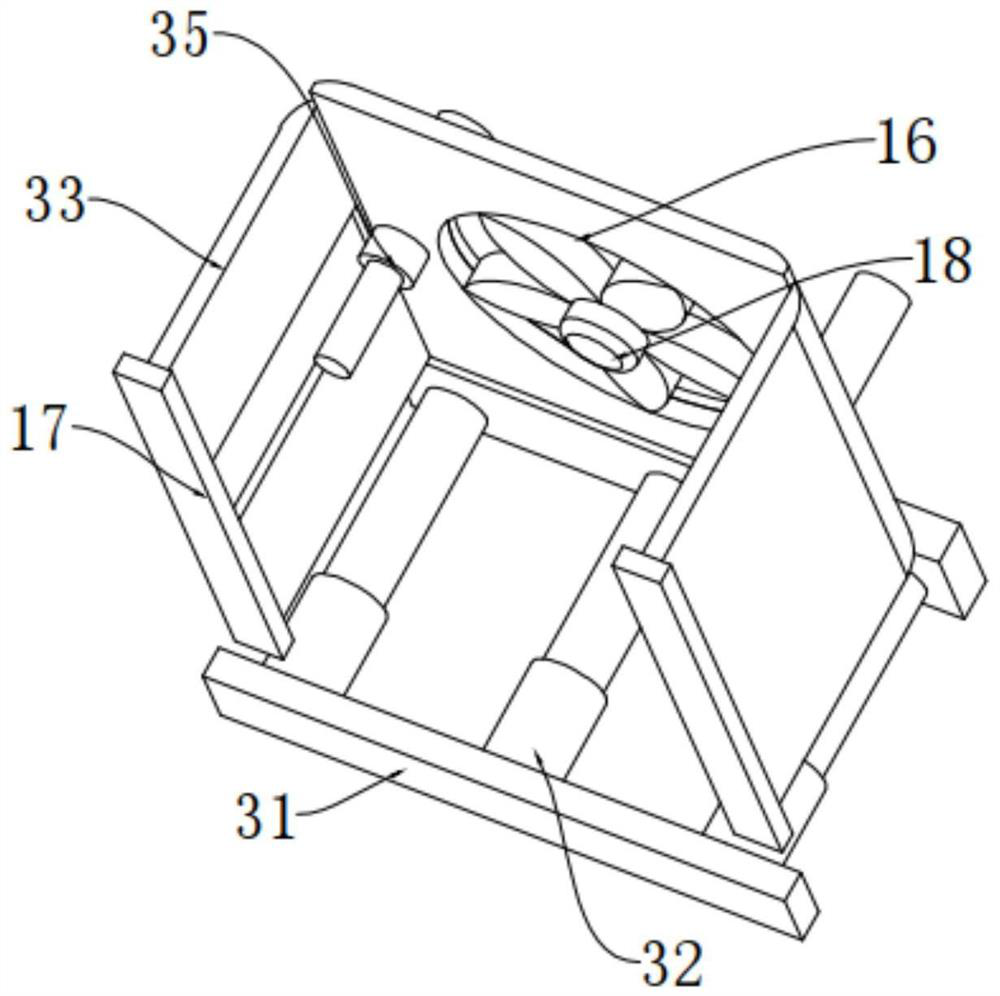

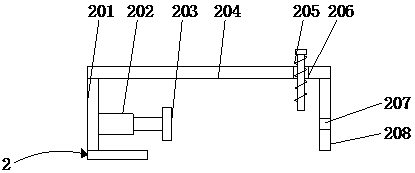

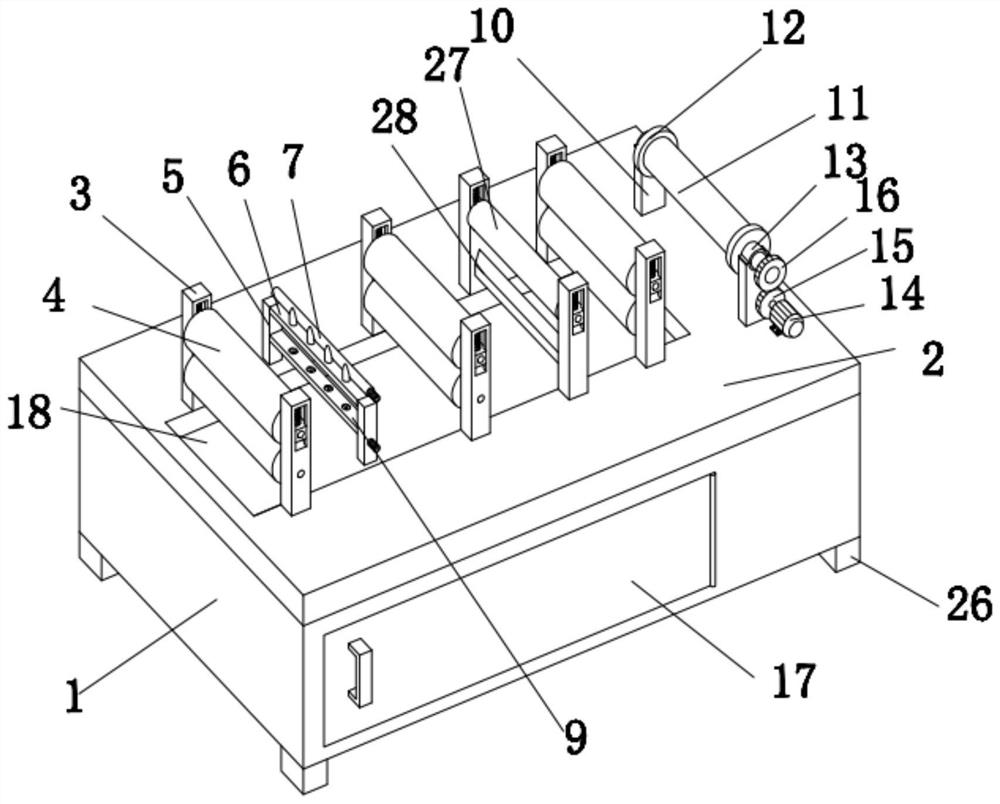

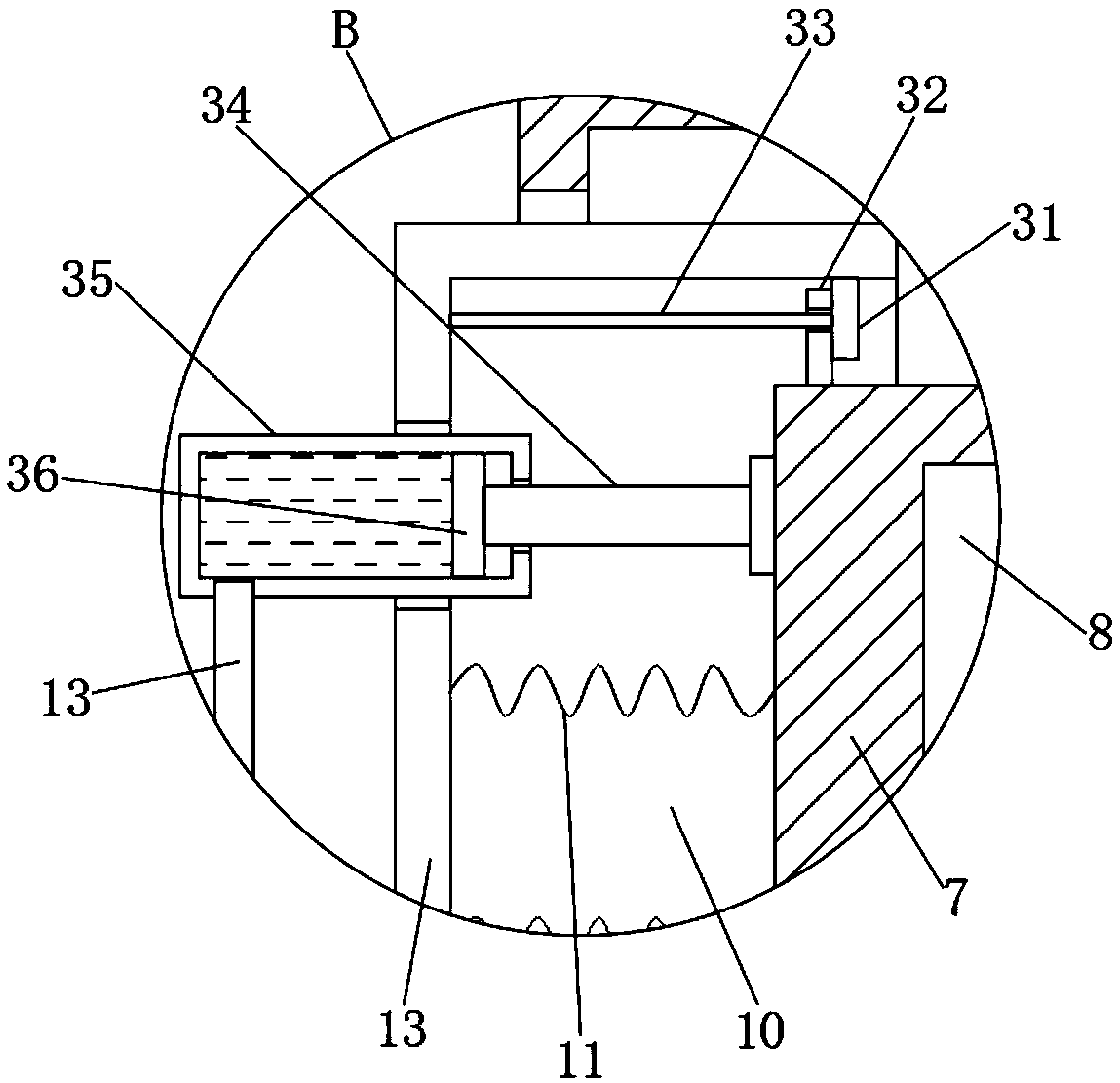

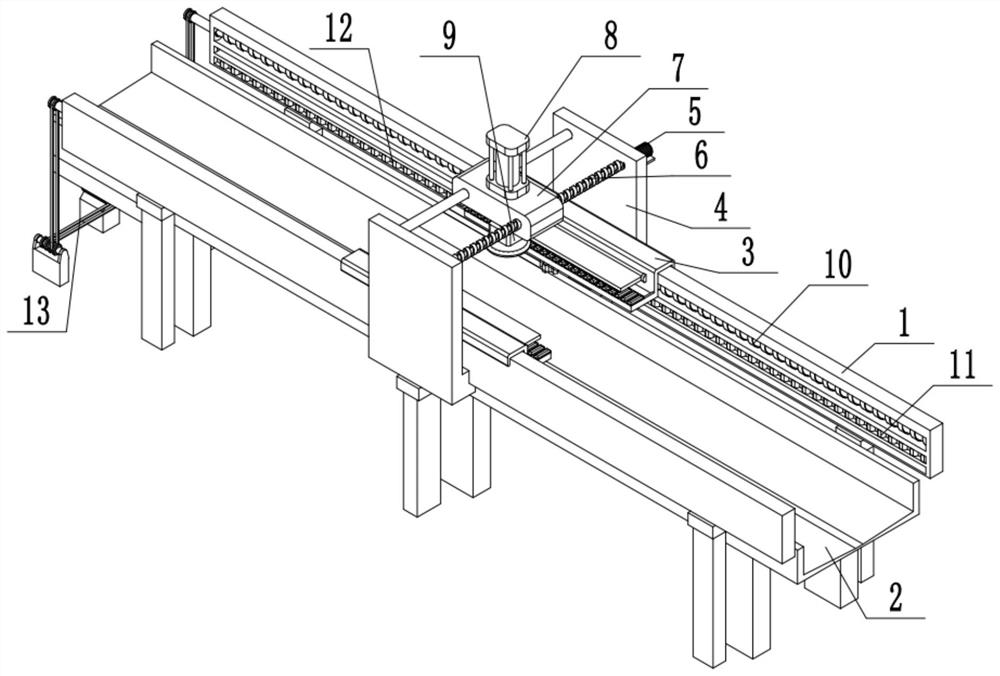

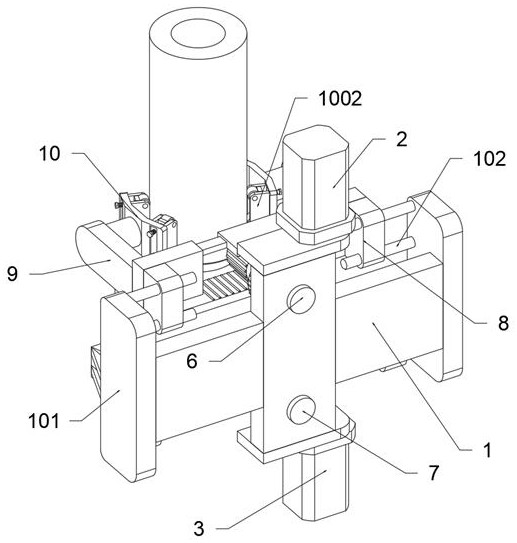

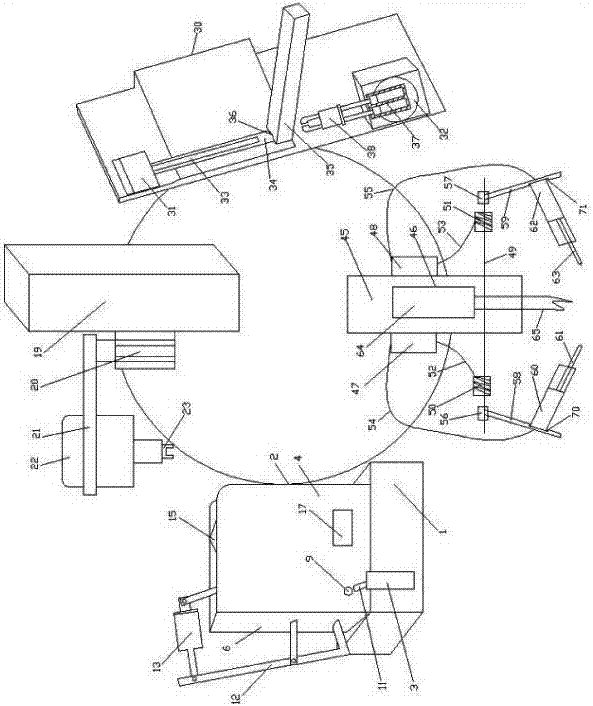

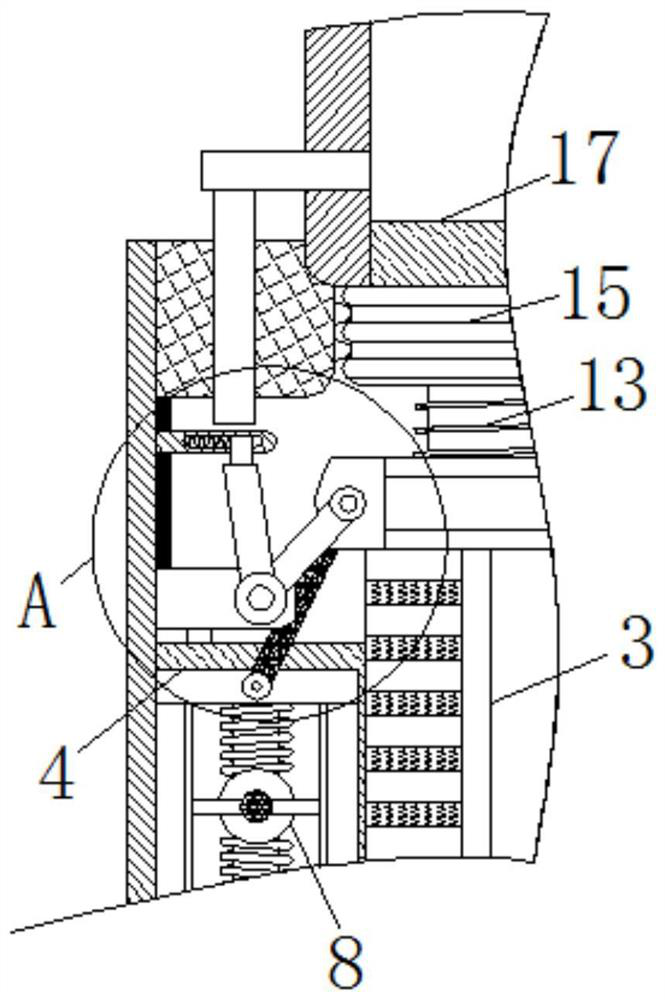

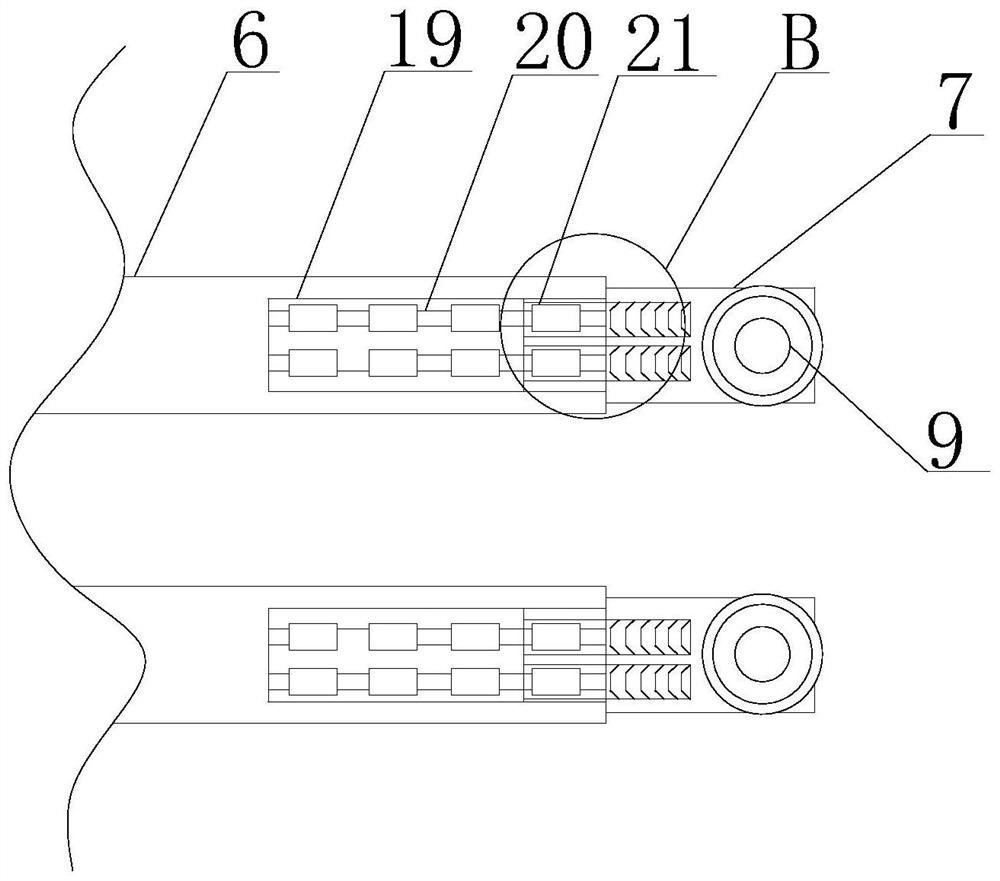

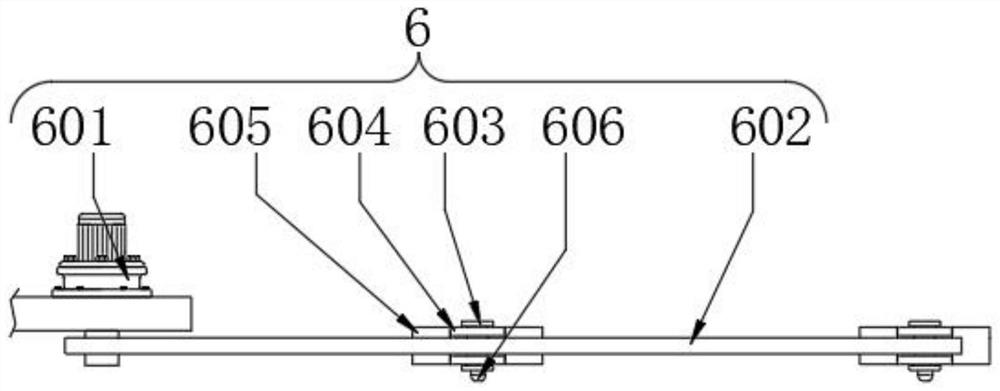

Machining device for circular pipe spiral groove

ActiveCN110712086APlay a clamping effectEasy to cutMetal sawing devicesGrinding drivesStructural engineeringMachining

The invention relates to the field of machining, and specifically relates to a machining device for a circular pipe spiral groove. The machining device comprises a feeding assembly, a cutting assembly, a grinding assembly and a machining assembly, wherein the feeding assembly is arranged at one end of the cutting assembly; the grinding assembly is arranged at the end, away from the feeding assembly, of the cutting assembly; the machining assembly is arranged on one side of the grinding assembly, and the length direction of the machining assembly is perpendicular to the length direction of thegrinding assembly; the feeding assembly comprises a fixed clamp and a first movable clamp; the fixed clamp is arranged at the end, away from the cutting assembly, of the feeding assembly; the first movable clamp is arranged between the cutting assembly and the fixed clamp; and the fixed clamp, the first movable clamp, the cutting assembly and the grinding assembly are sequentially arranged in a straight line. The machining device solves the problem that when the surface of a circular pipe is machined into the spiral groove, manual fixing is often needed, the work efficiency is improved, and the circular pipe is better machined.

Owner:景宁丽恒模具加工厂

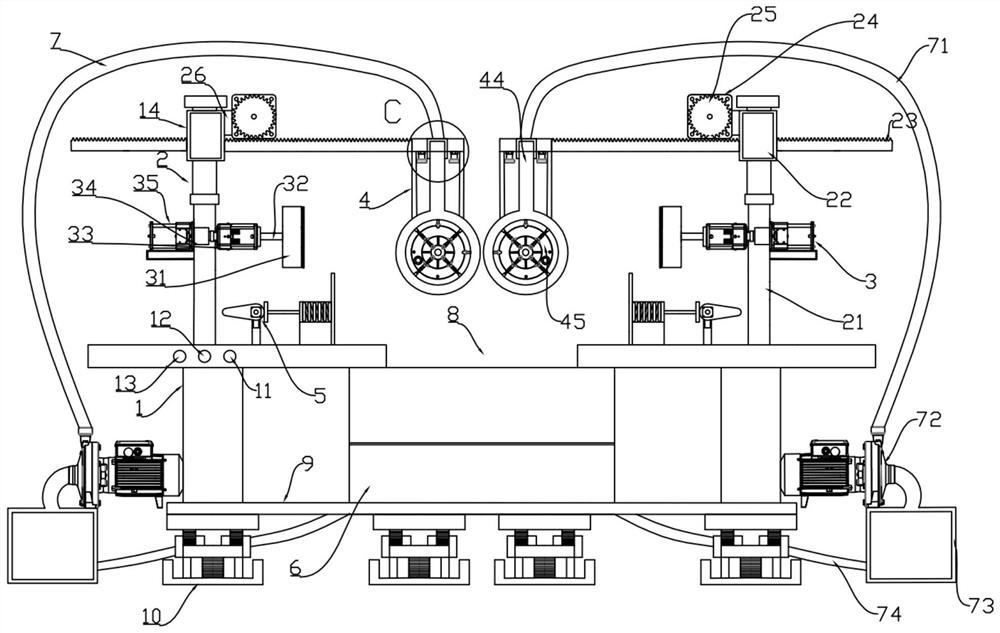

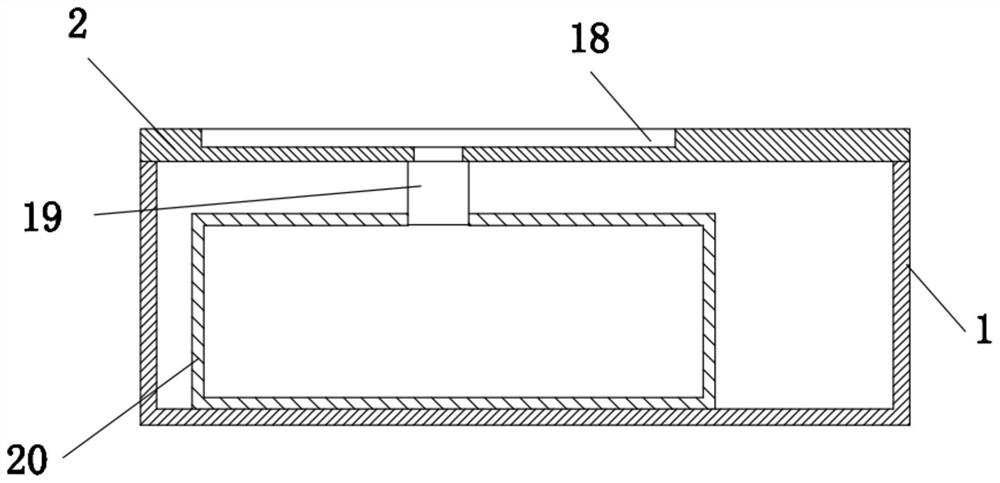

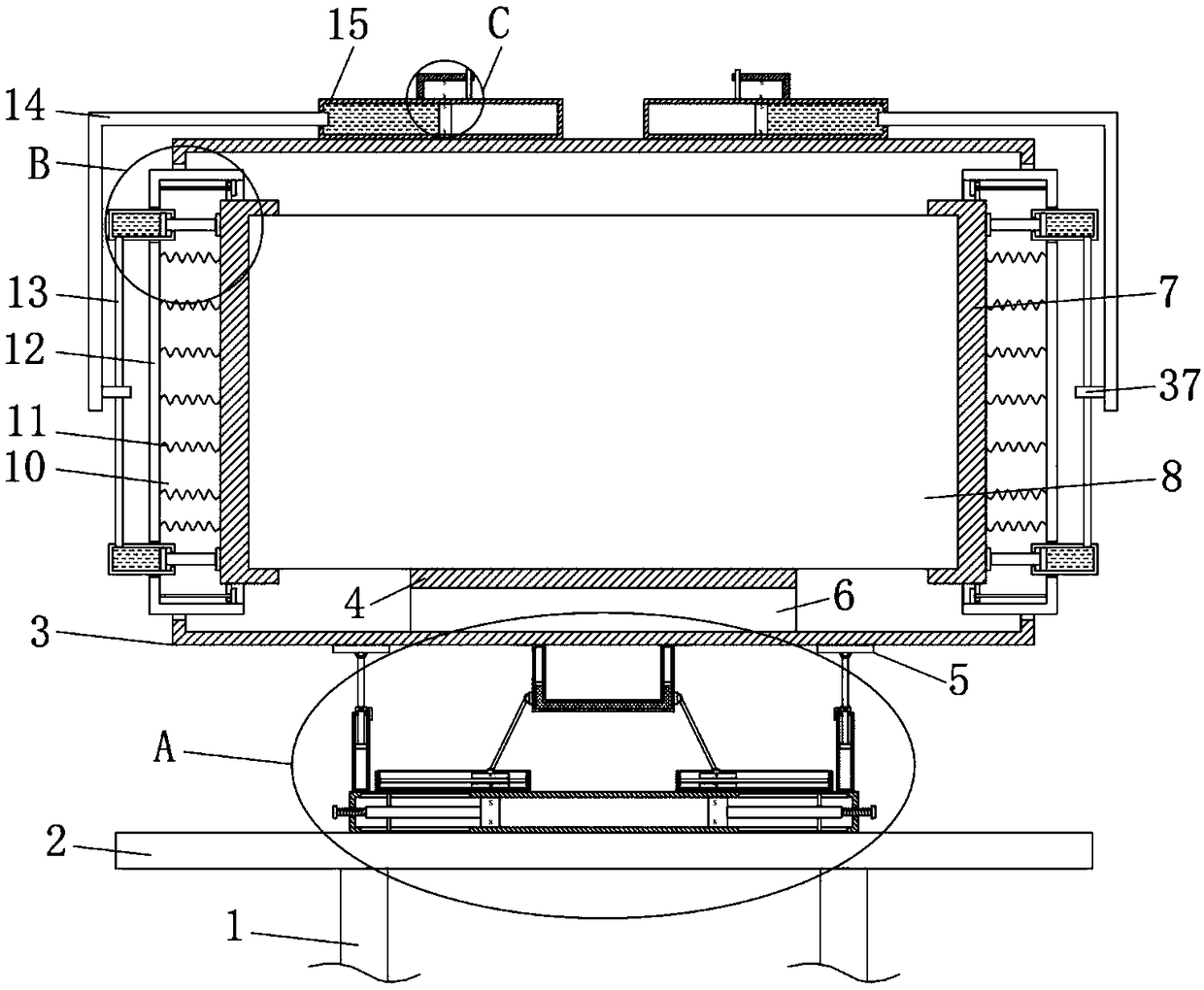

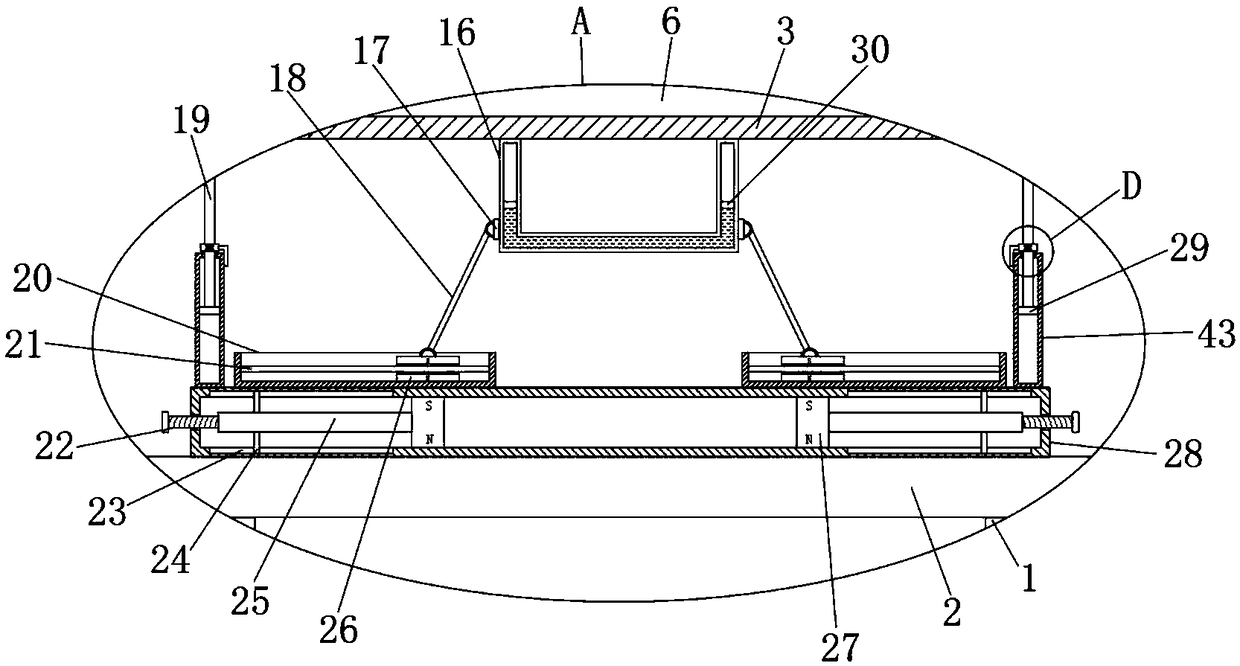

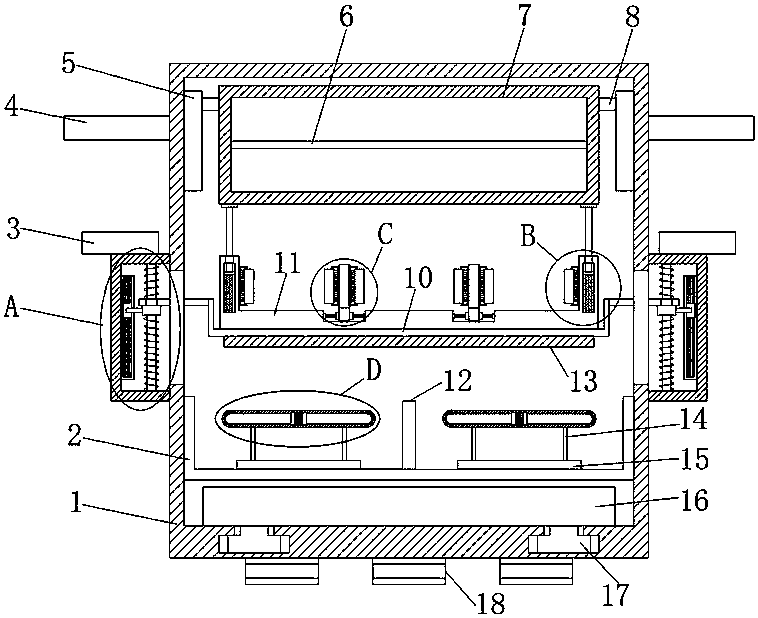

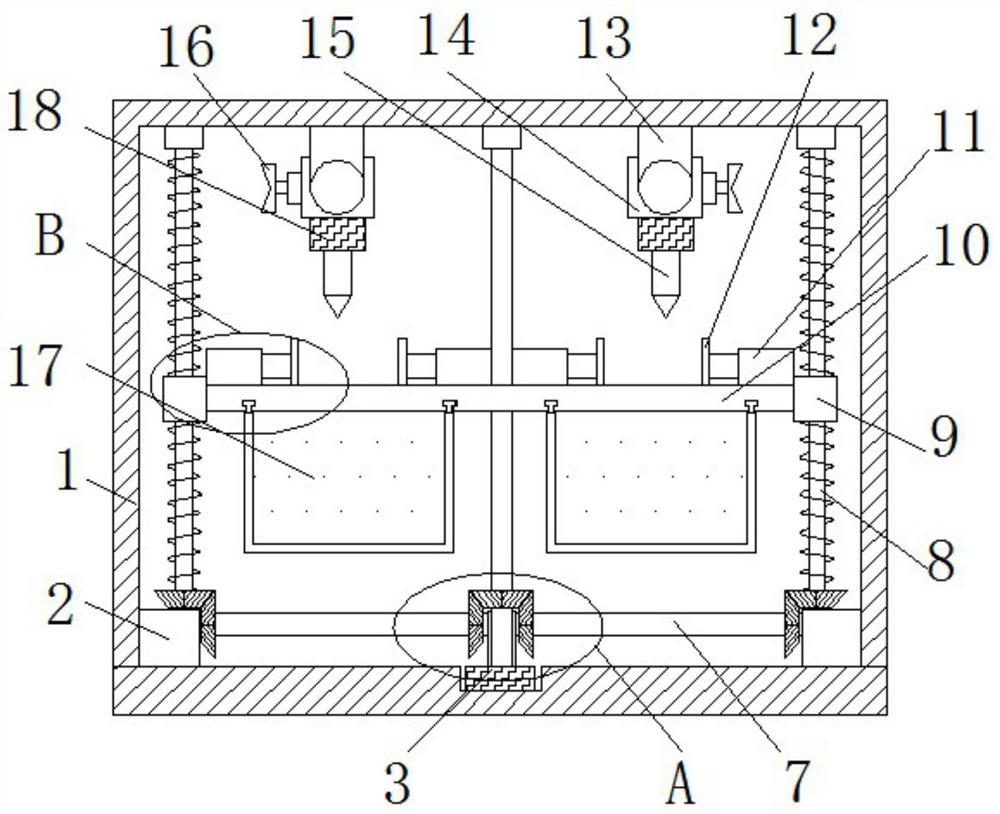

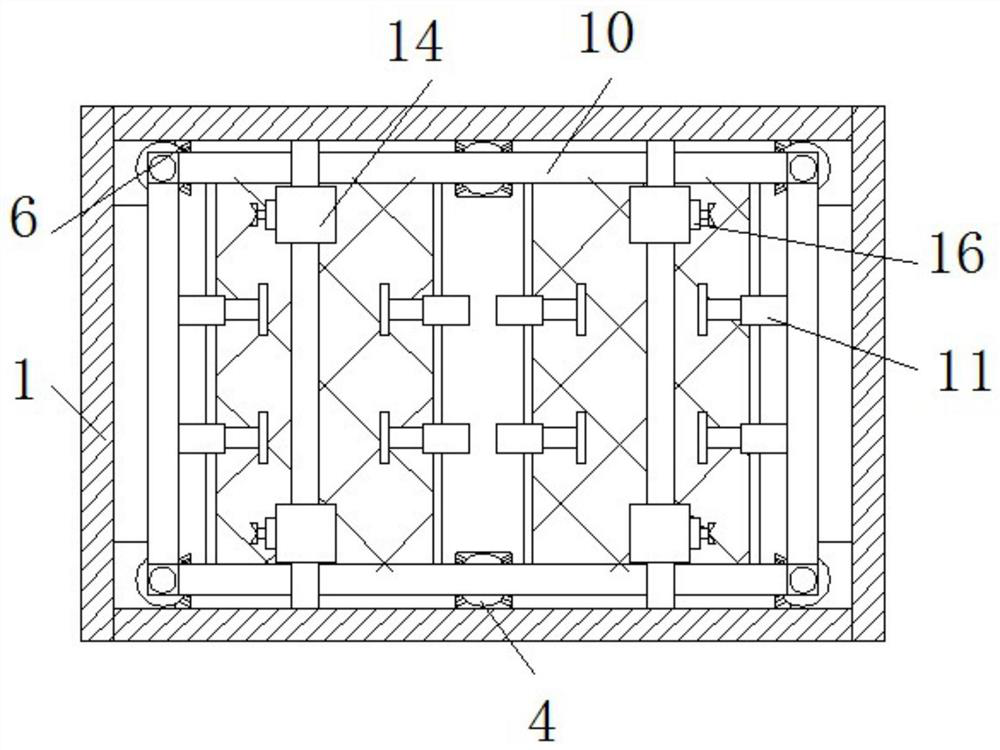

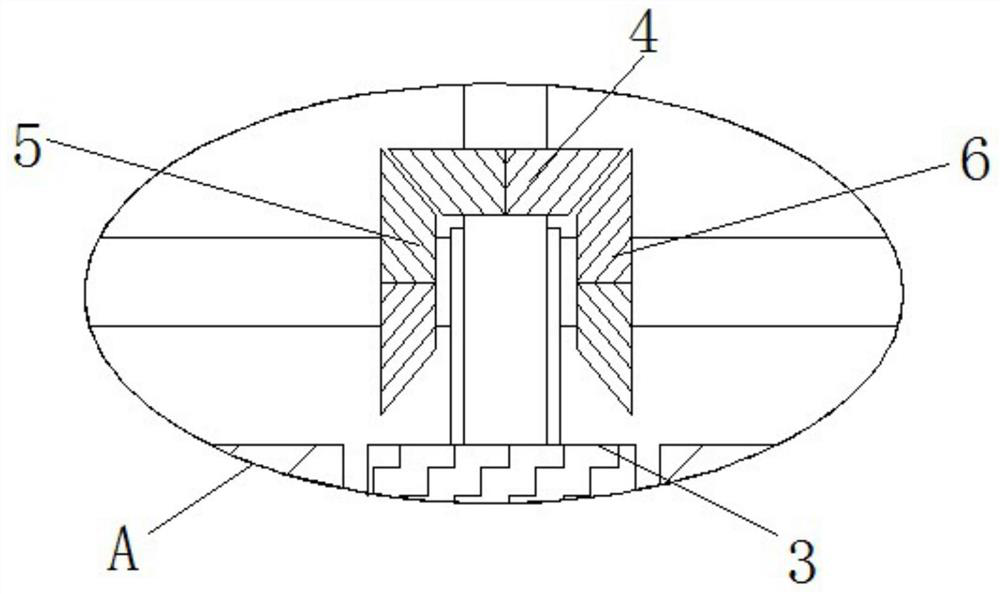

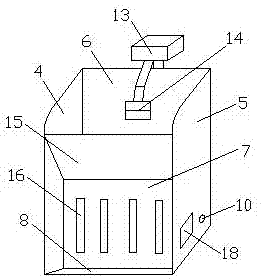

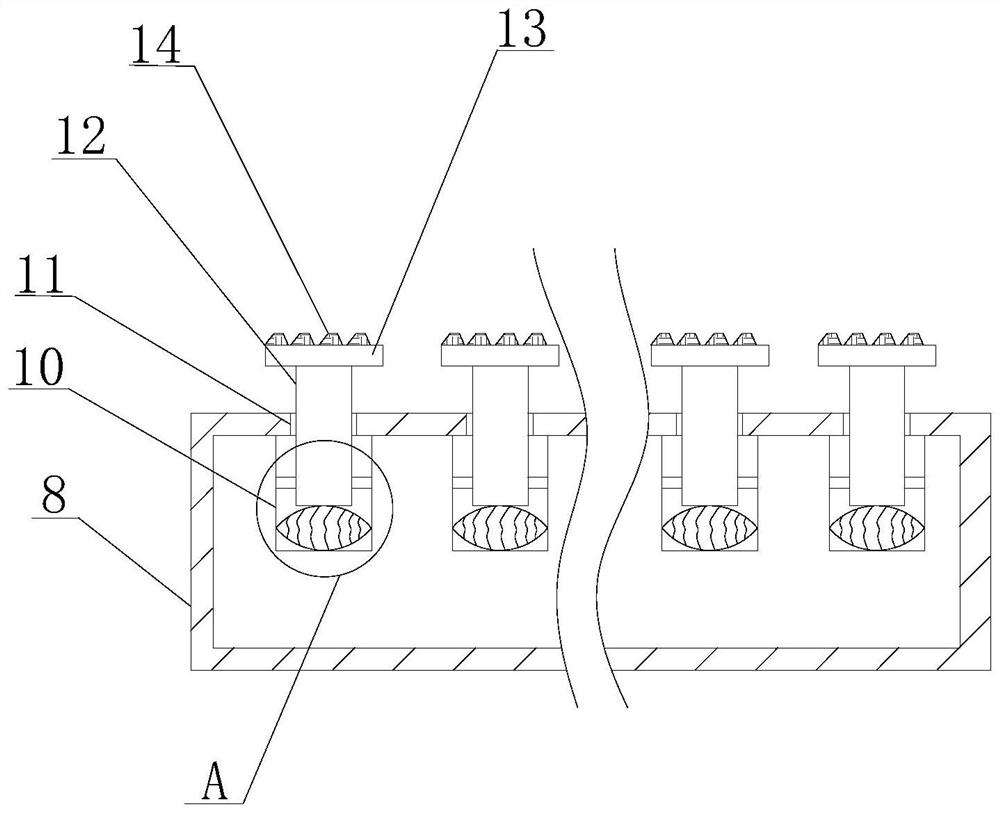

Preset self-adjusting full-positioning clamping device for automobile part drilling

ActiveCN114734276AImprove performanceIncrease contact areaWork clamping meansMeasurement/indication equipmentsControl engineeringSelf adaptive

The invention relates to a preset self-adjusting full-positioning clamping device for automobile part drilling, which comprises a rack, a drilling auxiliary clamping device, a human-hand-simulated self-resetting reciprocating type cleaning mechanism and a detachable self-separation recovery device, a dust collection hole is formed in the middle of the upper wall of the rack, the human-hand-simulated self-resetting reciprocating type cleaning mechanism is arranged on the upper wall of the rack, and the detachable self-separation recovery device is arranged on the lower wall of the rack. The drilling auxiliary clamping devices are symmetrically arranged on the machine frame, and the detachable self-separation recycling device is arranged under the dust collecting holes. The invention belongs to the technical field of clamping devices for drilling parts, and particularly provides a clamping device for drilling parts by utilizing a dynamic characteristic principle, a principle of changing harm into benefit and a pre-reaction principle and by virtue of a magnetic field as compensation. According to the preset self-adjusting full-positioning clamping device for drilling the automobile parts, all-directional dead-corner-free self-adaptive attaching type clamping can be carried out on various types of automobile parts with uneven clamping faces under the condition that no positioning element or other sensors exist, the efficiency is high, and the automation degree is high.

Owner:ZUNYI VOCATIONAL & TECH COLLEGE

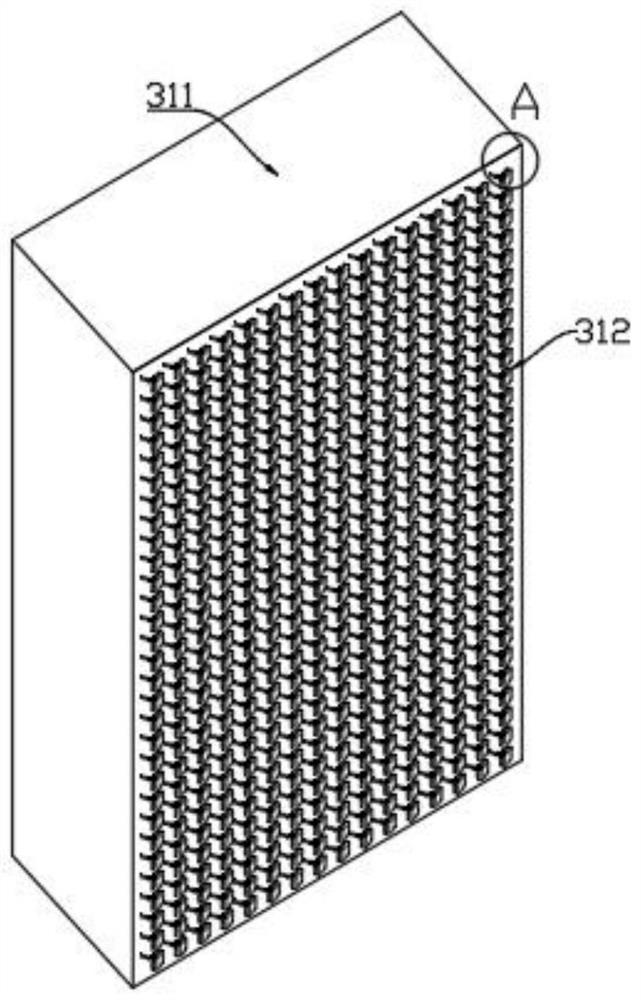

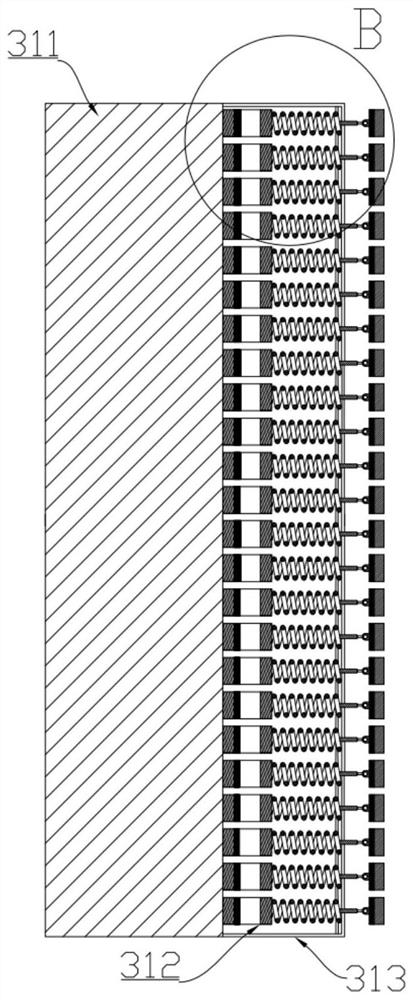

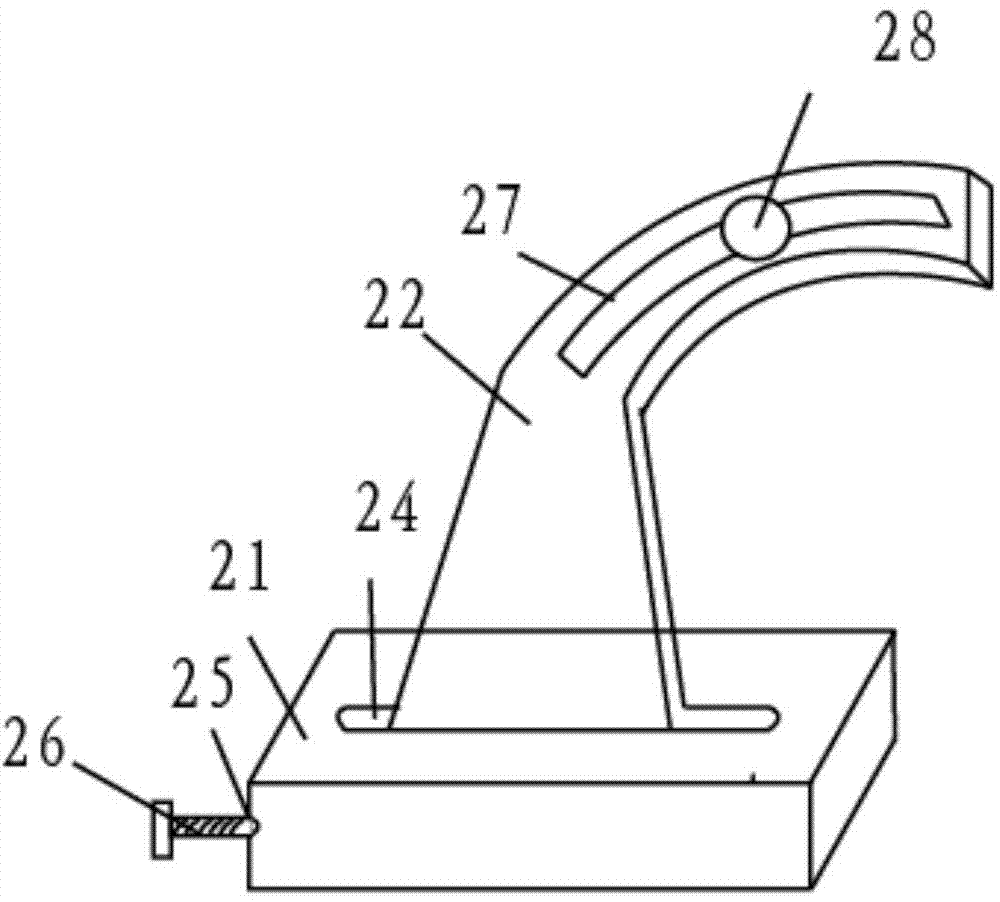

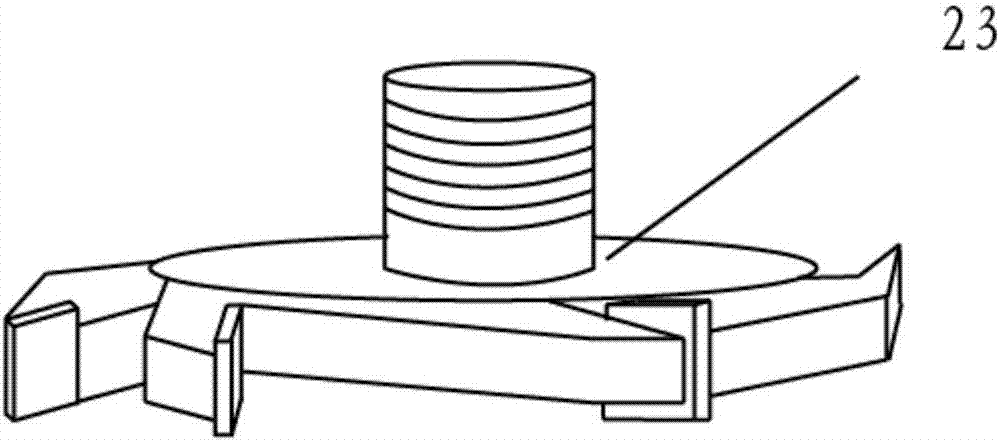

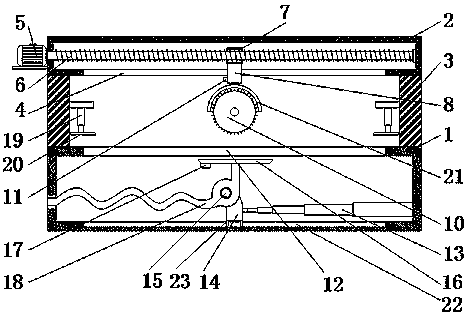

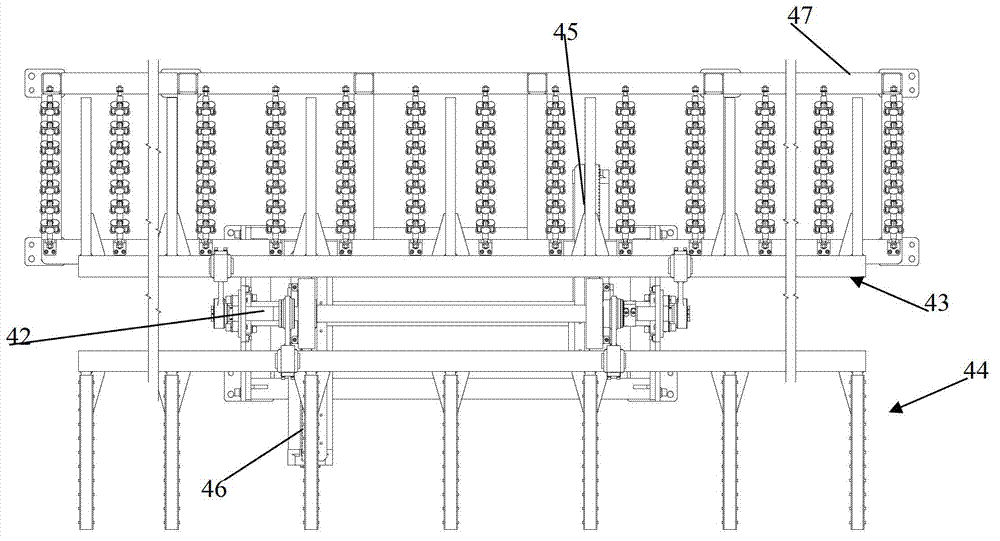

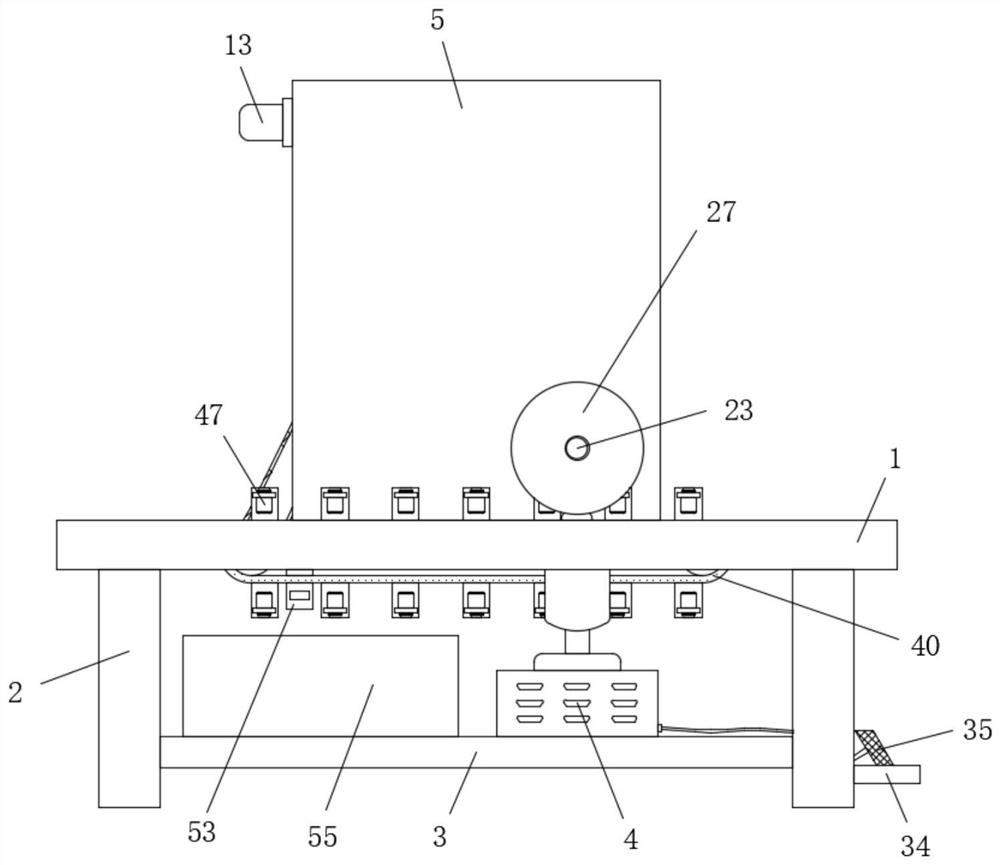

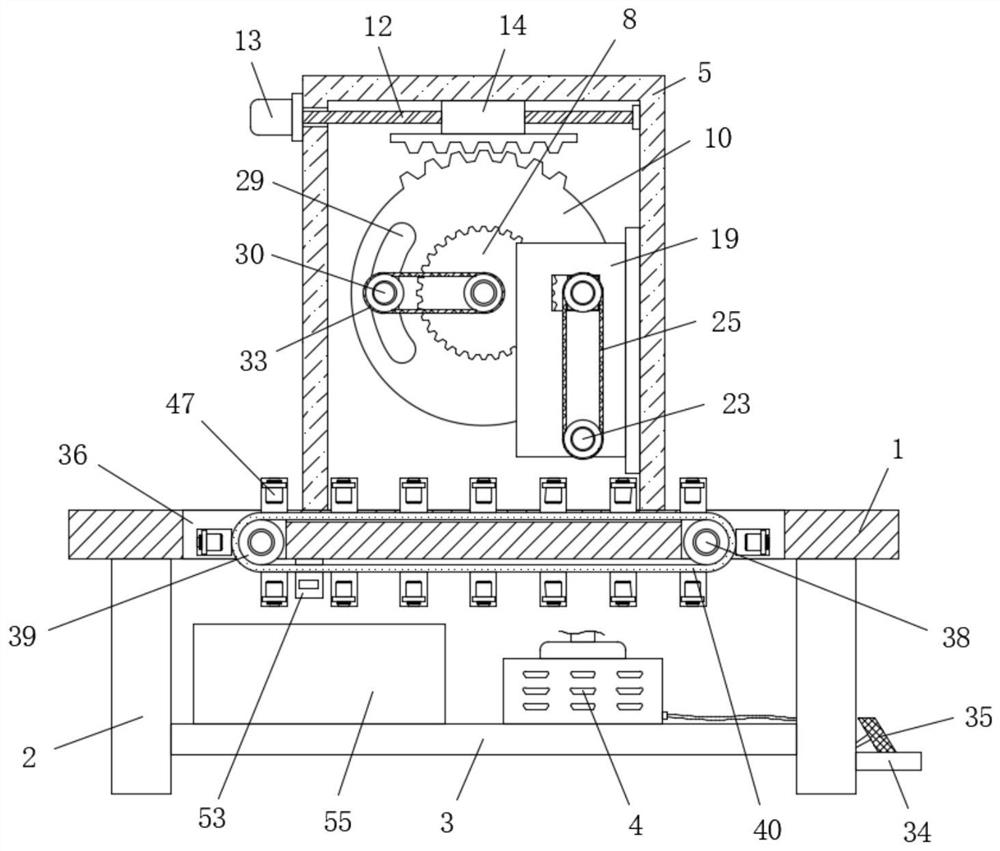

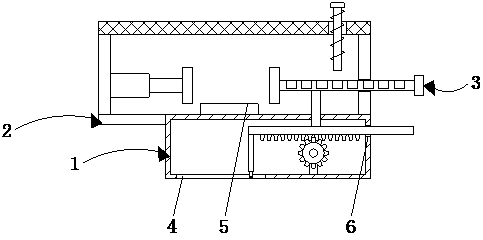

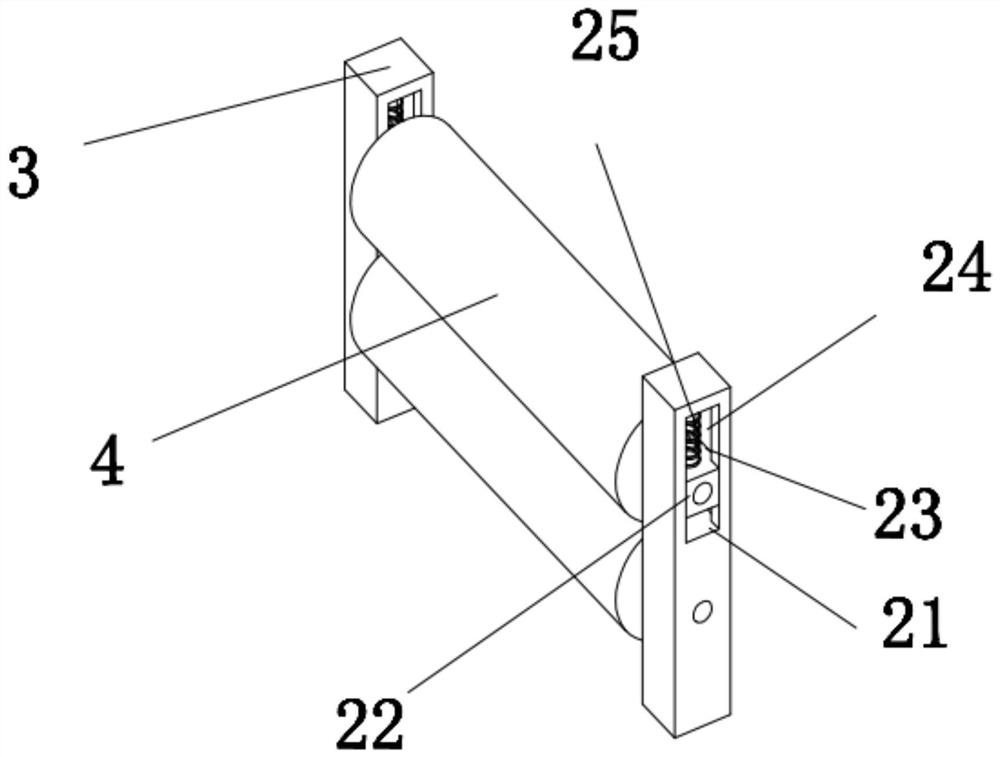

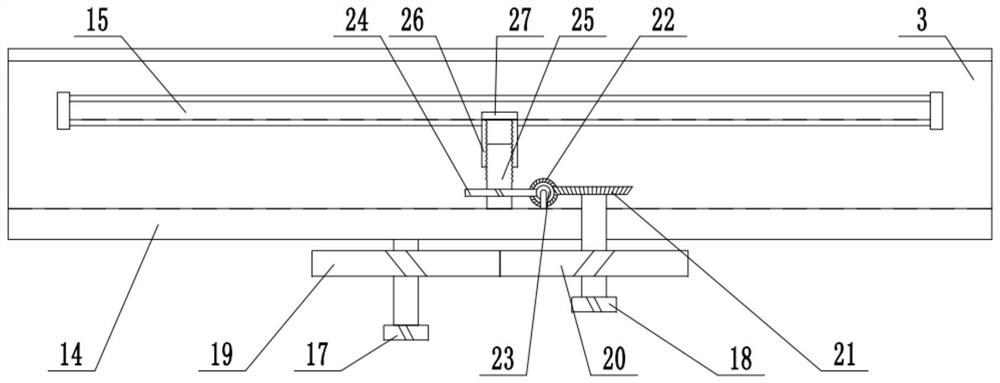

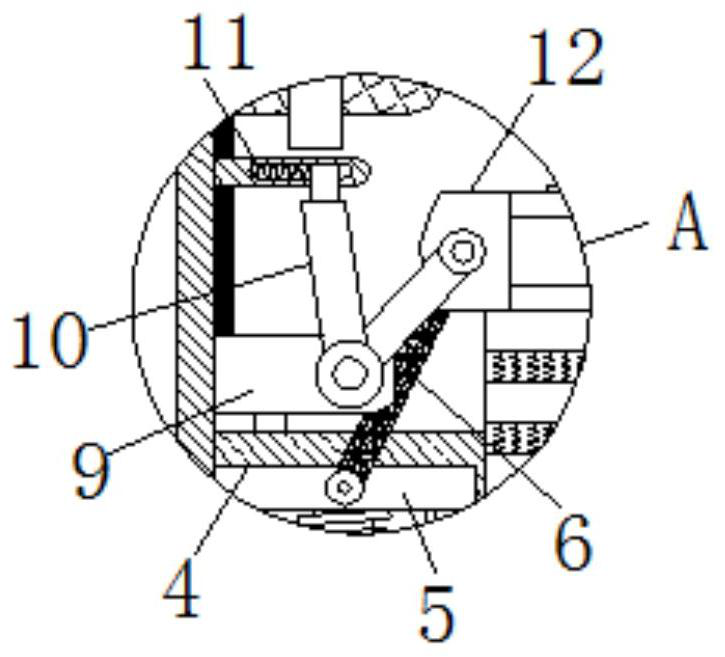

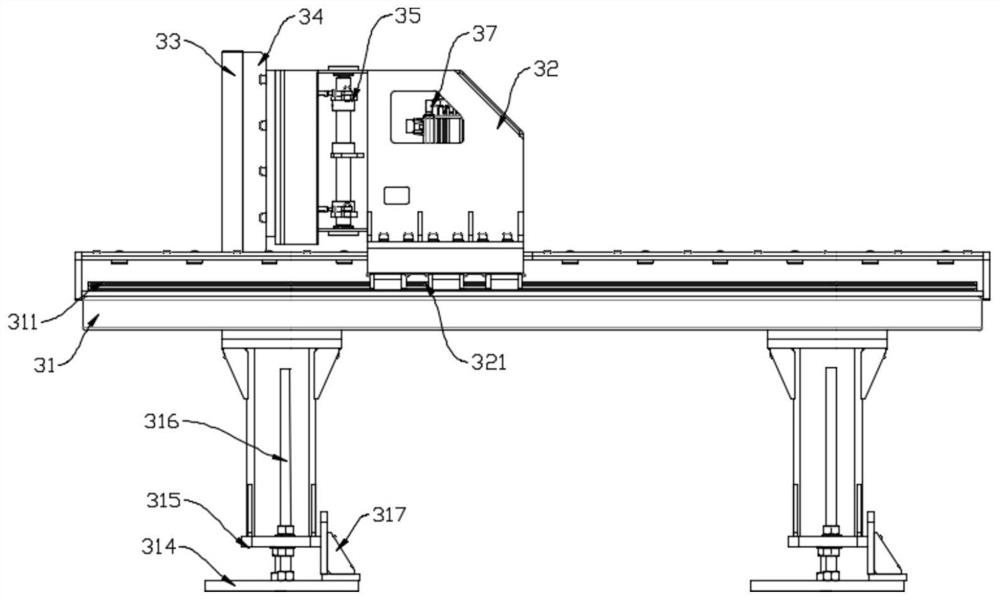

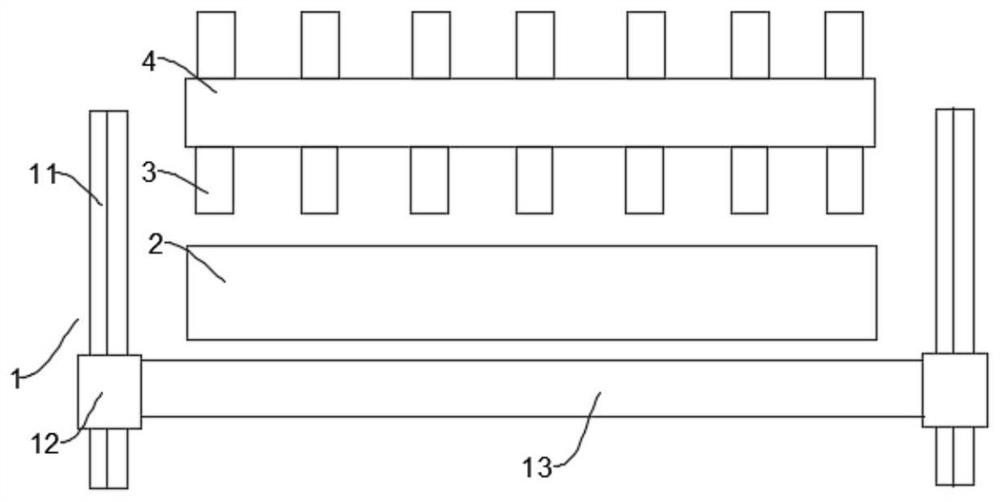

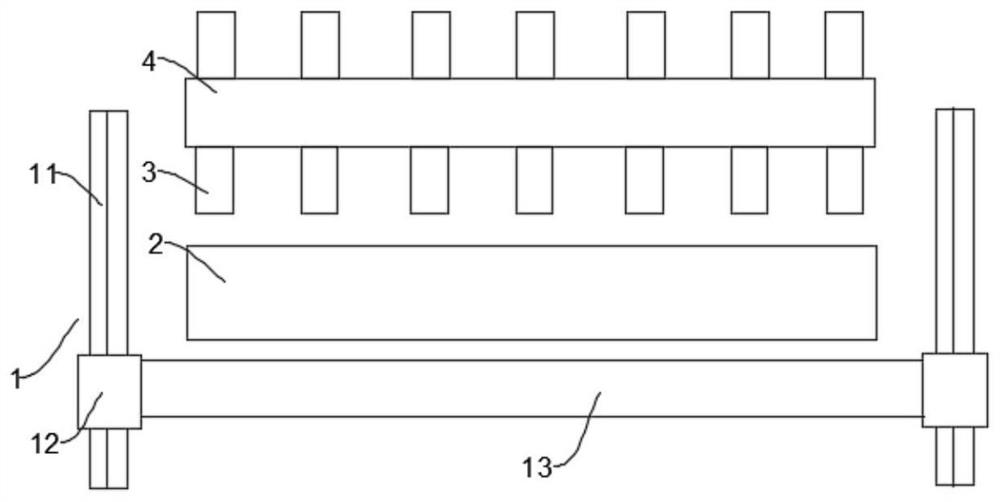

Slot wedge one-time forming device

ActiveCN104759671AReduce driftPlay a clamping effectLarge fixed membersMilling equipment detailsMilling cutterEngineering

The invention provides a slot wedge one-time forming device. The slot wedge one-time forming device comprises a polishing device, a milling device, a conveying device and a pressing holder. The conveying device comprises a plurality of pairs of paired rollers and a guide rail which are arranged on a conveying path of a slot wedge strip. The paired rollers include driving rollers and driven rollers, wherein the driven rollers are arranged above the driving rollers. The milling device comprises two milling machines arranged on the two sides of the conveying device respectively, and it is guaranteed that the two milling machines are staggered. Each milling machine comprises a base, an arc-shaped support and a third milling cutter. The pressing holder is used for clamping the slot wedge strip at the conveyed state. The slot wedge one-time forming device has the advantages that the automation degree is high, deviation of the slot wedge strip in the conveying process and sparks produced in the machining process are prevented, safety is improved, and timeliness of scrap cleaning is improved.

Owner:安徽省盛鑫绝缘材料有限公司

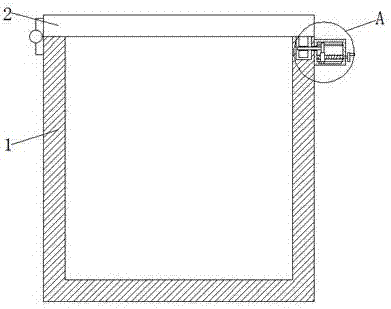

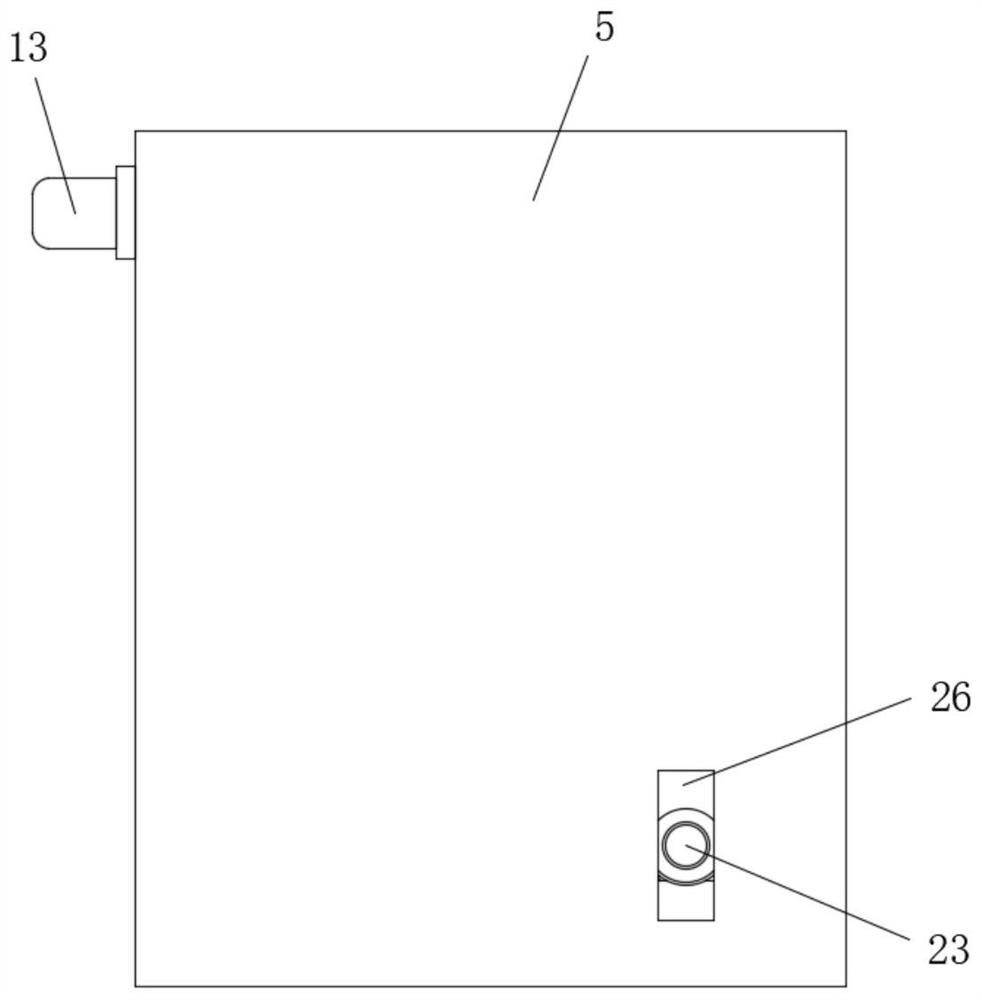

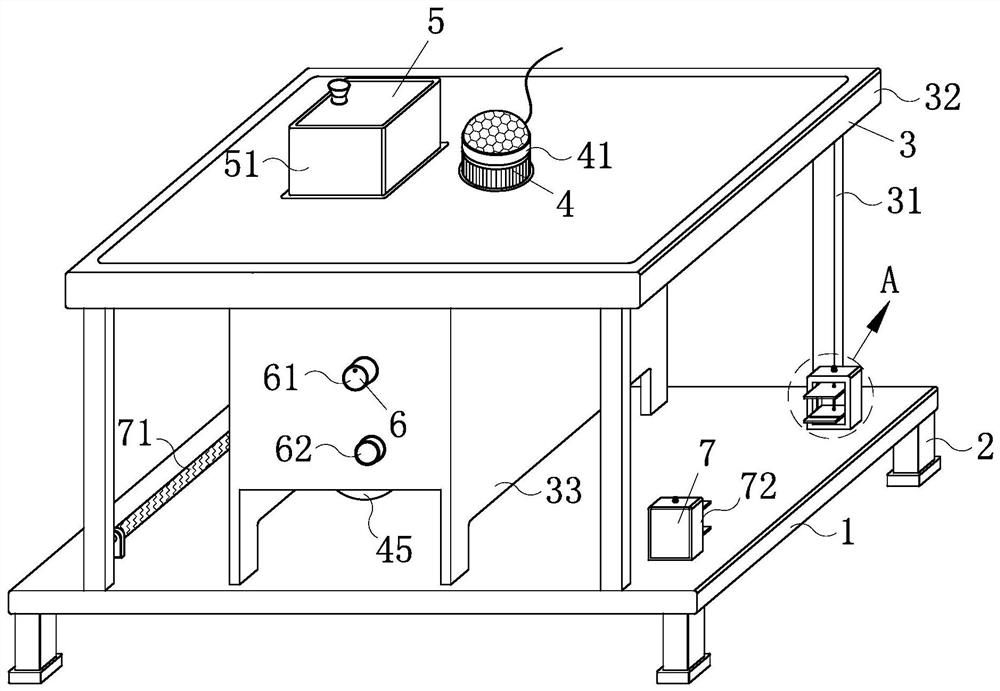

Fire extinguisher cabinet convenient to open

The invention discloses a fire extinguisher cabinet convenient to open. The fire extinguisher cabinet comprises a material storing box. A cover plate is movably connected to the top of the material storing box. A locating column is fixedly connected to the right side of the bottom of the cover plate. The right side of the top of the material storing box is provided with a locating groove used in cooperation with the locating column. The bottom of the locating column extends to the interior of the locating groove. A shell is fixedly connected to the top of the right side of the material storing box. The bottom of the right side of the shell is provided with a connecting column in a penetrating manner. According to the fire extinguisher cabinet, the material storing box, the cover plate, the locating column, the locating groove, the shell, the connecting column, a rotating disc, a handle, a screw, a screw block, a sliding rod and a clamping rod are arranged and used in cooperation, the problems that in the using process of an existing fire extinguisher cabinet, when a fire occurs, the fire extinguisher cabinet cannot be opened fast, and a fire extinguisher cannot be taken out, and the fire extinguisher cabinet convenient to open has the beneficial effect of being convenient to open, facilitates use of users, and reduces the economic loss of the users.

Owner:张文华

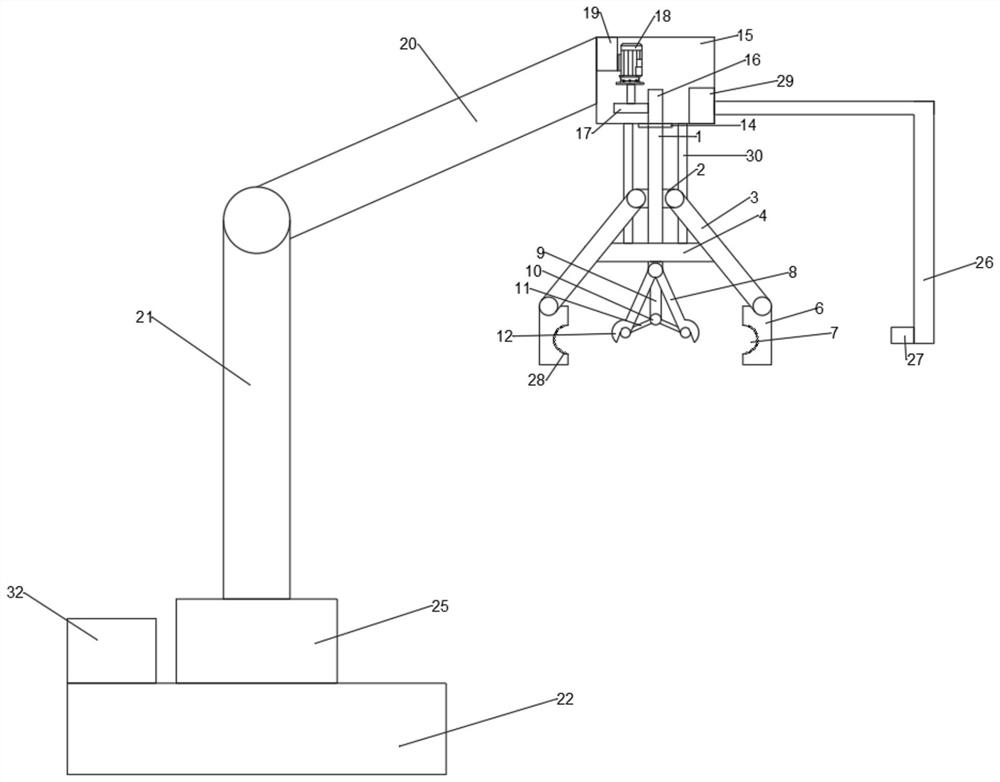

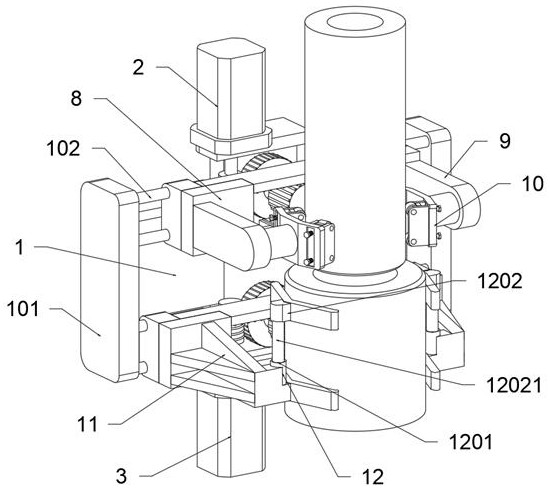

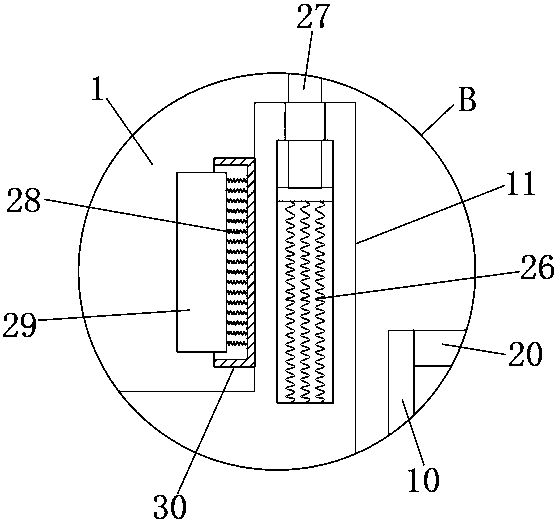

Mechanical arm with good clamping effect

Owner:泰州天融科技有限公司

Straw board manufacturing and production device good in safety

InactiveCN108544588AReduce frictionPlay a cutting effectProfiling/shaping machinesBark-zones/chip/dust/waste removalElectric machineryInfrared emitter

The invention discloses a straw board manufacturing and production device good in safety. The straw board manufacturing and production device comprises a cutting box and a cross beam; the two sides ofthe bottom of the cross beam are fixedly connected with supporting frames; the bottoms of the supporting frames are fixedly connected with the cutting box; and a sliding hole is formed in the bottomof the cross beam. With the adoption of a first motor, a threaded rod, a threaded sleeve, a first electric telescopic rod, a second motor and a cutting piece, the effect of cutting a straw board is played, and the effect of adjusting the cutting height is played; with the adoption of a dust suction pump, the effect of collecting waste chippings generated by cutting is played; with the adoption ofan infrared emitter and an infrared receiver, the effect that the dust suction pump can follow the second motor to move to suck dust is played; and the problems that existing cutting equipment is toosimple, the waste chippings generated during straw board cutting splash into eyes of workers easily, the health of the workers is harmed, the safety is poor, and the safety production concept is not conformed are solved.

Owner:许昌亚丹生态家居有限公司

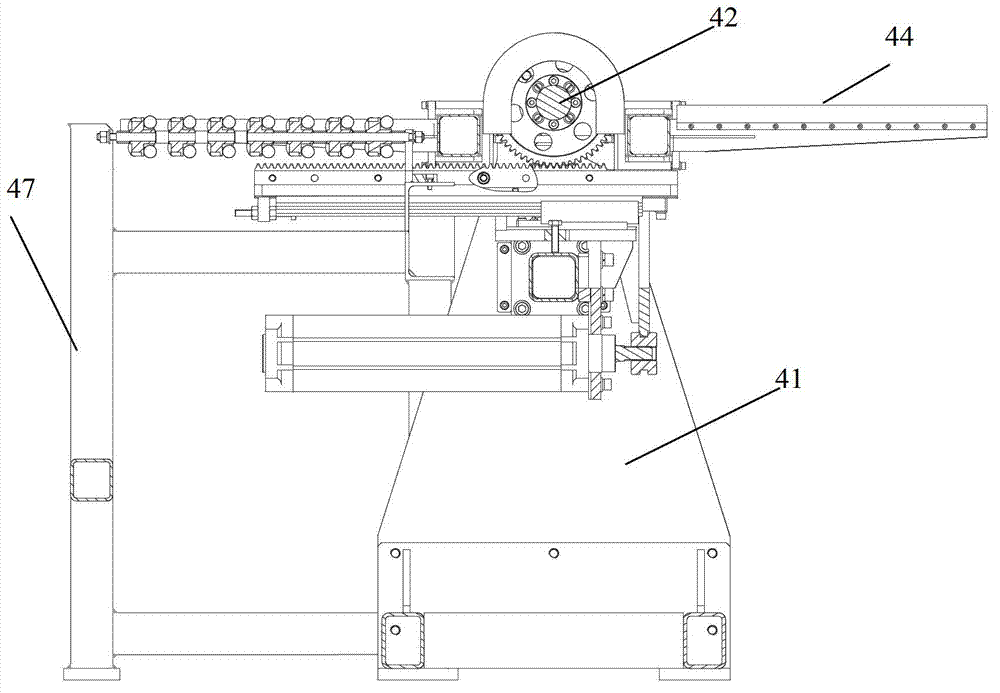

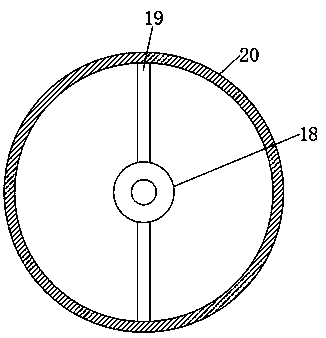

Tire tread turnover device

The invention discloses a tire tread turnover device. The tire tread turnover device comprises a turnover support, a rotating shaft, a turnover row, a first driving mechanism, a clamping row and a second driving mechanism, the rotating shaft is horizontally and fixedly arranged on top of the turnover support, the turnover row is fixedly connected with the rotating shaft, the first driving mechanism can drive the rotating shaft to rotate, the clamping row is rotatably connected with the rotating shaft, and the second driving mechanism can drive the clamping row to turn over relative to the rotating shaft. The tire tread turnover device has the advantages that the structure is simple, the control is convenient, an air cylinder is utilized for driving a gear rack to drive a gear wheel to rotate, the clamping effect on a tire tread can be achieved during the turnover through the controlling over the air cylinder, the turnover can be smoothly performed, the phenomenon that the tire tread is thrown out or sideslips is absent, the exchange from a tire tread carrying device to a tire tread lifting device can be simultaneously completed in one turnover process, and the efficiency of the whole production line is improved.

Owner:TIANJIN SAIXIANG TECH

Optical fiber cable cluster connector

InactiveCN113064237AAvoid the phenomenon of automatic falling offEasy flipCoupling light guidesEngineeringMechanical engineering

The invention discloses an optical fiber cable cluster connector which comprises optical fibers, an inserting shell, a connecting shell and a fixing assembly, the inserting shell and the connecting shell are fixedly installed at the ends of the two optical fibers respectively, the inserting shell is inserted into the connecting shell in a penetrating mode, the fixing assembly is arranged at the connecting position of the inserting shell and the connecting shell, the inserting shell can be fixedly connected into the connecting shell, and the inserting shell is prevented from falling out of the connection shell when the optical fibers are subjected to pulling force. The connector is scientific and reasonable in structure and safe and convenient to use, the inserting shell is inserted into the connecting shell in a penetrating mode, the connecting shell downwards extrudes a fixing block in an open groove in the leftward moving process, the fixing block extrudes a first spring, after the fixing block reaches the position, under the elastic force effect of the first spring, the fixing block is embedded into a fixing groove, and the connection strength of the inserting shell and the connecting shell can be guaranteed; when the connection part needs to be disconnected, a connector can press a lower pressing plate with a hand, so that the lower pressing plate extrudes a sliding rod to move downwards, the connecting rod moves downwards in a connecting hole, the fixing block is driven to be separated from the fixing groove, and the inserting shell is conveniently taken down from the connecting shell.

Owner:张东林

Cleaning device for lens production

The invention discloses a cleaning device for lens production. The cleaning device for lens production comprises a base, a supporting plate is vertically arranged at the upper end of the base, a firstfixed plate is fixedly connected to the side wall of the upper end of the supporting plate, a first telescopic device is arranged on the side wall of the first fixed plate in a penetrating mode, andthe lower end of the first telescopic device is fixedly connected with a second fixed plate; a rotating rod is arranged on the side wall of the second fixed plate in a penetrating mode, the upper endof the rotating rod is fixedly connected with a driven wheel, and the side wall of the upper end of the second fixed plate is fixedly connected with a motor; and the tail end of an output shaft of themotor is fixedly connected with a driving wheel engaged with the driven wheel, the lower end of the rotating rod is fixedly connected with a rotating plate, and two second telescopic devices are symmetrically arranged on the bottom side wall of the rotating plate. The cleaning device for lens production is reasonable in structure design, can not only achieve batch cleaning but also play a good role in clamping lenses, and guarantees that the lenses are not damaged.

Owner:江苏鸿晨集团有限公司

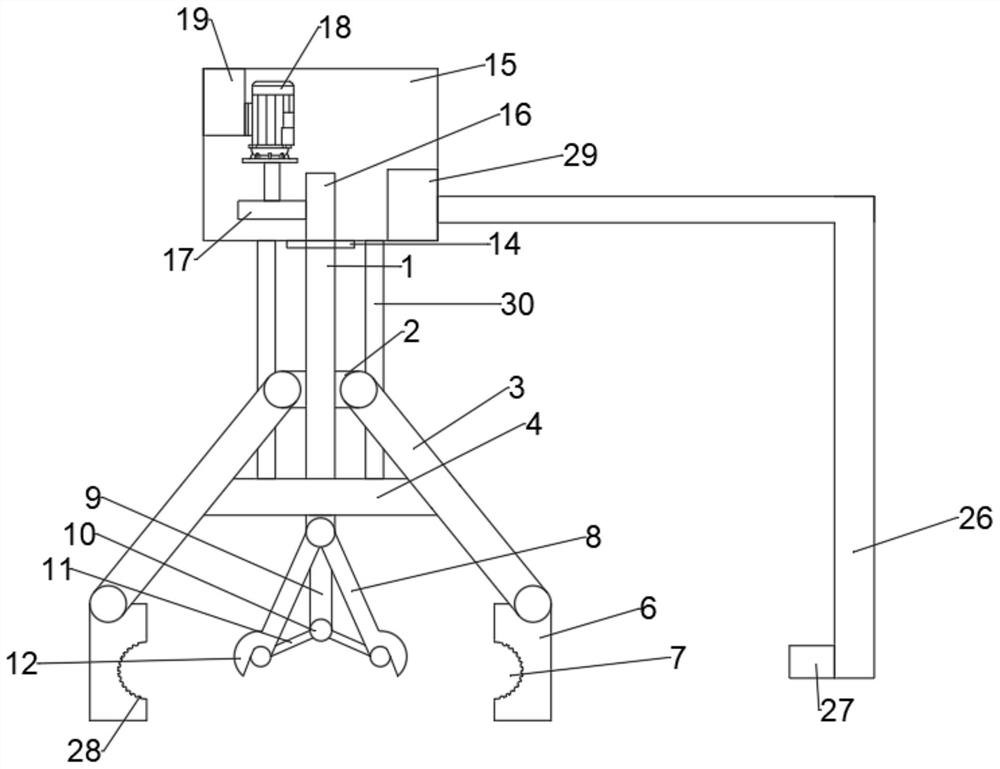

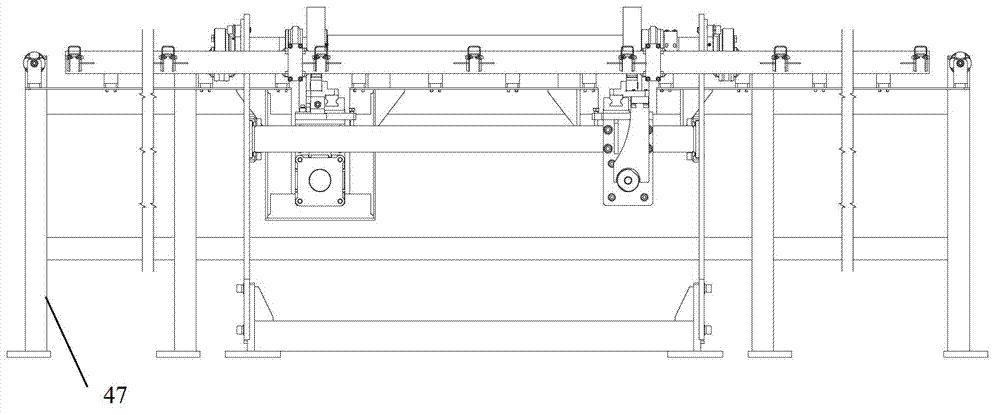

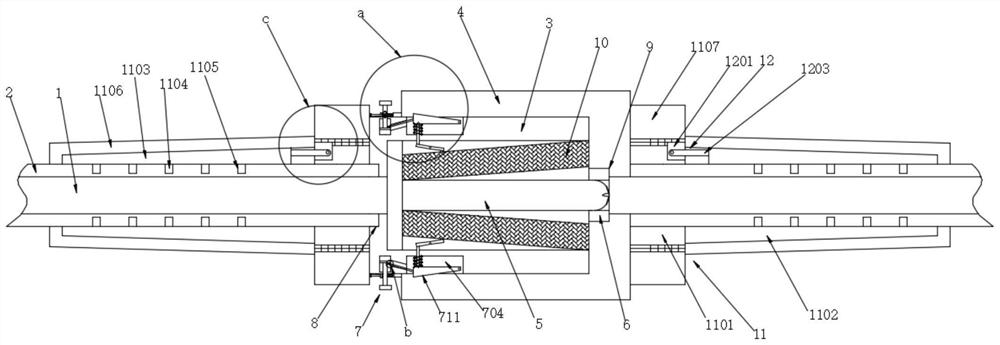

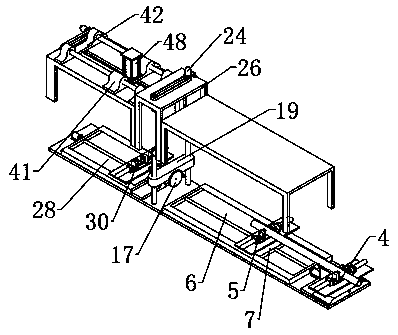

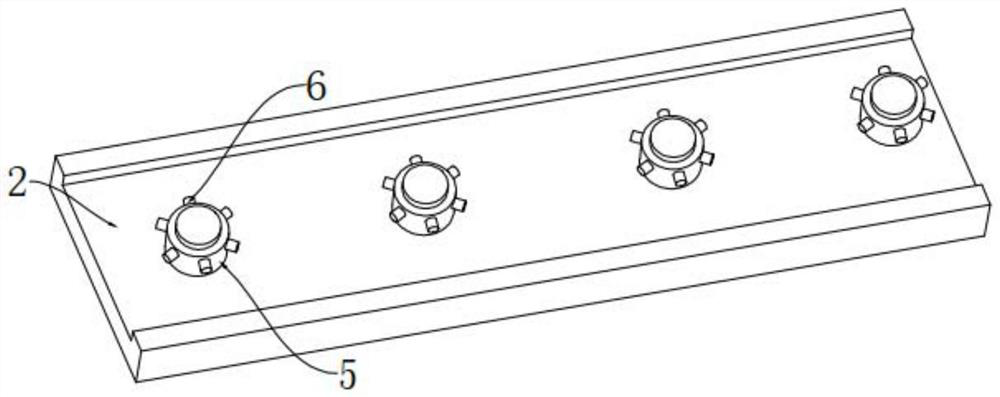

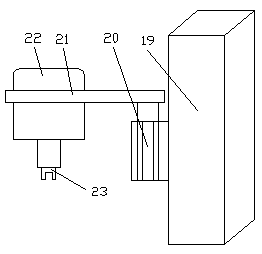

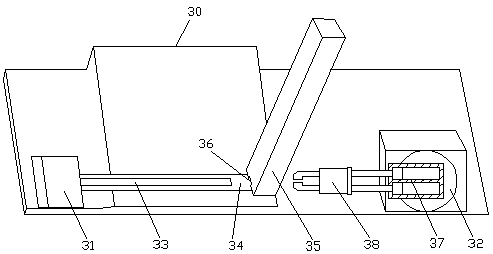

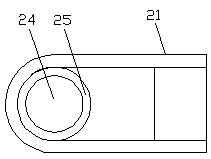

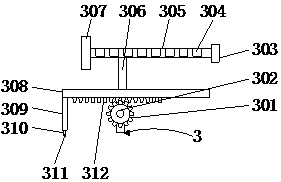

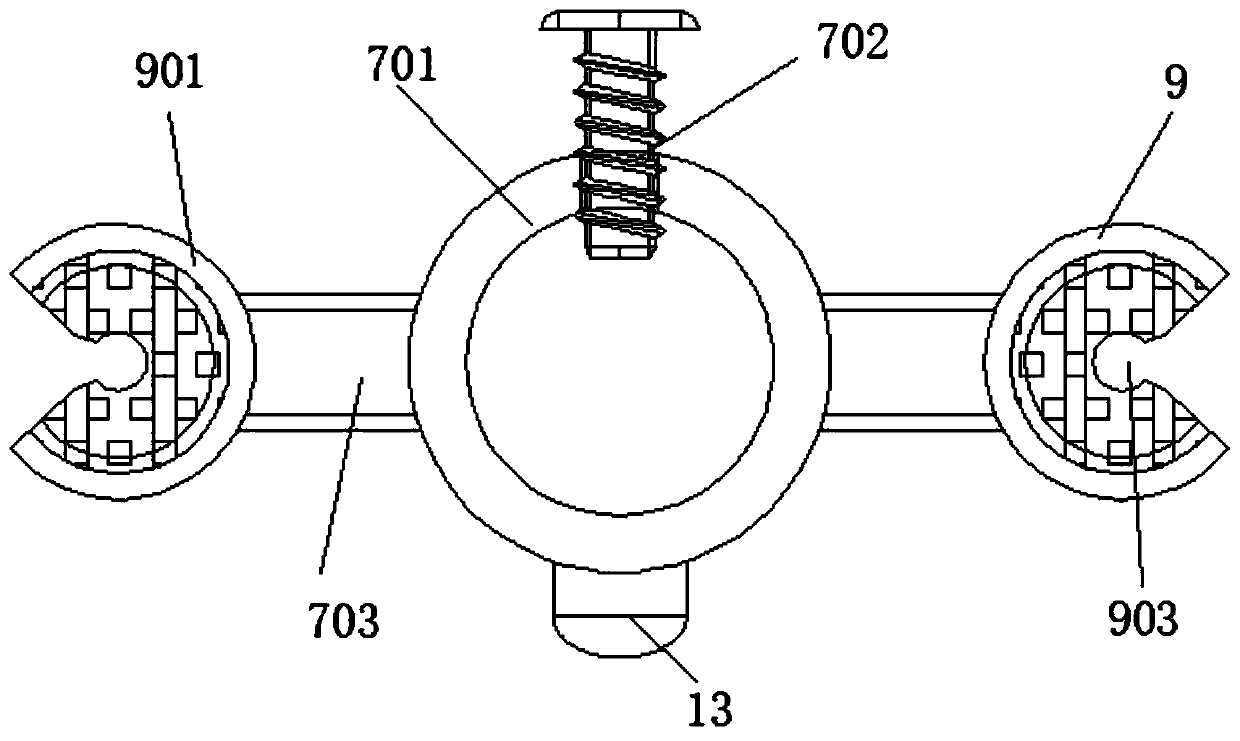

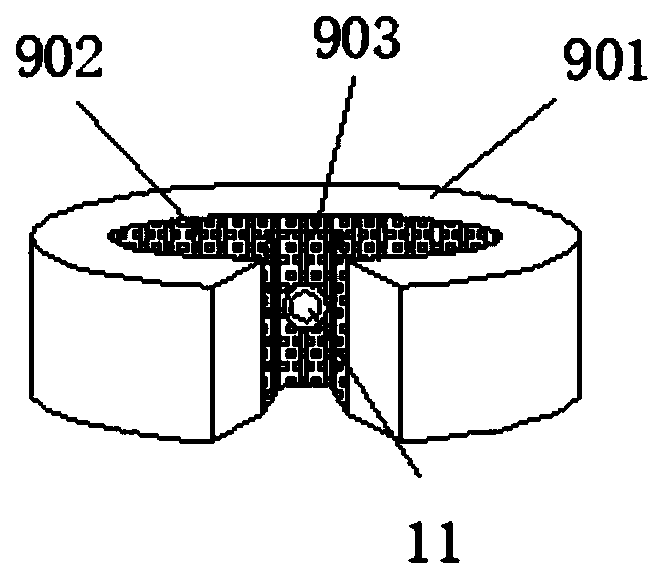

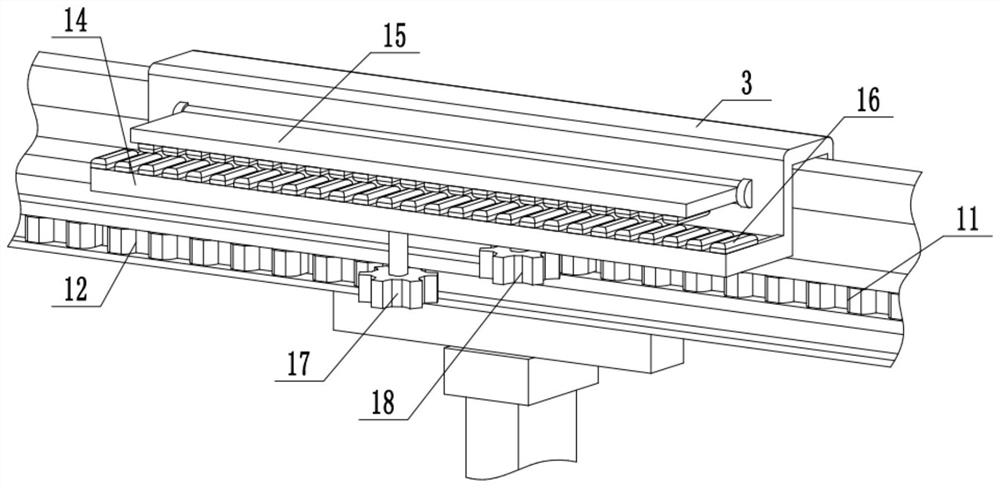

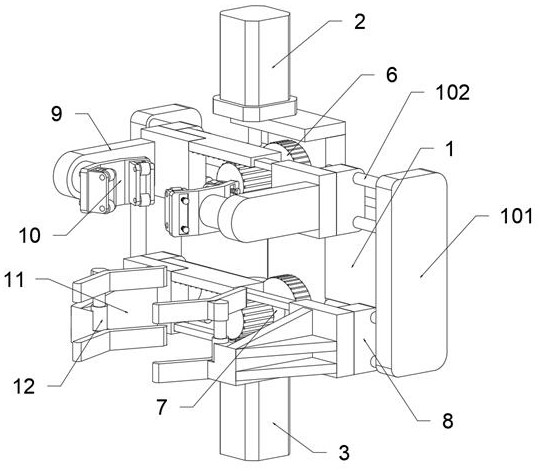

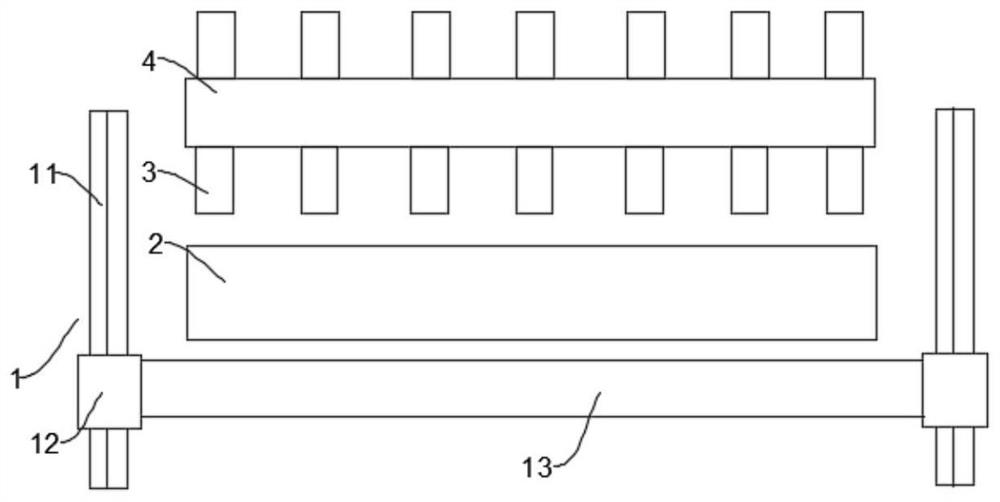

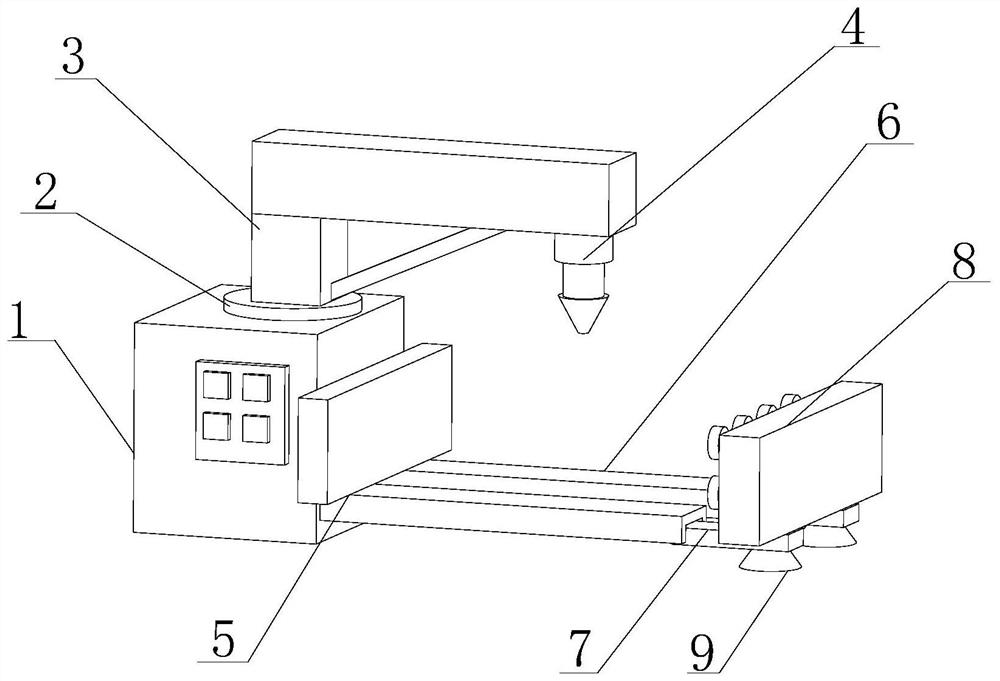

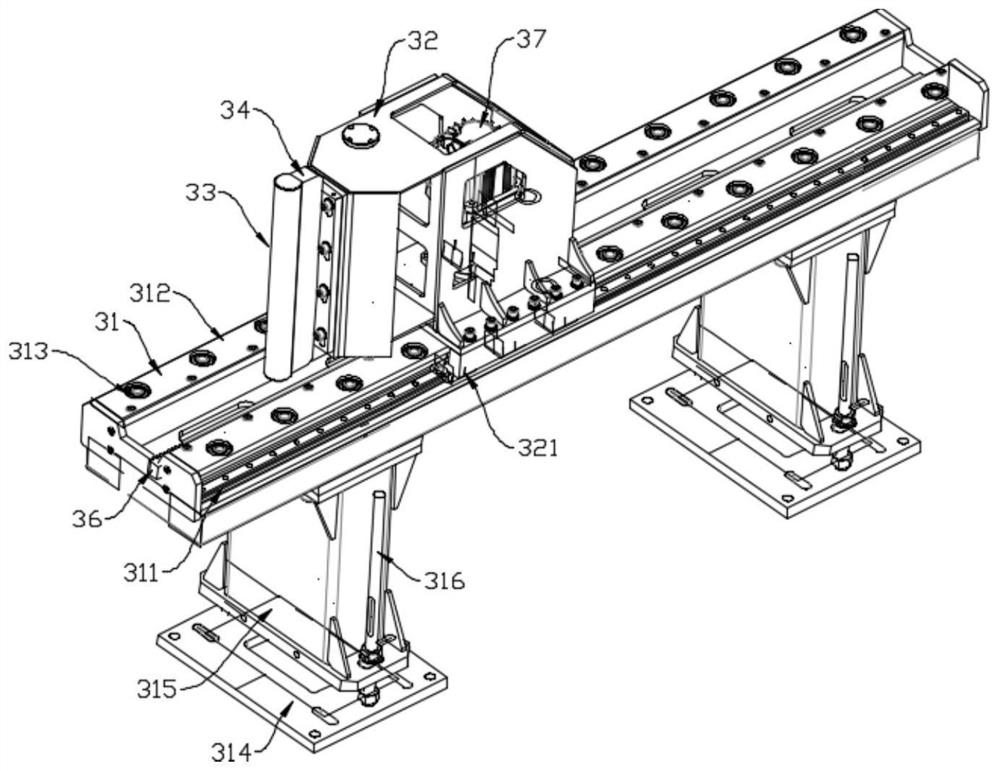

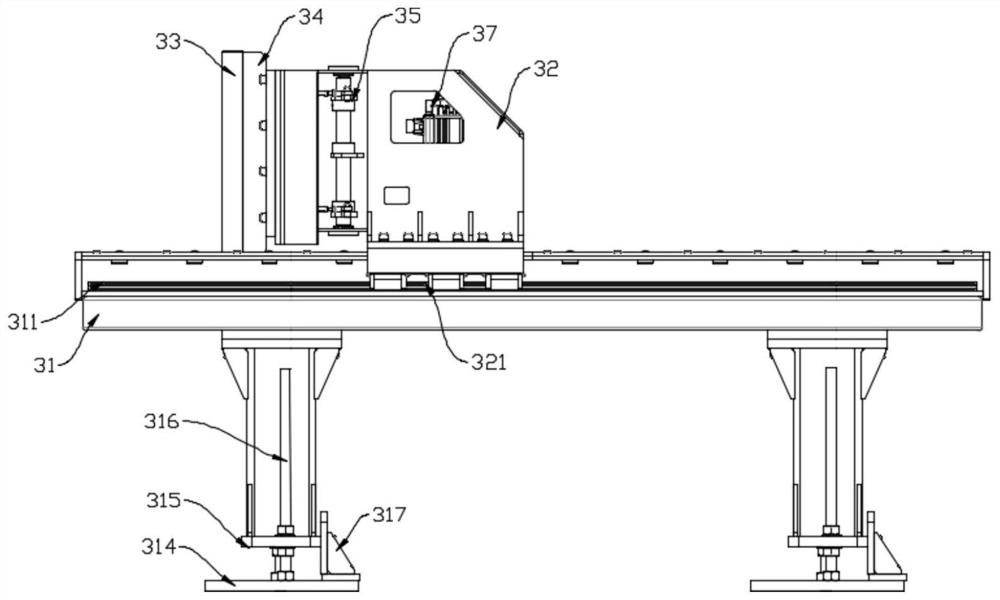

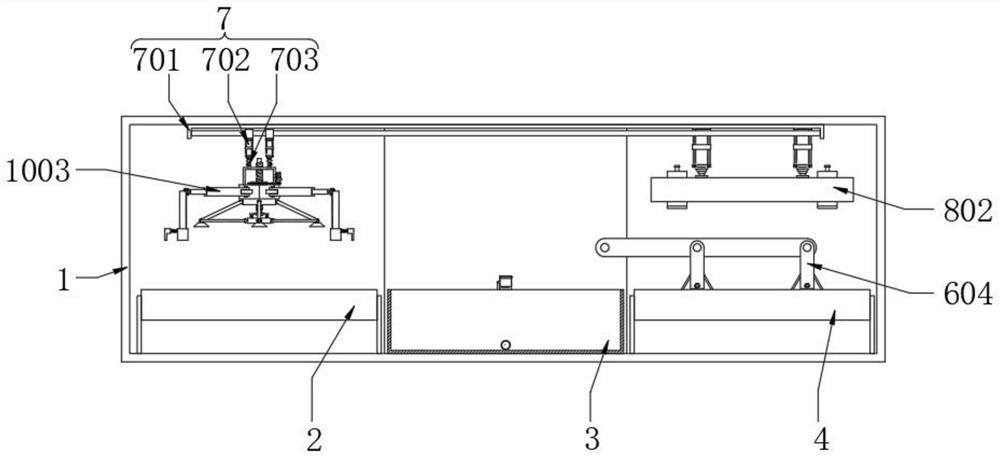

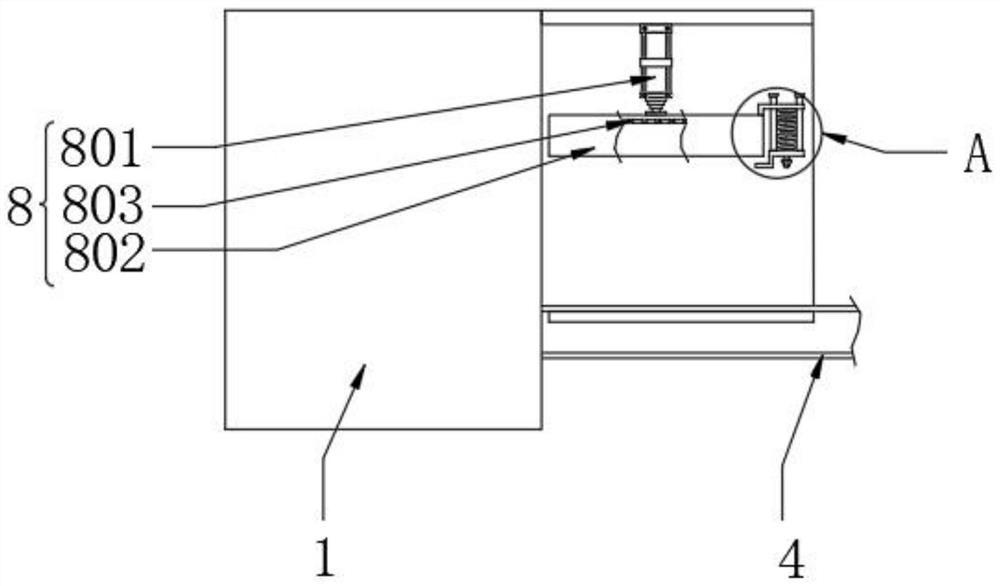

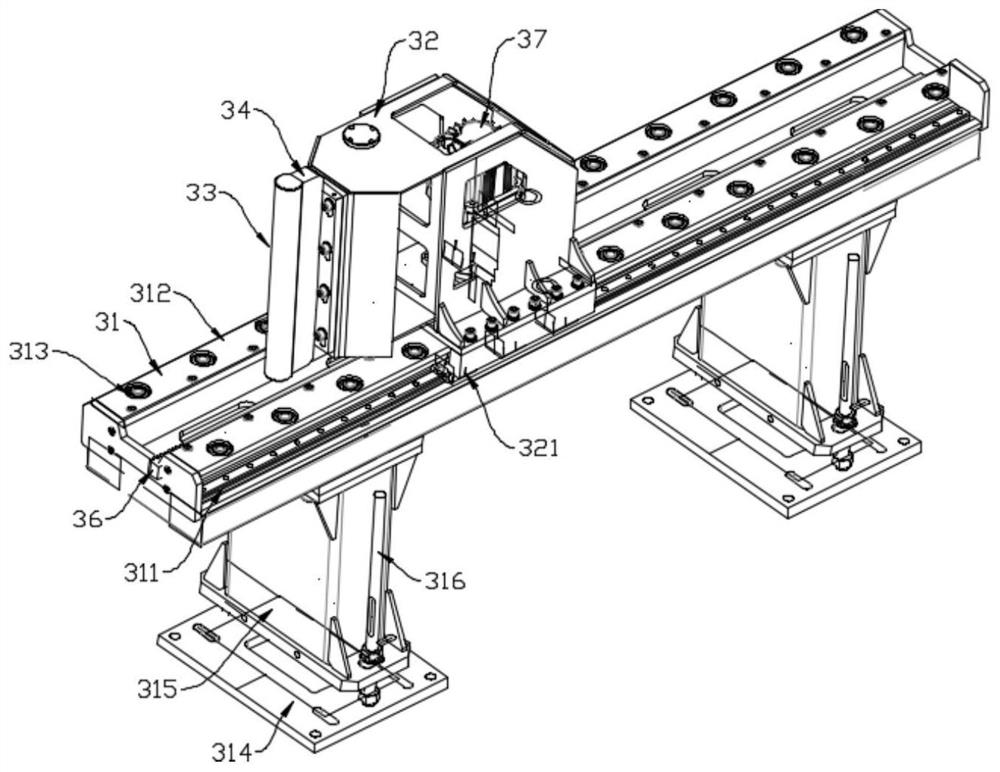

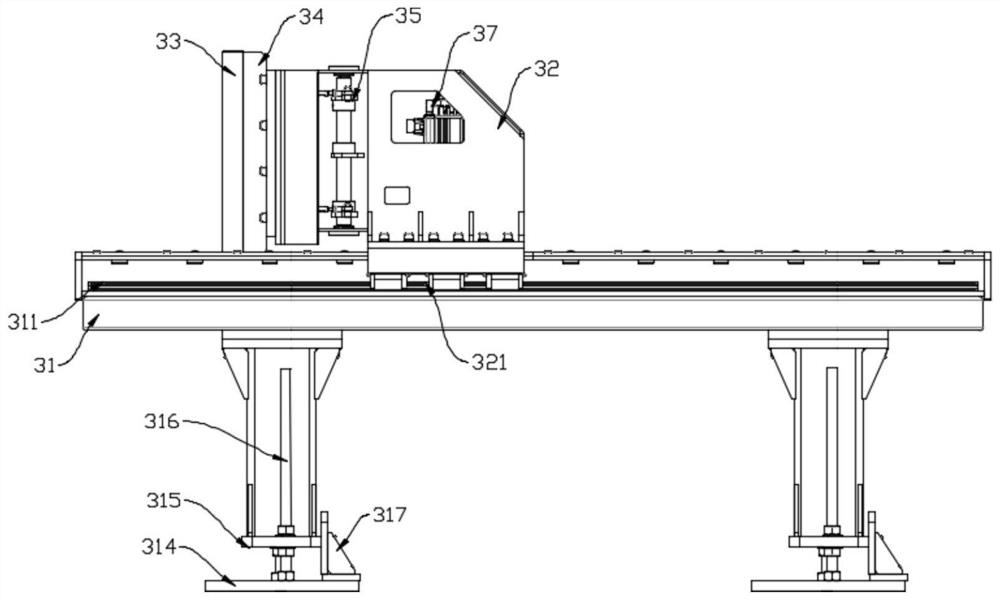

Circular tube cutting and surface drilling integrated equipment

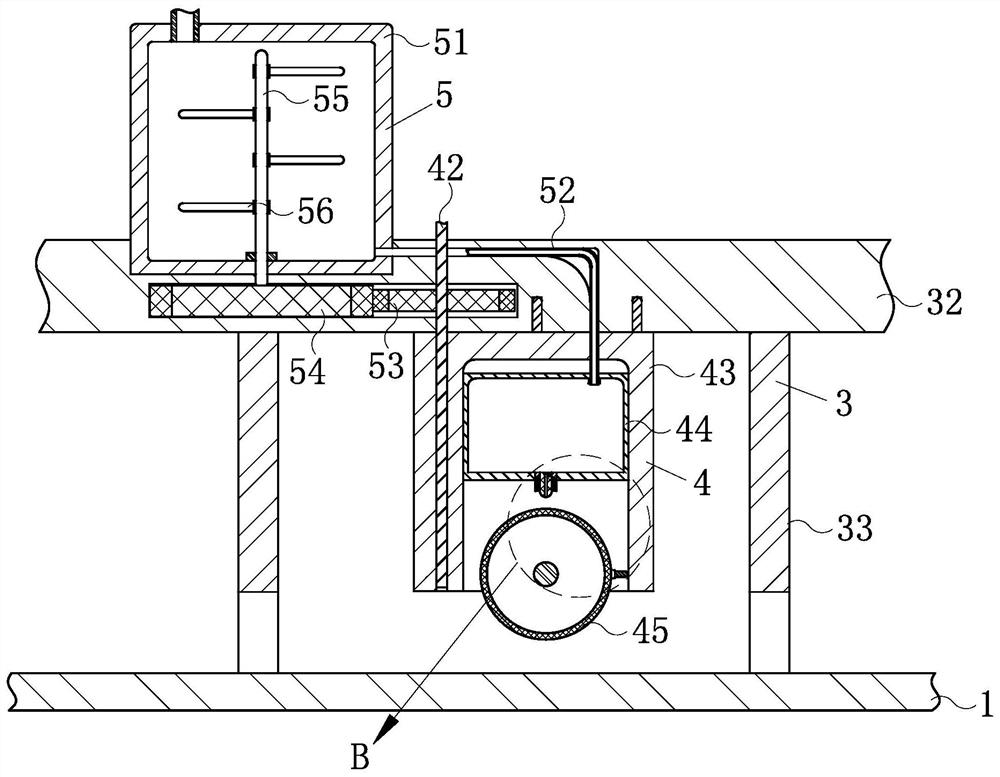

ActiveCN110625397APlay a clamping effectSolve cutting problemsWork clamping meansOther manufacturing equipments/toolsBiomedical engineering

The invention relates to the machining field, in particular to circular tube cutting and surface drilling integrated equipment. The circular tube cutting and surface drilling integrated equipment comprises a feeding assembly, a cutting assembly and a drilling assembly, wherein the feeding assembly is arranged at one side of the cutting assembly; the drilling assembly is arranged at one side, awayfrom the feeding assembly, of the cutting assembly; the feeding assembly, the cutting assembly and the drilling assembly are linearly arranged in sequence; the feeding assembly comprises a fixed clampand a first movable clamp; the fixed clamp is arranged at one end of the cutting assembly; and the first movable clamp is arranged between the fixed clamp and the cutting assembly. The circular tubecutting and surface drilling integrated equipment solves the problem that circular tube cutting and drilling cannot be performed simultaneously, improves working efficiency and saves time.

Owner:重庆优实管业有限公司

Electric vehicle wheel hub end cover polishing table

InactiveCN114260766AEasy to handlePlay a clamping effectRevolution surface grinding machinesGrinding drivesStructural engineeringMachine

The invention relates to the technical field of hub grinding equipment, in particular to an electric vehicle hub end cover grinding table which comprises a rack, a conveying belt, a positioning protection device and a turnover mechanism, the conveying belt is located above the rack, and a plurality of electric lifting columns capable of penetrating through hub center shaft holes are evenly and horizontally arranged on the conveying belt; a plurality of recycling rods capable of freely stretching out and drawing back are circumferentially distributed on the side wall, close to the top end, of the electric lifting column, a first side supporting table and a second side supporting table are arranged on one side of the rack, a first grinding machine is arranged on the first side supporting table, and a second grinding machine is arranged on the second side supporting table; the positioning protection device is installed on the portion, corresponding to the first grinding machine in position, of the machine frame, and the turnover mechanism is arranged on one side of the positioning protection device and arranged on the portion, between the first grinding machine and the second grinding machine, of the machine frame. And the hub on the grinding table can be automatically positioned, and chippings can be prevented from being splashed down to other hubs.

Owner:XUZHOU XIAOQIANG WHEEL TECH CO LTD

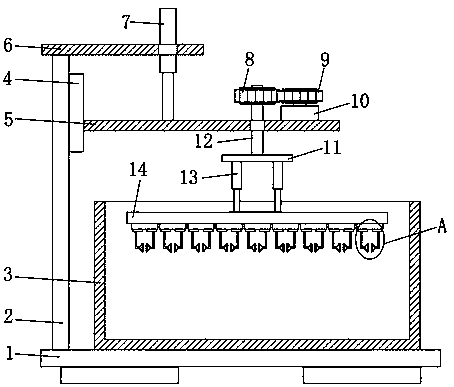

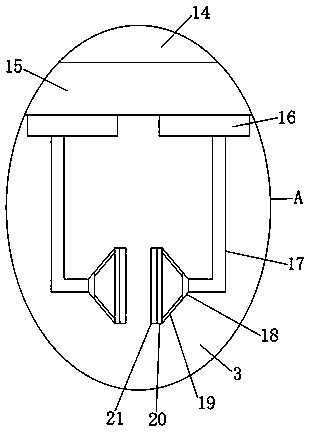

Installation method of blade

InactiveCN108177215AQuick take outHigh degree of automationRotary cutting toolsAutomationEngineering

The invention discloses an installation method of a blade. The installation method of the blade belongs to the technical field of cutter processing and preparing, and is characterized by comprising the following steps of a, placing a cutter body on a cutter clamping device; b, downwards moving an inserting plate of a cutter body alignment device, inserting the inserting plate into an inserting slot of the cutter body, rotating a stepping motor to drive the inserting plate to rotate, enabling the inserting slot of the cutter body to align at a placement position of a blade of a next process, upwards moving the inserting plate, and separating the inserting plate from the inserting slot; and c, pushing the blade out through a blade pushing air cylinder of a blade placement device, rotating the air cylinder to drive a double-shaft air cylinder to rotate clockwise at 90 degrees, clamping the pushed-out blade through a parallel clip on the double-shaft air cylinder, then anticlockwise rotating the blade at 90 degrees, and inserting the blade into the inserting slot of the cutter body. The installation method of the blade provided by the invention not only can be used for quickly aligningan installation position, corresponding to the blade, of the cutter body inserting slot, but also can be used for quickly taking the blade out for installing the blade, and is high in automation degree without the need for manual intervention, good in safety and high in efficiency.

Owner:成都恒成工具股份有限公司

Medical surgical gown intelligent composite equipment and using method

PendingCN112519376ADoes not affect normal rotationEasy to operateLamination plant layoutLamination ancillary operationsSurgical GownsElectric machinery

The invention discloses medical surgical gown intelligent composite equipment which comprises an operation table, two supporting plates are symmetrically and fixedly connected to the bottom of the operation table, and the bottoms of the sides, close to each other, of the two supporting plates are fixedly connected with the same transverse plate; the invention also discloses a using method. The equipment has the advantages that the rotating motor is started to drive the pattern wheel to rotate and drive the conveying belt to conduct transmission, energy utilization is improved, meanwhile, clothes are conveyed conveniently, the height of the pattern wheel can be adjusted by starting the lead screw motor, rotation of the pattern wheel is not affected, operation is easy, use is convenient, bypressing a pressing block, the effect of clamping and conveying the clothing materials can be achieved, alignment and pulling of the clothing materials are facilitated so that the sewing flatness of the clothing materials is improved, the labor intensity is reduced, through cooperation of triangular blocks, the effect of automatically loosening waste materials can be achieved, automatic collectionof the waste materials is facilitated through a waste material collection box, and the practicability is improved.

Owner:彭满先

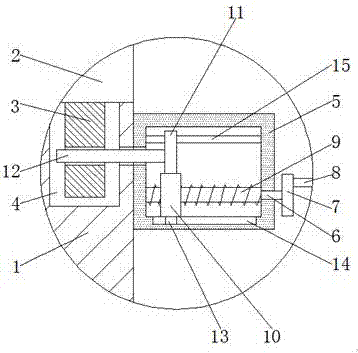

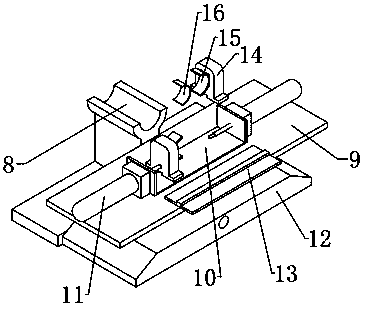

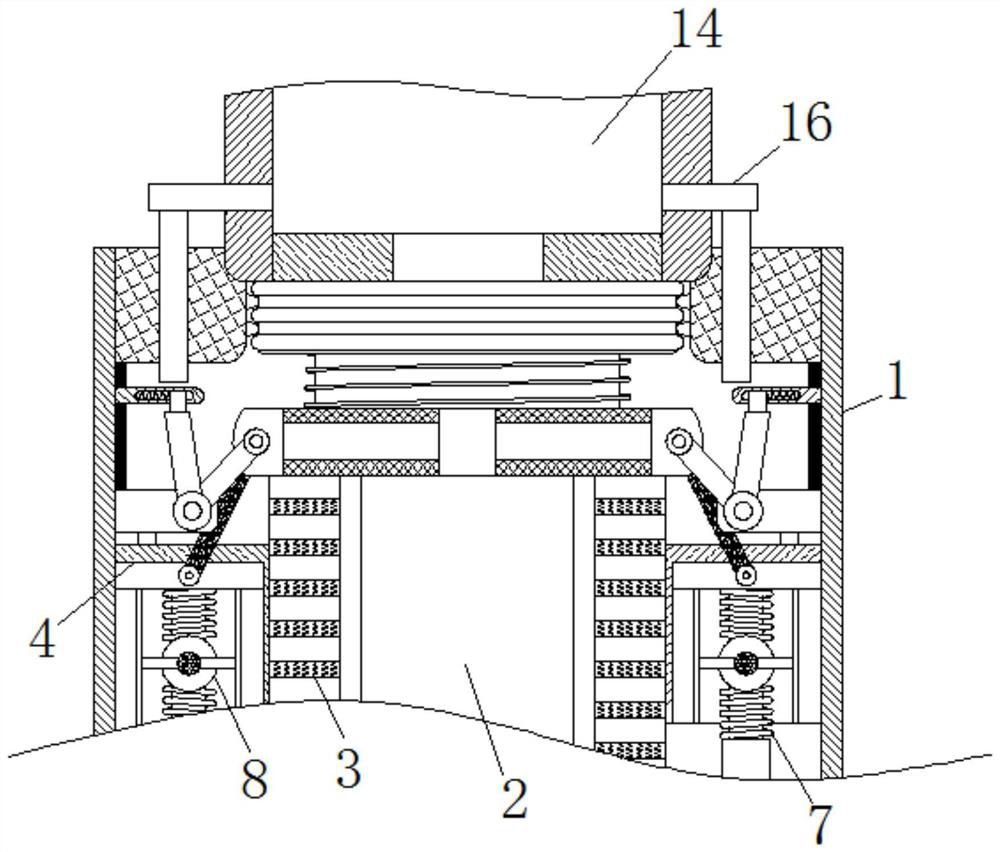

Fixing device for bearing machining

InactiveCN109159028APlay a fixed effectPlay a clamping effectGrinding work supportsEngineeringSlide plate

The invention discloses a fixing device for bearing machining. The fixing device comprises a body. A supporting plate is fixedly connected to the top of the left side of the body, the supporting platecomprises a first fixing column, an electric telescopic rod, a fixing plate, a top plate, a fixing rod, a screw hole, a reserved hole and a second fixing column, an installation plate is fixedly connected to the right side of the bottom of an inner cavity of the body, and the installation plate comprises a driving wheel, a servo motor, a limiting plate, grooves, clamping rods, a connecting plate,a clamping plate, a sliding plate, a connecting rod, a sliding rod, a pulley and a driven wheel. According to the fixing device for bearing machining, through cooperation of the driving wheel, the servo motor, the limiting plate, the clamping rods, the driven wheel and the clamping plate, and through cooperation of the electric telescopic rod and the fixing plate, the fixing effect is achieved; and through cooperation of the fixing rod and the grooves, the clamping effect is achieved, and the problems that the clamping effect of existing fixing devices on bearings is not ideal, the clamping distance is inconvenient to adjust, the machining quality is affected, and great inconvenience is brought for use of people are solved.

Owner:LEIYANG XINDAWEI TECH

Printing packaging film waste treatment equipment and method

PendingCN113183360AReduce wasteReduce processing costsPlastic recyclingDirt cleaningWaste processingStructural engineering

The invention provides printing packaging film waste treatment equipment with novel structural design and a treatment method of the printing packaging film waste treatment equipment. The printing packaging film waste treatment equipment comprises a bottom box, wherein a workbench is arranged on the outer wall of the top of the bottom box through bolts, four supporting frames are arranged on the outer wall of the top of the workbench through screws, two clamping rollers are rotationally connected between the outer walls of the opposite sides of the three supporting frames through rotating shafts, a fixing frame is arranged on the outer wall of the top of the workbench through bolts, and an upper mounting plate and a lower mounting plate are arranged between the inner walls of the opposite sides of the fixing frame through bolts. According to the printing packaging film waste treatment equipment, a spray head, a friction roller and a scraper are arranged, the two surfaces of a packaging film are sprayed through the spray head, then the outer wall of the top and the outer wall of the bottom of the packaging film are cleaned through the friction roller and the scraper respectively, so that residual printing marks and residues on the packaging film can be removed, then the packaging film can be reused, waste of resources is relieved, and the processing cost can be reduced.

Owner:滁州远达彩印包装有限公司

Textile printing adjustment device based on Internet-of-Things big data technology

ActiveCN111907206AImprove liquidityAvoid rapid thickeningRotary pressesPrinting press partsTextile printerMechanical engineering

The invention relates to the technical field of textile printing, in particular to a textile printing adjustment device based on an Internet-of-Things big data technology. The device comprises a bottom plate, supporting legs, a supporting mechanism, an impressing mechanism, a feeding mechanism, an adjusting mechanism and limiting mechanisms. During use, the feeding mechanism is arranged at one side of the impressing mechanism, and dye in a storage box is continuously stirred and adjusted through a corresponding gear transmission structure, so that the fluidity of the dye is enhanced, and the situation that the dye is quickly thickened is avoided; the adjusting mechanism is arranged in the supporting mechanism, and corresponding blending liquid can be conveniently and intermittently added into the storage box through the corresponding gear transmission structure and a ratchet structure, therefore, the situation that the dye is thickened can be further avoided, and meanwhile convenienceis brought to the use process; and the limiting mechanisms are arranged at the two sides of the top of the bottom plate, a textile fabric can be conveniently clamped in the whole printing process, therefore, wrinkling or deviating of the textile fabric can be avoided, and the printing quality is guaranteed.

Owner:深圳市汇泰锦纺织有限公司

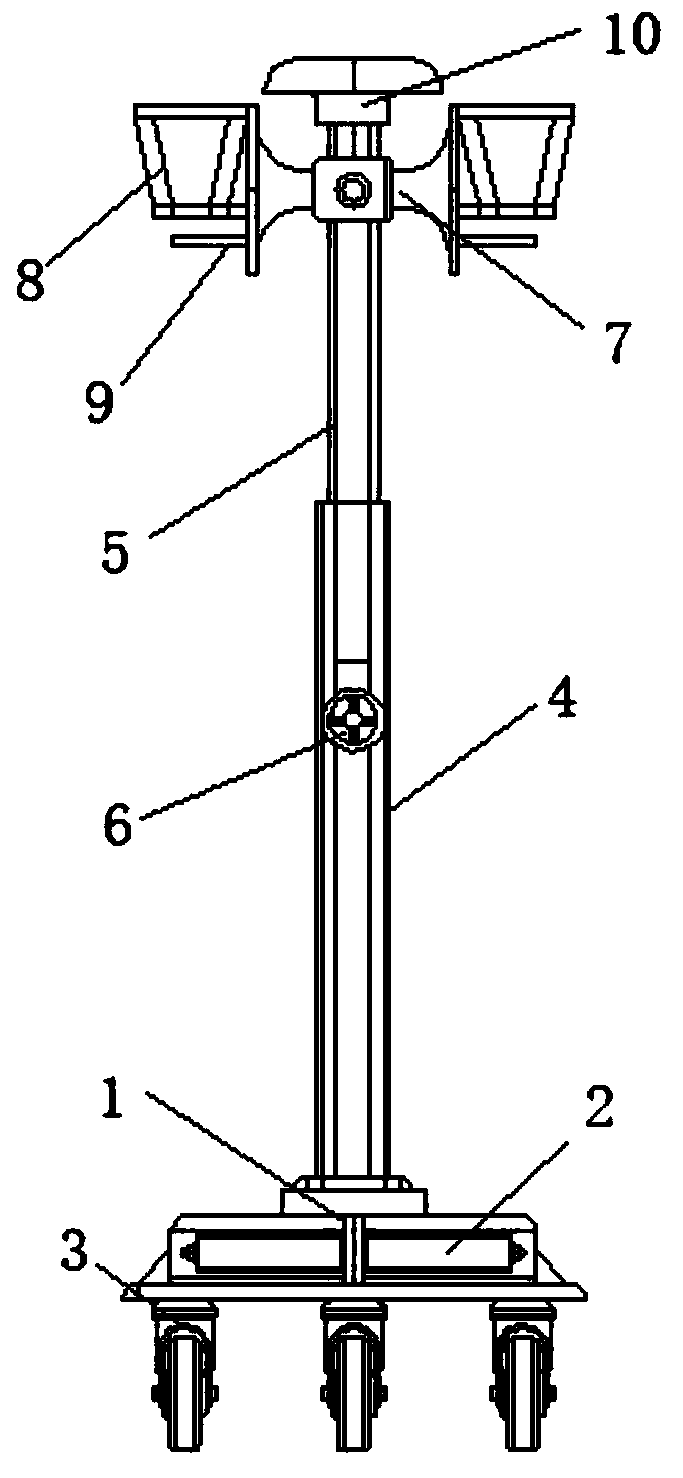

Mounting support device for land surveying and mapping

ActiveCN108801317AAchieve fine-tuningAchieve horizontalityMeasurement apparatus componentsEngineeringSurveyor

Owner:连云港四方测绘勘察有限公司

Intelligent device for preventing permeation of intravenous infusion for nursing in operating room

PendingCN111529805AGuaranteed stabilityEasy to storeMedical devicesFlow monitorsOperating theatresBiomedical engineering

The invention discloses an intelligent device for preventing permeation of intravenous infusion for nursing in an operating room. The intelligent device comprises a bearing base, a position adjustmentstructure, an intravenous infusion bag placement structure and an anti-permeation structure. The lower end of the bearing base is connected with wheels, a rechargeable battery is installed inside thebearing base, a telescopic rod is connected to the upper end of the inner part of a supporting column pole, the position adjustment structure is installed on the outside of the telescopic rod, and analarm is fixed to the front end of the position adjustment structure. The intravenous infusion bag placement structure is arranged on the outer side of the position adjustment structure, and the anti-permeation structure is arranged below the intravenous infusion bag placement structure. The humidity inside a sponge pad can be detected through a humidity sensor, so that whether liquid permeationoccurs at the connection between an infusion tube and an infusion bag or not can be found in time, and the alarm can emit sound and light to prompt nursing staff in time, so that the intelligence of the device in use can be improved.

Owner:胡晓春

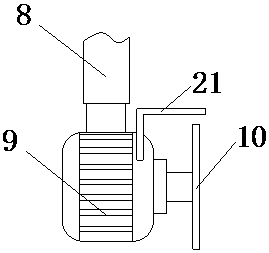

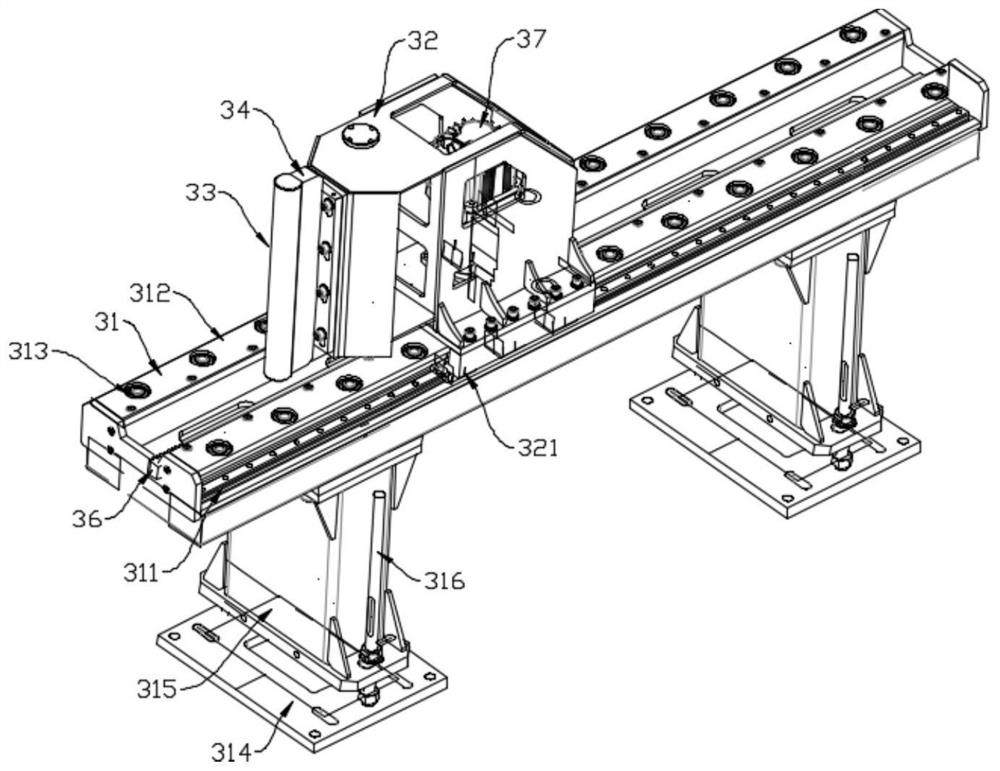

Machining and polishing equipment for automobile parts

ActiveCN114227504AReduce work contentHigh degree of intelligencePolishing machinesGrinding drivesGear wheelEngineering

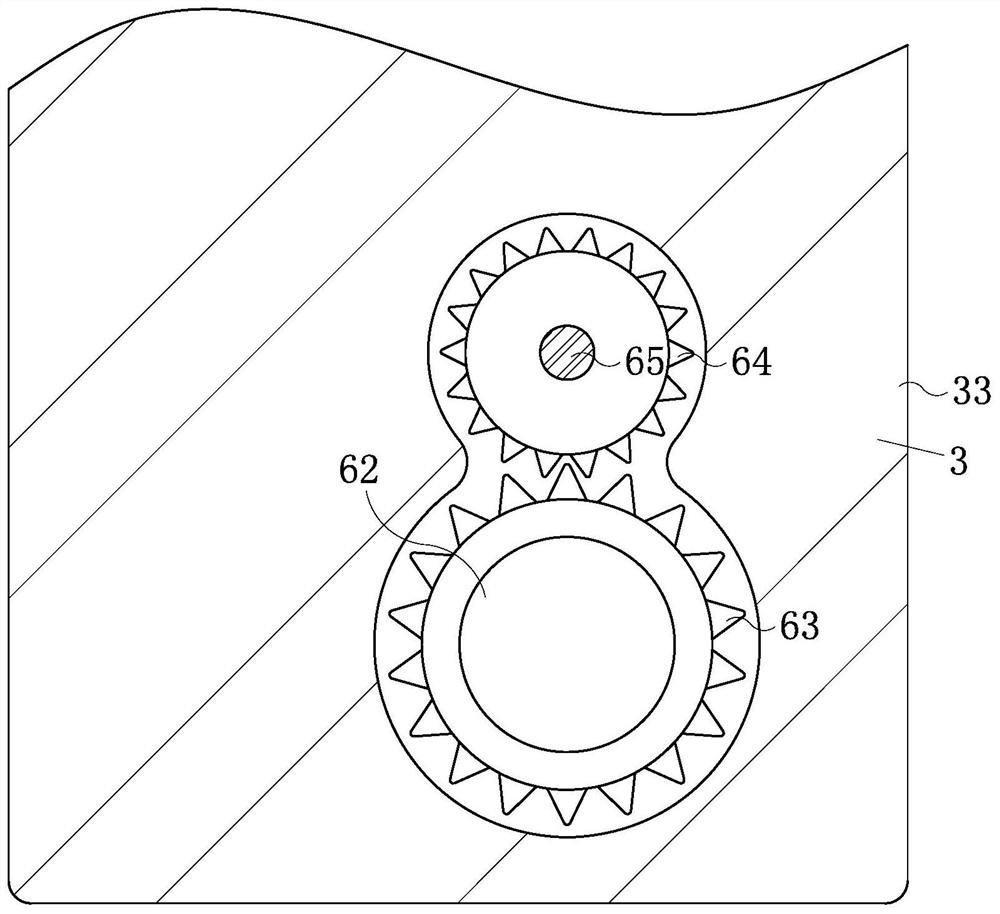

The invention relates to the technical field of automobile part machining, and particularly discloses automobile part machining and polishing equipment. Comprising guide rails which are symmetrically arranged, clamping mechanisms which are respectively connected with the guide rails in a sliding manner and are used for clamping automobile parts, a driving mechanism which can drive the clamping mechanisms to slide, and a polishing mechanism which is fixedly connected with the guide rails and is used for polishing the automobile parts, the driving mechanism comprises a first power piece, a first lead screw rotationally connected to the side wall of the guide rail and a transmission piece arranged between the first power piece and the first lead screw, the clamping mechanism comprises a sliding base, a bearing plate fixedly connected to the side wall of the sliding base and a pressing plate rotationally connected to the side wall of the sliding base, and a rack is arranged on the side wall of the guide rail; the bearing plate is rotationally connected with a gear meshed with the rack, a screw driven by the gear to rotate is rotationally connected between the bearing plate and the pressing plate, the screw is in threaded connection with a lifting rod, the top end of the lifting rod is slidably connected into the pressing plate, and the problem that in the traditional polishing process, work of technicians is tedious is solved.

Owner:重庆乐迪龙鑫科技股份有限公司

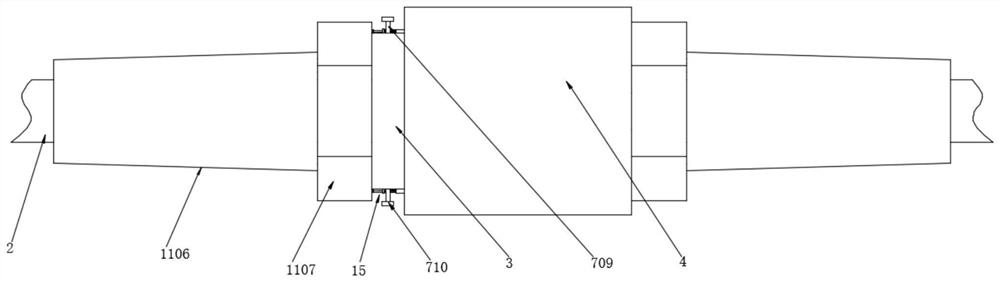

High-precision instrument welding clamping mechanism

ActiveCN114589448AProblems Affecting Weld StrengthOptimize assembly processWelding/cutting auxillary devicesAuxillary welding devicesButt jointWeld strength

The invention provides a high-precision instrument welding clamping mechanism, and relates to the technical field of high-precision instrument manufacturing. A clamping driving piece is fixedly connected to the upper portion of the welding tool main frame body, and a centering driving piece is fixedly connected to the lower portion of the welding tool main frame body. The tool has the function of measuring and limiting a workpiece at a butt joint position, the direction and the position of the tool and the butt joint position can be accurately determined through the centering mechanism, the axis position of the workpiece of a cylindrical structure is determined, the position and the direction of a splicing piece are fixed, the coaxiality of two connecting pieces is accurate, the assembly process is further improved, and the assembly efficiency is improved. The invention relates to a positioning tool for butt joint of cylindrical parts, which solves the problems that the position relation between two parts needs to be adjusted and kept for the assembly of the parts of the traditional tubular structure at present, and the coaxiality deviation of the two sections of workpieces after welding and assembly is larger, the instrument precision is reduced and the welding strength is influenced due to inaccurate centering when the existing positioning tool for butt joint of the cylindrical parts is used.

Owner:常州盛海仪表有限公司

Meal delivering box for meal delivery

InactiveCN108341144APlay a limiting effectPlay a clamping effectContainers to prevent mechanical damageExternal fittingsEngineeringMechanical engineering

The invention discloses a meal delivering box for meal delivery. The meal delivering box for meal delivery comprises a box body; a hollow cavity is formed inside the box body; a first opening communicating with the hollow cavity is formed in the front side wall of the box body in a penetrating mode; a first sealing door is arranged at the first opening; the opposite inner side walls of the hollowcavity are connected with a first U-shaped board; water through holes are formed in the side walls of the first U-shaped board in a penetrating mode; two clamping devices are symmetrically arranged onthe side wall of the upper end of the first U-shaped board; a partition plate is vertically arranged on the side wall of the upper end of the first U-shaped board and located between the two clampingdevices; and communication grooves communicating with the hollow cavity are formed in the side walls of the two ends of the box body in a penetrating mode. The meal delivering box for meal delivery is reasonable in structural design and easy to operate, has the better buffering effect, can ensure the effect that vegetables are not prone to being scattered and leaked in the conveying process, canfacilitate classified storage for users, and improves the meal delivery efficiency of men for takeaway.

Owner:朱宝会

Industrial production material punching equipment convenient to position

InactiveCN112893927APrecise positioningDifferent shapesPositioning apparatusBoring/drilling componentsDrive wheelPunching

The invention discloses industrial production material punching equipment convenient to position, which comprises a shell, a first motor, an electric telescopic rod, a riser and a drill bit. The first motor is fixed to the bottom end of the shell; a driving wheel is arranged above the first motor; the left side of the driving wheel is connected with a left driven wheel; the right side of the driving wheel is connected with a right driven wheel; transverse rods are fixed to the inner surfaces of the left driven wheel and the right driven wheel; threaded rods are arranged on the surfaces of the top ends of connecting blocks; a transverse plate is connected between first sliding blocks; an electric telescopic rod is mounted on the surface of the top end of the transverse plate; a connecting rod is mounted on the lower surface of the top end of the shell; and locking bolts are mounted on the surfaces of the right sides of second sliding blocks. According to the industrial production material punching equipment convenient to position, materials can be well positioned, the material punching distance and size can be adjusted, and dust and impurities generated in the punching process can be collected and cleaned.

Owner:常州创合机械设备有限公司

Tool manufacturing equipment

ActiveCN107962266AImprove push efficiencyReduce weightMetal working apparatusSolder feeding devicesEngineeringMachining

The invention discloses tool manufacturing equipment, and belongs to the field of tool machining and manufacturing. The tool manufacturing equipment is characterized in that a tool body pushing devicecomprises an installation base, and a tool body storage bin and a tool pushing cylinder are fixed to the installation base; a tool body alignment device comprises a support, a lifting cylinder is fixed to the support, a supporting frame is fixed to the lifting cylinder, and a stepping motor is fixed to the supporting frame; a blade installation device comprises a fixed base, a blade pushing cylinder and a rotating cylinder are arranged on the fixed base, a double-shaft cylinder is fixed to the rotating cylinder, and a parallel clamp is fixed to the double-shaft cylinder; and a blade welding device comprises a vertical base, an electromagnetic heater is fixed to the vertical base, a first wire feeder is fixed to one side of the vertical base, and a second wire feeder is fixed to the otherside of the vertical base. According to the tool manufacturing equipment, tool bodies can be conveyed continuously, a tool body insertion groove can be rapidly aligned with the installation position corresponding to a blade, and the blade can be taken out rapidly to be installed; and the contact portions of the blade and the tool body can be welded from the two sides at the same time, and the welding uniformity and the welding effect are ensured.

Owner:雅安恒成精密刀具有限公司

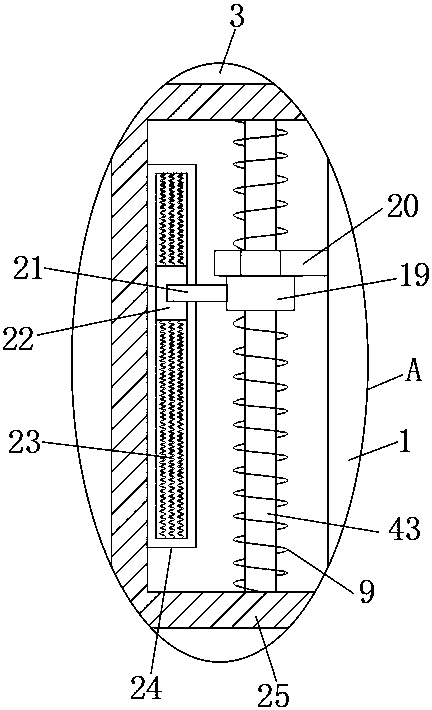

Sand-shooting sealing auxiliary equipment for core sand filling equipment of core making machine

InactiveCN112453331APlay a clamping effectImprove gripMoulding machine componentsMoulding machinesEngineeringSlide plate

The invention relates to the technical field of core making machines, and discloses sand-shooting sealing auxiliary equipment for core sand filling equipment of a core making machine. The sand-shooting sealing auxiliary equipment comprises a sand mold cavity, wherein a forming cavity is formed in the sand mold cavity, and heating plates are fixedly mounted at the left end and the right end of theforming cavity; and fixing frames are fixedly mounted in the sand mold cavity and on the opposite surfaces of the heating plates. According to the sand-shooting sealing auxiliary equipment for the core sand filling equipment of the core making machine, when a sand shooting gun gets close to the sand mold cavity, moving rods are matched to drive sliding rods to move downwards in the sand mold cavity, on one hand, connecting rods are driven to move, the connecting rods drive butt joint plates to move upwards and be lifted upwards to be matched with the sand shooting gun, and therefore the sealing effect in the sand-shooting process is improved; and on the other hand, extrusion rods are matched to drive sliding plates to slide in the fixing frames, in cooperation with the effect of air outletbags, dust on the butt joint plates can be blown away when the sand shooting gun is separated from the sand mold cavity, and therefore the effect of automatic cleaning is achieved.

Owner:厦门艺琉如机械有限公司

Automatic feeding, positioning and bending method for plates

ActiveCN112139299APrecise positioningImprove bending efficiencyMetal-working feeding devicesPositioning devicesStructural engineeringManufacturing engineering

The invention discloses an automatic feeding, positioning and bending method for plates, and belongs to the field of plate machining. The method comprises the following steps that after a conveying device conveys a to-be-machined workpiece from a workpiece placing device to a feeding device located on one side of a bending machine, a box body driving mechanism in the feeding device works to drivea blocking column to push the workpiece to move towards the other side of the bending machine, and when the blocking column on the feeding device on the other side touches the workpiece, an electric control device receives signals that the feeding devices on the two sides of the bending machine sense that the workpiece reaches a machining position at the same time, the box body driving mechanism is controlled to stop working, and the workpiece stays at the machining position. According to the method, the specific feeding devices are adopted, so that the bending position of the plate can be accurately positioned while the plate is fed, and the feeding devices can be conveniently and rapidly adjusted when the same workpiece is bent for multiple times.

Owner:ANHUI JACO NC MACHINE MFG

Welding calibration device for yacht production

PendingCN114473295AAvoid excessive noiseImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesPhysicsEngineering

The invention discloses a welding calibration device for speedboat production, and relates to the technical field of calibration devices.The welding calibration device comprises a welding calibration main body, a control element is fixedly connected to the front face of the welding calibration main body, a movable disc is arranged at the upper end of the welding calibration main body, and a protection panel is arranged at the right end of the welding calibration main body; the lower end of the protection panel is fixedly connected with a supporting bottom frame, and a supporting plate is arranged at the right end of the supporting bottom frame. Through the arrangement of the stable damping rods, the sliding rods, the damping elements, the damping buffer layers and the damping springs, in the process that the speed boat extrudes the stable disc, pressure can be transmitted to the outer portions of the damping elements through the stable damping rods, and then the transmitted pressure is buffered through the arrangement of the damping elements and the damping buffer layers; and the situation that the service life of the device is seriously affected due to the fact that the device is damaged due to the fact that the impact force is large is avoided, and in addition, through arrangement of a stable disc and a friction buffer block, the device can be clamped in the clamping process.

Owner:浙江洛洋游艇制造有限公司

Intelligent numerical control machine tool clamping mechanism

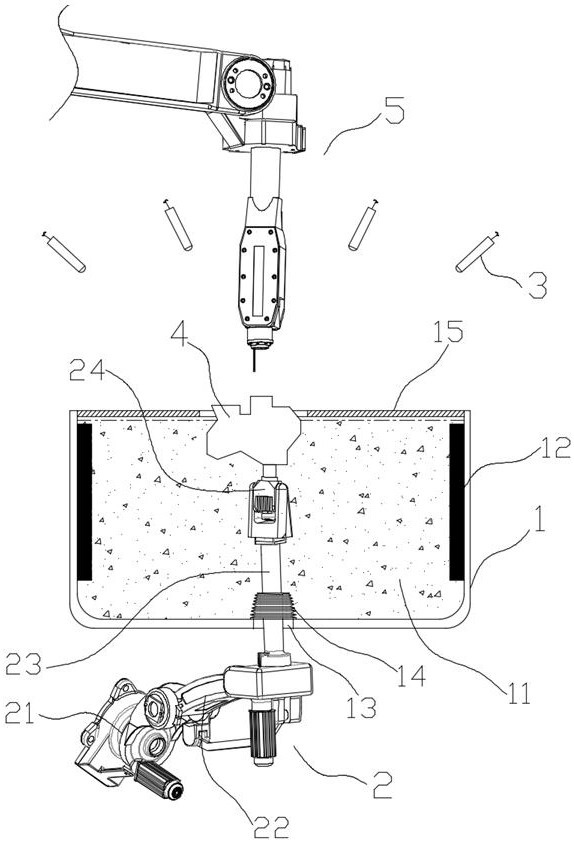

PendingCN114453927AImprove processing efficiencyFlexible adjustmentPositioning apparatusMetal-working holdersNumerical controlHemt circuits

The invention discloses an intelligent numerical control machine tool clamping mechanism which comprises a liquid pool, a multi-axis posture adjusting arm, a multi-angle laser posture position measuring device and a controller. The liquid pool is filled with electrorheological fluid, and electrodes are oppositely arranged on the inner walls of the two sides of the liquid pool; an external circuit applies a strong electric field to the electrorheological fluid through the electrodes; the multi-axis posture adjusting arm grabs and fixes a workpiece from the bottom of the workpiece to be machined and adjusts the posture of the workpiece. According to the clamping mechanism, liquid-solid conversion is achieved through the characteristics of electrorheological fluid, so that the clamping mechanism is suitable for clamping different special-shaped workpieces, full-wrapping clamping is adopted, the clamping force is stable, and the special-shaped workpieces are not prone to being damaged; according to the clamping mechanism, the multi-axis posture adjusting arm is combined with the multiple sets of laser position detectors, the posture of the special-shaped workpiece is flexibly and accurately adjusted, posture adjustment and clamping can be rapidly and automatically achieved in combination with the characteristics of electrorheological fluid, and therefore the machining efficiency of the workpiece is improved.

Owner:厦门工学院

A method for automatically feeding and positioning bending of plates

ActiveCN112139299BPrecise positioningImprove bending efficiencyMetal-working feeding devicesPositioning devicesEngineeringMachine

Owner:ANHUI JACO NC MACHINE MFG

A patch device with heat equalization function for intelligent manufacturing of tablet computers

The invention relates to a patch device with a heat soaking function for intelligent manufacturing of tablet computers, comprising an equipment casing and a positioning assembly. The box and the second belt conveyor, the inner rear wall of the equipment casing is equipped with a shielding component, the front end of the first motor is connected with a rotating rod, and the outside of the rotating rod is connected with a shielding plate through a connecting pin, the said The left and right sides of the shielding plate are connected with auxiliary support feet, and the lower end of the shielding plate is connected with a first contact sensor. The beneficial effects of the present invention are: the patch device with heat soaking function used in the intelligent manufacture of tablet computer can facilitate the flow of glue liquid, thereby facilitating the gluing of the equipment, and the shielding and positioning components of the equipment can be rotated, thereby facilitating the shielding and positioning of the equipment , the device can accurately heat the patch to facilitate the adhesion of the glue, the device can position the patch, and the device can hold the patch stably.

Owner:深圳市阿龙电子有限公司

A bending system for automatic feeding and positioning of plates

ActiveCN112139300BPrecise positioningImprove bending efficiencyMetal-working feeding devicesPositioning devicesElectrical connectionEngineering

The invention discloses a bending system for automatic feeding and positioning of plates, which belongs to the field of plate processing. It includes a conveying device, a workpiece placing device, a feeding device, a bending machine and an electric control device. The workpiece placing device is set on one side of the bending machine, and the conveying device is used to transport the workpiece from the workpiece placing device to the feeding device. On the other hand, there are at least one pair of feeding devices, which are symmetrically arranged on both sides of the bending machine. The feeding device includes a frame, a box body and a blocking column arranged at the front end of the box body. Guide rails are arranged on the frame along the feeding direction, and sliders matching the guide rails are provided at the bottom of the box body. The electric control device and the box body driving mechanism are electrically connect. After the blocking column senses that the workpiece is in the processing position, the electric control device receives an instruction and controls the drive mechanism of the box to stop working. The present invention can realize accurate positioning of the bending position of the plate while feeding the plate, and the adjustment of the feeding device is convenient and fast when the same workpiece is bent multiple times.

Owner:ANHUI JACO NC MACHINE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com