Membrane bioreactor and use thereof in wastewater treatment

A membrane bioreactor, biochemical reactor technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problem of limited cleaning effect and achieve friction Good cleaning effect, high biochemical reaction efficiency, and thorough cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. Membrane bioreactor

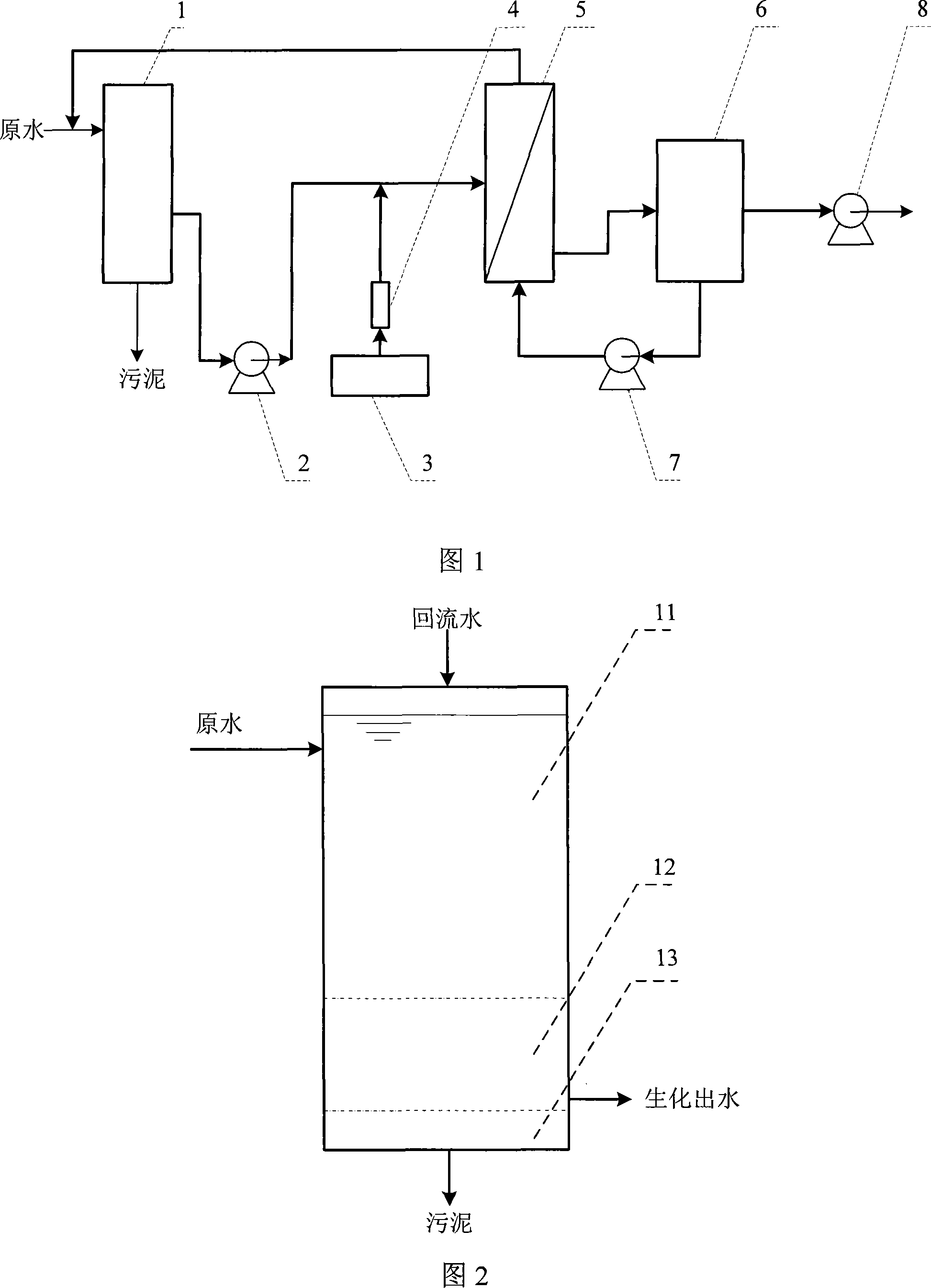

[0049] The membrane bioreactor includes: a biochemical reactor 1, a slurry pump 2, an air compressor 3, a pulse valve 4, a membrane module 5, a water production tank 6, a backwash water supply pump 7, and a water production pump 8.

[0050] The biochemical reactor 1 is equipped with a granular biofilm medium, which is made of olive shell activated carbon, with an average particle size of 1.5 mm, a uniformity coefficient of 1.1 to 1.2, a molasses value of >150 mg / g, and a strength of ≮97%. The bulk density is 500-520g / L, and the filler dosage is 30-60% (based on the volume ratio of the granular biofilm medium to the waste water in the biochemical reactor 1).

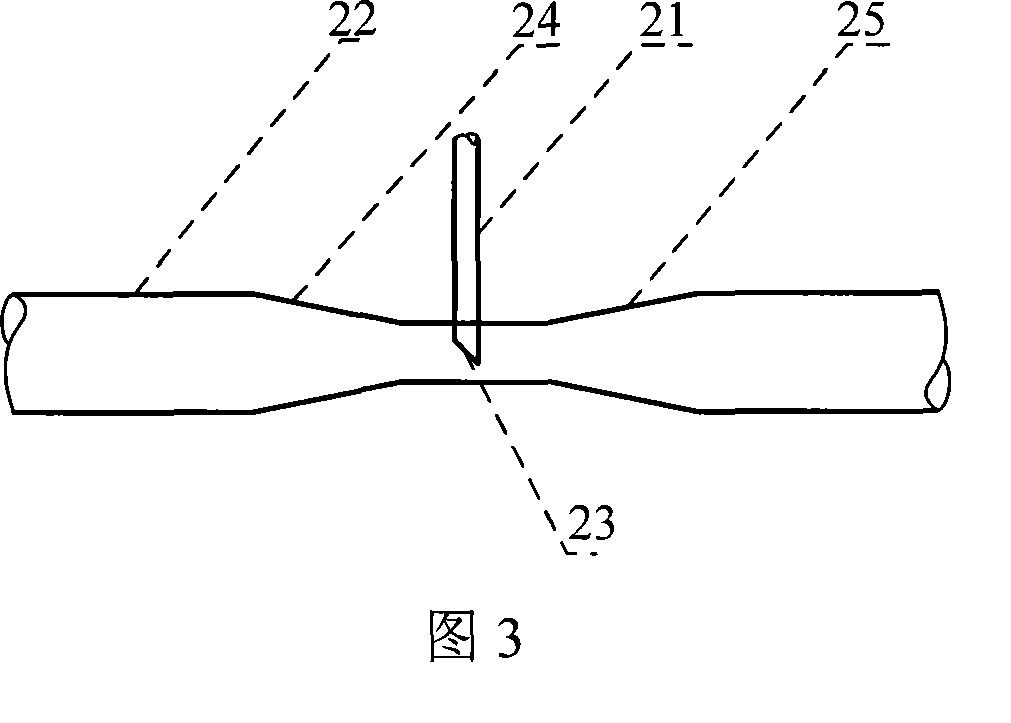

[0051] The biochemical reactor 1 is a tank, the upper part of which is a biochemical reaction zone 11 , the lower part is a granular biofilm medium sedimentation zone 12 , and the bottom is an activated sludge concentration zone 13 . The biochemical reaction zone 11 is provided with a wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com