Installation method of blade

An installation method and blade technology, applied in the direction of rotary cutting tools, wood processing appliances, manufacturing tools, etc., can solve the problems of high labor intensity, low efficiency, tool deformation, etc., and achieve a high degree of automation, easy installation, and good safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for installing a blade, comprising the steps of:

[0051] a. Place the cutter body on the cutter holder;

[0052] b. Move the blade of the cutter body aligning device down and insert it into the slot of the cutter body, and drive the blade to rotate through the rotation of the stepping motor, so that the slot of the cutter body is aligned with the placement position of the blade in the next process. removed from the slot,

[0053] c. The blade is pushed out through the pusher cylinder of the blade placement device, the rotating cylinder drives the double-axis cylinder to rotate clockwise 90 degrees, the parallel clamp on the double-axis cylinder clamps the pushed blade and then rotates 90 degrees counterclockwise, and inserts the blade into the knife in the slot of the body.

[0054] This embodiment is the most basic implementation mode, "a. place the cutter body on the cutter holder; b. move down the insertion piece of the cutter body aligning device and ins...

Embodiment 2

[0056] A method for installing a blade, comprising the steps of:

[0057] a. Place the cutter body on the cutter holder;

[0058] b. Move the blade of the cutter body aligning device down and insert it into the slot of the cutter body, and drive the blade to rotate through the rotation of the stepping motor, so that the slot of the cutter body is aligned with the placement position of the blade in the next process. remove from the slot;

[0059] c. The blade is pushed out through the pusher cylinder of the blade placement device, the rotating cylinder drives the double-axis cylinder to rotate clockwise 90 degrees, the parallel clamp on the double-axis cylinder clamps the pushed blade and then rotates 90 degrees counterclockwise, and inserts the blade into the knife in the slot of the body.

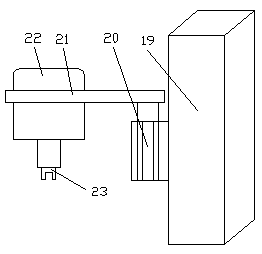

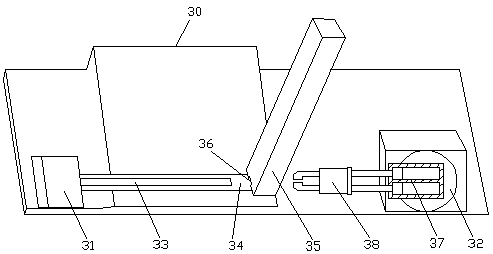

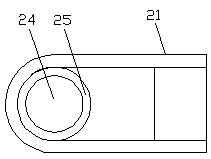

[0060] Described cutter body aligning device comprises support 19, is fixed with elevating cylinder 20 on the support 19, is fixedly connected with support 21 horizontally on the elevati...

Embodiment 3

[0065] A method for installing a blade, comprising the steps of:

[0066] a. Place the cutter body on the cutter holder;

[0067] b. Move the blade of the cutter body aligning device down and insert it into the slot of the cutter body, and drive the blade to rotate through the rotation of the stepping motor, so that the slot of the cutter body is aligned with the placement position of the blade in the next process. remove from the slot;

[0068] c. The blade is pushed out through the pusher cylinder of the blade placement device, the rotating cylinder drives the double-axis cylinder to rotate clockwise 90 degrees, the parallel clamp on the double-axis cylinder clamps the pushed blade and then rotates 90 degrees counterclockwise, and inserts the blade into the knife in the slot of the body.

[0069] Described cutter body aligning device comprises support 19, is fixed with elevating cylinder 20 on the support 19, is fixedly connected with support 21 horizontally on the elevati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com