Motherboard of holographic concave blazed grating and manufacturing method of motherboard

A blazed grating, concave grating technology, applied in diffraction grating, microlithography exposure equipment, photolithography process exposure device and other directions, can solve the problem of affecting the diffraction efficiency of concave grating, no diffraction efficiency, large distribution changes, etc., to achieve transfer accuracy High, durable, and the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Prepare a master plate of a holographic concave blazed grating with an aperture of 20 mm, a radius of curvature of 80 mm, and a grating period of 500 lines / mm. The grating teeth of the master plate are triangular.

[0034] The preparation steps are as follows:

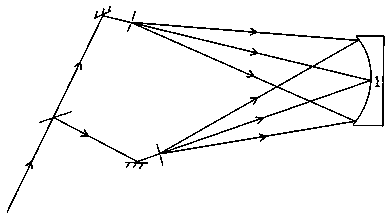

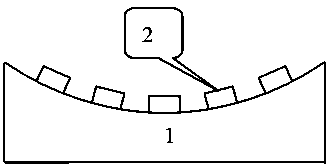

[0035] (1) Arranging the optical path for holographic recording such as figure 1 As shown, a photoresist is coated on a concave mirror substrate 1 with a radius of curvature of 80mm, and after exposure and development, a holographic concave grating mask 2 is formed. The grating period is 500line / mm, and the height of the grating teeth is 500nm. is a rectangle;

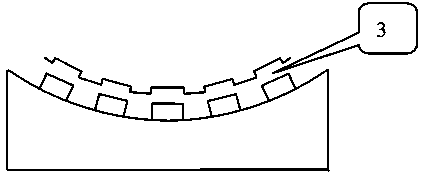

[0036] (2) On the holographic concave grating mask 2, an electroforming process is used to deposit a nickel metal layer 3, and the thickness of the nickel metal layer 3 is 2um, which is greater than the height of the grating teeth;

[0037] (3) Coating epoxy resin adhesive 4 on the nickel metal layer 3 surface, it is bonded and solidified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com