A drive assembly used for a hybrid vehicle

A technology for driving components and vehicles, which is applied to the arrangement of multiple different prime movers of hybrid vehicles, vehicle components, and general power units, can solve problems such as unavailability and insignificant axial structural space, and save structural space. , The effect of saving axial structure space and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

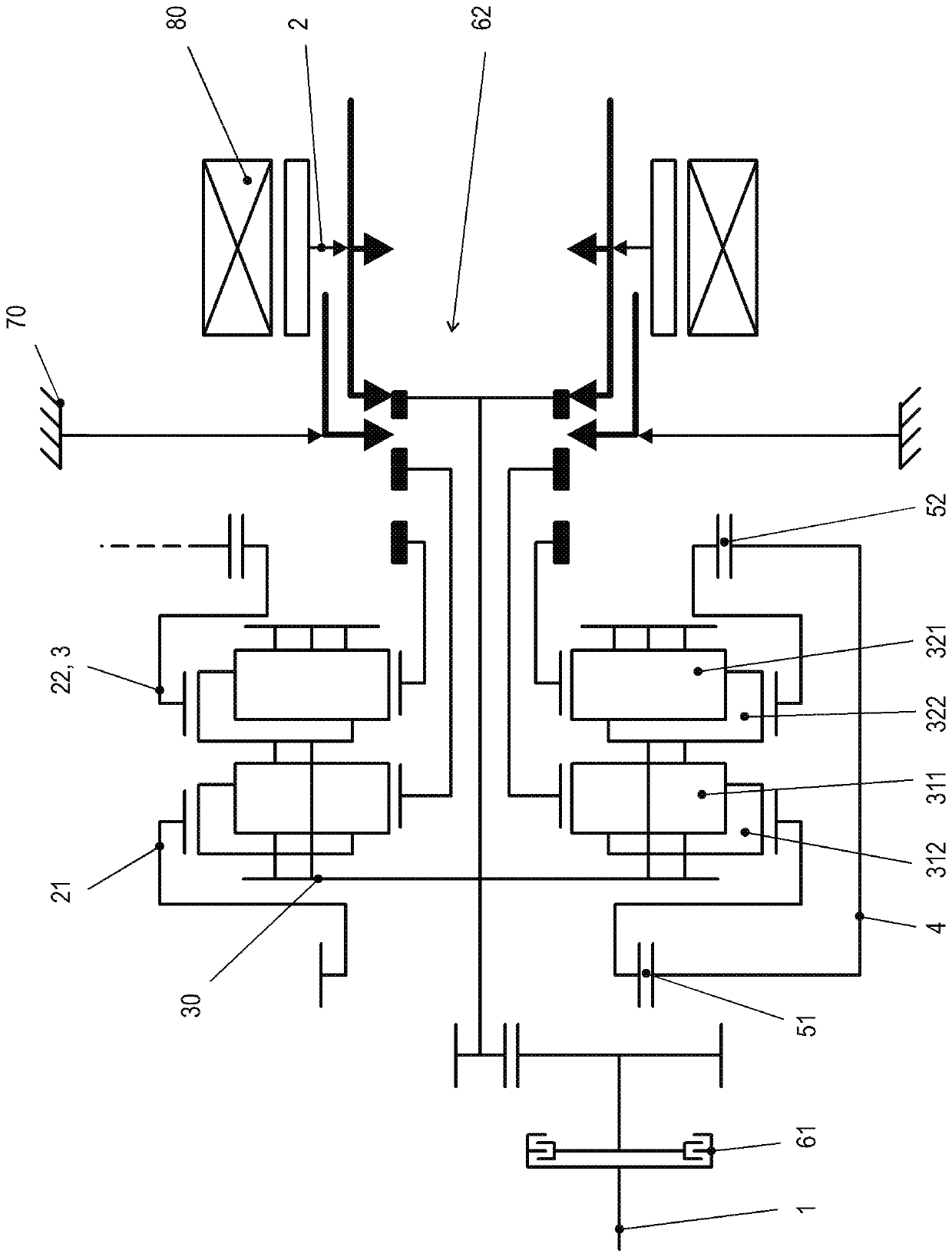

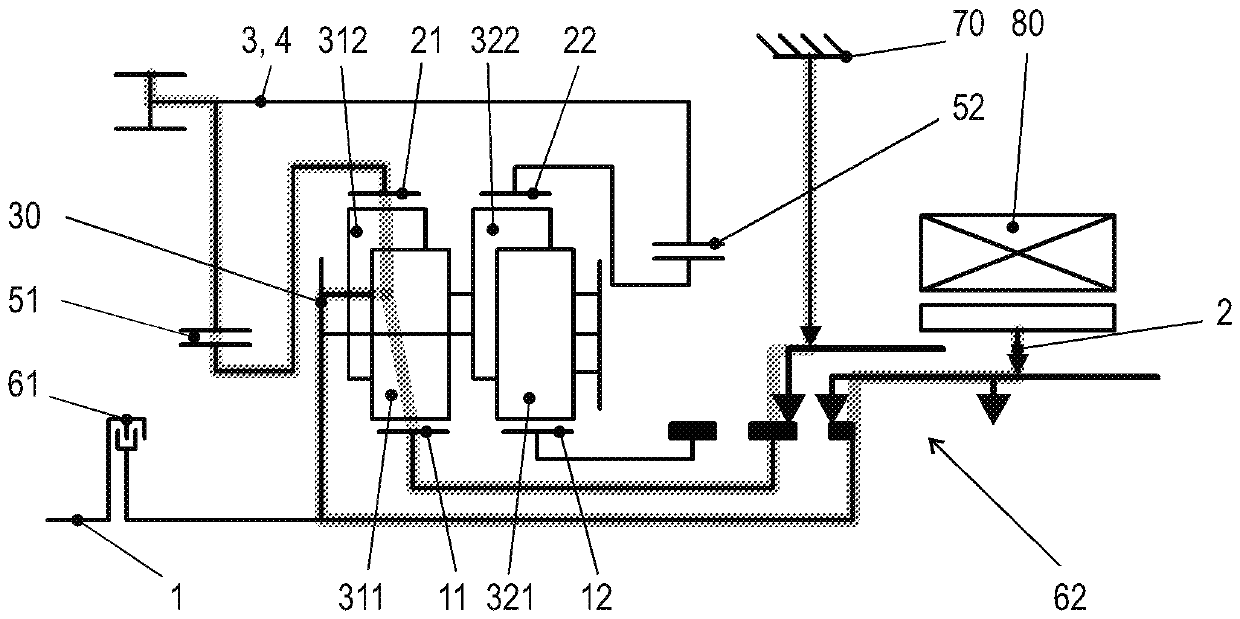

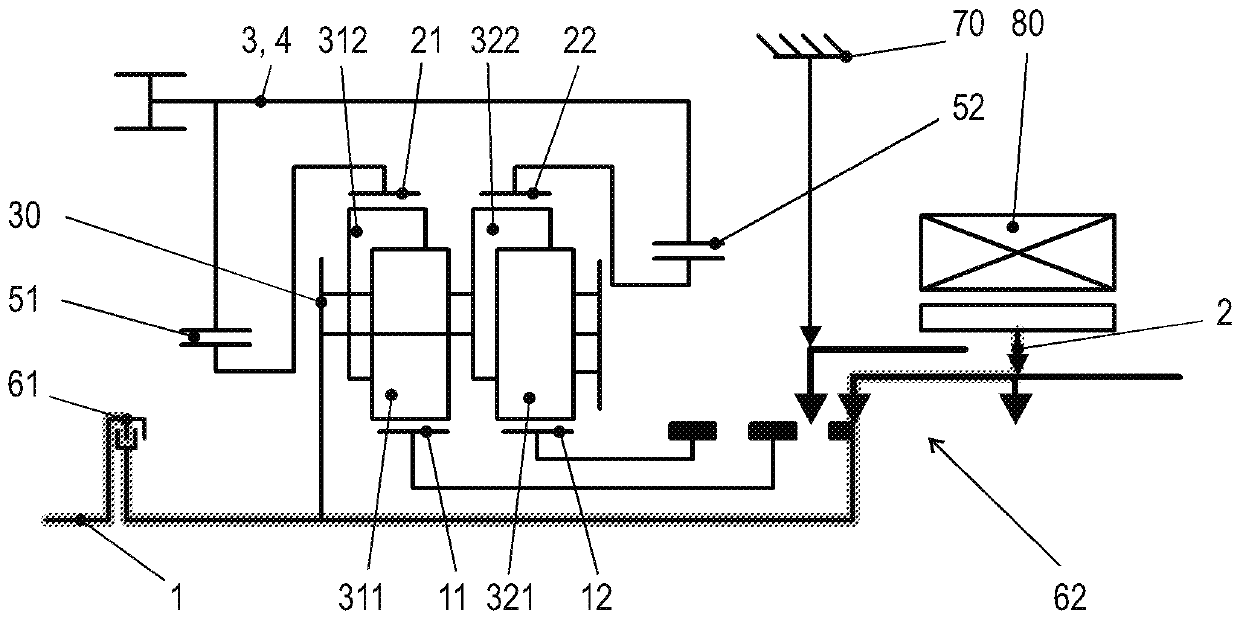

[0057] figure 1 A particularly preferred embodiment of the drive assembly according to the invention is shown. The internal combustion engine input shaft 1 of the shown drive assembly is connected in a manner not shown to a likewise not shown internal combustion engine, in particular to its crankshaft. The drive unit is connected via its electric motor input shaft 2 to an electric motor 80 , which preferably can also be operated as a generator. Via the output shaft of the drive unit, the shown drive unit is connected to a power output (not shown in greater detail), in particular to a differential of the motor vehicle.

[0058] The core section of the drive assembly is formed by a planetary gear consisting of two simple double planetary sets arranged on a common bridge 30 . Further, the first sun element 11 , the first ring gear 21 , the first subset 311 of the first planet wheels and the second subset 312 of the first planet wheels belong to the first planet set. Here, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com