A method for automatically feeding and positioning bending of plates

An automatic material feeding and sheet metal technology, applied in the field of sheet metal processing, can solve problems such as error prone and troublesome positioning, achieve accurate and fast positioning, improve bending efficiency, and ensure processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

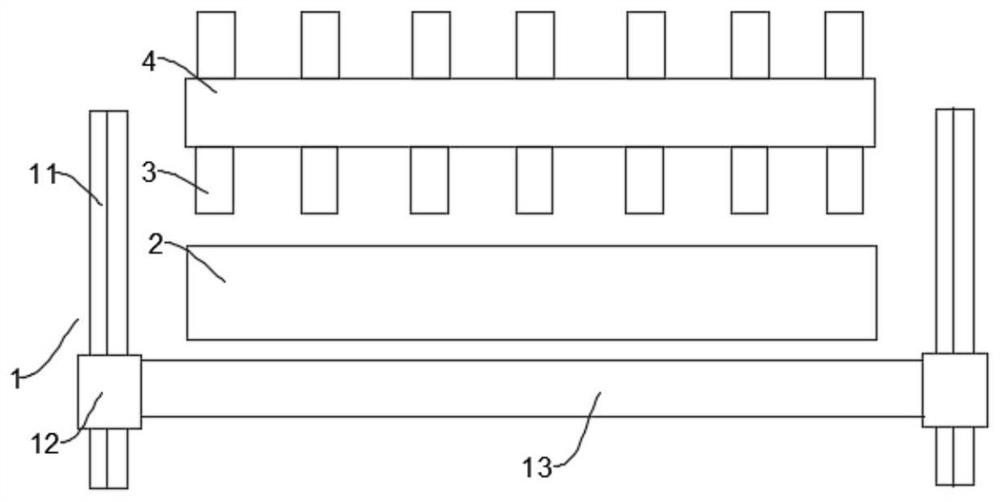

[0040] As shown in Figure 1, a bending system for automatic feeding and positioning of a plate is used for bending the plate,

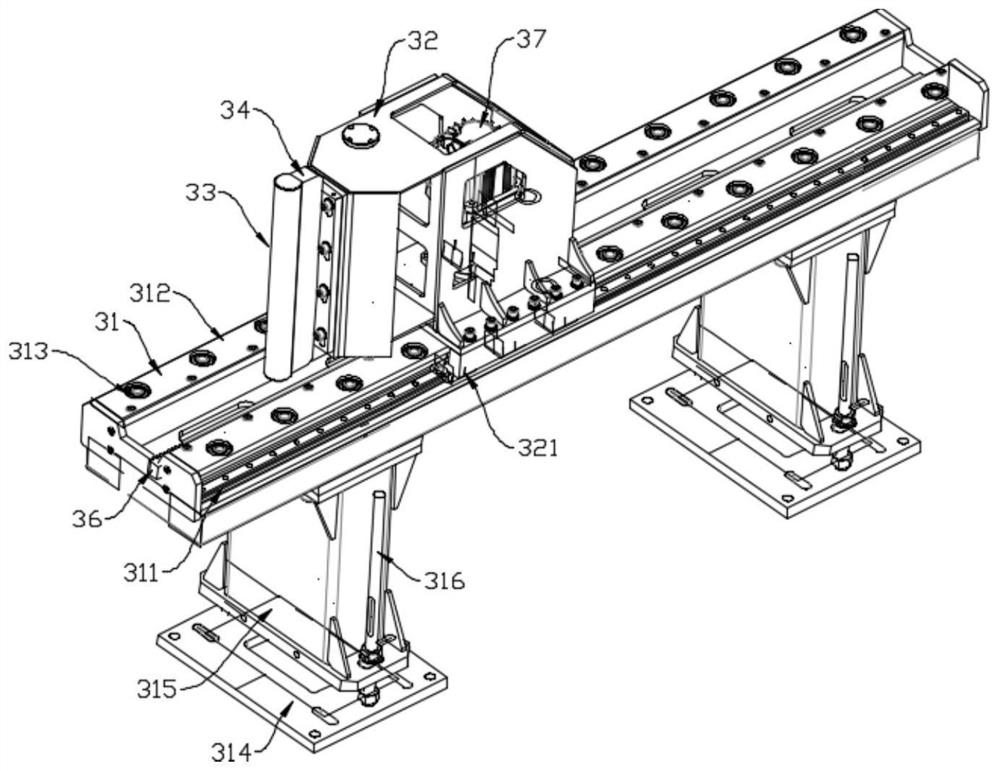

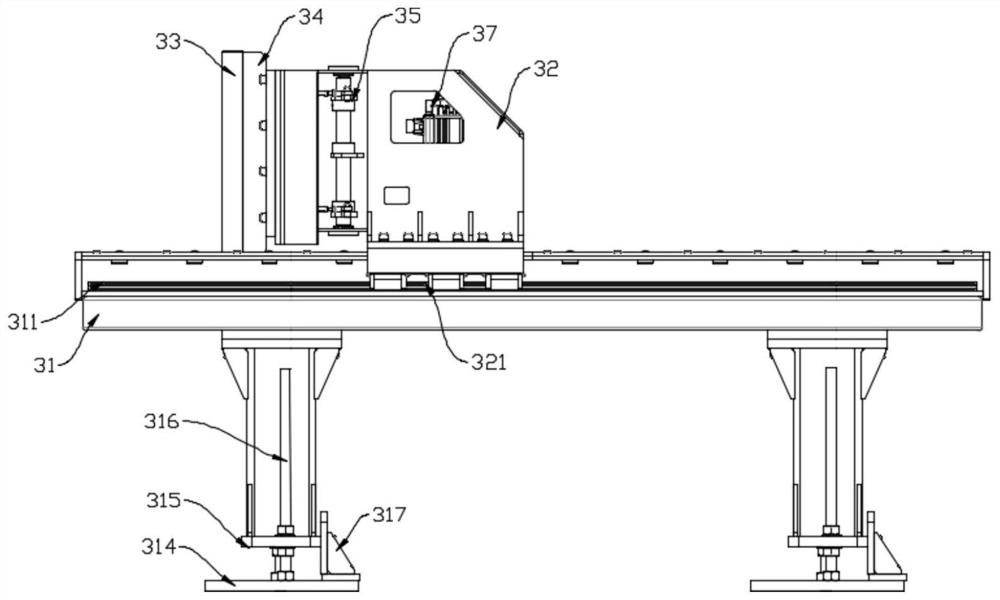

[0044] Among them, the rack 31 includes two uprights and a mounting seat installed on the upper end surface of the uprights. Both sides of the mounting seat are

[0046] In this embodiment, the electronic control device adopts a PLC controller. The induction device can use a conventional power supply device, the power supply

[0050] In addition, the box body 32 is only supported by the slider 321 and arranged on the guide rail I 311, which is easy for the slider 321 and the guide rail I 311

[0052] As shown in FIG. 6 , the lifting mechanism includes a base 314, a bottom plate 315, a screw 316 and a connecting plate 317. Among them, the base 314

Embodiment 2

[0055] The bending system of a kind of plate automatic feeding and positioning of the present embodiment is basically the same as the structure of the embodiment 1.

[0056] The mechanical sensing mechanism 35 includes a rotating shaft 351, a guide rod 352, a connecting arm 353, a sensing arm 354 and a sensor. Among them, turn

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com