Tire tread turnover device

A technology of turning device and tread, applied in the rubber field, can solve the problems of product quality decline, waist damage, curling, etc., and achieve the effects of simple structure, improved efficiency and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0019] In the field of tire production, after the tread is extruded, it is generally transported by a shutter car. During transportation, the surface to be bonded of the tread faces up to avoid affecting its viscosity. Therefore, whether it is manual tread feeding or automatic tread feeding Material must have a tread turning action, and the present invention provides a tread turning device based on this need, which is arranged between the feeding step and the centering step or lifting step.

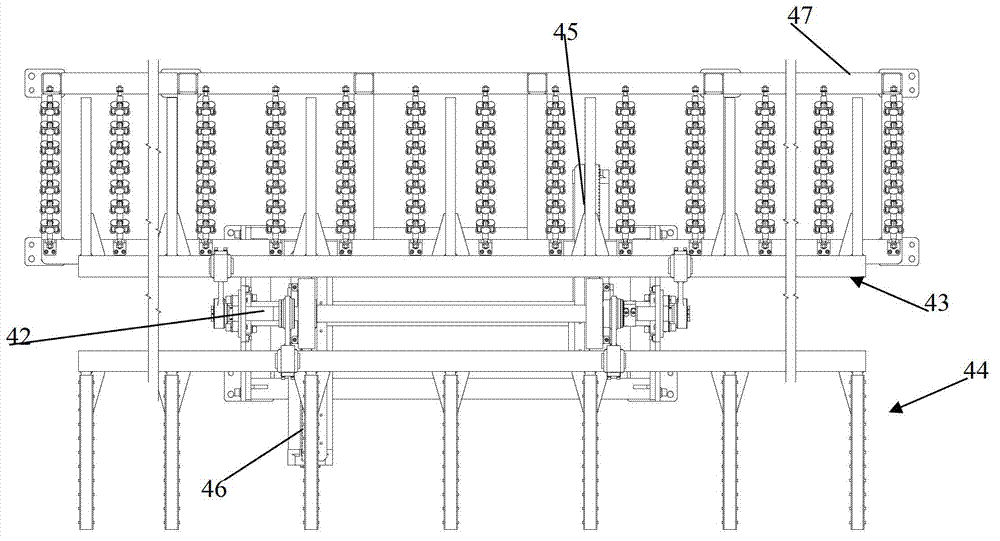

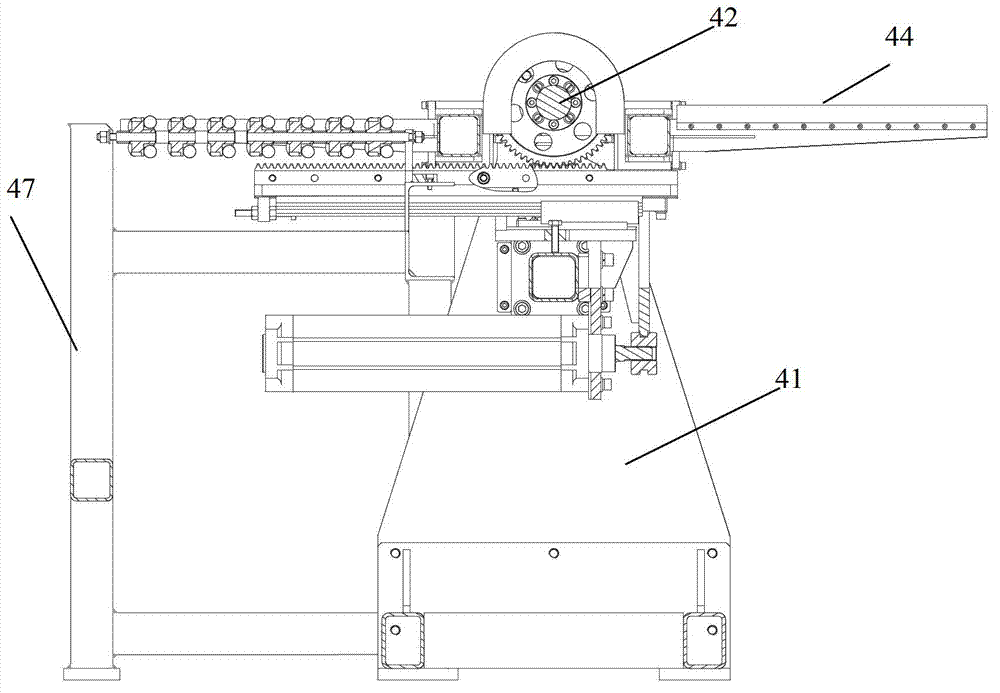

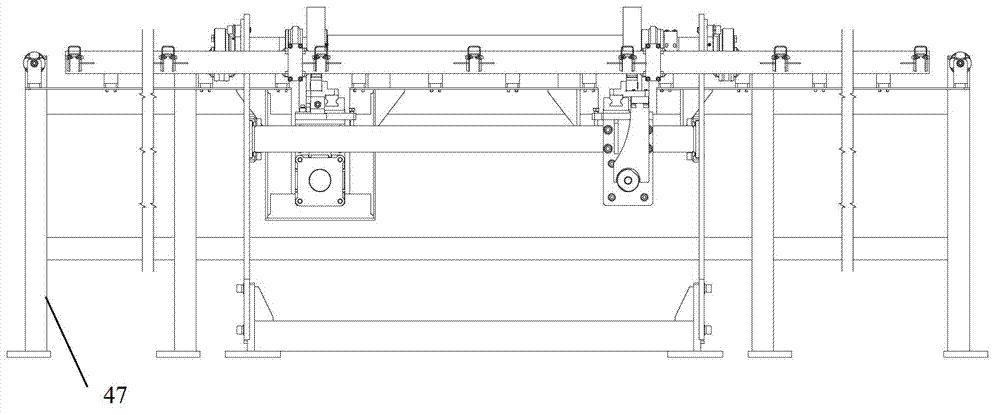

[0020] like Figure 1-3 As shown, the turning device 4 includes a turning bracket 41, a rotating shaft 42 fixed horizontally on the top of the bracket, a turning row 43 fixedly connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com