Special trimming machine for high-precision laser positioning die ejector rod

A laser positioning and mold ejector technology, which is applied in the direction of manufacturing tools, grinding/polishing equipment, grinding machine parts, etc., can solve the problem of large errors in the flatness and dimensional accuracy of ejector pins, which cannot be used in mold production and processing Requirements, poor effect of ejector rod grinding, etc., to achieve the effect of ensuring grinding accuracy, ensuring grinding quality, and convenient maintenance and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

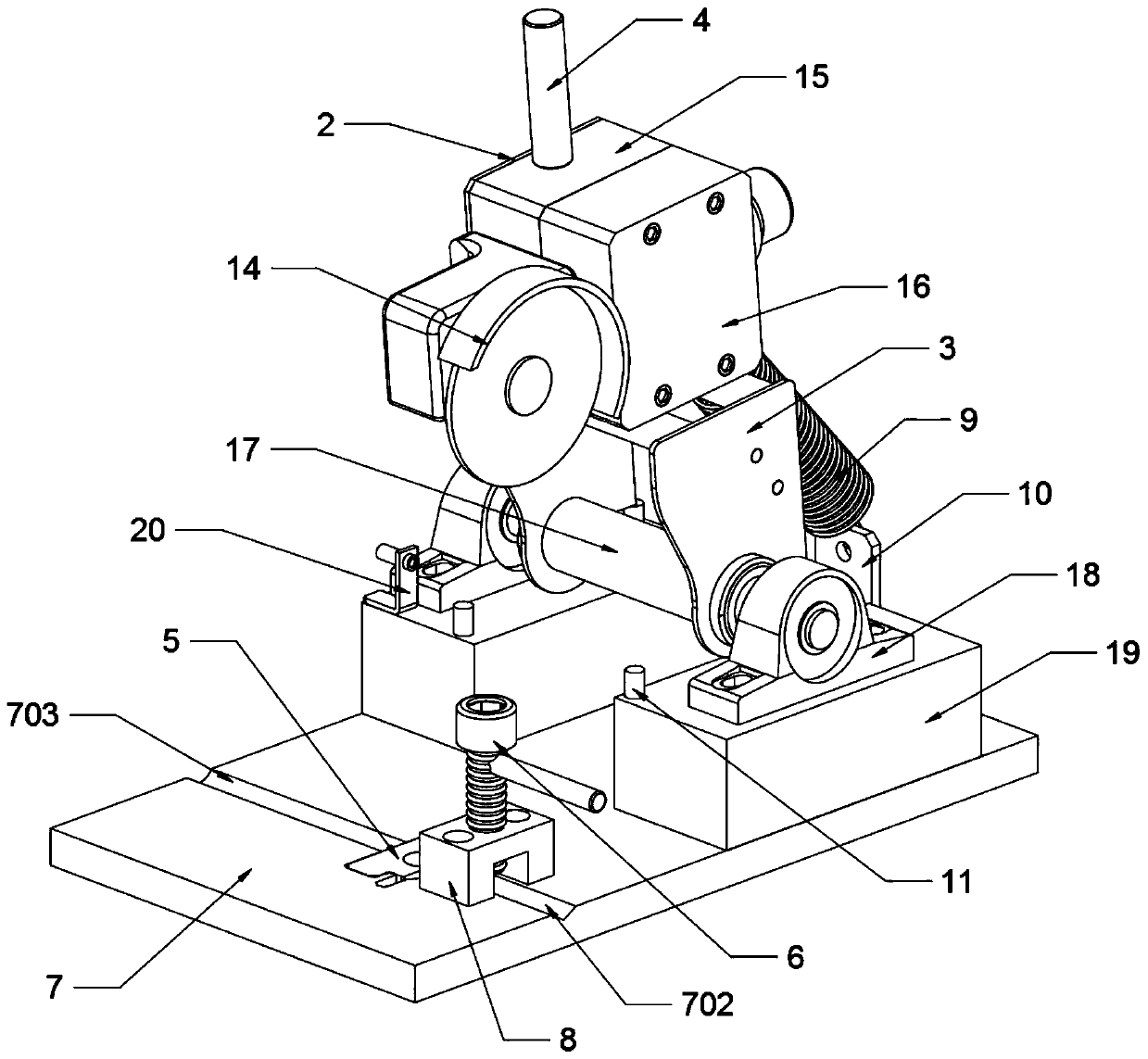

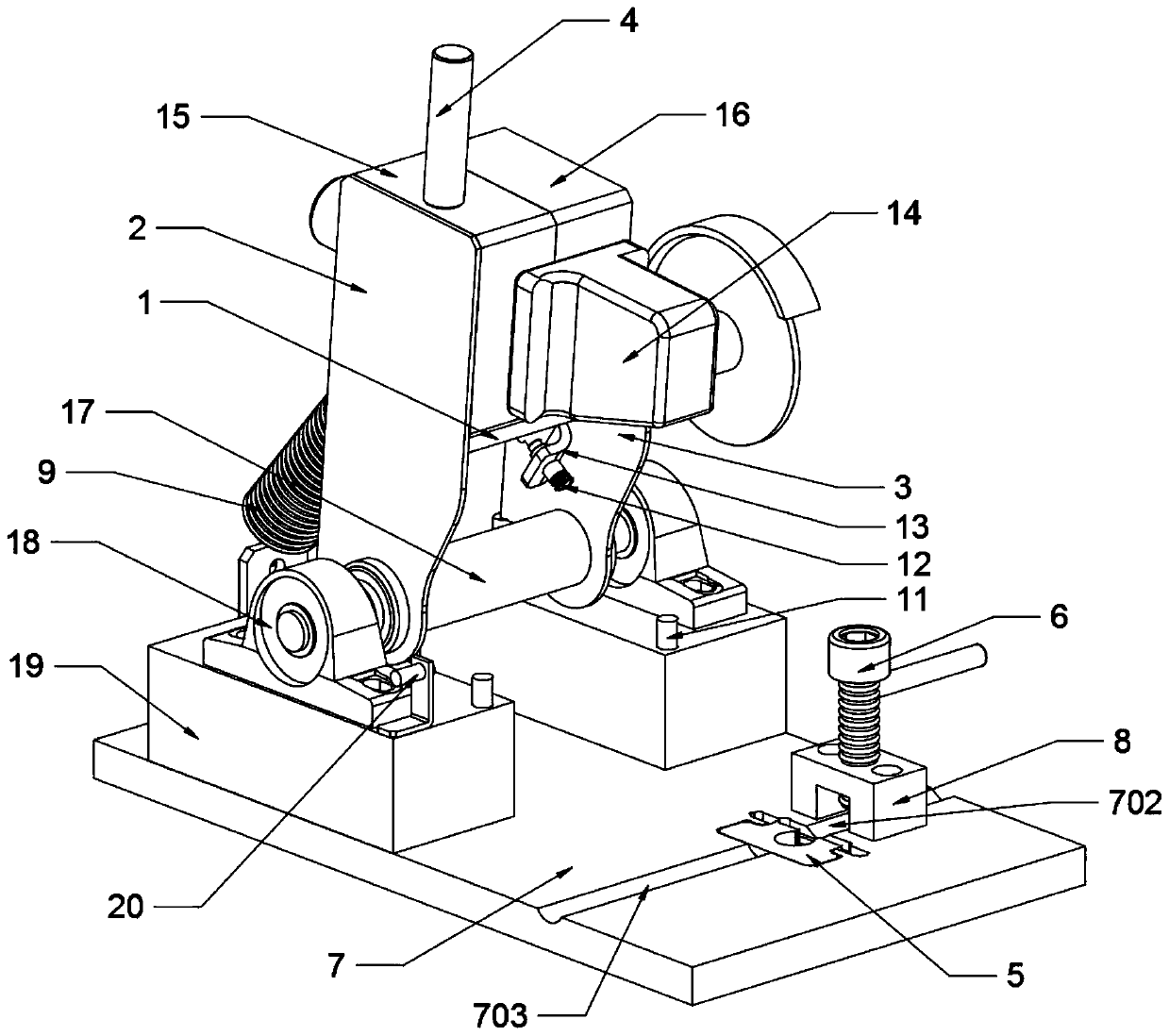

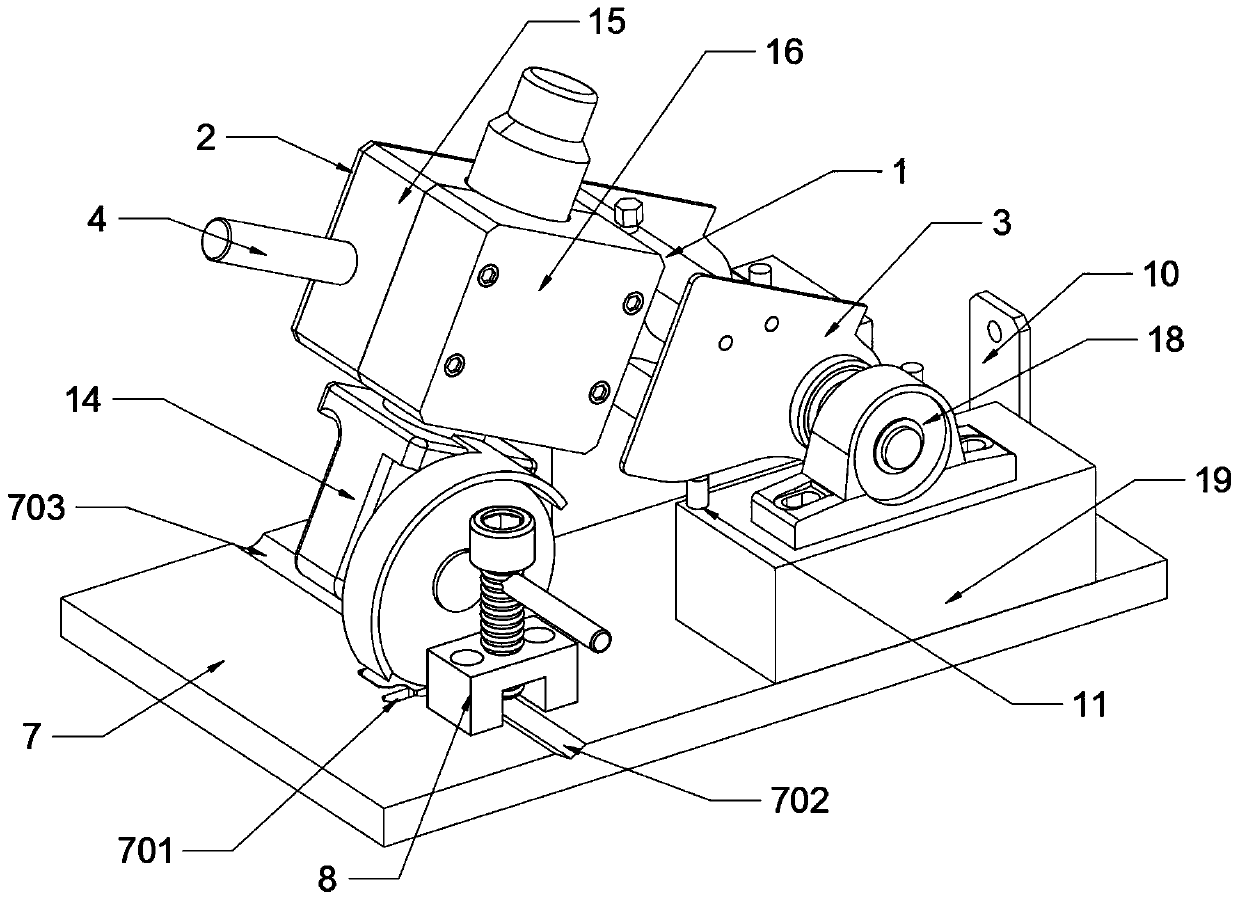

[0031] as attached figure 1 to attach Figure 6 Shown:

[0032]The present invention provides a high-precision laser positioning mold ejector pin dedicated mold repairing machine, which includes a main and auxiliary connecting rod 1, a cutting head main board 2, a cutting head auxiliary board 3, a pressing handle 4, a positioning cutting block 5, and a positioning round hole 501, Positioning screw 6, base 7, grinding groove 701, V-shaped positioning groove 702, ejector rod escape groove 703, ejector rod locking pressure block 8, spring 9, spring hanging plate 10, support column 11, laser marking line Device 12, laser assembly block 13, angle grinder 14, angle grinder installation block 15, angle grinder disassembly block 16, rotating shaft 17, bearing 18, bearing support seat 19 and proximity switch 20; the main and auxiliary connecting rod 1 There are two places, and the left end of the main and auxiliary connecting rod 1 is connected to the inner wall on the right side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com