Bearing device with separate axial and radial supports for intermediate shafts in disconnect clutches for hybrid modules

A technology for separating clutches and intermediate shafts, which is applied to clutches, friction clutches, electric clutches, etc., can solve the problems of limited axial structure space design and large axial structure space, and achieves optimization of radial structure space and reduction of structure. The effect of space and structural space optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

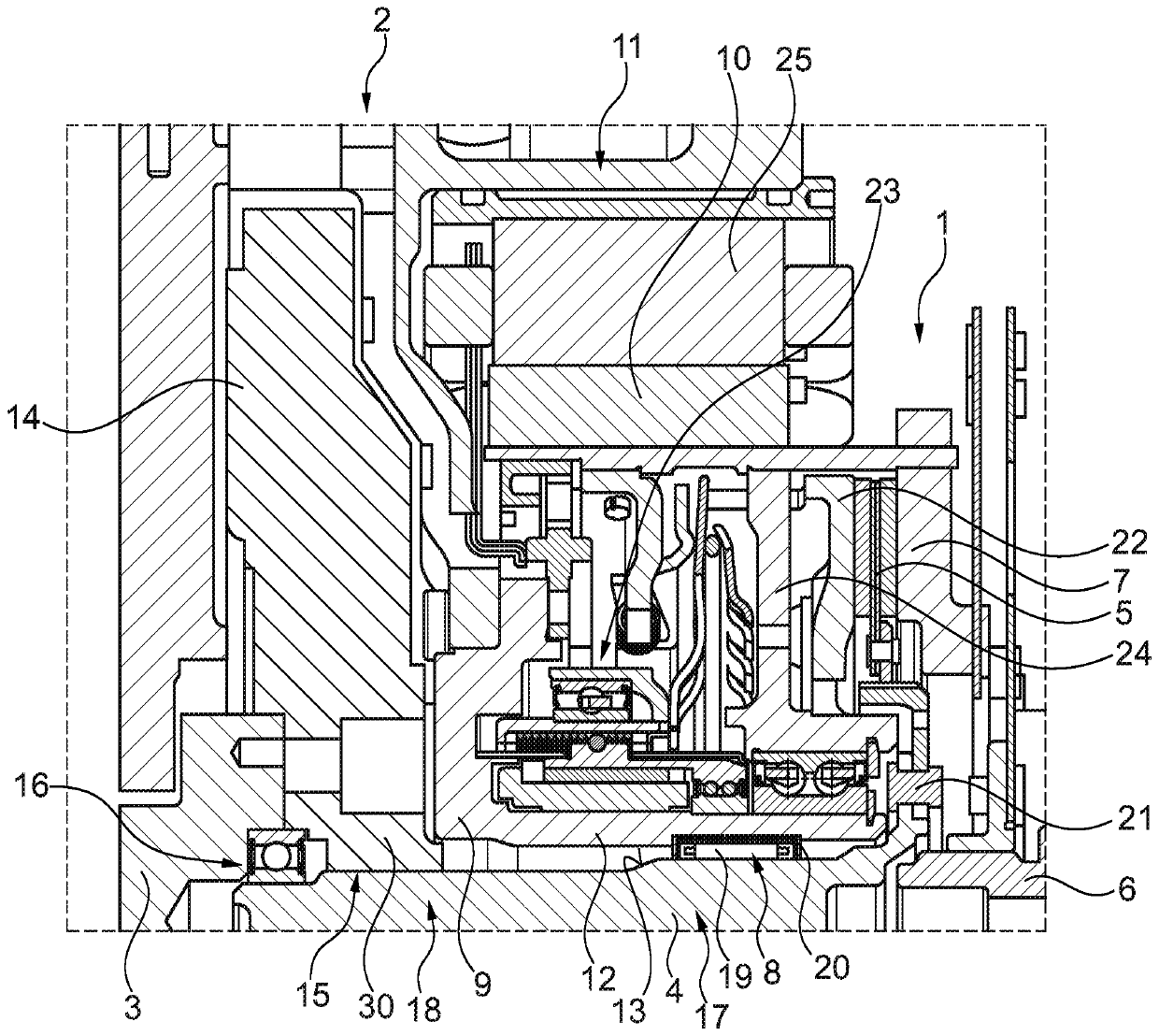

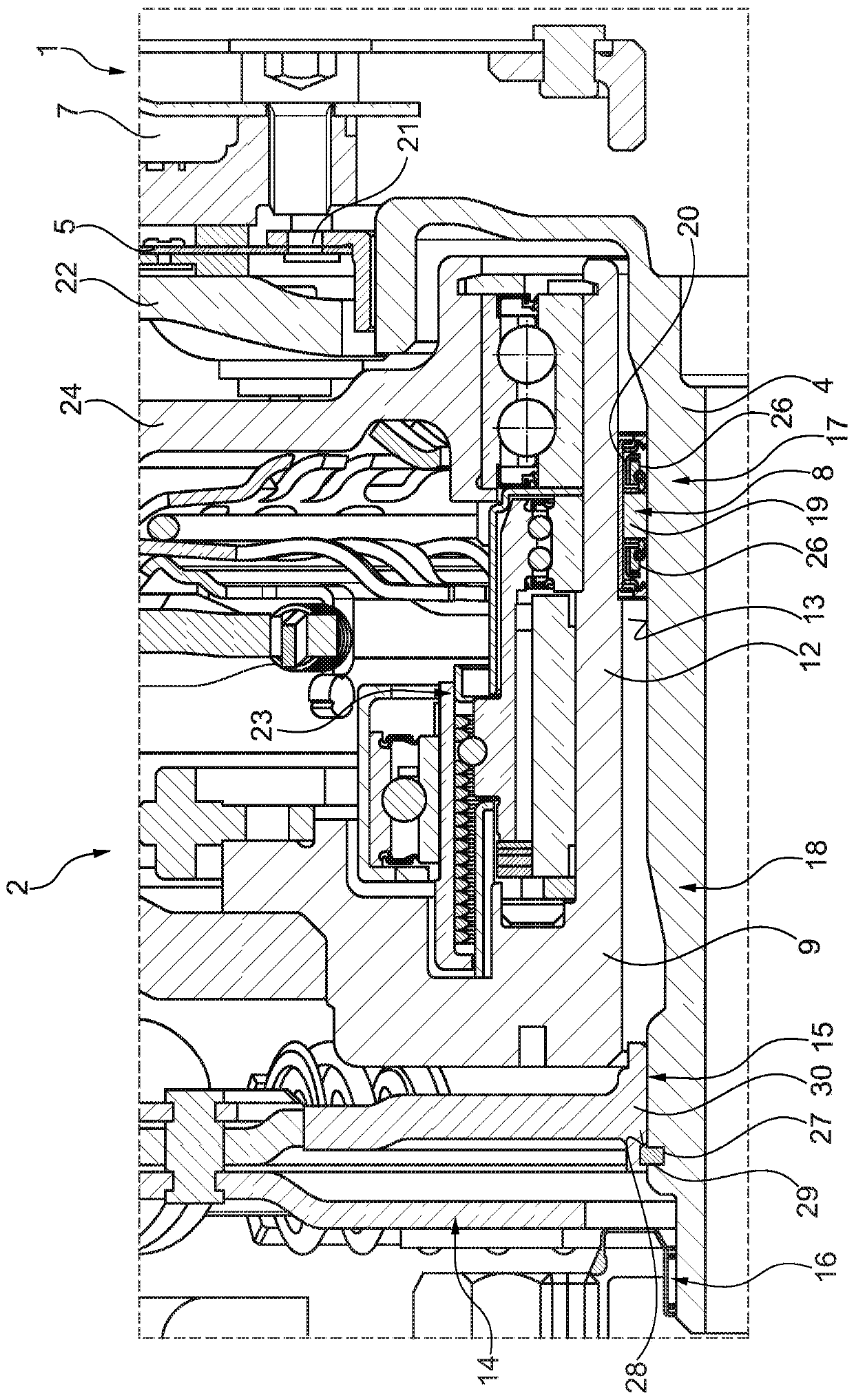

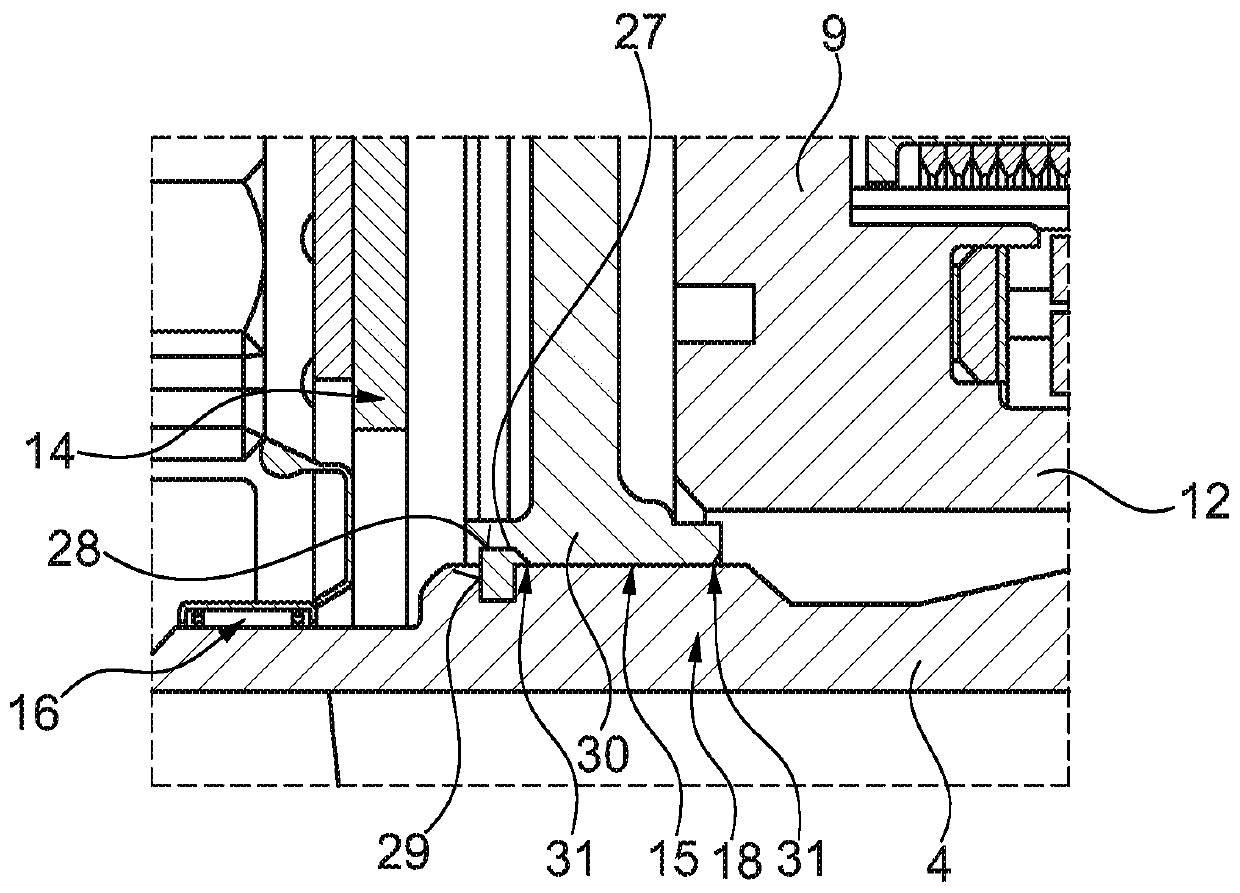

[0027] In two implementations, such as Figure 1 to Figure 3 Shown is always a separating clutch 1 according to the invention for a hybrid module 2 of a motor vehicle, for example a passenger car, a van, a bus or an agricultural vehicle. In this case, the separating clutch 1 always has a centrally arranged countershaft 4 that can be driven by the crankshaft 3 . The separating clutch 1 also has a clutch disc 5 which is connected in a rotationally fixed manner to the countershaft 4 and a counterplate 7 which can be connected to the transmission input shaft 6 . The counterplate 7 is non-rotatably connected to the clutch disk 5 in at least one engaged position of the separating clutch 1 . The separating clutch 1 also has a first rolling bearing 8 which is designed to radially support the countershaft 4 . Furthermore, the carrier element 9 provided for radially supporting the rotor 10 of the electric motor 11 is also supported in a fixed manner relative to the mixing module housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com