Multi-target optimization method for bath voltage in aluminum electrolysis process

A multi-objective optimization and cell voltage technology, applied in the field of aluminum electrolysis, can solve problems such as time-consuming, high operator dependence, and space reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by specific embodiments.

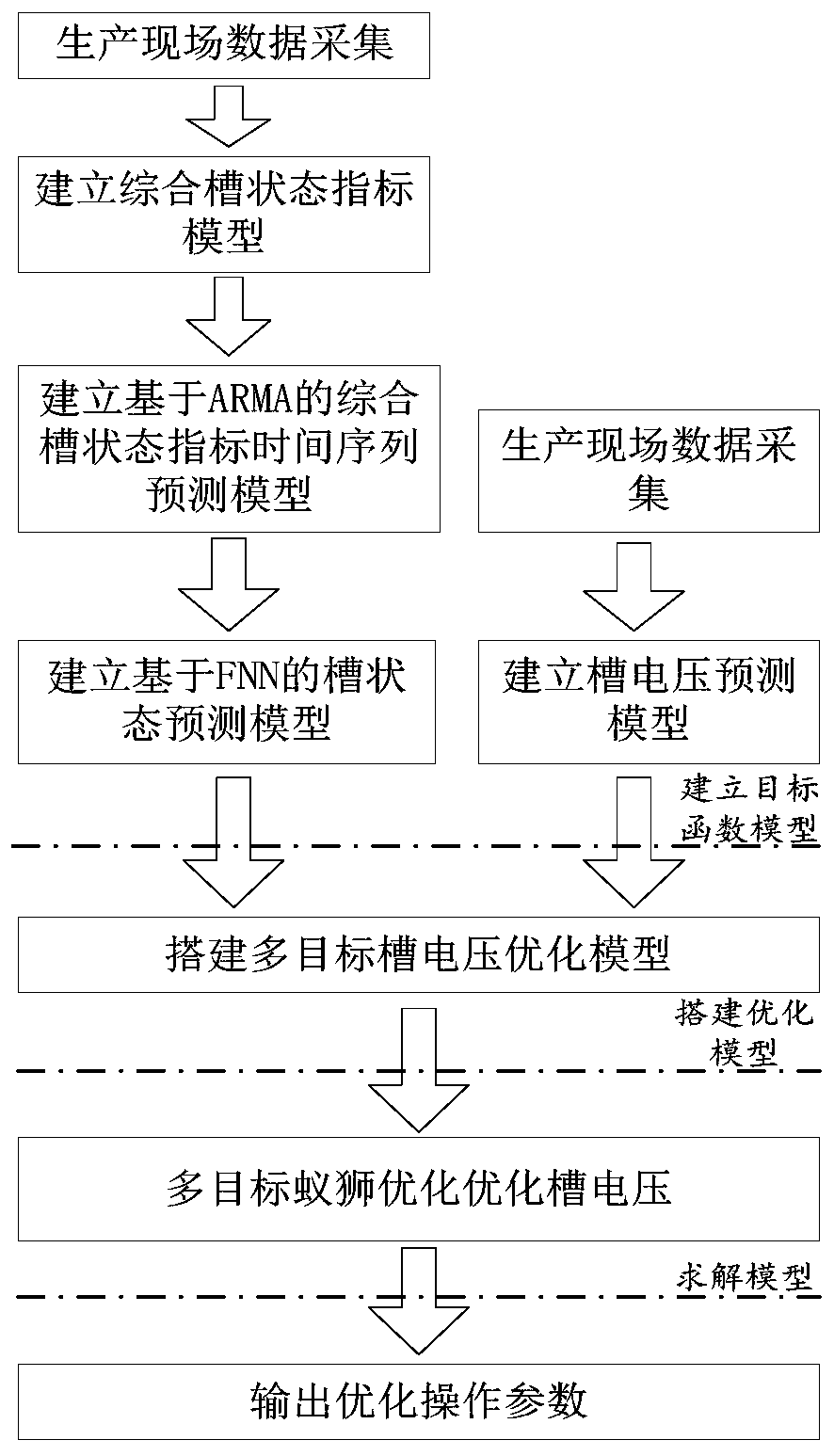

[0034] In aluminum electrolytic production, controllable parameters include cell resistance, molecular ratio, and alumina concentration, while other parameters are uncontrollable or cannot be precisely controlled. The invention establishes a multi-objective optimization model of the tank voltage, seeks a set of optimal controllable parameter setting values, and achieves the effect of reducing the tank voltage by controlling the set of parameters within the target range, thereby achieving stable and energy-saving production goals. There are three main links in the specific implementation, establishing the objective function model, building the optimization model, and solving the model, as shown in the attached figure 1 shown.

[0035] Reducing cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com