Tool manufacturing equipment

A technology of equipment and cutter body, applied in the field of cutter preparation equipment, can solve the problems of cutter deformation, low welding efficiency, high labor intensity, etc., and achieve the effects of reducing weight, convenient movement and installation, and improving pushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

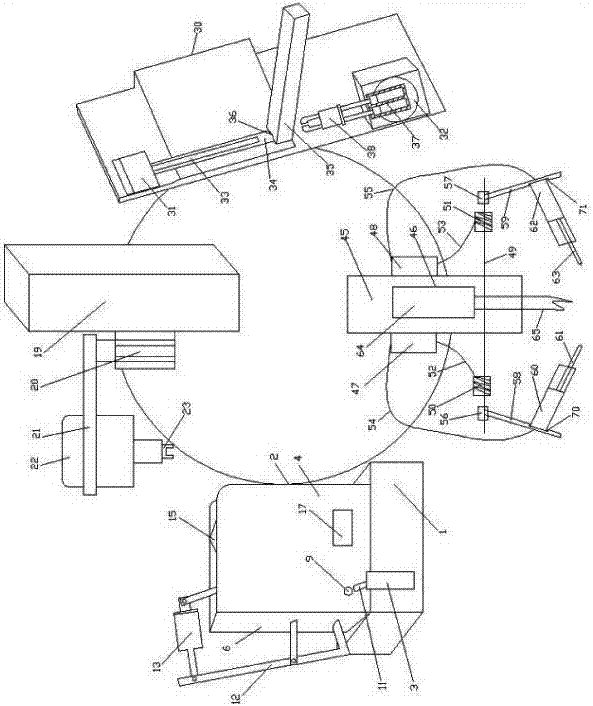

[0073] A cutting tool preparation device, comprising a cutting device pushing device, a cutting device aligning device, a blade placing device and a blade welding device;

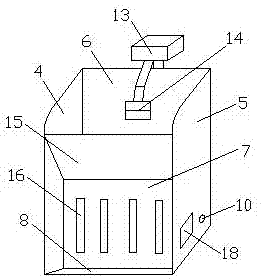

[0074] The cutter body pushing device includes a mounting seat 1, on which a cutter body reserve bin 2 and a pusher cylinder 3 are fixed, and the cutter body reserve bin 2 includes a first side plate 4, a second side plate fixedly connected together. Two side plates 5, the first baffle plate 6, the second baffle plate 7 and the base plate 8, the bottom of the first side plate 4 has a first through hole 9, and the bottom of the second side plate 5 has a first through hole 9. The second through hole 10 corresponding to the hole 9, the pusher cylinder 3 is fixed with a push rod 11, and the push rod 11 is on the same level as the first through hole 9;

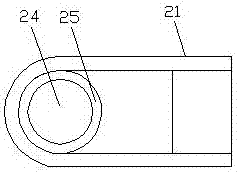

[0075]Described cutter body aligning device comprises support 19, and described support 19 is fixed with lift cylinder 20, and described lift cylinder 20 is hor...

Embodiment 2

[0080] A cutting tool preparation device, comprising a cutting device pushing device, a cutting device aligning device, a blade placing device and a blade welding device;

[0081] The cutter body pushing device includes a mounting seat 1, on which a cutter body reserve bin 2 and a pusher cylinder 3 are fixed, and the cutter body reserve bin 2 includes a first side plate 4, a second side plate fixedly connected together. Two side plates 5, the first baffle plate 6, the second baffle plate 7 and the base plate 8, the bottom of the first side plate 4 has a first through hole 9, and the bottom of the second side plate 5 has a first through hole 9. The second through hole 10 corresponding to the hole 9, the pusher cylinder 3 is fixed with a push rod 11, and the push rod 11 is on the same level as the first through hole 9;

[0082] Described cutter body aligning device comprises support 19, and described support 19 is fixed with lift cylinder 20, and described lift cylinder 20 is ho...

Embodiment 3

[0088] A cutting tool preparation device, comprising a cutting device pushing device, a cutting device aligning device, a blade placing device and a blade welding device;

[0089] The cutter body pushing device includes a mounting seat 1, on which a cutter body reserve bin 2 and a pusher cylinder 3 are fixed, and the cutter body reserve bin 2 includes a first side plate 4, a second side plate fixedly connected together. Two side plates 5, the first baffle plate 6, the second baffle plate 7 and the base plate 8, the bottom of the first side plate 4 has a first through hole 9, and the bottom of the second side plate 5 has a first through hole 9. The second through hole 10 corresponding to the hole 9, the pusher cylinder 3 is fixed with a push rod 11, and the push rod 11 is on the same level as the first through hole 9;

[0090] Described cutter body aligning device comprises support 19, and described support 19 is fixed with lift cylinder 20, and described lift cylinder 20 is ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com