Camshaft regulator

A technology of camshafts and adjusters, applied in machine/engine, valve details, valve devices, etc., can solve problems such as high assembly costs, assembly errors, and large numbers, and achieve the effect of low unit cost and low assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

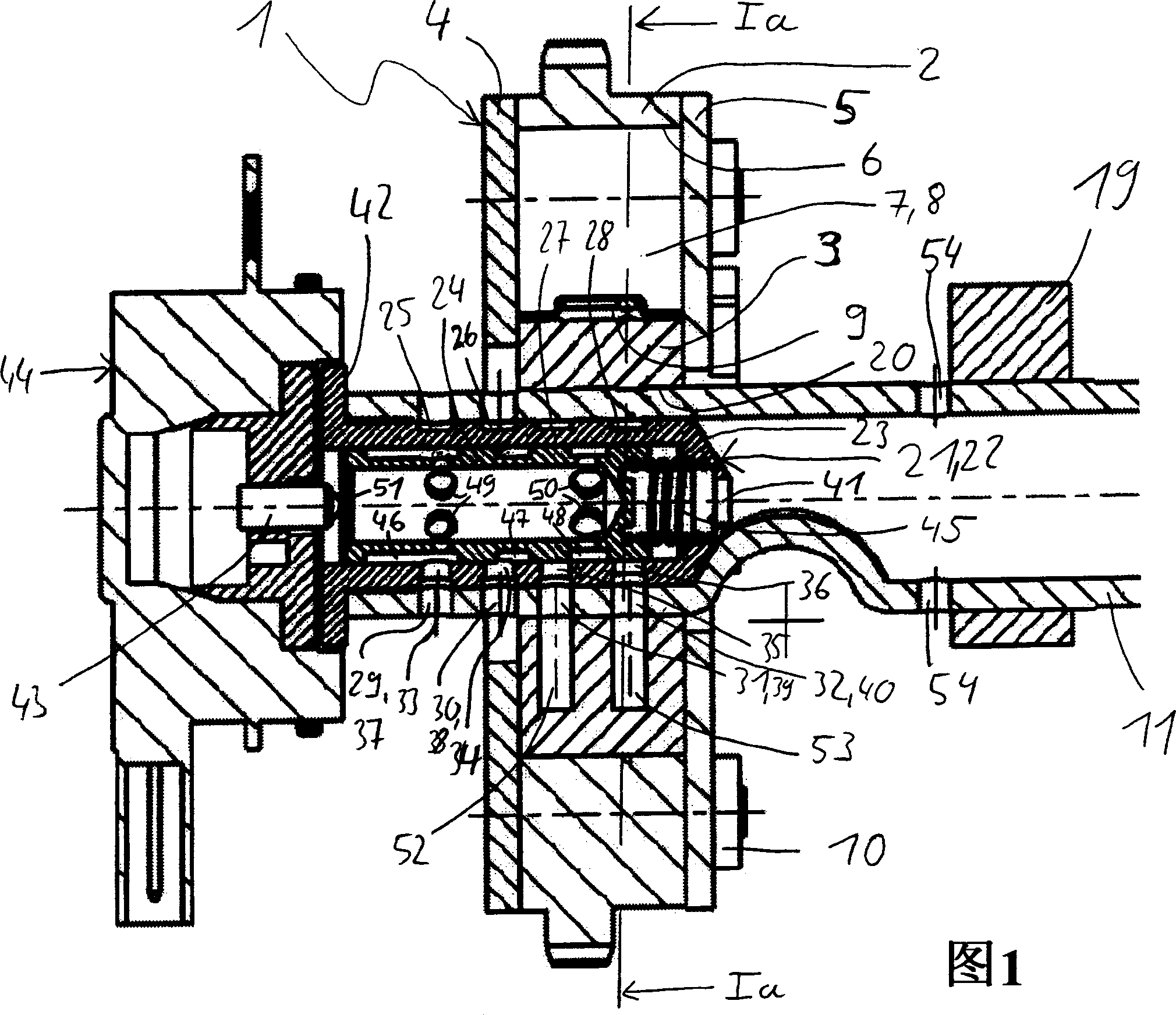

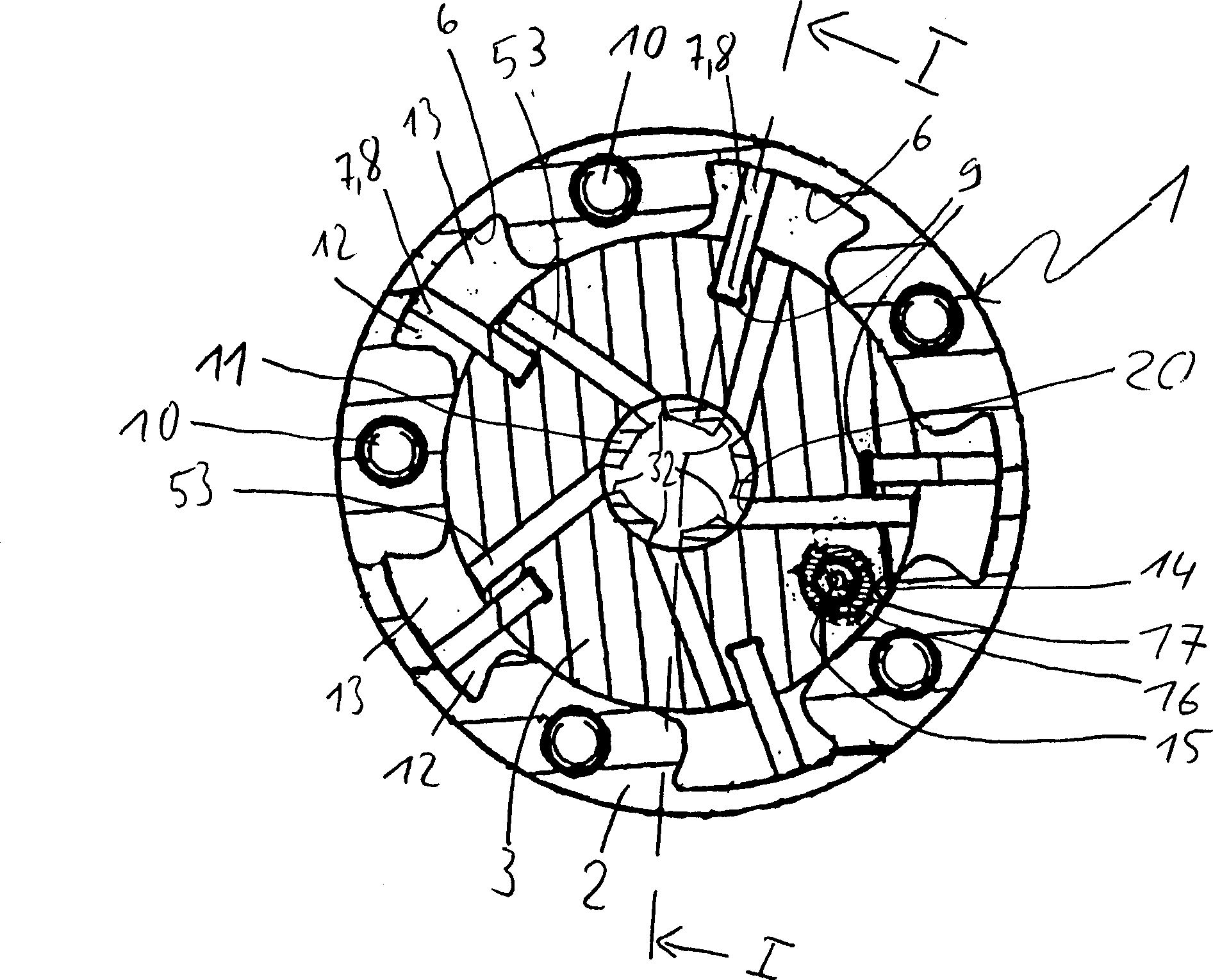

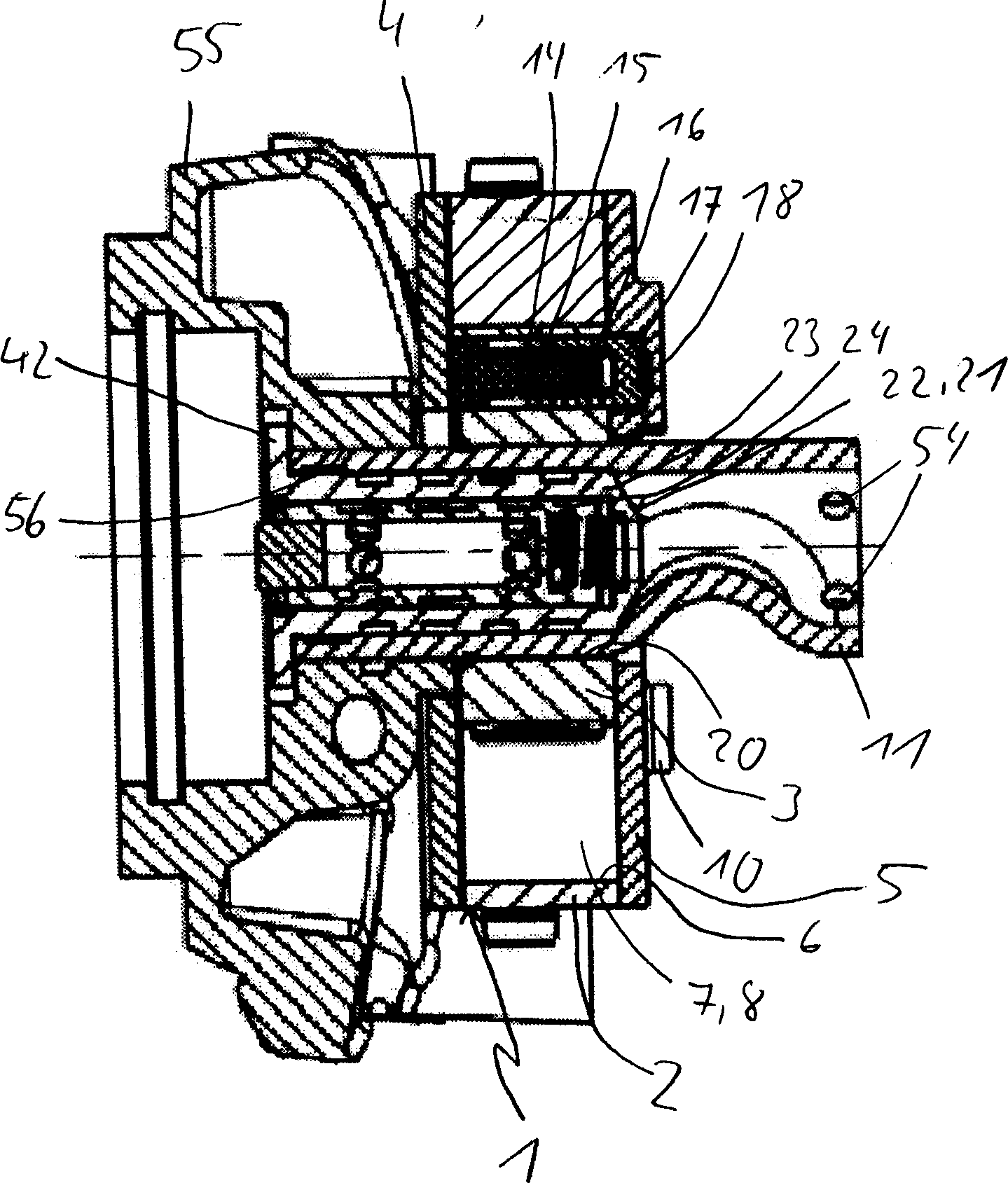

[0031] Figure 1a , 1 to 3 show the device for changing the control timing of the internal combustion engine (camshaft adjuster 1). However, in FIGS. 1 and 1 a the basic construction of the camshaft adjuster 1 is shown in the form of a rotary piston, whereas in FIGS. figure 2 and 3 show two camshaft adjusters according to the invention in different assembly variants. Of course, the hydraulically driven camshaft adjuster 1 can likewise also be of other embodiments, for example an axial piston adjuster. The camshaft adjuster 1 basically comprises a drive wheel 2 , an output part 3 and two disk-shaped side walls 4 and 5 . In the embodiment shown, drive wheel 2 is designed as a sprocket, which is connected to a crankshaft (not shown) via a drive chain. The following embodiment is also possible in that the driving wheel 2 is designed as a belt pulley or a gear, which is driven by a gear belt or a gear transmission of the crankshaft. The drive wheel 2 and the driven part 3 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com