Welding calibration device for yacht production

A calibration device and speedboat technology, applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve problems such as poor shock absorption, speedboat shaking, poor stability, etc., to increase stability, avoid excessive noise, and facilitate welding Processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

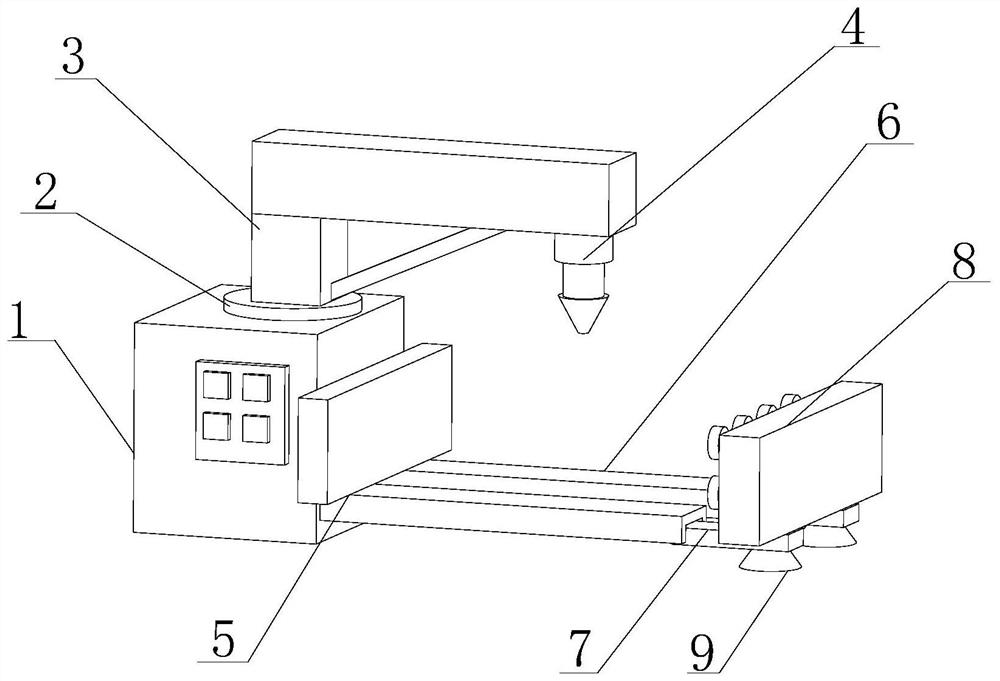

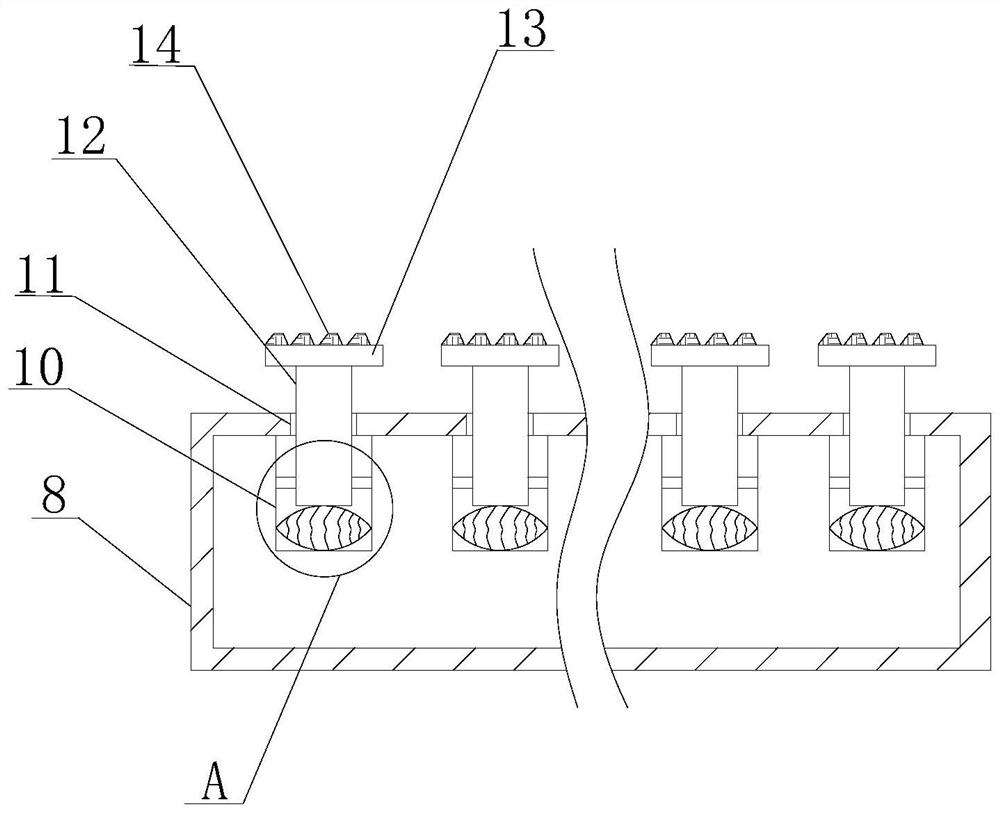

[0036] Such as Figure 1-6 As shown, the present invention provides a welding calibration device for speedboat production, comprising a welding calibration main body 1, the front of the welding calibration main body 1 is fixedly connected with a control element, the upper end of the welding calibration main body 1 is provided with a movable disc 2, and the welding calibration main body The right end of 1 is provided with a protective panel 5, and the lower end of the protective panel 5 is fixedly connected with a support chassis 6, and the setting of the welding calibration main body 1, the movable disc 2, the L-shaped support frame 3 and the welding telescopic element 4 is convenient for the staff to support The stable speedboat at the upper end of the underframe 6 is welded, the right end of the support underframe 6 is provided with a support plate 7, the upper end of the support plate 7 is fixedly connected with a stabilizing element 8, a protective panel 5, a supporting und...

Embodiment 2

[0040] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the upper end of the movable disc 2 is provided with an L-shaped support frame 3, and the right end of the L-shaped support frame 3 is fixedly connected with a welding telescopic element 4 , and the lower end of the welding telescopic element 4 is fixedly connected with a welding head, and the right end of the L-shaped support frame 3 is fixedly connected with a rope belt, and the setting of the rope belt can stabilize the L-shaped support frame 3, and the right end of the rope belt It is fixedly connected with the right end of the set L-shaped support frame 3, the welding telescopic element 4 is connected with the set control element wire, and the protective panel 5 is symmetrically set with the set stabilizing element 8.

[0041] In this embodiment, the rope straps provided can stabilize the two ends of the L-shaped support frame 3, and at the s...

Embodiment 3

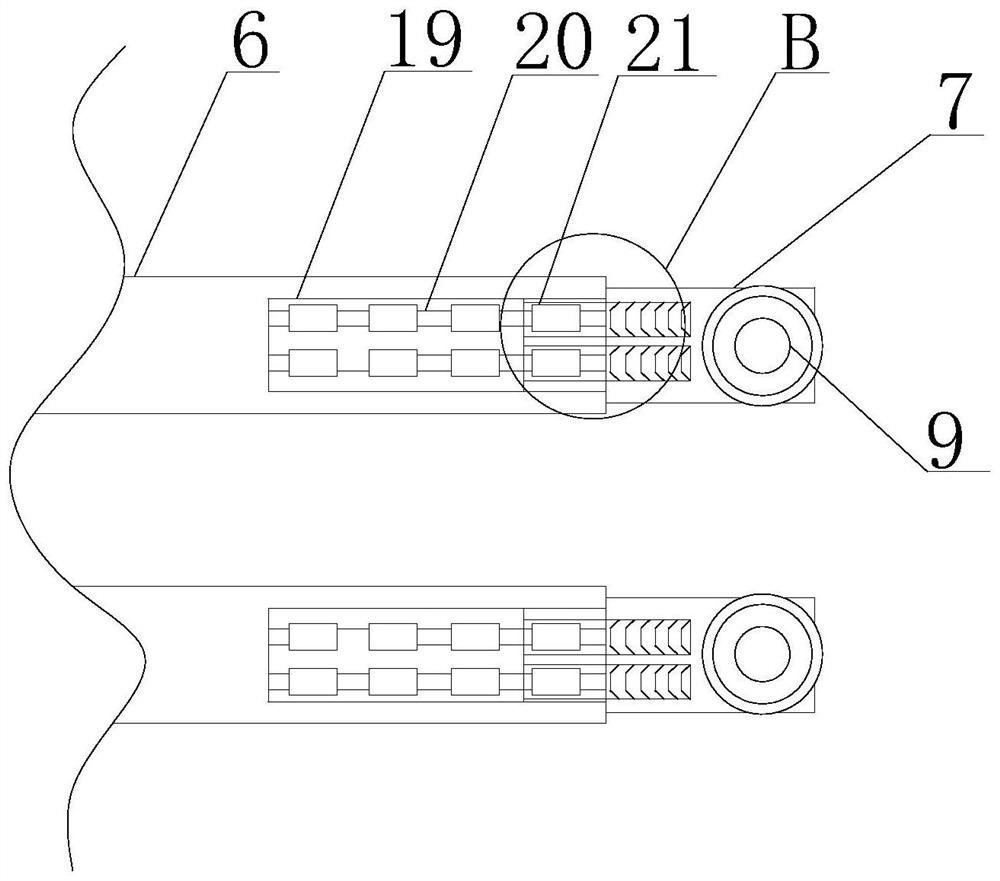

[0043] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the inside of the support chassis 6 is provided with a chute 19, the inside of the chute 19 is provided with a support rod 20, and the middle part of the support rod 20 is movable A movable gear 21 is connected.

[0044] The lower end of the support plate 7 is provided with a rack plate 26, and the outside of the support plate 7 is compatible with the inside of the chute 19 provided, and the lower end of the rack plate 26 meshes with the outside of the movable gear 21 provided.

[0045] The setting of support plate 7, chute 19, support bar 20, movable gear 21 and rack plate 26 is convenient to determine the position of stable element 8 by observation before clamping, and the support plate 7 is moved and fixed thereupon, which is convenient to The stability of the speedboat avoids the phenomenon of movement during the processing, which will affect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com