Lower bearing device without grease pollution of tube centrifuge and lubricating method

A tubular centrifuge and bearing device technology, which is applied in the direction of engine lubrication, centrifuge, bearing components, etc., can solve the problems of affecting product quality, complex lubrication channel design, high cost, etc., to achieve convenient maintenance and disassembly operations, and eliminate grease The effect of atomization pollution and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

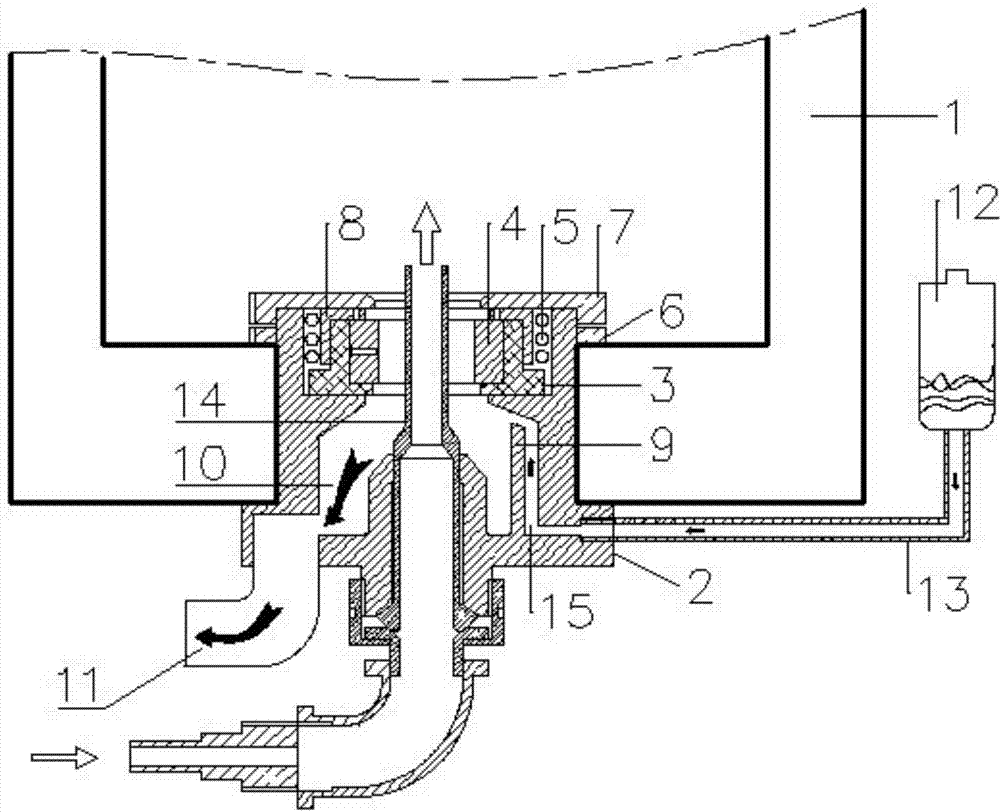

[0022] Such as figure 1 As shown, a lower bearing device of a tubular centrifuge without grease pollution includes a lower bearing seat 2, a bearing sleeve 3 and a bearing 4, the bearing sleeve 3 is fixed in the lower bearing housing 2, and the bearing 4 is installed in the bearing sleeve 3. The lower bearing device also includes a container 12 , and the lower bearing housing 2 is provided with a liquid inlet 15 , a liquid outlet 11 and a corresponding channel 10 , and the liquid inlet 15 is connected to the container 12 through a transfusion tube 13 .

[0023] In practical application, the lower bearing device is fixed on the base 1 of the centrifuge body. In order to facilitate the disassembly, cleaning and replacement of accessories of the lower bearing device during maintenance, save operating time and enhance work efficiency, the lower bearing device also includes a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com