Torque converters for motor vehicles

A technology for hydraulic torque converters and motor vehicles, applied in the field of hydraulic torque converters, can solve problems such as damage, noise of starting components, etc., and achieve the effect of reducing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

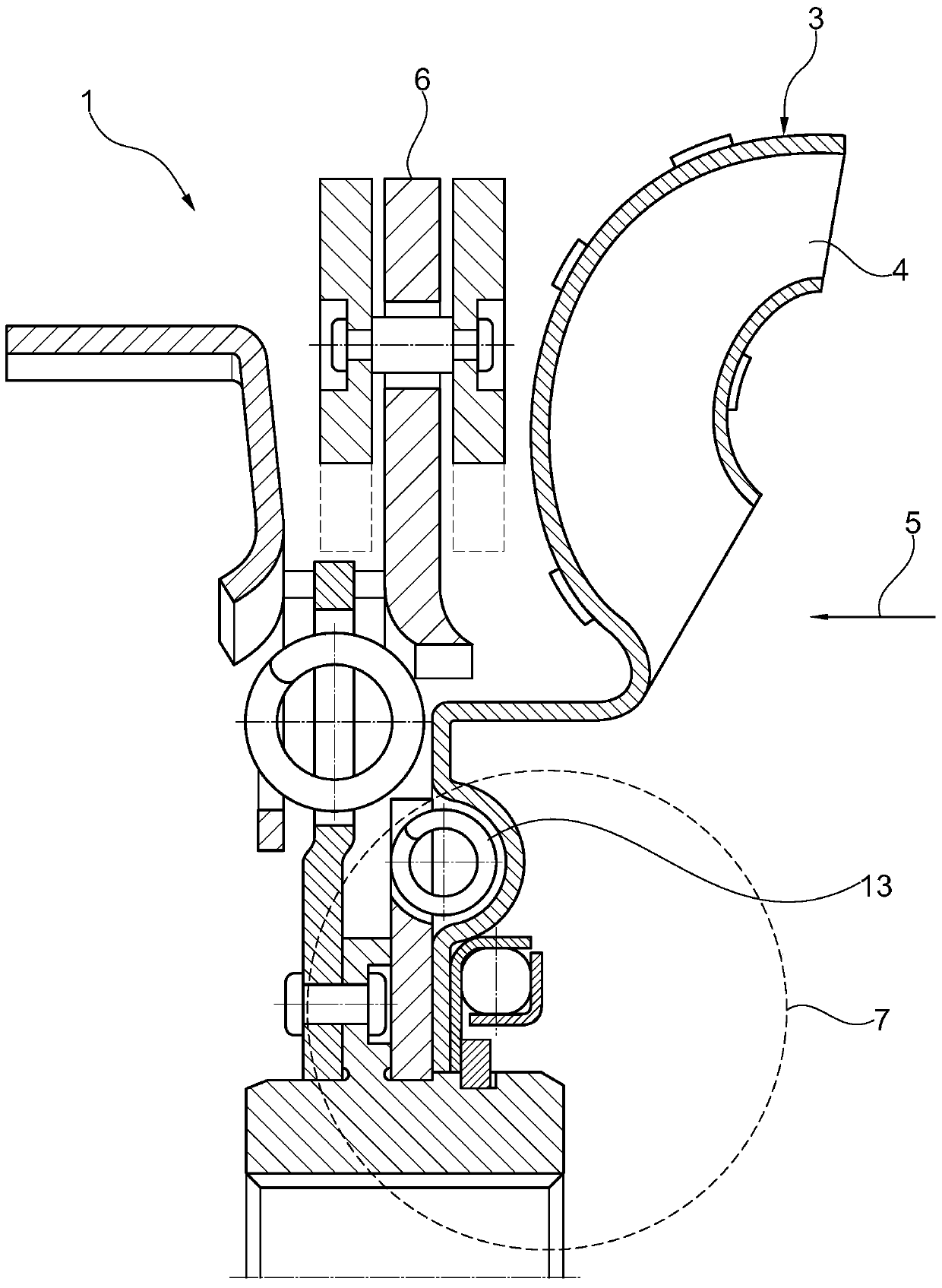

[0038] exist figure 1 shows a torque converter 1 with a turbine 3 , here only the turbine blades 4 of which can be seen, which can be driven by a hydraulic fluid 5 . In this case, the anti-vibration device 6 , here a centrifugal pendulum, is connected via an elastic connecting element 7 . In this case, the elastic connecting element 7 is formed by a bow spring 13 which also has dissipative properties at the same time.

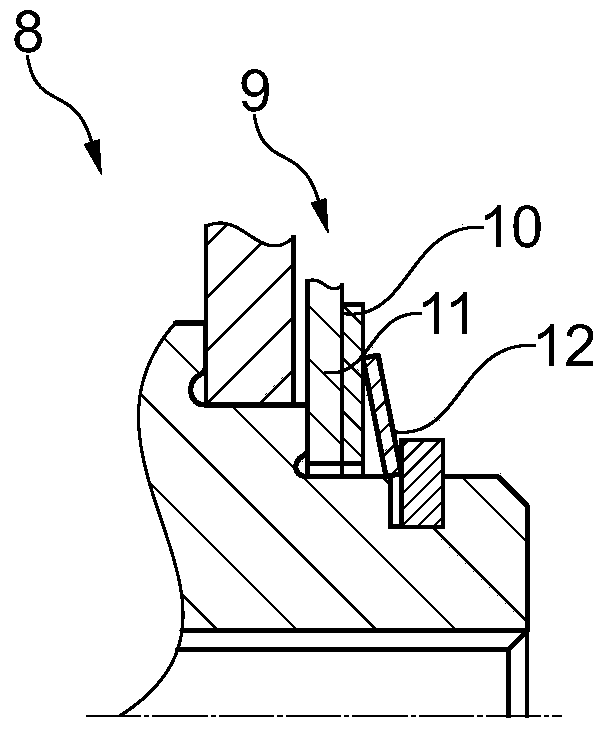

[0039] exist figure 2 A section of a hydraulic torque converter 1 is shown in , that is, a dissipating element 8, which is arranged as figure 1 In the position of the elastic connecting element 7 . In this case, the dissipating element 8 is formed by a friction-fit connection 9 which is produced by a first friction surface 10 and a second friction surface 11 which are pressed against each other by means of a disc spring 12 pressure.

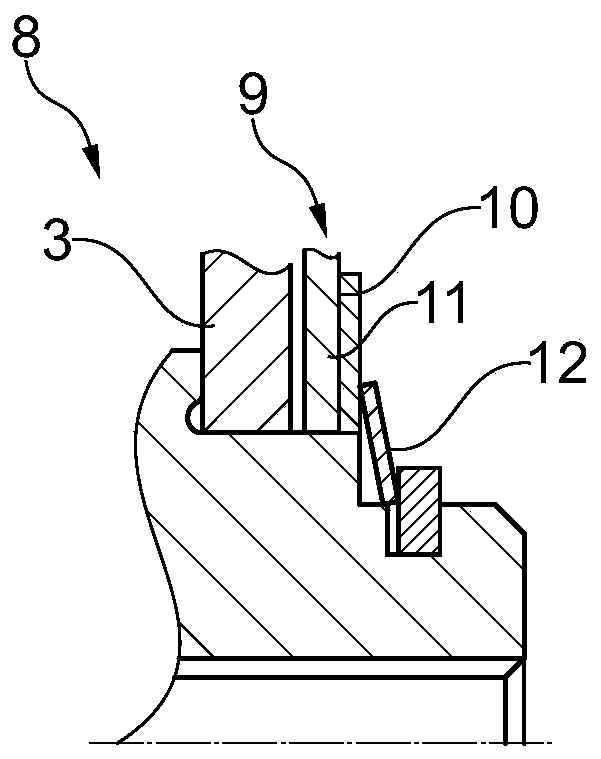

[0040] exist image 3 shown in figure 2 A similar arrangement as in , wherein here the first friction surface 10 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com