Oversize continuous-production energy-saving environment-friendly aluminum electrolysis cell

An energy-saving and environment-friendly aluminum electrolytic cell technology, which is applied in the field of aluminum electrolytic cells, can solve the problems of damaging the stability of electrolytic cells, high comprehensive energy consumption, and difficult energy consumption of electrolytic cells, achieving continuous and high-efficiency production, lower cell voltage, The effect of efficient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, but the protection scope of the present invention is not limited by embodiment.

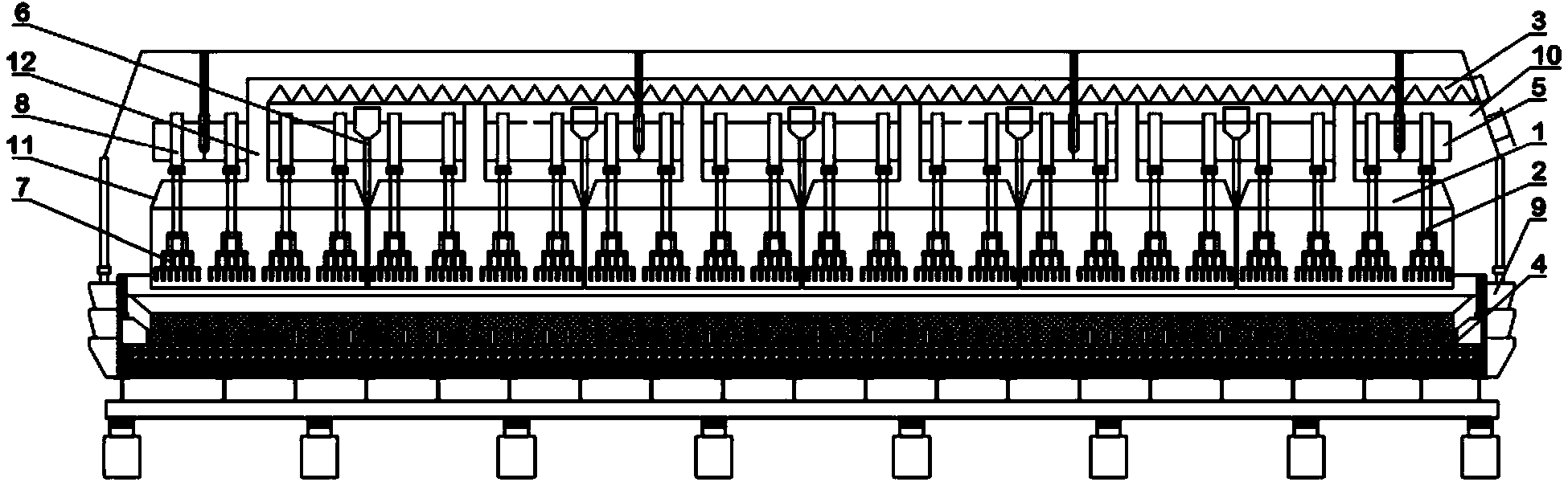

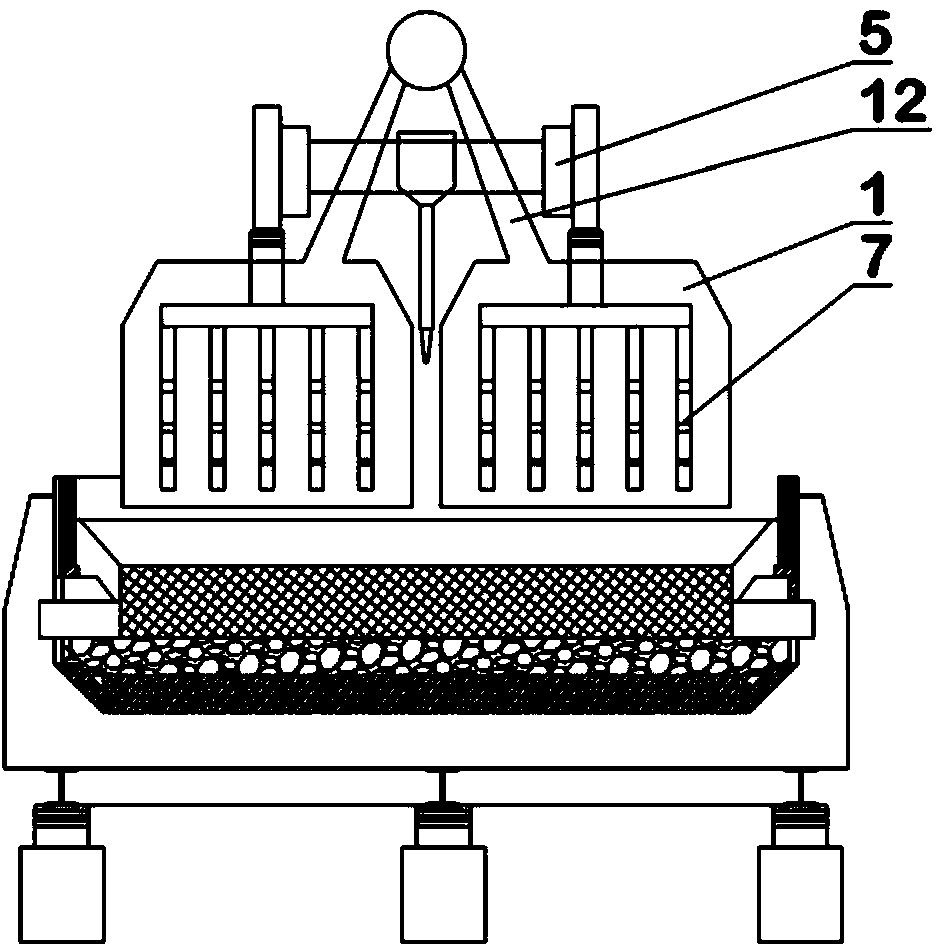

[0023] like figure 1 and figure 2 As shown, the current intensity is more than 400kA, and the large-scale continuous production of energy-saving and environmentally friendly aluminum electrolytic cell includes the cell shell 9, the electrolytic cell liner 4 and the upper structure 10, and at least 4 continuous automatic roasting anodes 1 are arranged in the electrolytic cell. The continuous automatic roasting anode 1 is equipped with an anode mesh conductive system 2. The anode mesh conductive system 2 is composed of a mesh steel conductive rod 7 and an aluminum guide rod 8 connected to the mesh steel conductive rod 7 by explosive welding. The cross-section of the steel conducting rod 7 is circular or rectangular. The upper structure 10 is also provided with an alumina blanking system 6 , an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com