Automatic feeding, positioning and bending method for plates

An automatic feeding and plate technology, applied in the field of plate processing, can solve problems such as troublesome positioning and prone to errors, and achieve the effects of improving bending efficiency, precise positioning, and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

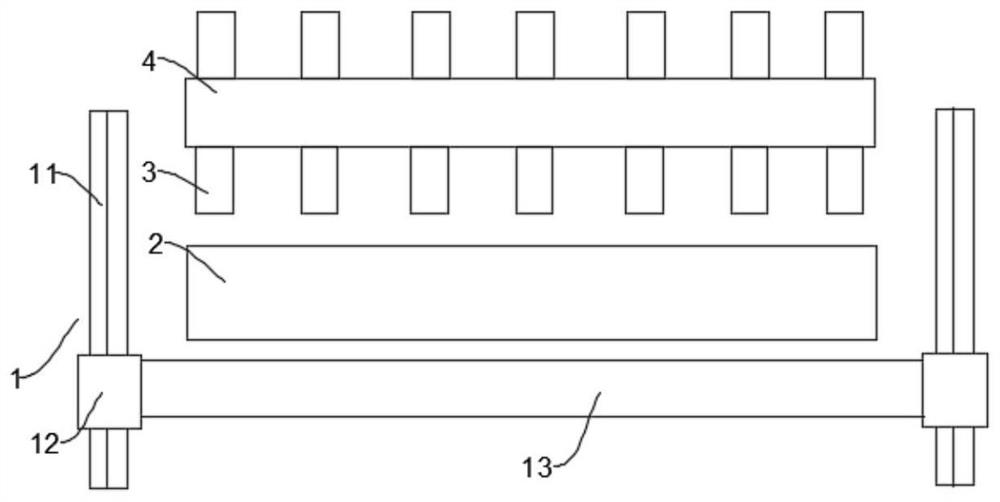

[0040] Such as figure 1 As shown, a bending system with automatic feeding and positioning of plates is used for bending and processing of plates, and mainly includes four parts: a feeding device 1, a workpiece placing device 2, a feeding device 3 and a bending machine 4.

[0041] Wherein, there is at least one pair of feeding devices 3, and each pair of feeding devices 3 is symmetrically arranged on both sides of the bending machine 4. Usually, at least two pairs of feeding devices 3 are generally arranged, and the two pairs on the same side of the bending machine 4 The feeding device 3 is respectively arranged at the front and rear ends of the bending machine 4. By adjusting the pushing position of the feeding device 3 at the front and rear ends for the workpiece, the slope of the workpiece entering the bending machine 4 can be adjusted to meet different processing requirements. The workpiece placement device 2 is arranged on one side of the bending machine 4, outside the fee...

Embodiment 2

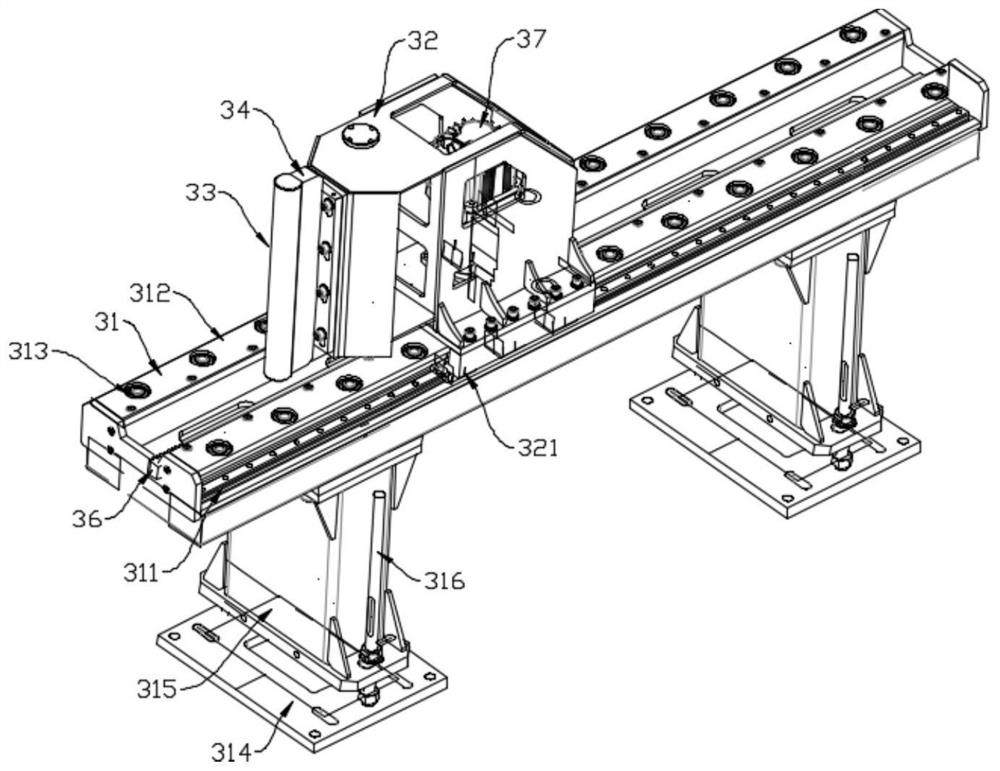

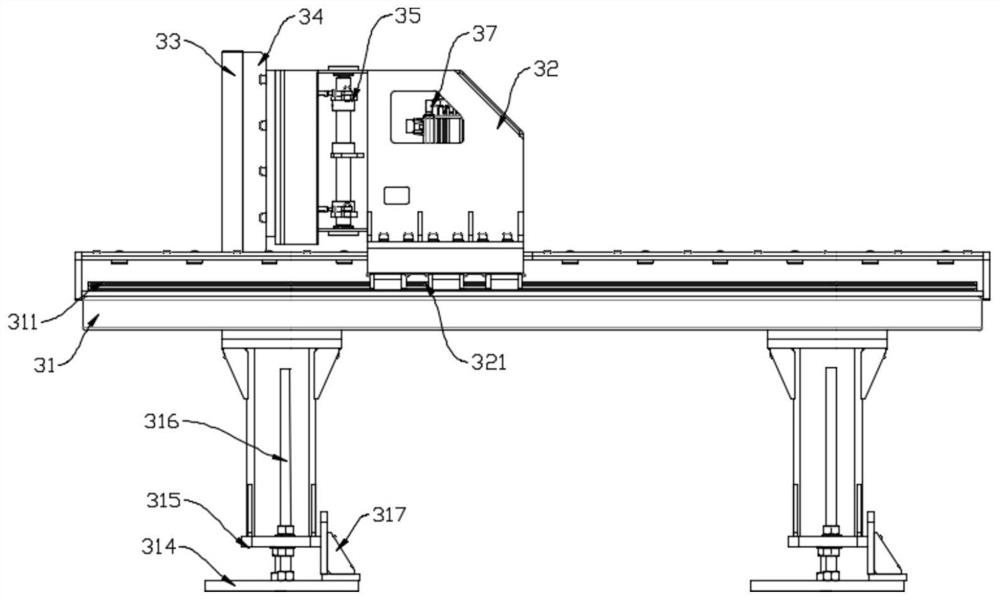

[0055] A bending system for automatic feeding and positioning of plates in this embodiment is basically the same in structure as in Embodiment 1, only the sensing mechanism of the blocking column 33 is improved. Such as image 3 with Figure 4 As shown, in this embodiment, the stop post 33 realizes the positioning of the workpiece through the mechanical induction mechanism 35 .

[0056] The mechanical sensing mechanism 35 includes a rotating shaft 351 , a guide rod 352 , a connecting arm 353 , a sensing arm 354 and a sensor. Wherein, the rotating shaft 351 is vertically arranged, and its upper and lower ends are respectively hingedly connected with the upper and lower end surfaces of the box body 32 through rotating bearings. There are two guide rods 352 and two connecting arms 353 , the two connecting arms 353 are respectively sleeved on the upper part and the lower part of the rotating shaft 351 , and the two guide rods 352 are respectively connected to the upper part and ...

Embodiment 3

[0060] A bending method for automatic feeding and positioning of plates, using a bending system for automatic feeding and positioning of plates in Embodiment 1 or Embodiment 2, the process is as follows: the transport device 1 transports the workpiece to be processed from the workpiece placement device 2 to After being located on the feeding device 3 on one side of the bending machine 4, the box driving mechanism in the feeding device 3 works, and the driving stopper 33 pushes the workpiece to move to the other side of the bending machine 4. When the feeding device on the other side After the stop post 33 on the device 3 touches the workpiece, the electronic control device simultaneously receives the signal that the feeding device 3 on both sides of the bending machine 4 senses that the workpiece has reached the processing position, and controls the drive mechanism of the box to stop working, and the workpiece stays in the processing position. Location.

[0061] When the bendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com