Riveting machine

A riveting machine, progressive technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of low processing efficiency, poor quality of circuit boards, difficult to take out, etc., to achieve not easy to crack and deform, and the process of taking out the workpiece is fast Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

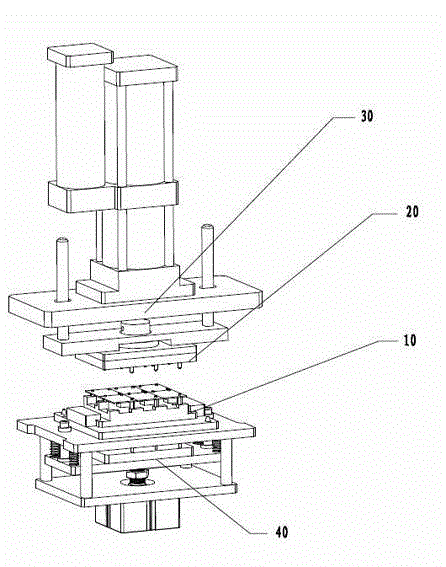

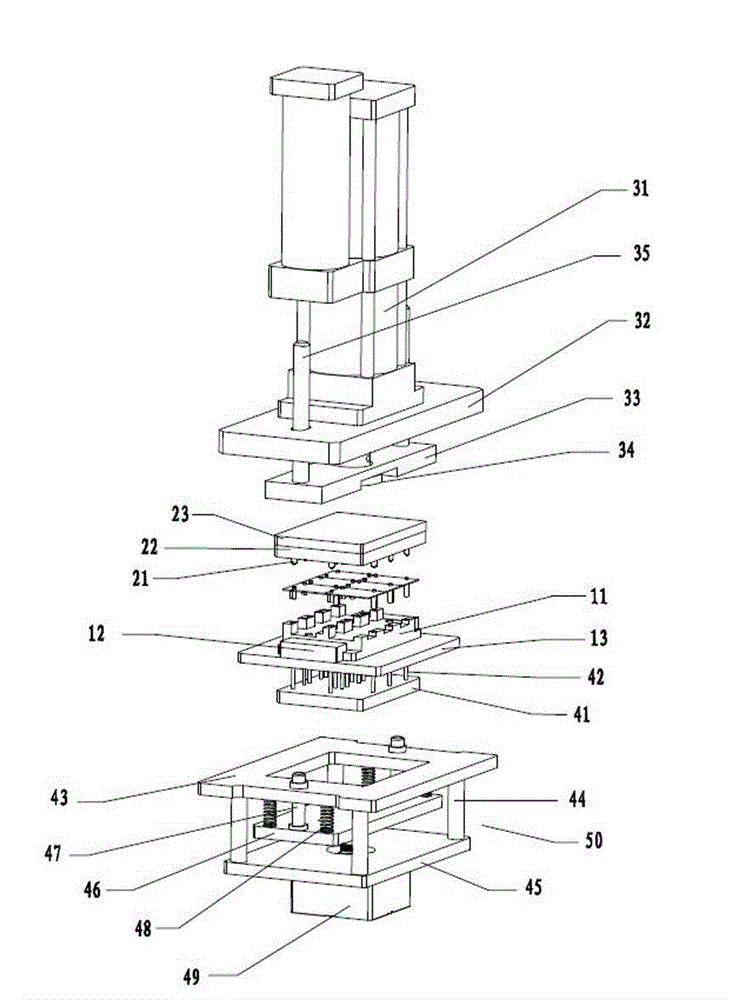

[0048] see figure 1 , which is a structural schematic diagram of the present invention, the riveting machine includes a progressive pressure unit 30 , an upper die unit 20 , a lower die unit 10 and a jacking unit 40 . The upper mold unit 20 is arranged at a corresponding position below the progressive pressure unit 30, and provides power for the upper mold unit 20, so that the upper mold unit 20 performs progressive riveting of fast forwarding, riveting and holding pressure. The moving parts in the progressive pressure unit 30 are fixedly connected to the upper mold unit 20, the lower mold unit 10 is arranged at a corresponding position below the upper mold unit 20, and the ejector unit 40 is arranged at a corresponding position below the lower mold unit 10. Location. After the workpiece is riveted, the ejector unit 40 automatically ejects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com