Flexible area of the plate in the double clutch for recalibration of parallelism

A clutch and area technology, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve the problems of not guaranteeing the plane parallelism of each plate, parallelism errors, etc., to reduce friction loss, eliminate parallelism errors, and reduce waste heat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The drawings are only schematic in nature and are used only for understanding the invention. Identical elements are provided with the same reference numerals. The features of the various embodiments can be exchanged with each other.

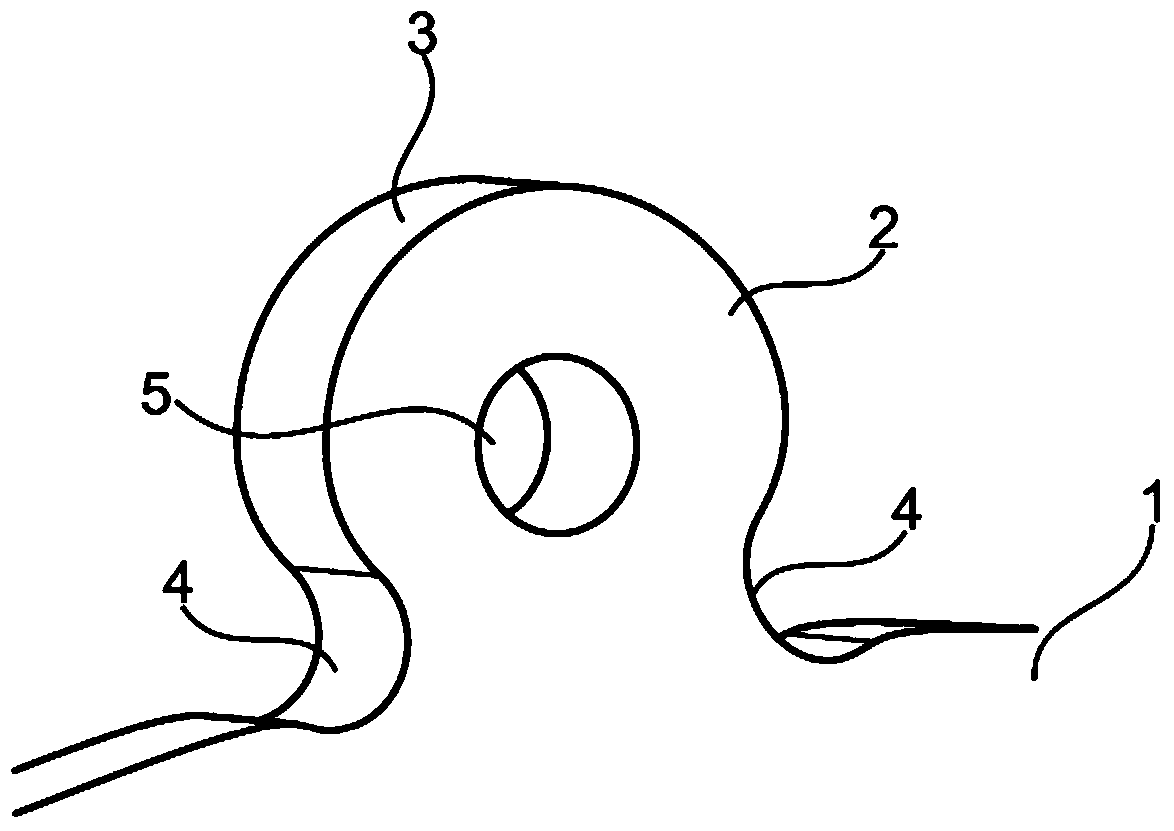

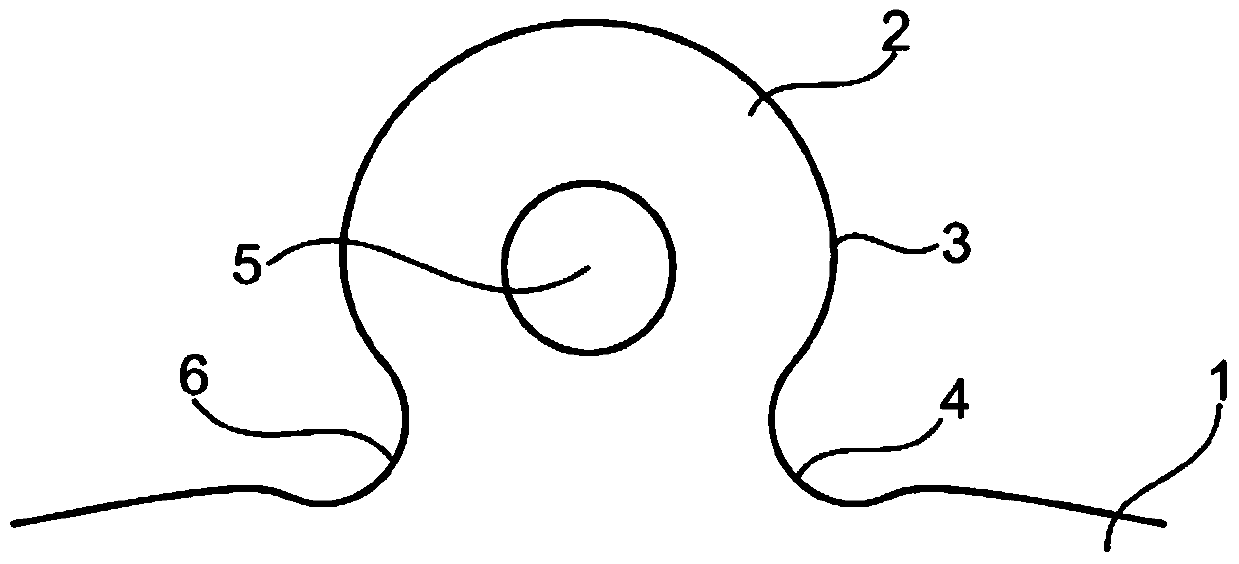

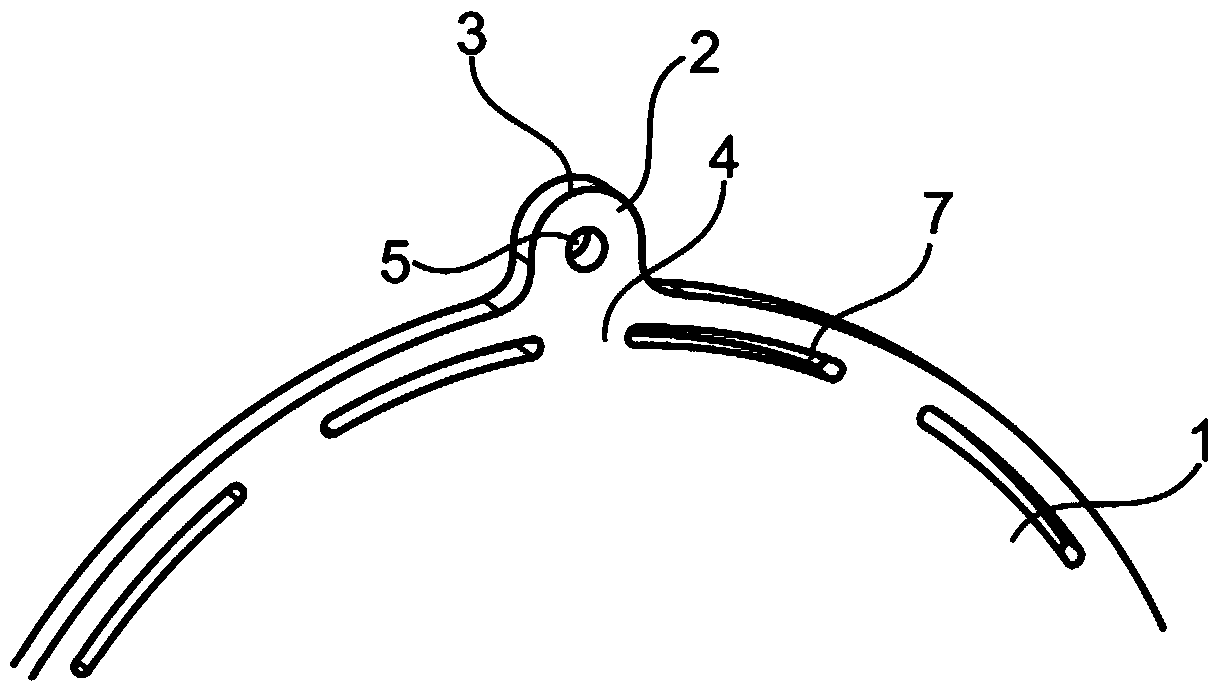

[0031] figure 1 A pressure plate 1 for a clutch of a motor vehicle is shown, which has a rivet receiving area 2 designed to accommodate rivets by means of which a pressure plate 1 can be fastened to another pressure plate 1 . Such a rivet is not shown, but can be formed according to conventional forms, for example as a blind rivet or as a solid rivet. Furthermore, the rivets can be realized by stepped bolts which provide abutment possibilities for the respective pressure plate 1 .

[0032] The rivet receiving area 2 forms a web 3 . The web 3 is connected to the rest of the pressure plate 1 via the joint area formed by the flexible area 4. Furthermore, the rivet opening 5 can be seen in the rivet receiving area 2 . The rivet sockets a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com