Control method and system for automated manipulator arm

A technology of a robotic arm and a control method, applied in the field of automation, can solve the problems of inability to provide timely feedback, complicated operations, damage to the objects operated by the manipulator, and achieve the effects of improving production efficiency, product quality, and working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] A method for controlling an automated mechanical arm, comprising the steps of:

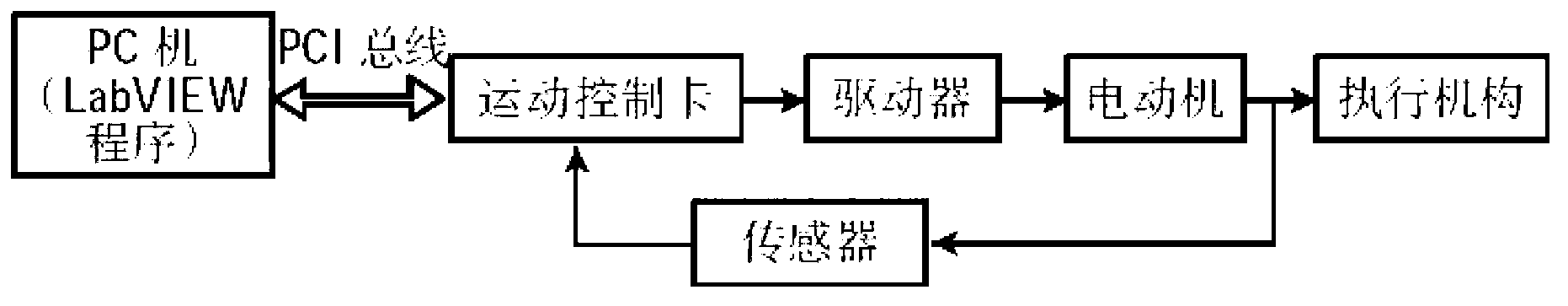

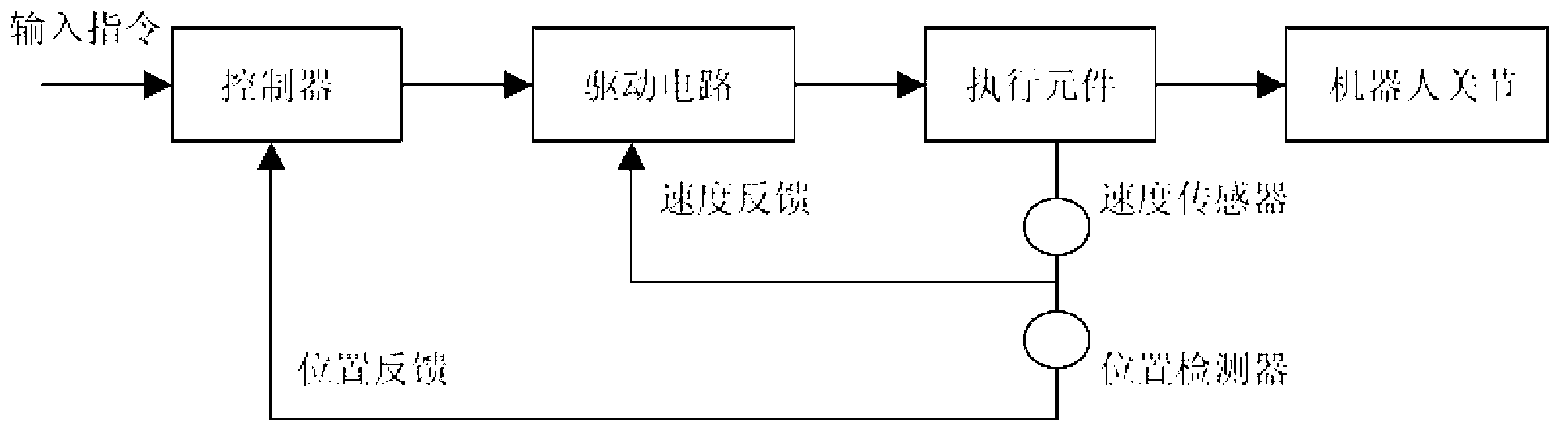

[0023] 1) The body of the robot arm is set, and the actuator, monitoring mechanism and control mechanism are set on the body of the robot arm. The control mechanism includes a PC and a motion control card;

[0024] 2) Set up the LabVIEW software development platform on the PC, and set up the upper layer control software based on the LabVIEW software development platform, as the upper computer, complete the setting of the parameters of the multi-axis movement of the manipulator, complete the non-real-time processing tasks, and realize the coordination of motion control , management and real-time control;

[0025] 3) Connect the motion control card to the PC through the PCI bus, as a lower computer, receive the control signal from the PC and process it in real time, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com