Patents

Literature

158results about How to "Reduce waste heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

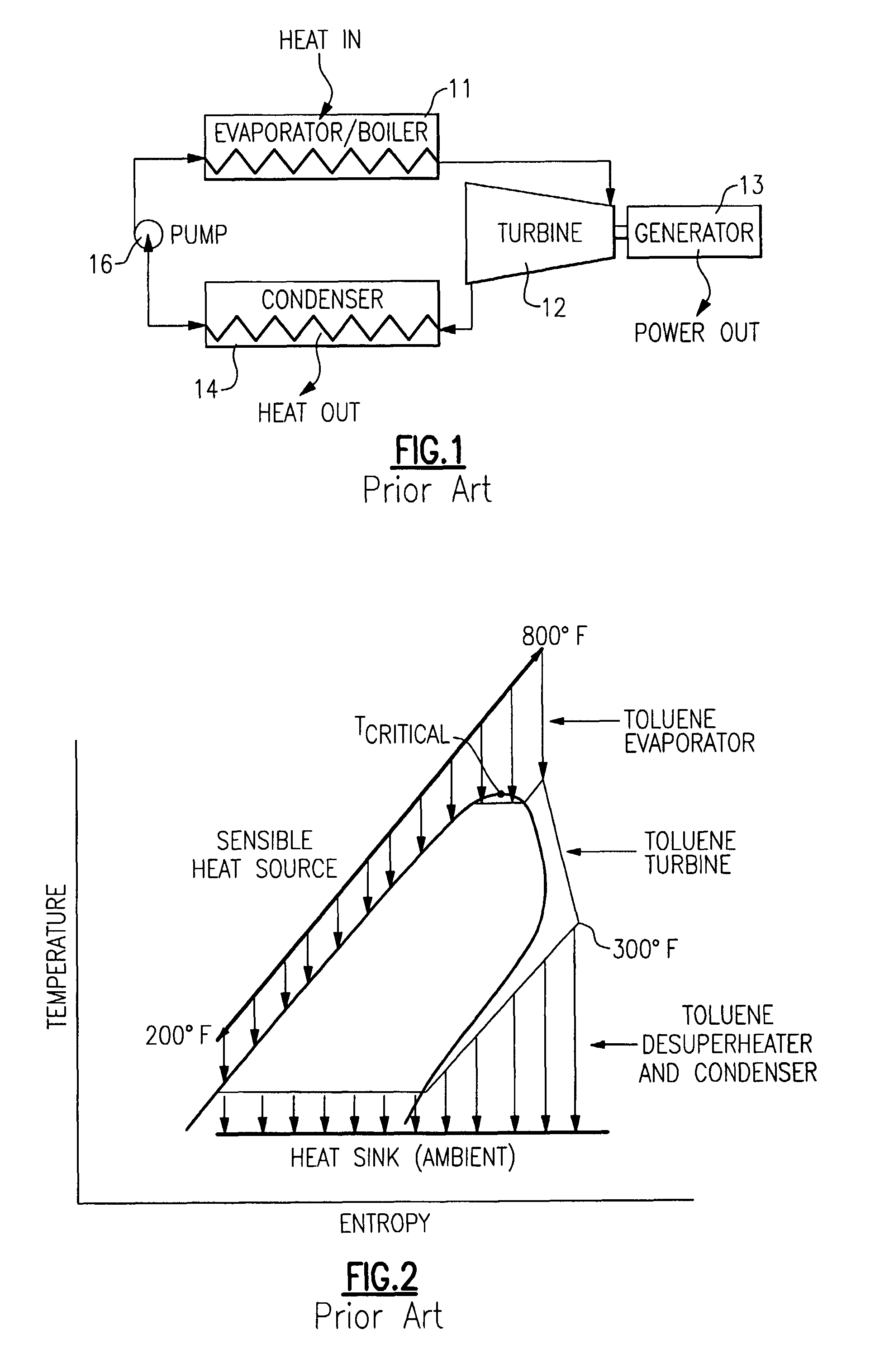

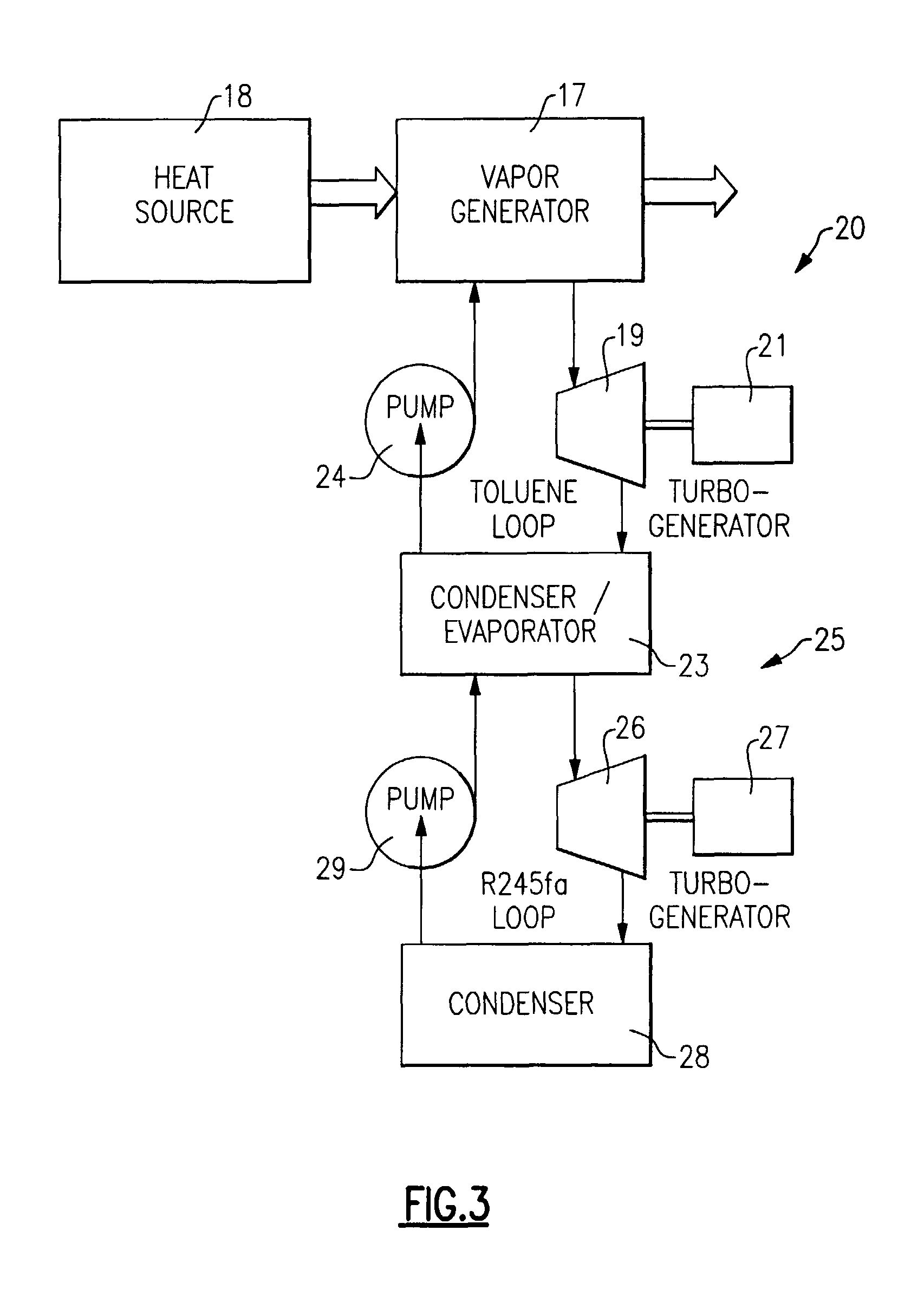

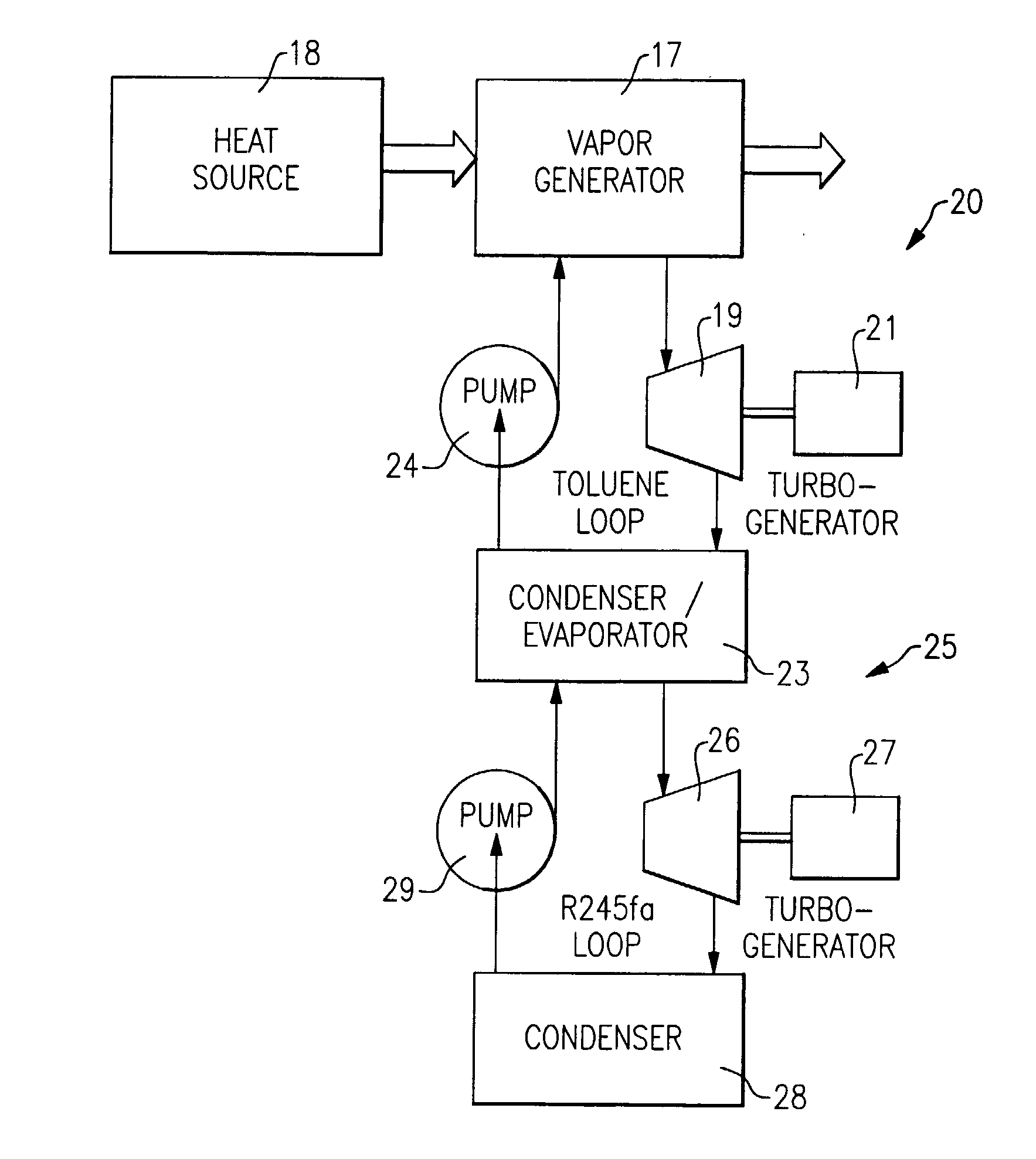

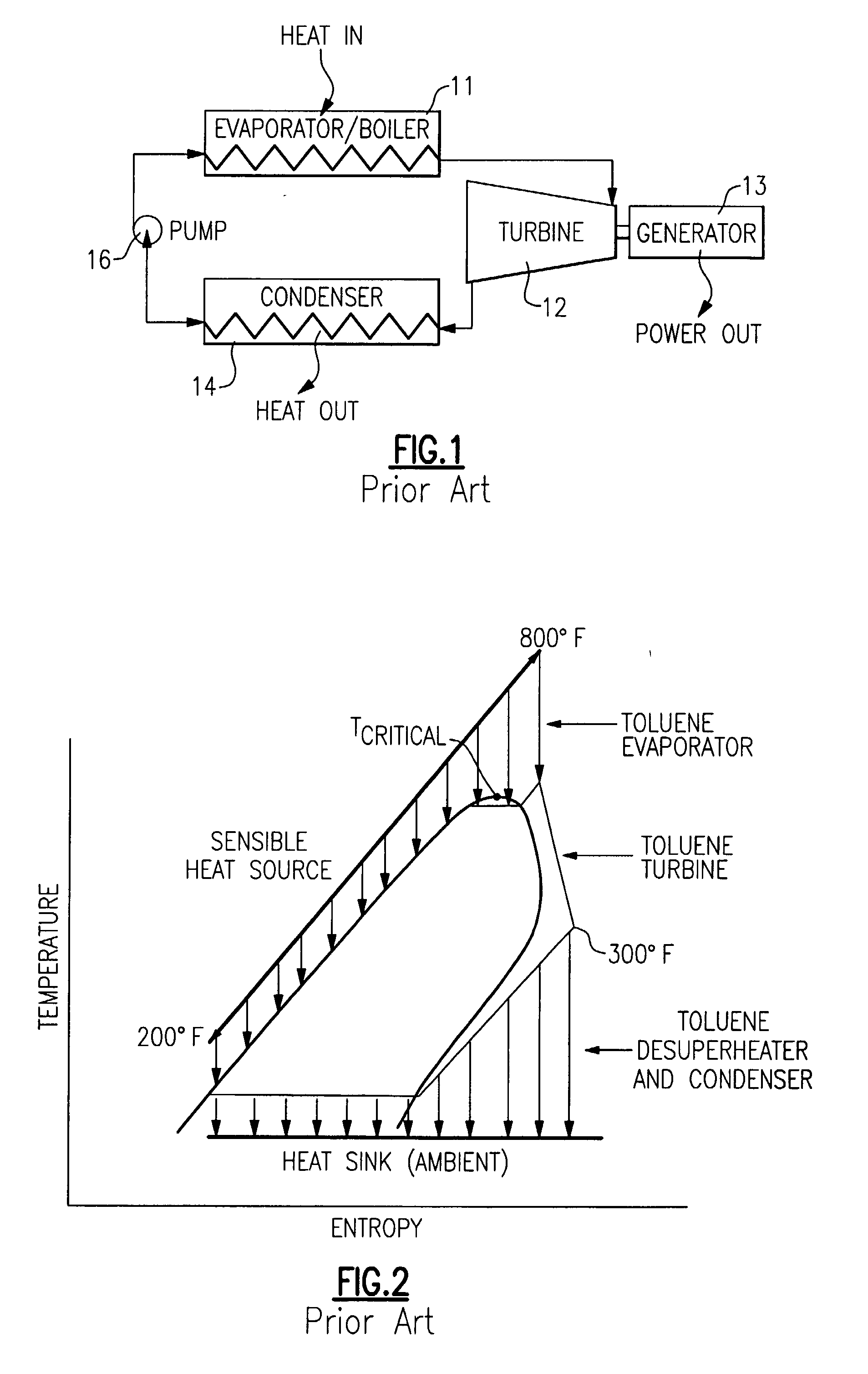

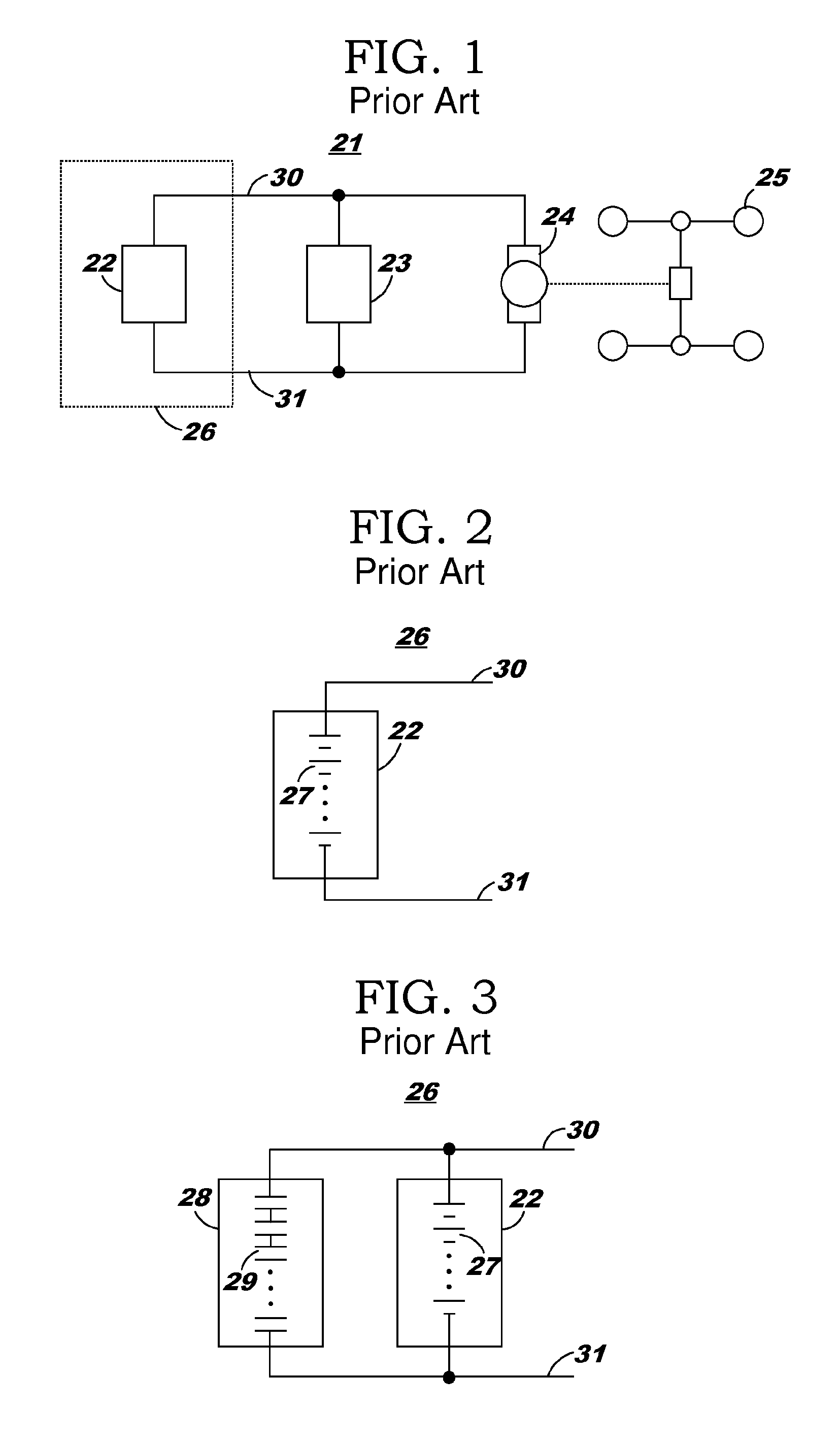

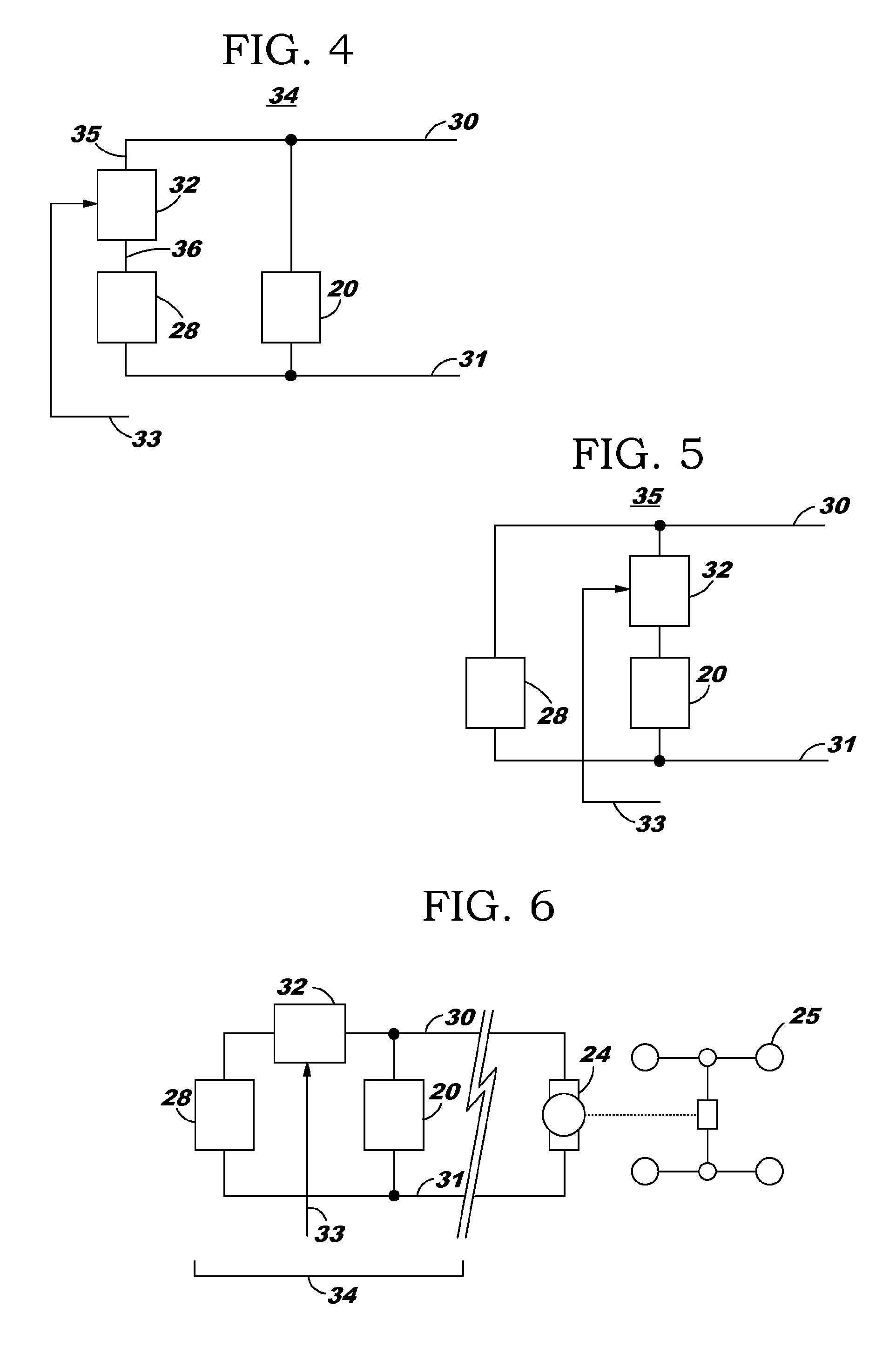

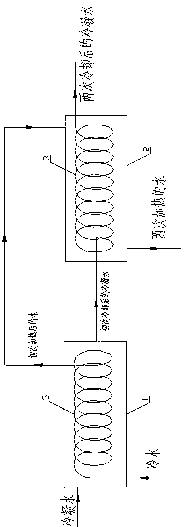

Cascaded organic rankine cycles for waste heat utilization

InactiveUS7942001B2Improve efficiencyReduce waste heatSteam engine plantsWorking fluidOrganic Rankine cycle

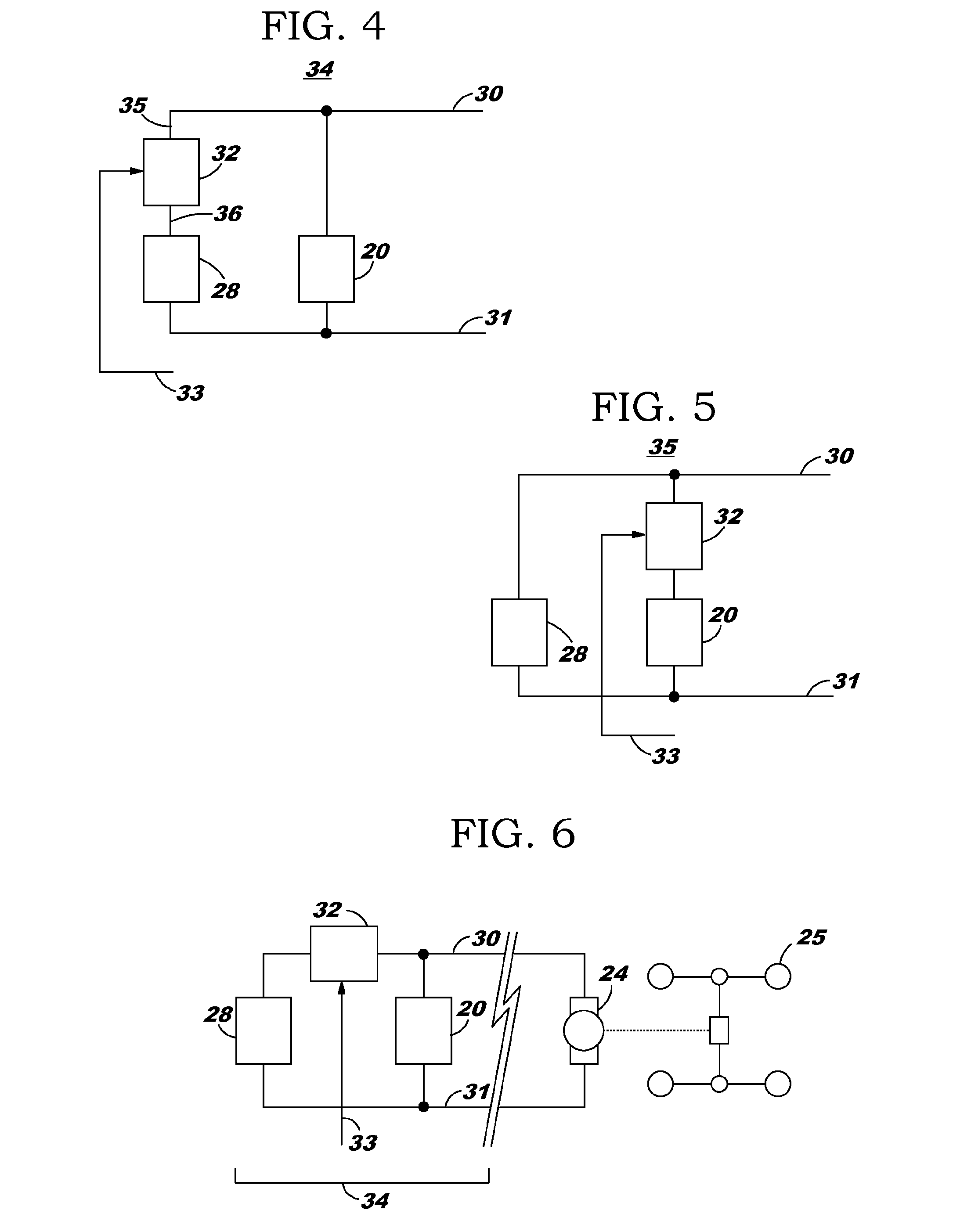

A pair of organic Rankine cycle systems (20, 25) are combined and their respective organic working fluids are chosen such that the organic working fluid of the first organic Rankine cycle is condensed at a condensation temperature that is well above the boiling point of the organic working fluid of the second organic Rankine style system, and a single common heat exchanger (23) is used for both the condenser of the first organic Rankine cycle system and the evaporator of the second organic Rankine cycle system. A preferred organic working fluid of the first system is toluene and that of the second organic working fluid is R245fa.

Owner:INT FUEL CELLS

Cascaded Organic Rankine Cycles for Waste Heat Utilization

InactiveUS20080168772A1Improve efficiencyReduce waste heatSteam engine plantsWorking fluidOrganic Rankine cycle

A pair of organic Rankine cycle systems (20, 25) are combined and their respective organic working fluids are chosen such that the organic working fluid of the first organic Rankine cycle is condensed at a condensation temperature that is well above the boiling point of the organic working fluid of the second organic Rankine style system, and a single common heat exchanger (23) is used for both the condenser of the first organic Rankine cycle system and the evaporator of the second organic Rankine cycle system. A preferred organic working fluid of the first system is toluene and that of the second organic working fluid is R245fa.

Owner:INT FUEL CELLS

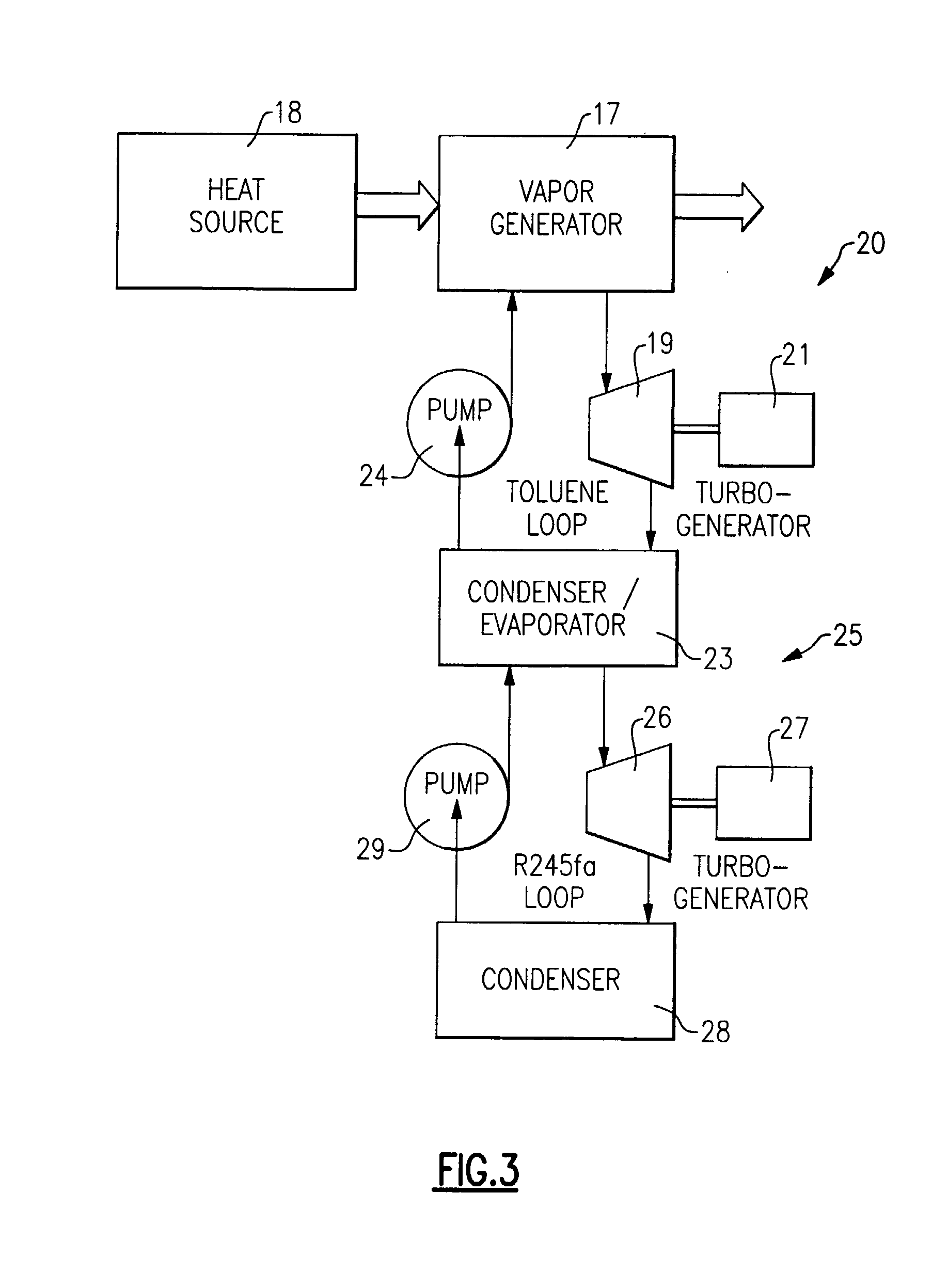

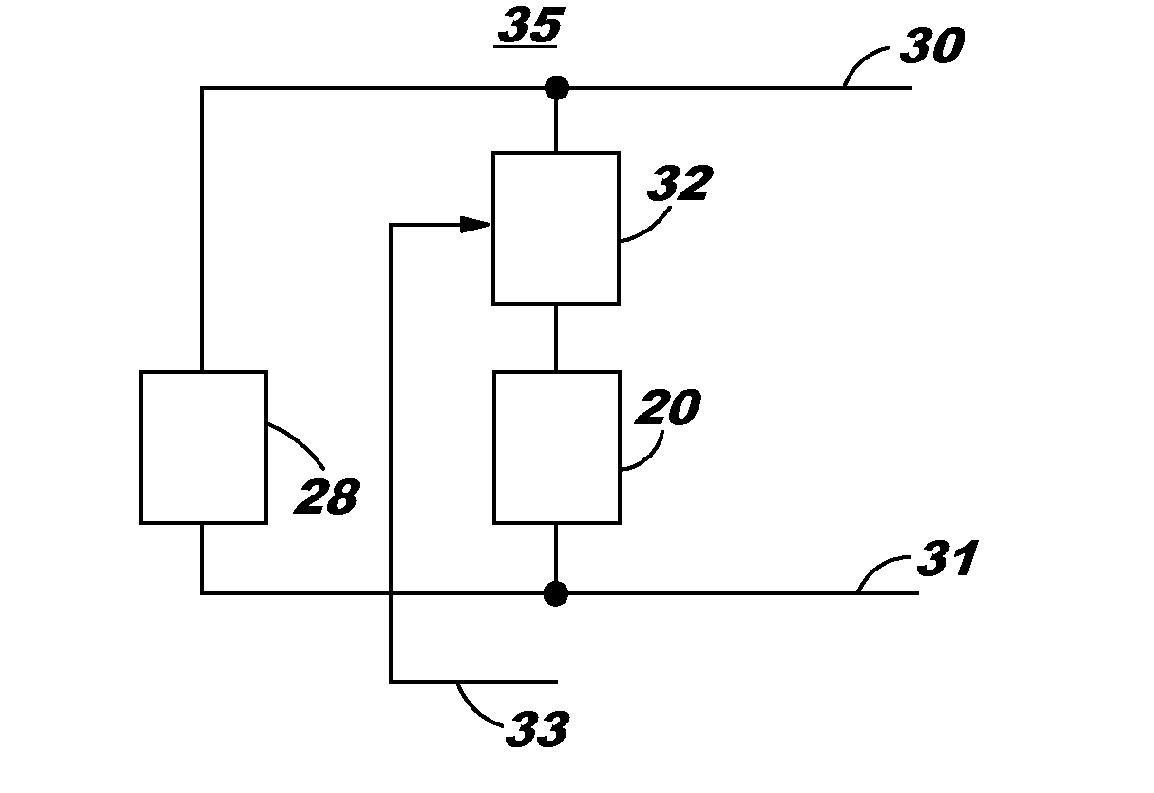

Energy storage systems and methods

ActiveUS20120319471A1Good and more sophisticated controlEasy to controlBatteries circuit arrangementsPropulsion by batteries/cellsFast Fourier transformState of charge

In an energy storage system that includes a battery and an ultracapacitor, the state of charge (SOC) of the capacitor is the subject of a dynamic set-point. This dynamic set-point control is a function of the load regime to which the storage system is exposed, for example a hybrid automobile or electric automobile. The control may be based in part upon real-time fast Fourier transform analysis of load current, permitting real-time adjustment of control coefficients. In this way, it is possible to minimize the occurrence of the capacitor being fully charged at a time when it would be desired to be able to absorb high current, for example from regenerative braking. Likewise it is possible to minimize the occurrence of the capacitor being nearly discharged at a time when it would be desirable to have boost power available. A result is that even a relatively small ultracapacitor (having perhaps one two-hundredth the energy storage capacity of the battery) can permit greatly reducing waste heat dissipated in the battery, and can reduce otherwise unnecessary cycling of current into and out of the battery. This can extend battery life and battery performance.

Owner:UCAP POWER INC

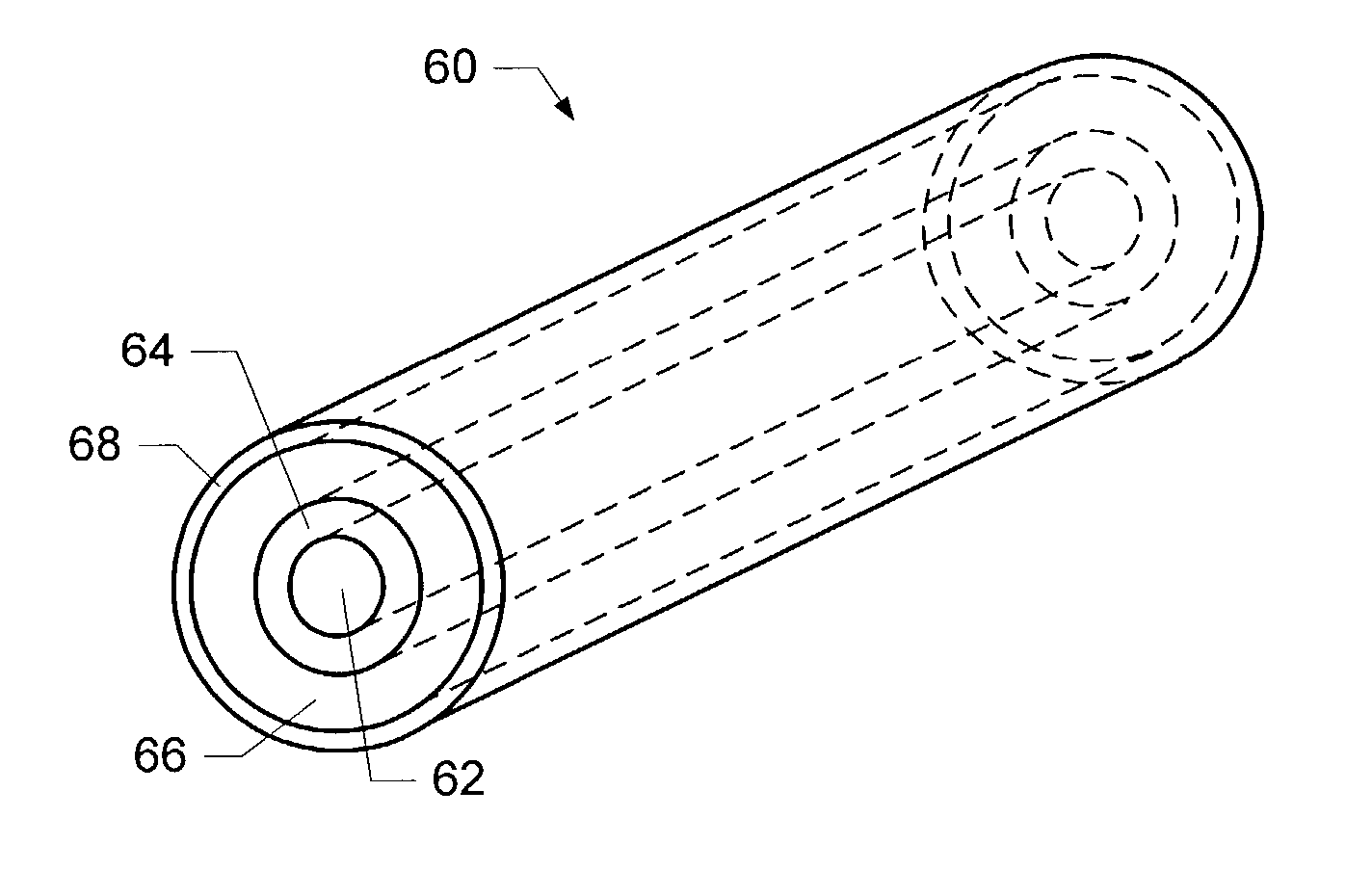

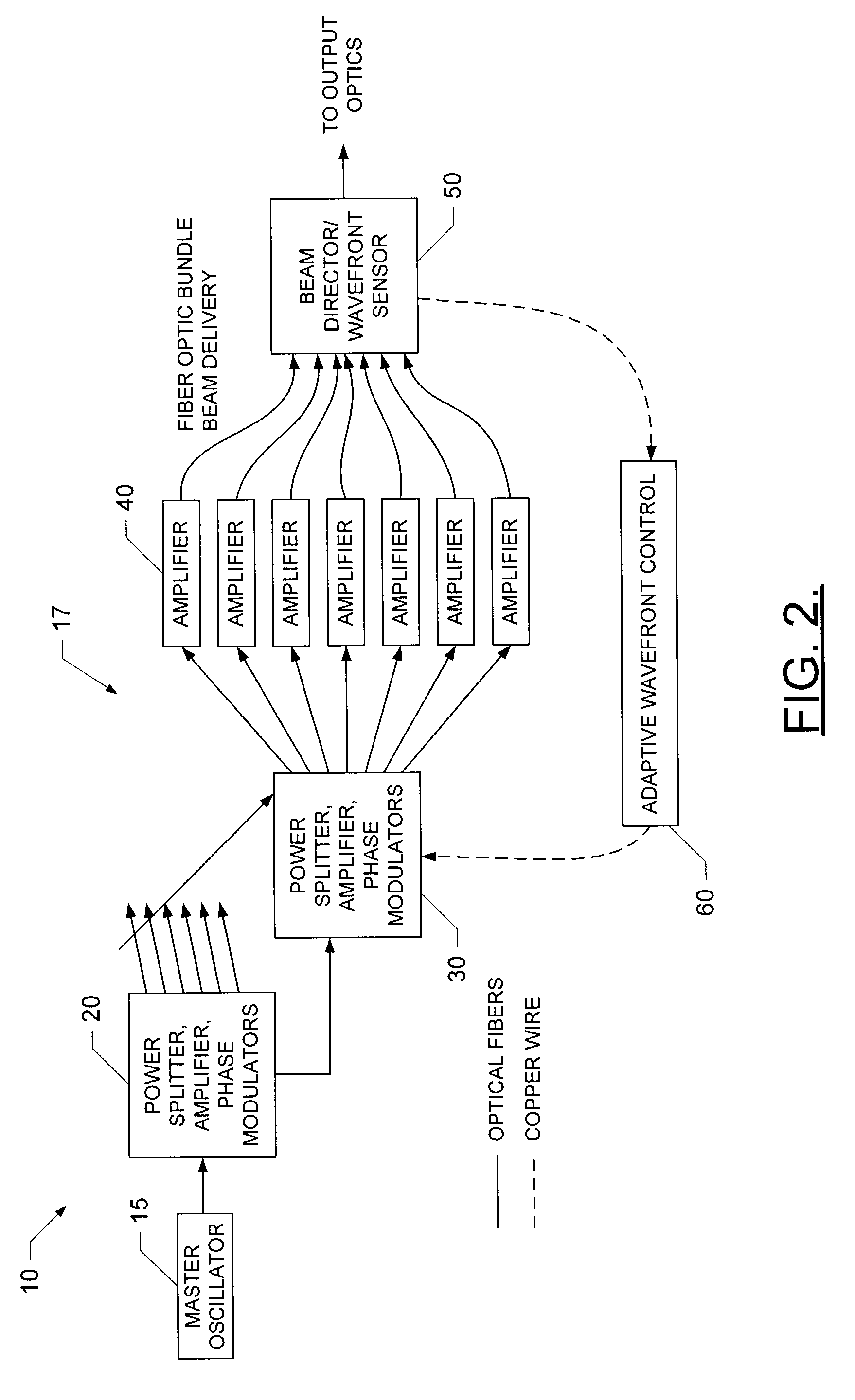

Fiber amplifier having a non-doped inner core and at least one doped gain region

ActiveUS6965469B2Minimizes waste heatOvercomes inherent intensity limitationLaser using scattering effectsFibre transmissionNon dopedEngineering

A fiber amplifier includes at least one longitudinally extending non-doped inner core capable of transmitting signals. At least partially surrounding the inner core and extending at least partially therealong, the fiber amplifier also includes at least one gain region capable of amplifying signals propagating therethrough. The fiber amplifier also includes an outer core surrounding the gain region and the inner core and extending longitudinally therealong. The outer core is capable of transmitting pump energy such that the pump energy at least partially amplifies signals propagating through the inner core according to a nonlinear amplification process, such as a Raman or a Brillouin amplification process.

Owner:THE BOEING CO

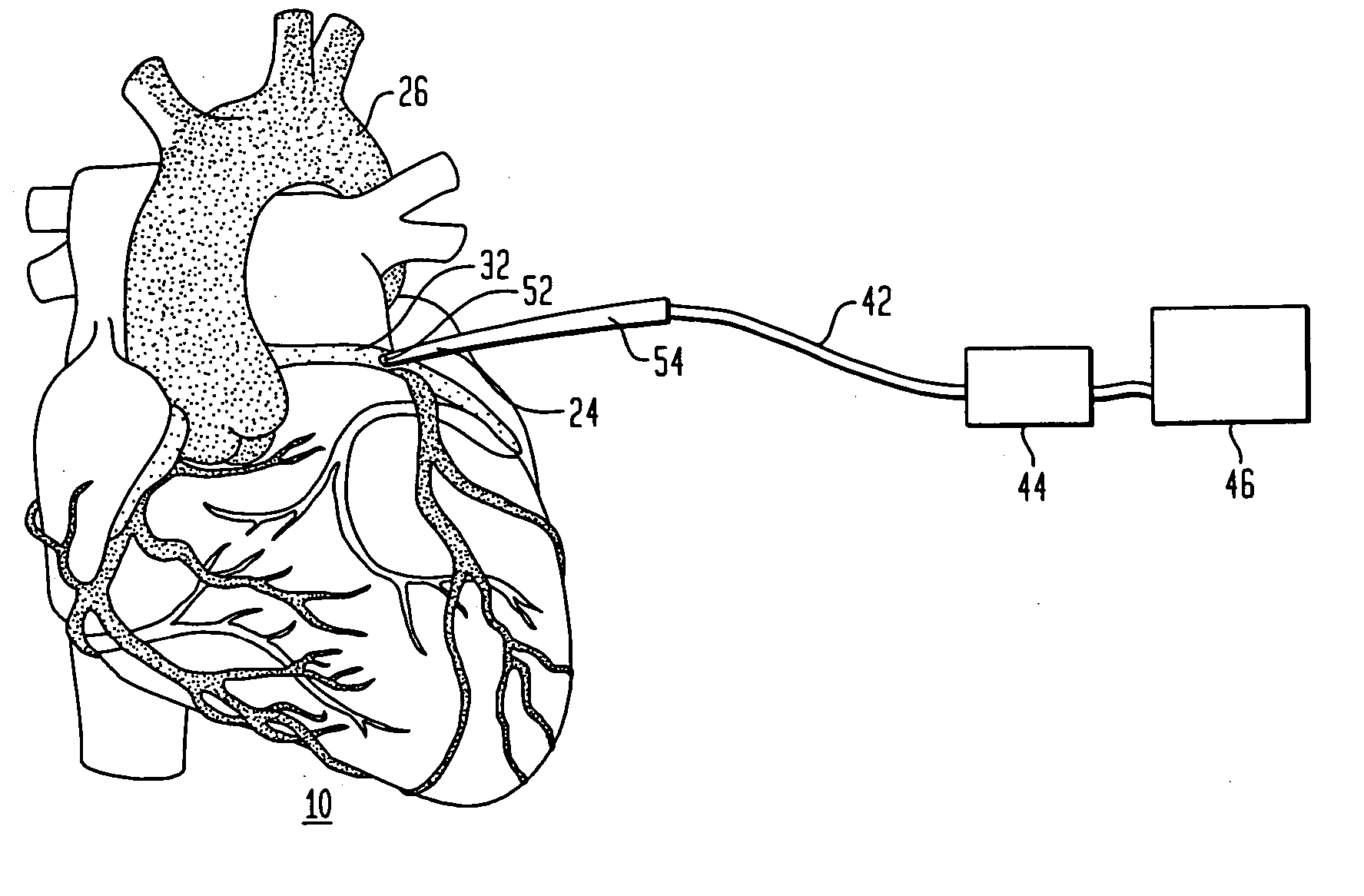

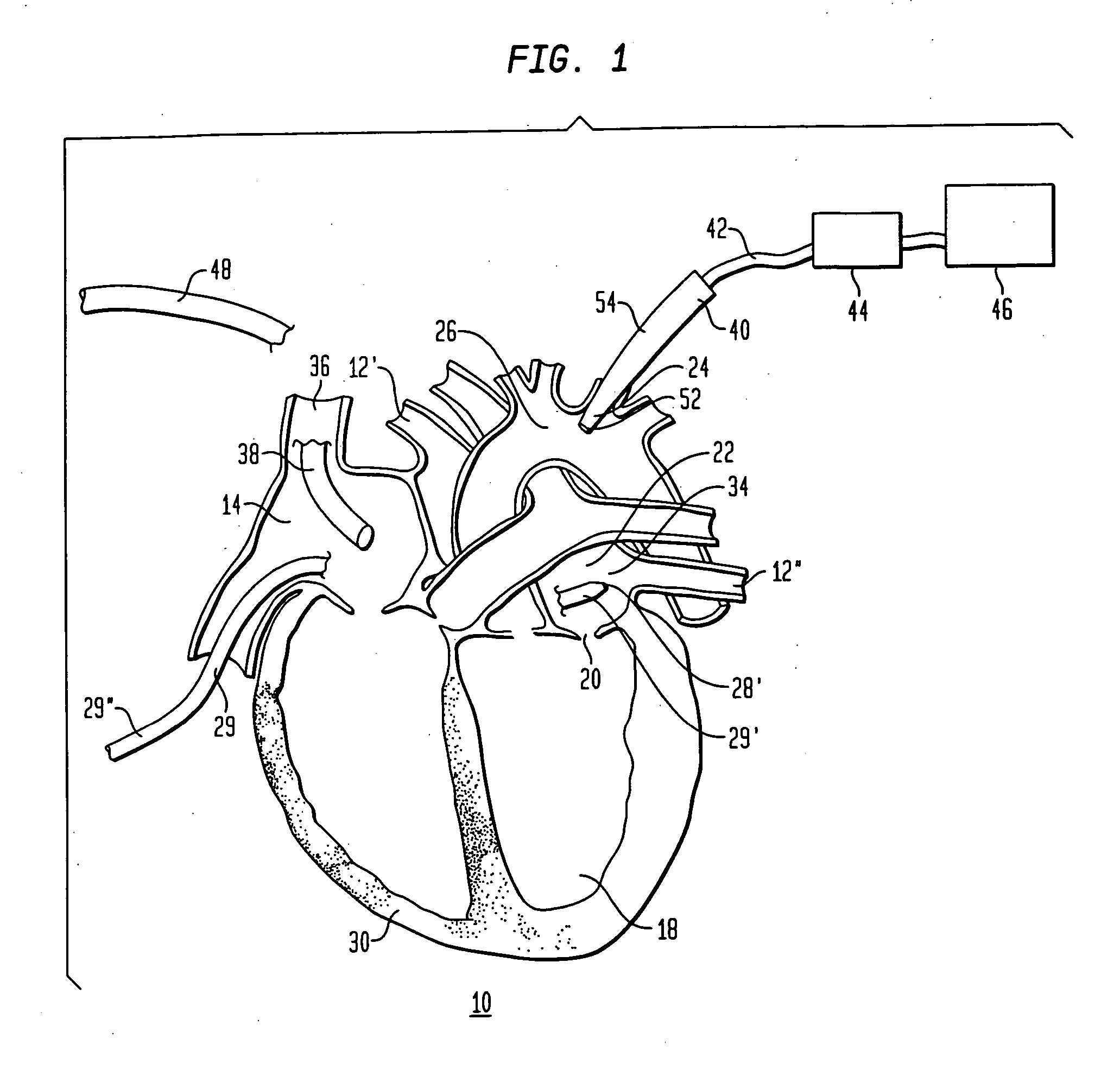

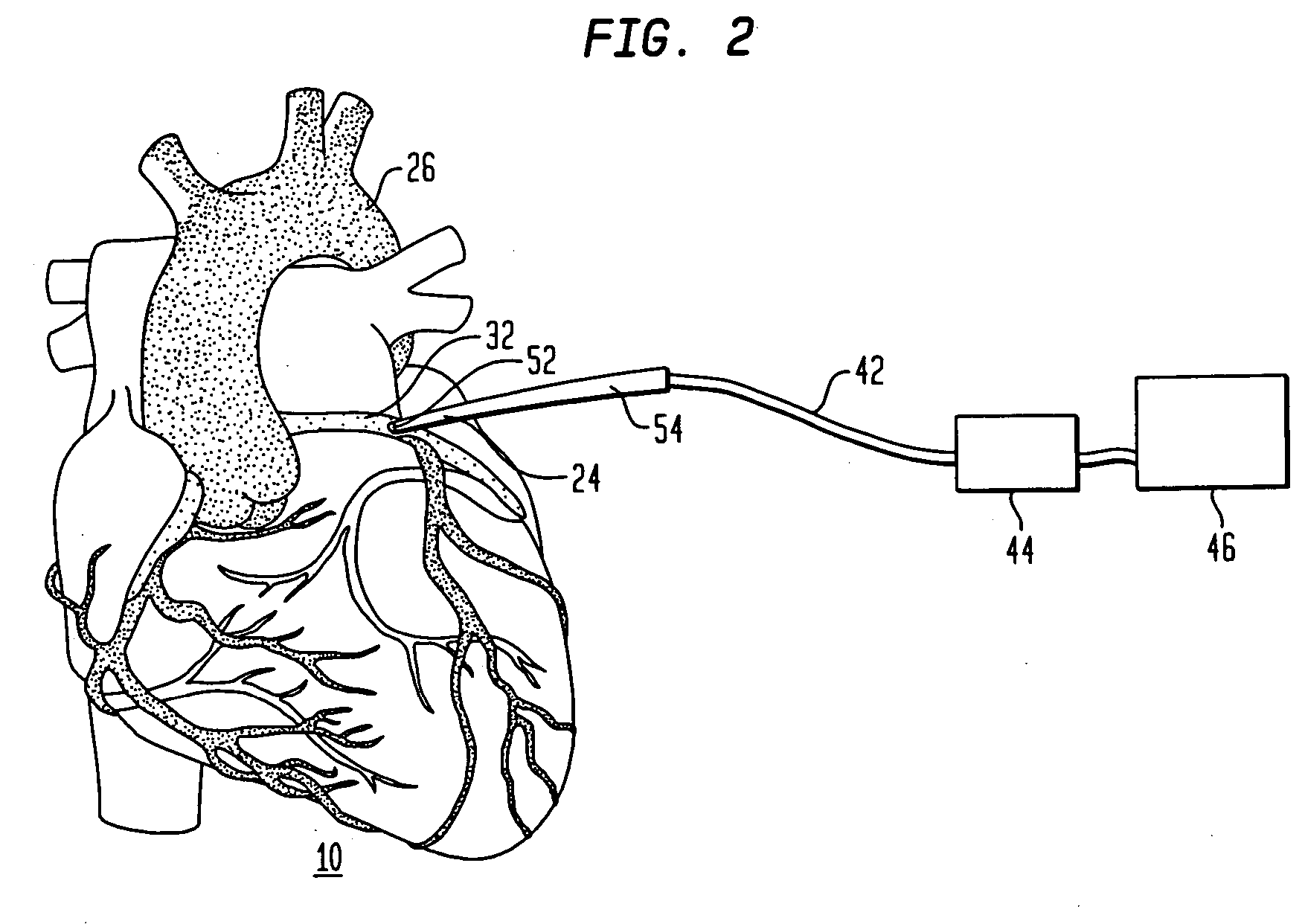

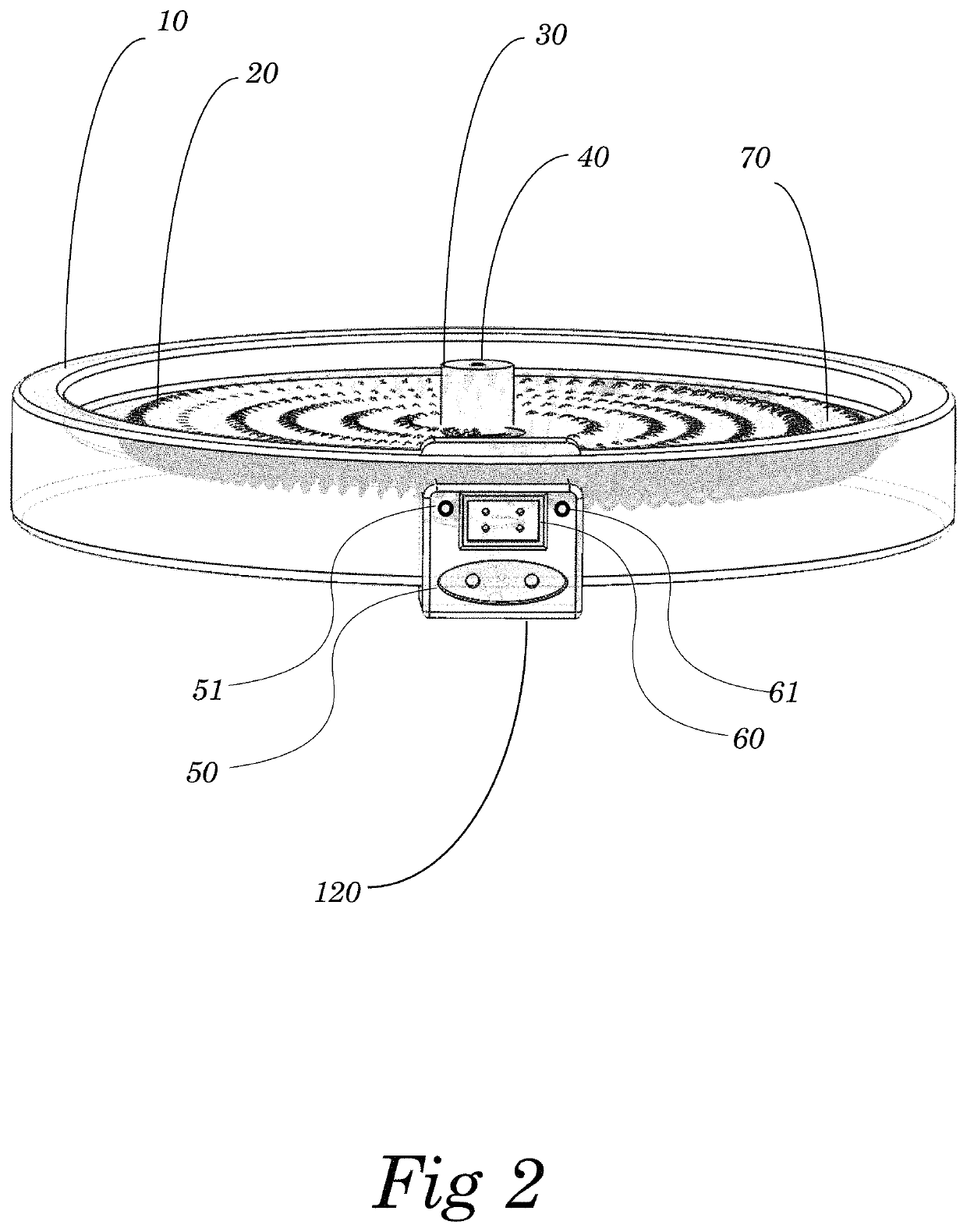

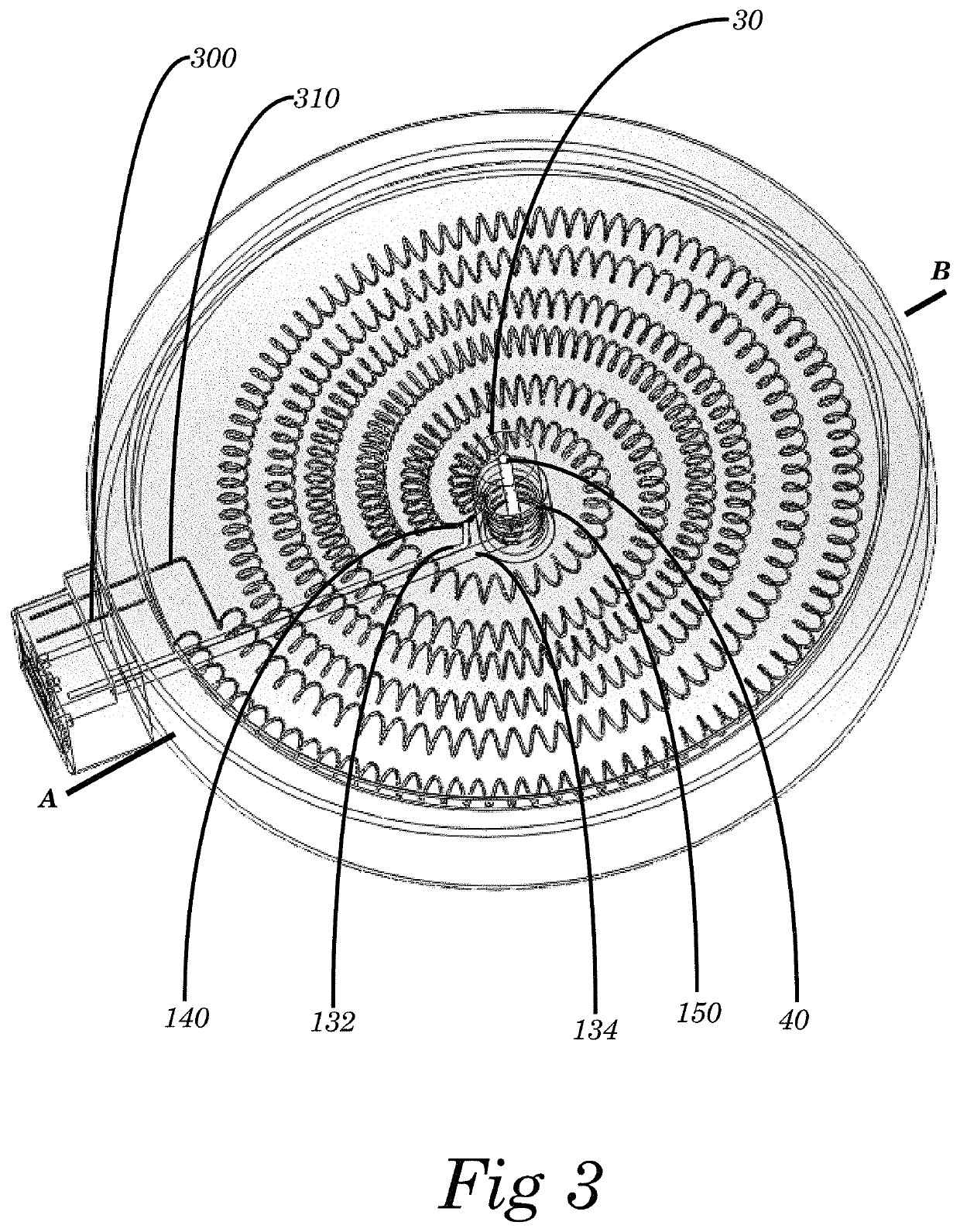

Cardiac ablation using microbubbles

InactiveUS20060100514A1Minimize dilutionReduce selection requirementsUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySonificationBlood vessel

In a cardiac ablation procedure, ultrasonic energy is emitted from an ultrasonic ablation device (28) and is focused on myocardial tissue (30) within the wall of the heart or within the wall of a blood vessel connected to the heart (10). Ultrasound attenuation of the cardiac tissue is selectively increased by introducing microbubbles into the circulatory system of the subject so that the microbubbles enter the coronary arteries and pass into the myocardial tissue.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

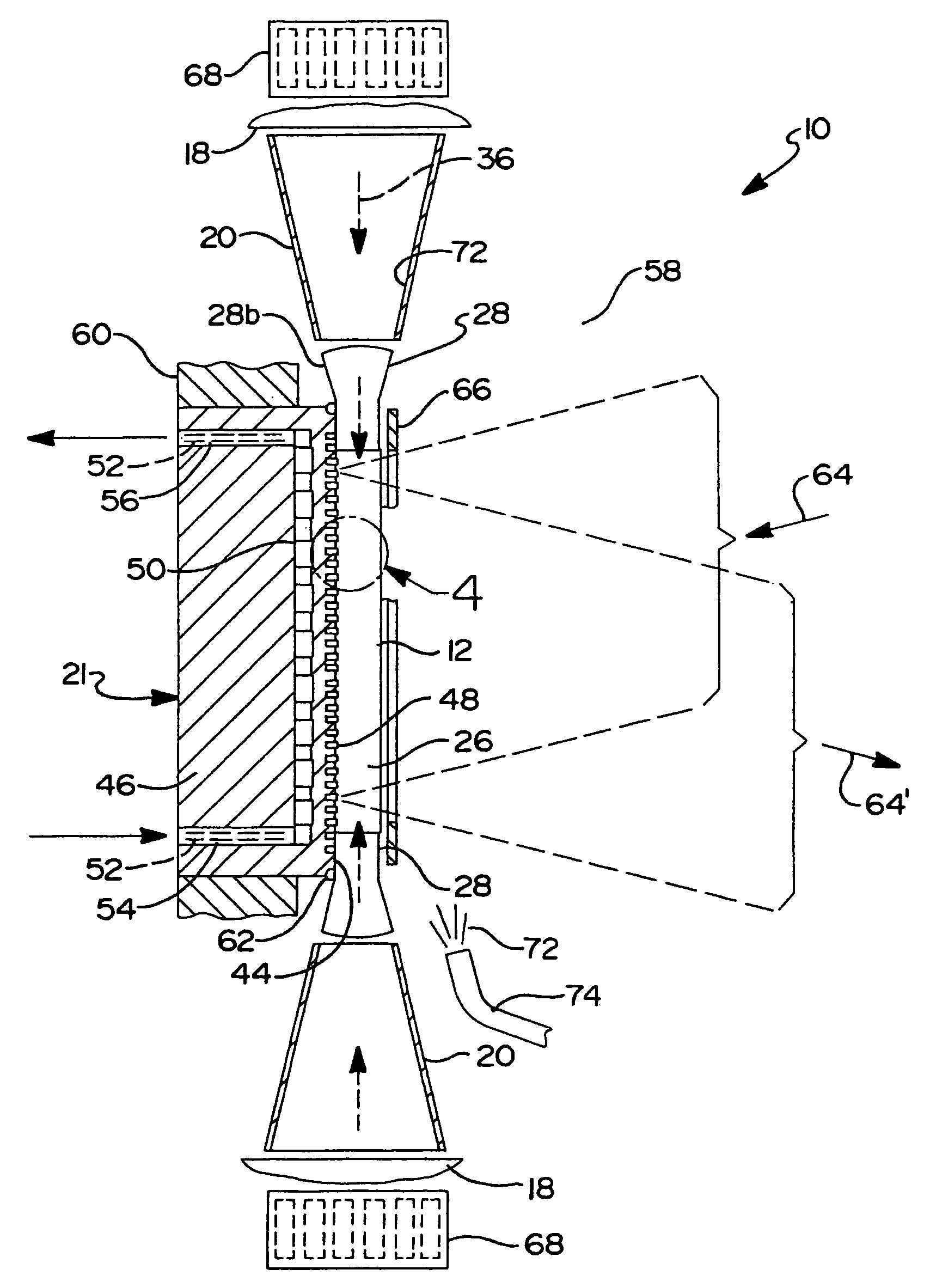

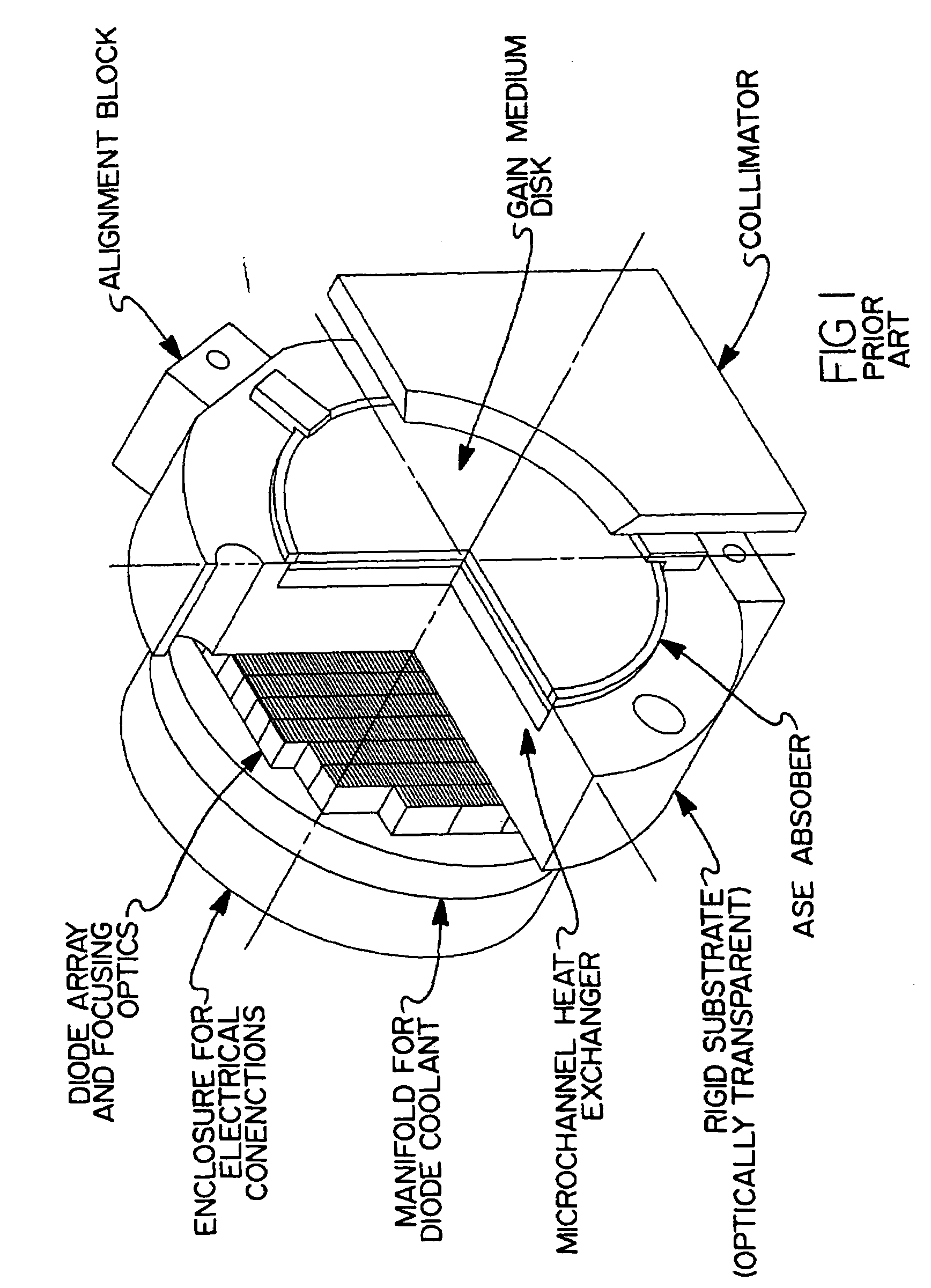

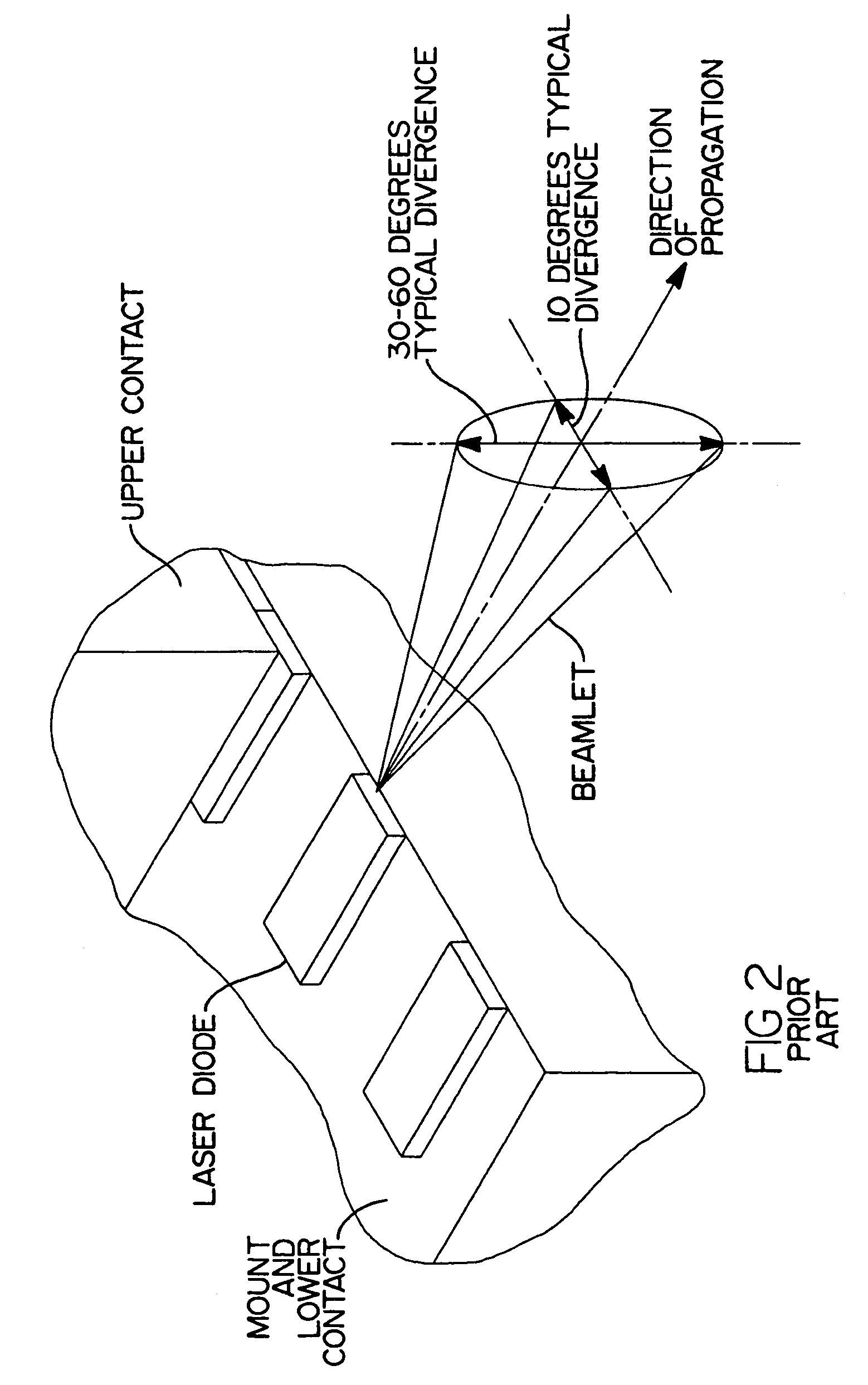

Side-pumped solid-state disk laser for high-average power

InactiveUS7200161B2Reduce feedbackReduce thermal stressOptical resonator shape and constructionActive medium materialOptical communicationCooling fluid

A solid state laser module for amplification of laser radiation. The module includes a laser gain medium having a pair of generally parallel surfaces that form a disc-like shape, that receive and transmit laser radiation. At least one perimetral optical medium is disposed adjacent a peripheral edge of the laser gain medium and in optical communication therewith. A source of optical pump radiation directs optical pump radiation into the perimetral optical medium generally normal to the parallel surfaces and the perimetral optical medium transports the optical pump radiation into the laser gain medium to pump the laser gain medium to a laser transition level. Alternative embodiments include arrangements for directing cooling fluids between adjacently disposed laser gain media.

Owner:THE BOEING CO

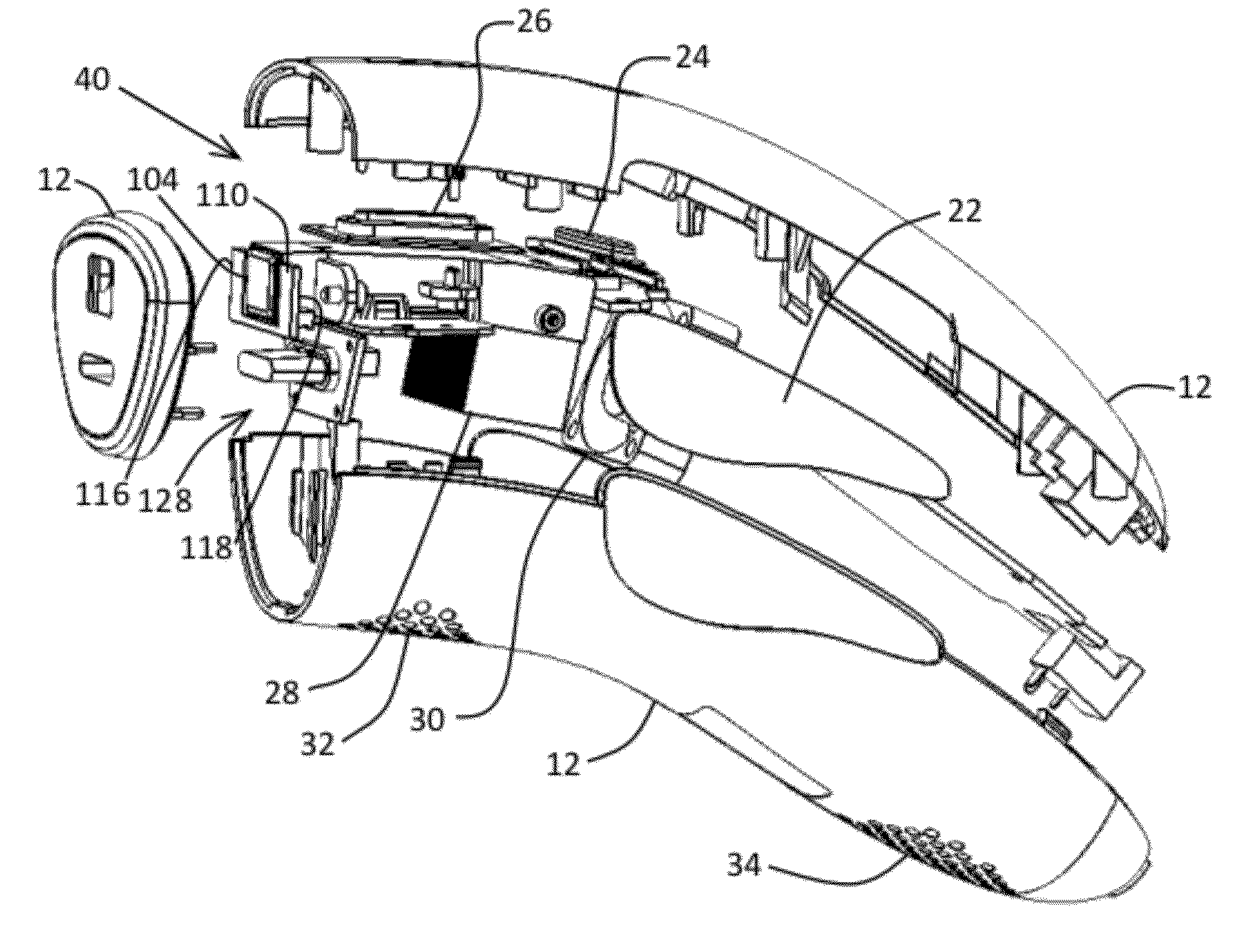

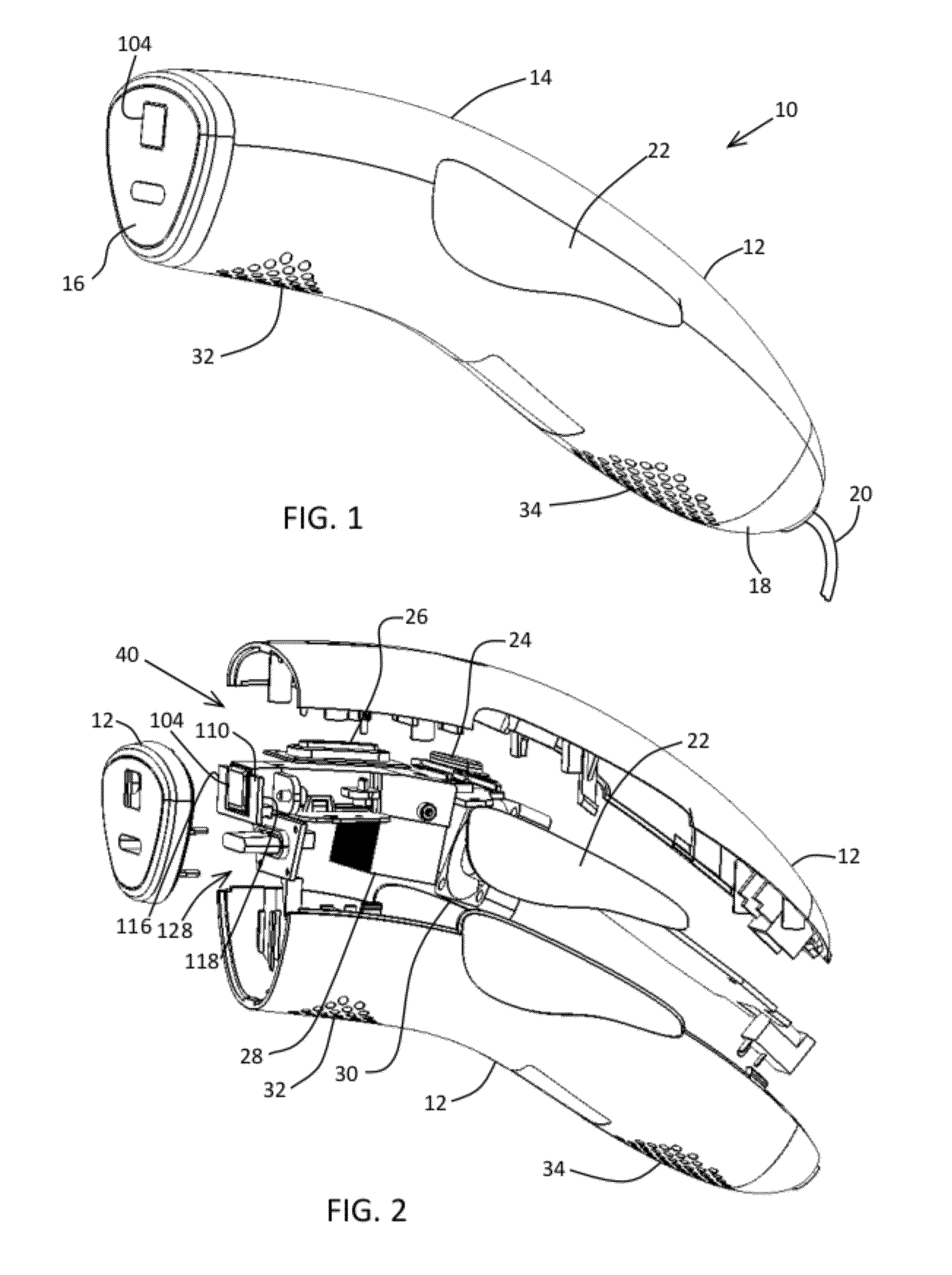

Skin color and capacitive sensor systems

InactiveUS20120165682A1Less powerGenerate efficientlyRadiation pyrometryDiagnostics using lightLight pipeSkin color

A hair removal device utilizes a system for sensing the presence and color of skin. The system includes a skin color sensor assembly and a capacitive sensor assembly disposed in a housing. The skin color sensor assembly includes a light pipe communicating with a color sensor aperture of the housing and having one or more notches defining receiving and emitting light propagation regions, a color sensor and one or more light emitting diodes, and a holder having at least one standoff mated to the notches thereby directing light emitted by the light emitting diodes through the light pipe for reflection of an external surface and receipt by the sensor for detection of surface color. The capacitive sensor assembly includes a plurality of copper elements in proximity to a device aperture and contacting an interior surface of the housing and for detection of an object in contact with the copper elements.

Owner:NLIGHT INC

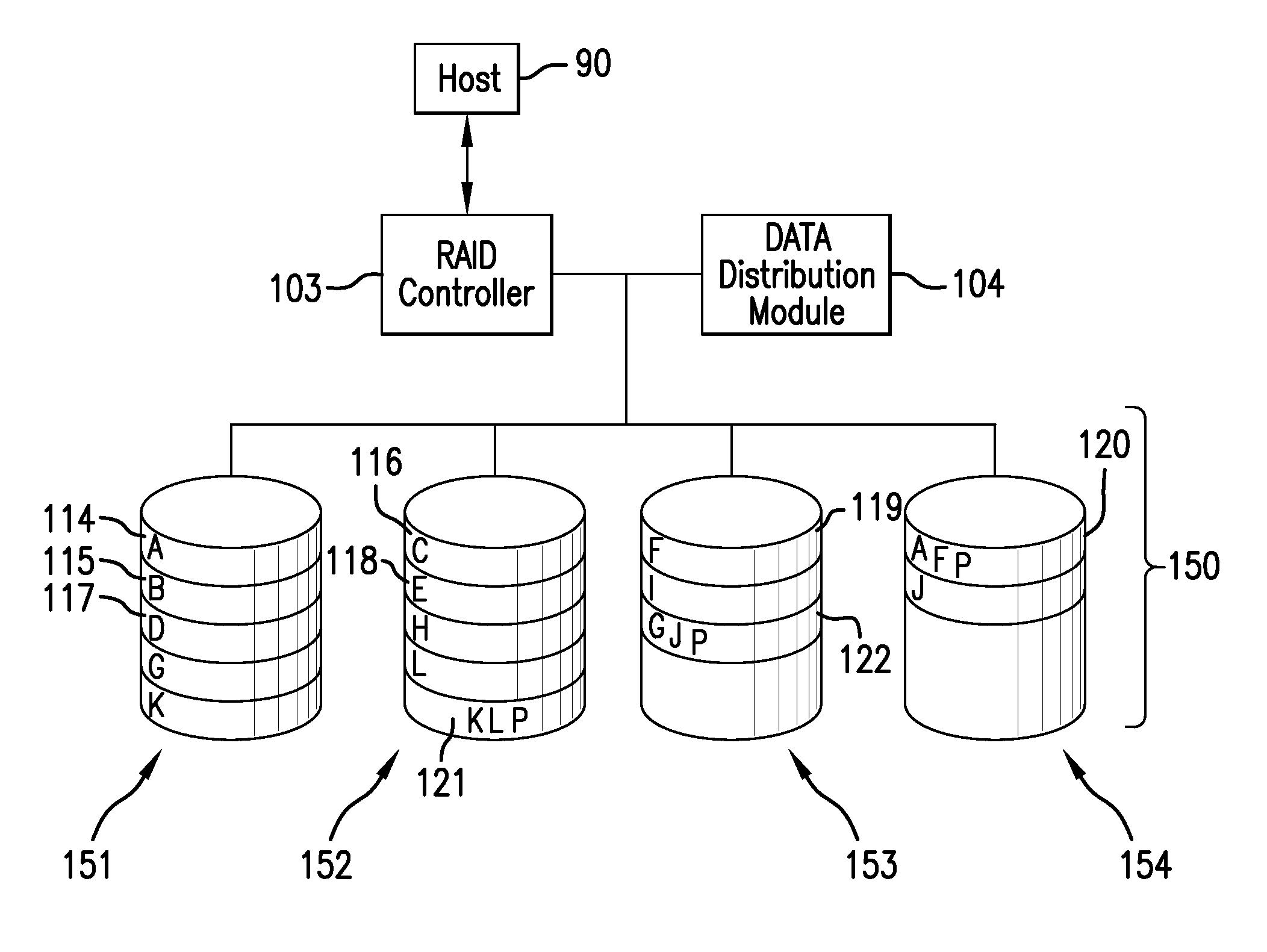

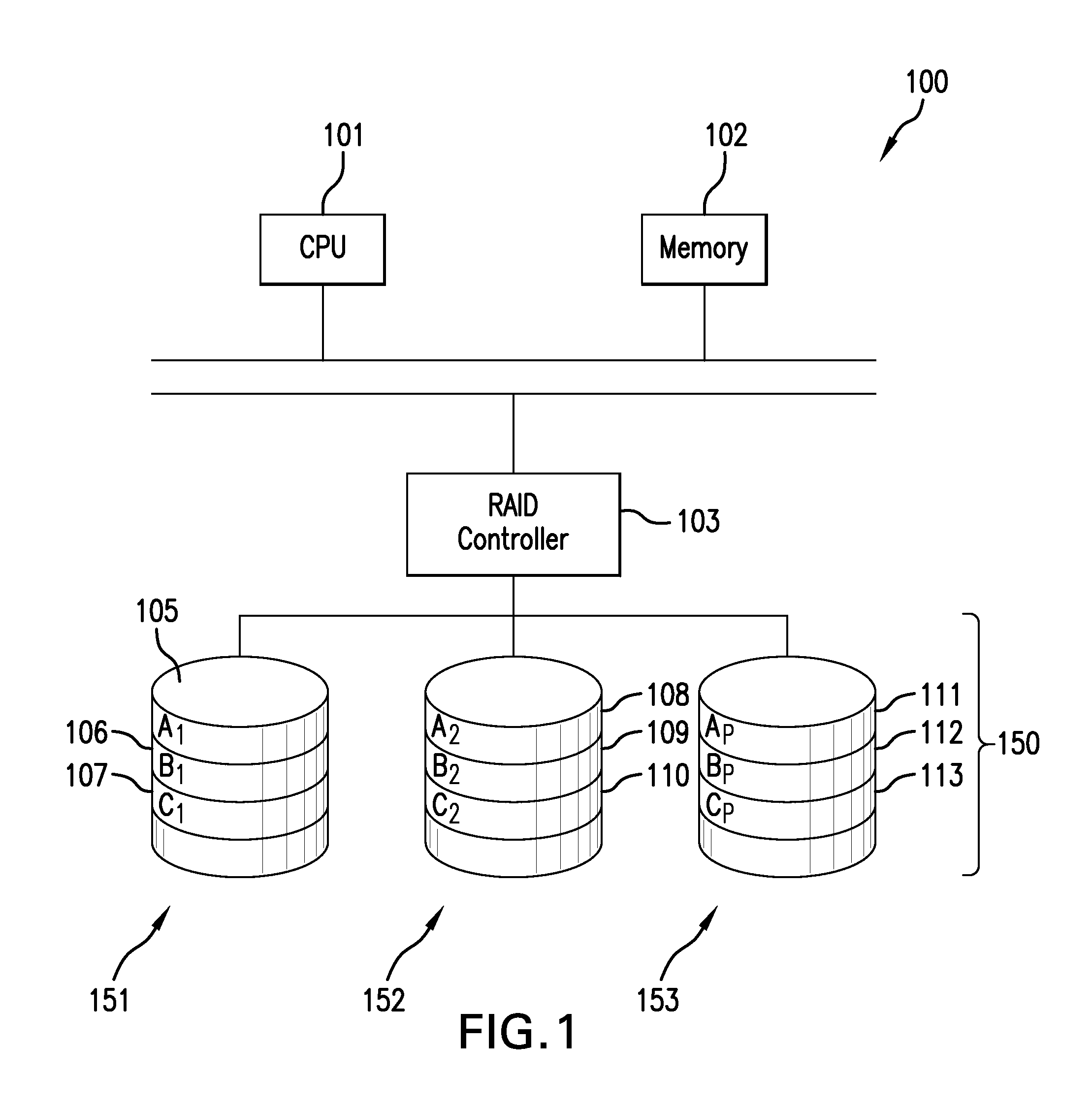

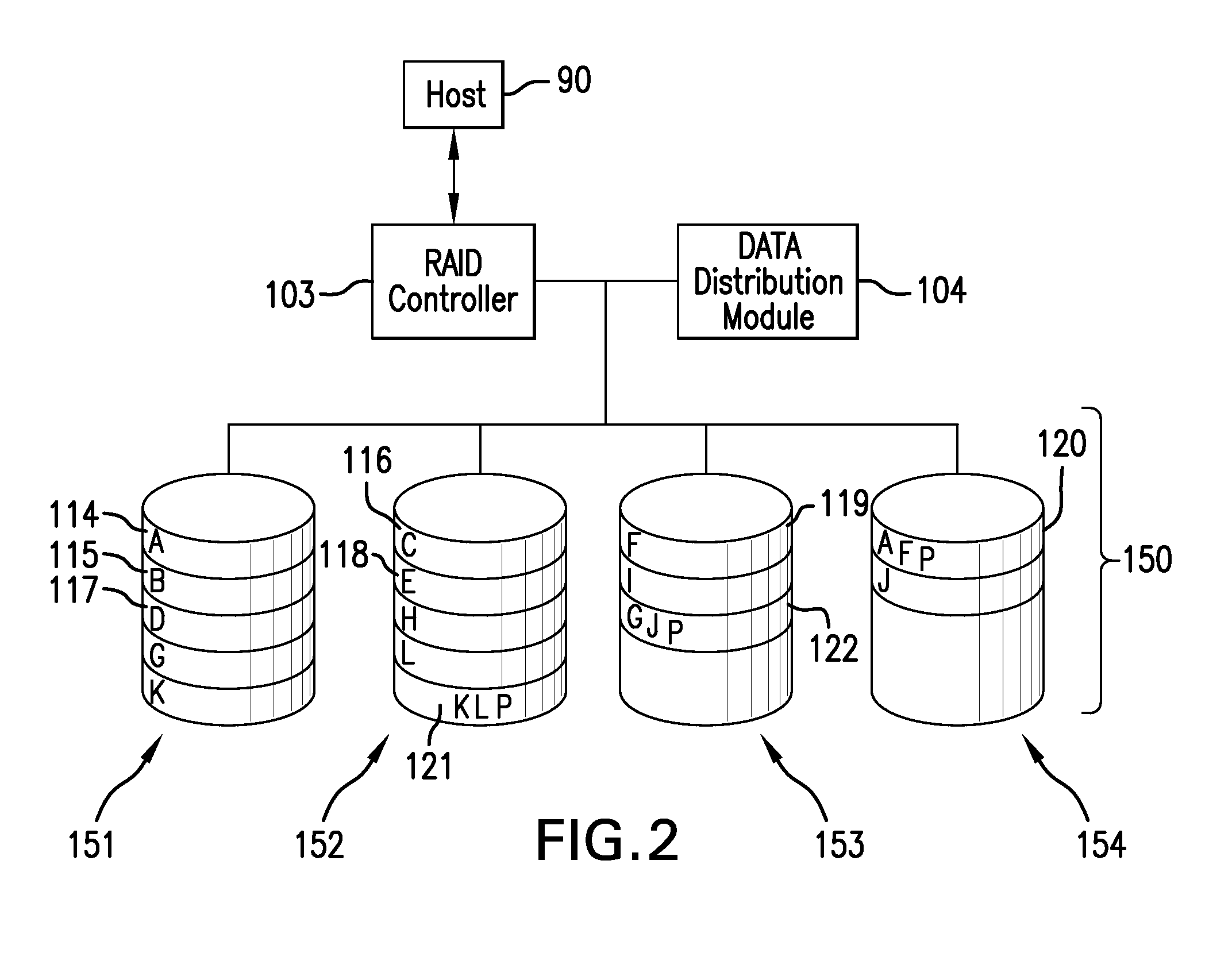

System and method for allocating data in memory array having regions of varying storage reliability

ActiveUS9448883B1Efficient measurementIncrease capacityMemory architecture accessing/allocationMemory adressing/allocation/relocationProbability of errorMemory array

A system and method are provided for efficient allocation of data in a memory array having regions of varying storage reliability. Storage locations for bands of data are selectively allocated in a manner which evenly distributes the probability of error in the data when stored in the memory array in spite of the varying storage reliability. A distribution controller is provided to effect such distribution of data to maintain a collective error rate of each data band within a preselected or predetermined range. The system and method also generally provide for storing at least a first and a second data band in different corresponding sets of storage channels. The system and method also generally provide for at least one of the data bands being stored in regions of differing reliability across the set of storage channels therefor.

Owner:CADENCE DESIGN SYST INC

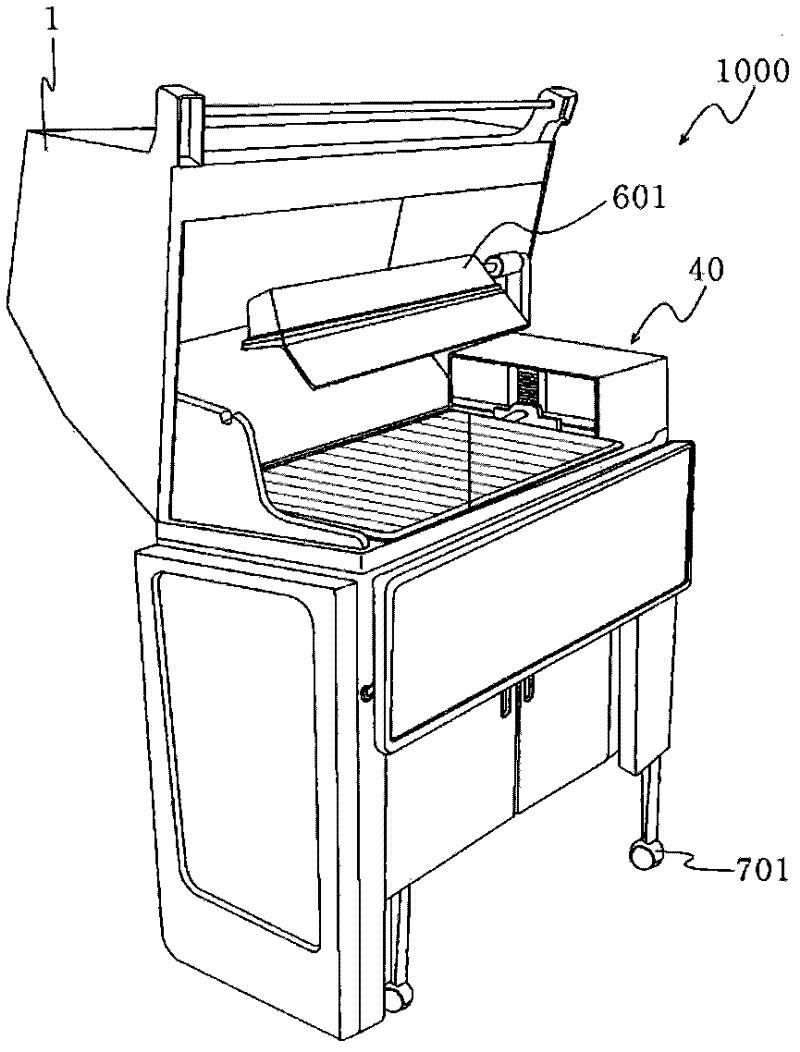

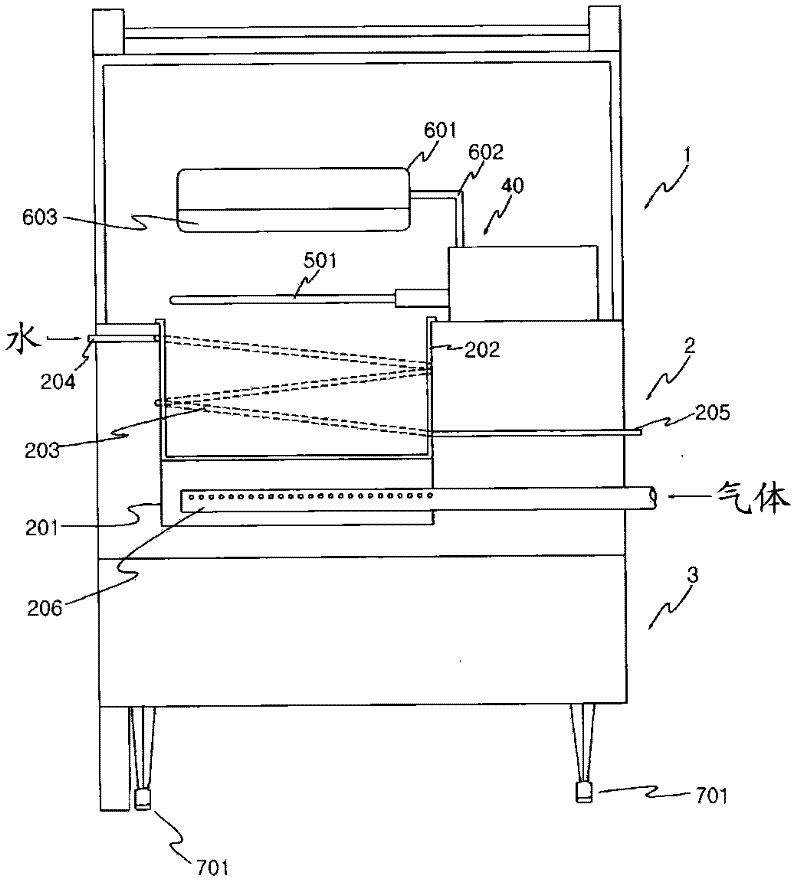

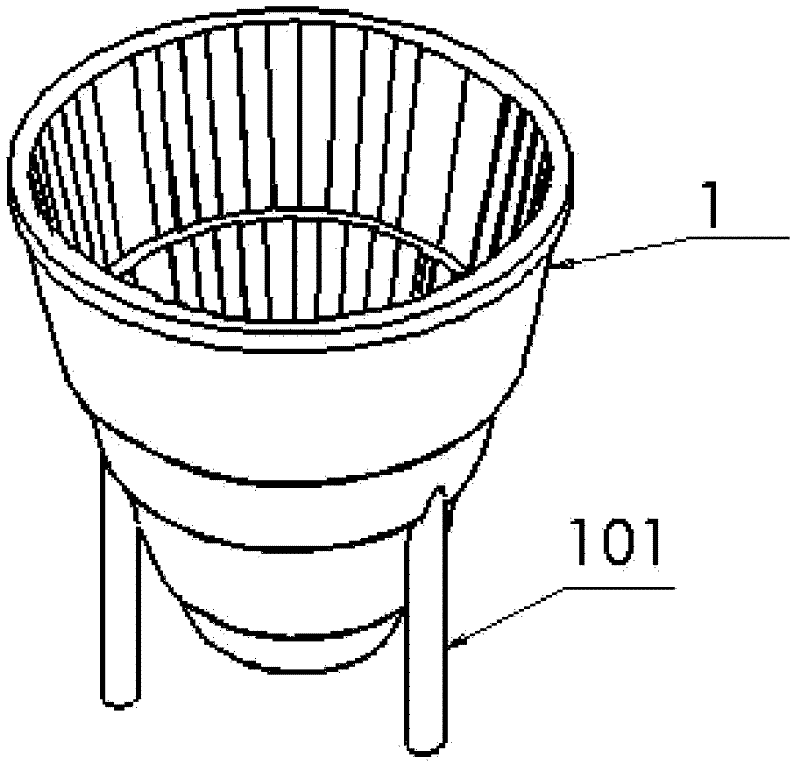

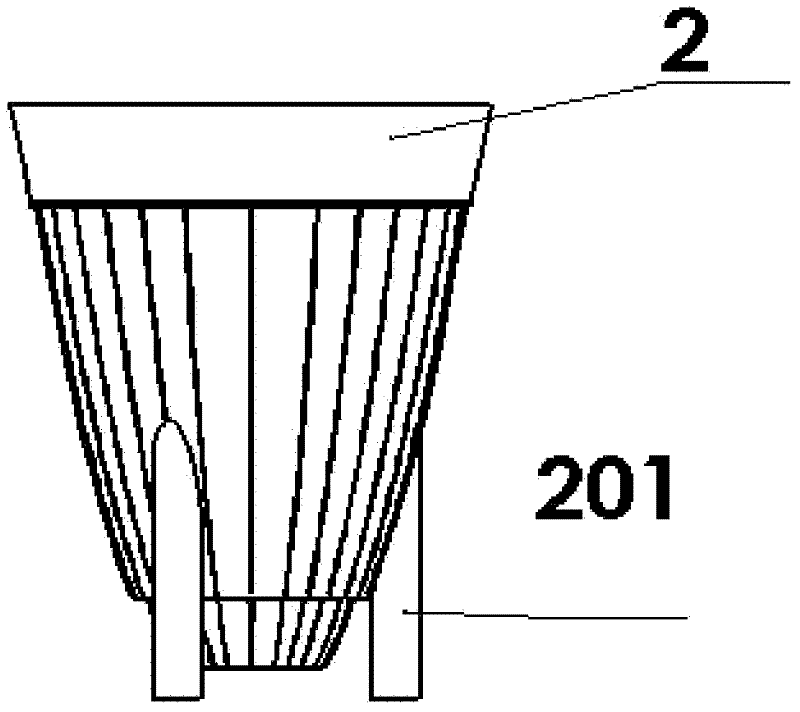

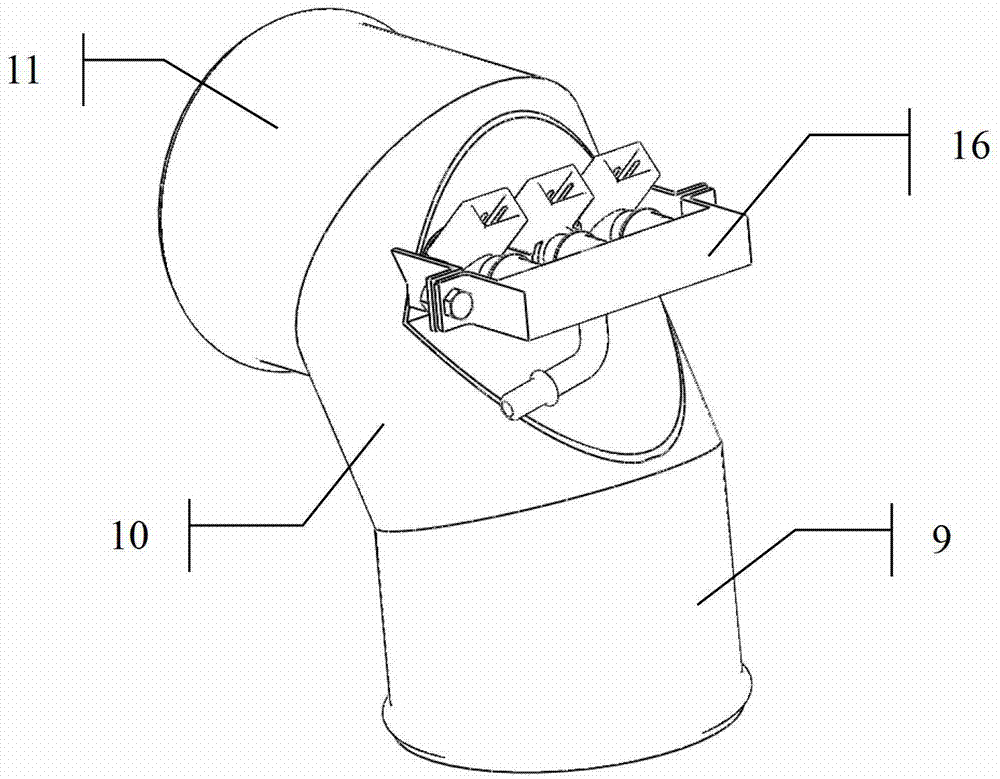

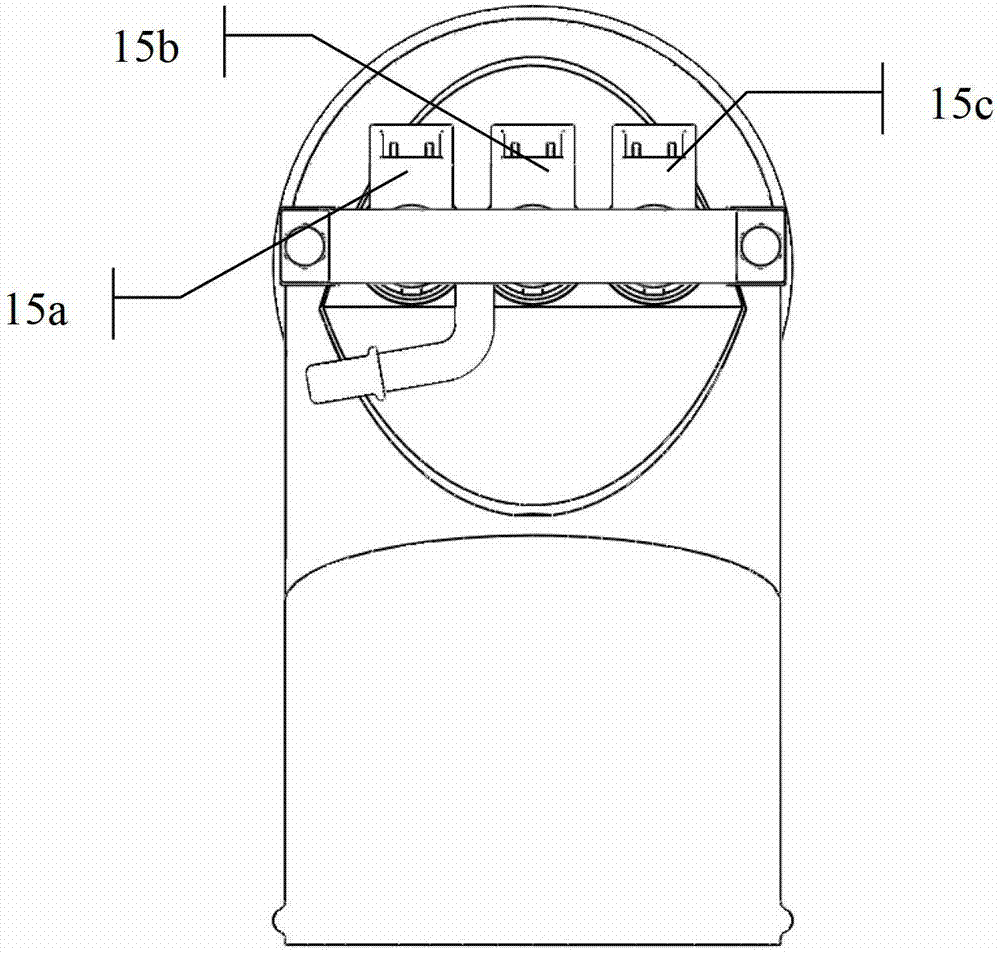

Mobile meat roaster

ActiveCN102378591AImprove work convenienceFree from inhalationRoasting apparatusEngineeringGrilled food

Owner:崔光镐

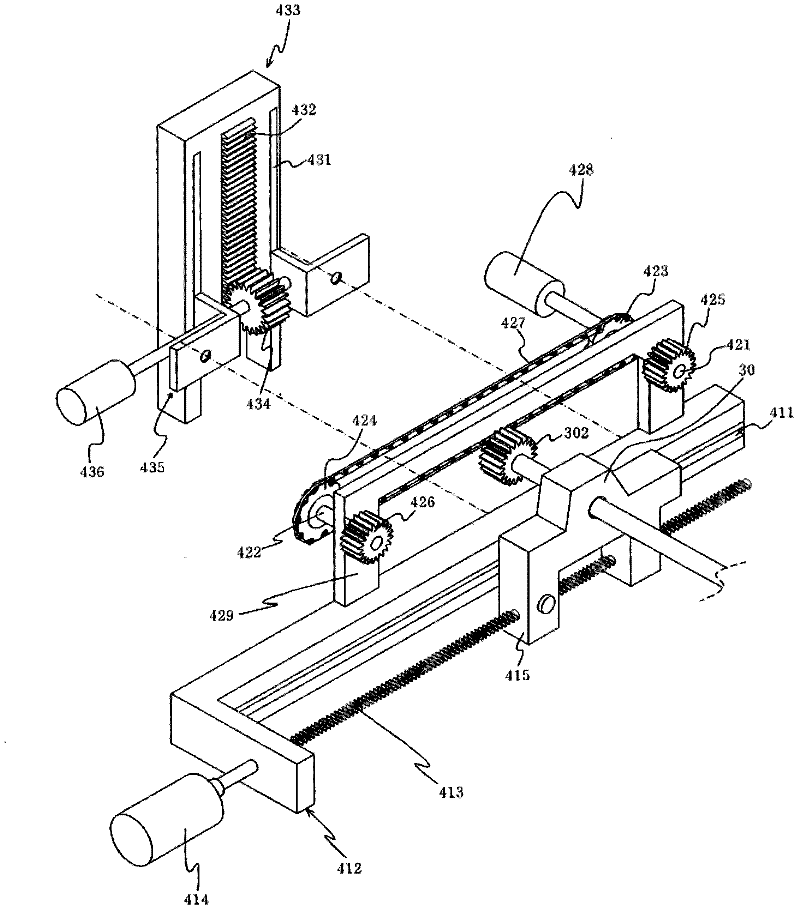

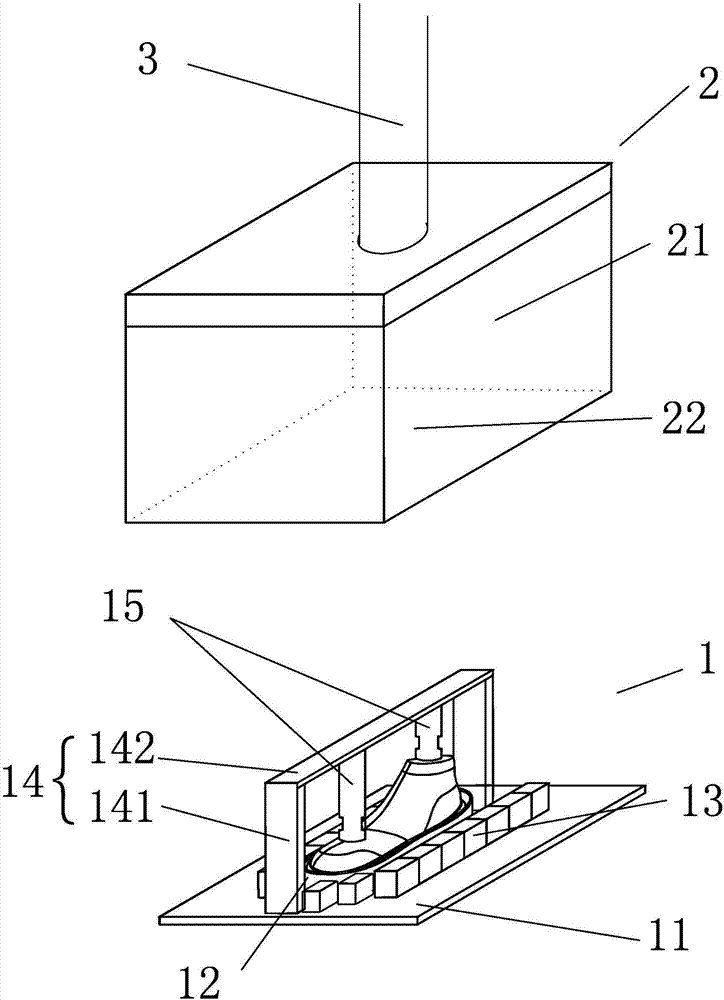

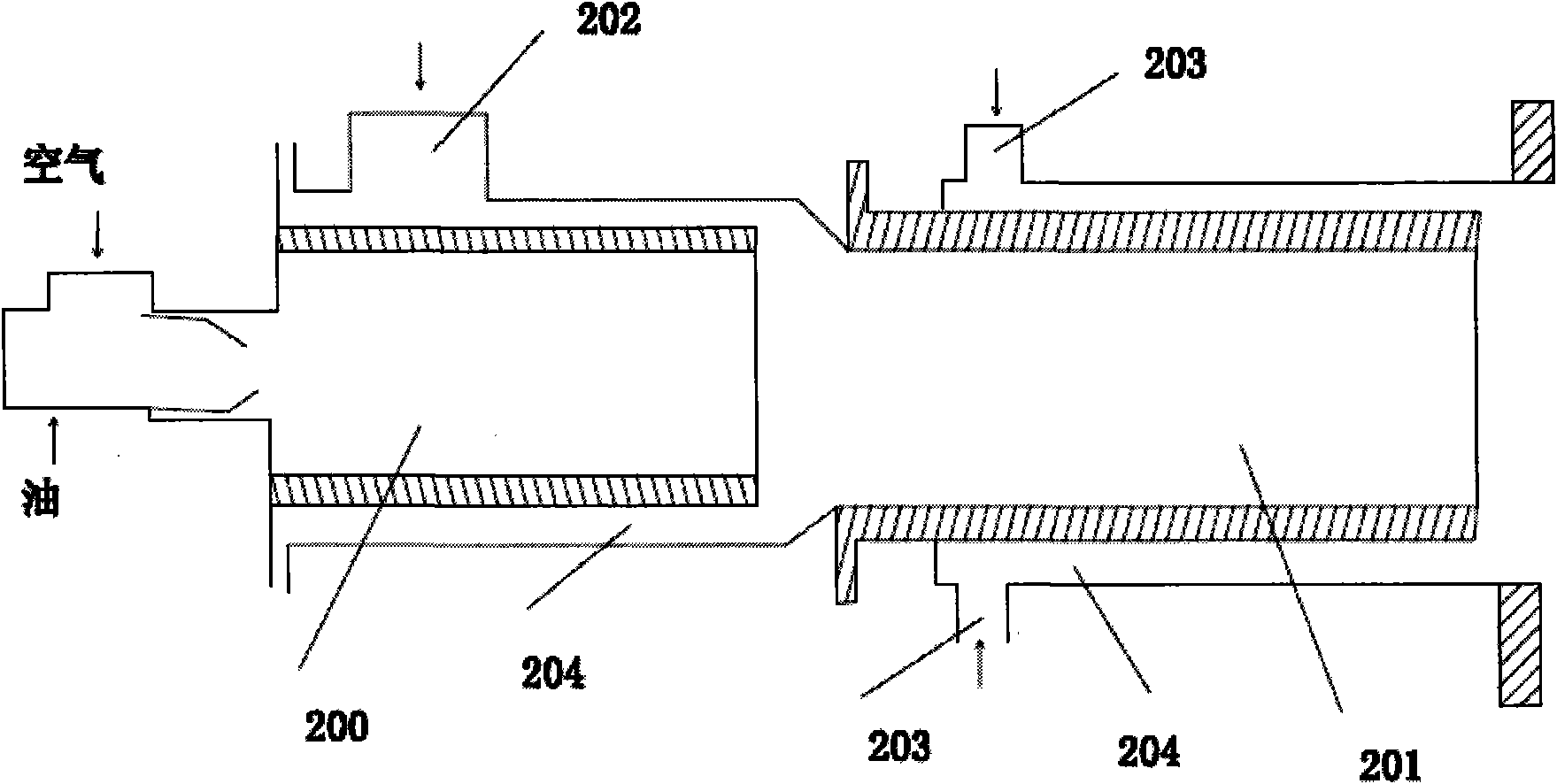

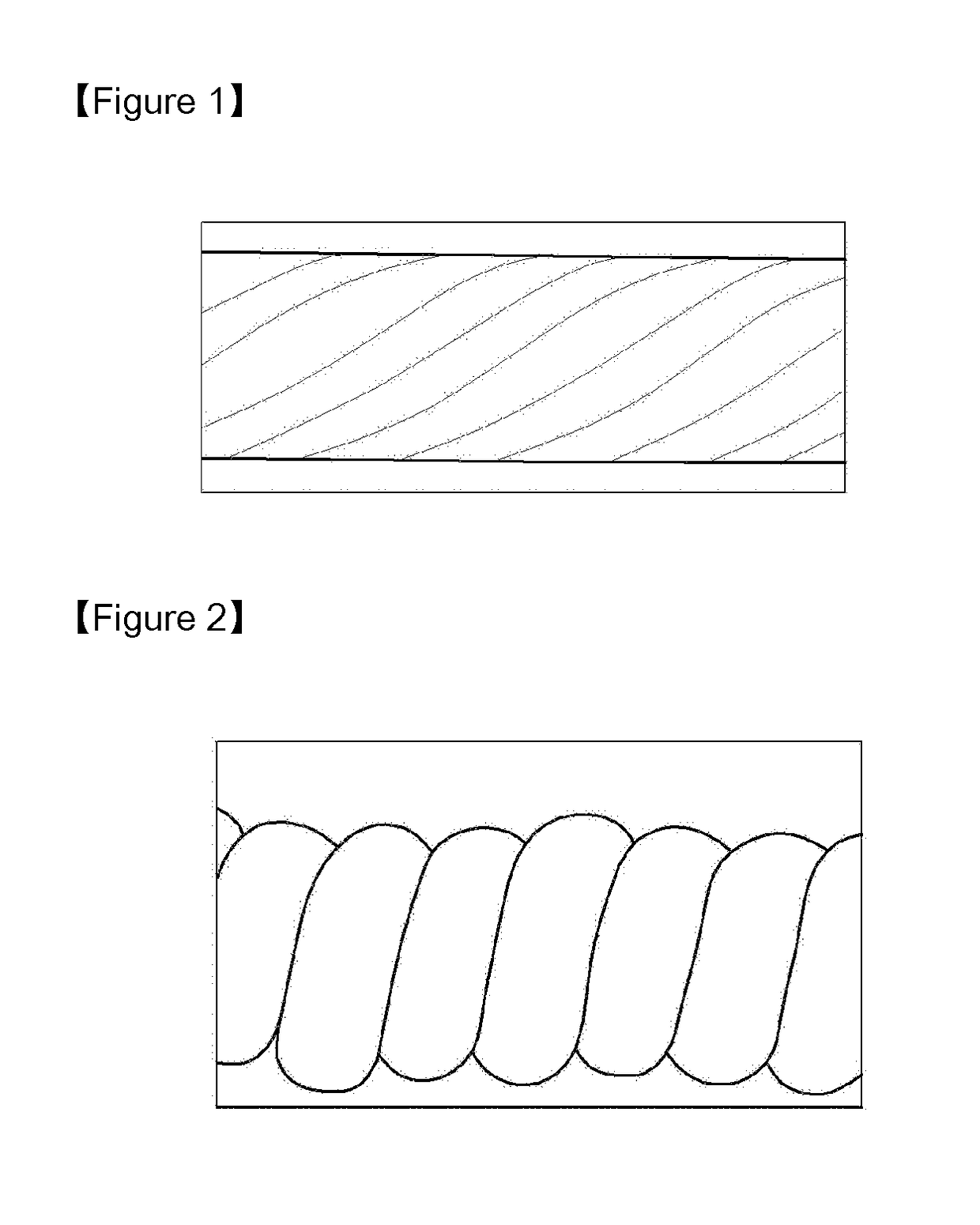

Shoe material thermal-laminating process, shoe material thermal-laminating device and production line thereof

The invention discloses a shoe material thermal-laminating process. The shoe material thermal-laminating process comprises the following steps that 1, shoe materials to be processed are prepared, wherein the shoe materials include a first shoe material and a second shoe material which are to be laminated, a zone to be laminated of the first shoe material and / or a zone to be laminated of the second shoe material undergoes adhesive coating treatment, an adhesive layer is formed through the adhesive coating treatment, and the zones to be laminated and / or an adhesive contain moisture; 2, the zone to be laminated of the first shoe material and / or the zone to be laminated of the second shoe material obtained in the step 1 are correspondingly adhered, and adhesion is kept to obtain a shoe material adhered part; 3, the shoe material adhered part in the step 2 is subjected to microwave heating heat treatment through a microwave heating device to make the first shoe material and the second shoe material bonded and fixed together, and then the first shoe material and the second shoe material which are bonded and fixed together are subjected to low-temperature cold-shaping treatment. The shoe material thermal-laminating process has the advantages of being short in consumed time and simple and reducing the energy consumption.

Owner:SINCETECH FUJIAN TECH CO LTD

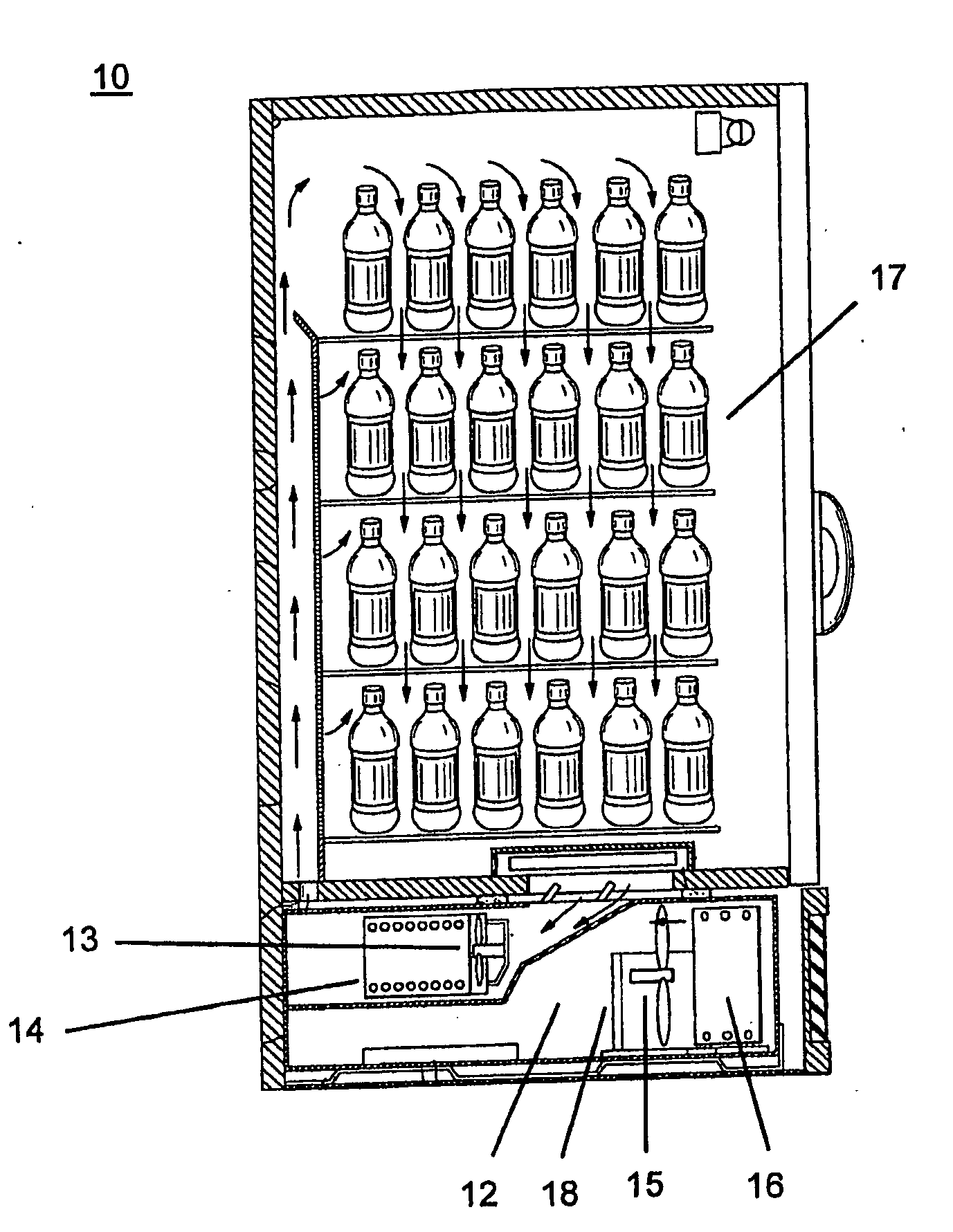

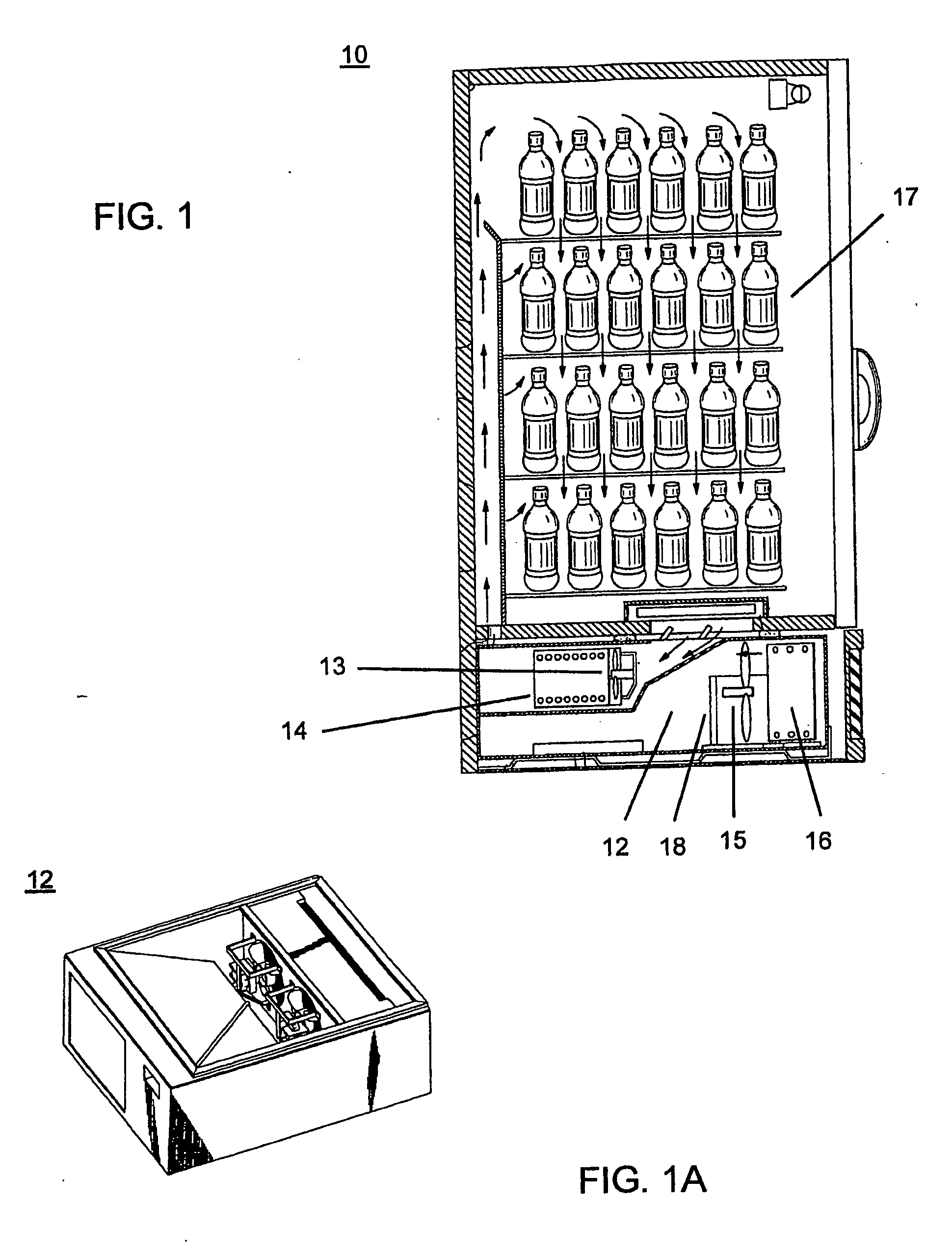

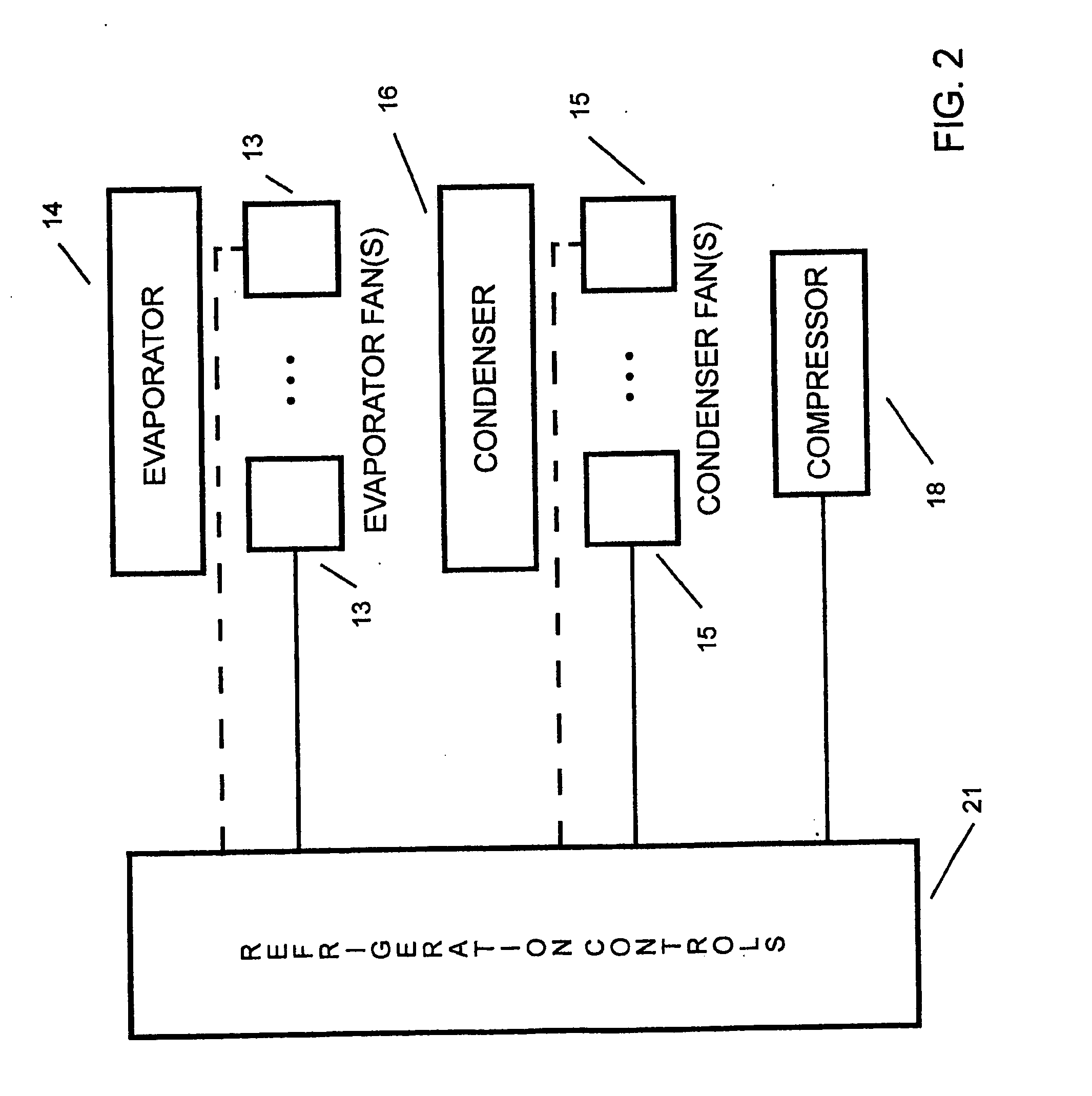

Evaporator fan motor control in a refrigerated merchandiser

InactiveUS20100242506A1Raise transfer toReduce energy consumptionShow cabinetsEvaporators/condensersThermal energyEngineering

A refrigeration apparatus having an evaporator fan motor control includes an evaporator to remove heat energy from the air in a cooled storage space. The evaporator transfers the heat energy to a refrigerant. At least one evaporator fan moves air from the cooled storage space across the evaporator to improve the transfer of heat energy into the refrigerant. The one or more evaporator fans have an energy consumption and generate a waste heat energy. A refrigeration control unit at least controls the operation of the one or more evaporator fans. During an off mode, the one or more evaporator fans are operated in a reduced energy consumption mode to reduce the energy consumption of the one or more evaporator fans and to reduce the waste heat while still defrosting the evaporator in the off mode.

Owner:UNIVERSAL NOLIN

Electrolytic aluminum prebaked anode anti-oxidation insulating coating and preparation method thereof

ActiveCN110964352AHigh strengthHigh purityFireproof paintsAnti-corrosive paintsMetallurgyAluminium oxides

The invention provides an electrolytic aluminum prebaked anode anti-oxidation insulating coating. The electrolytic aluminum prebaked anode anti-oxidation insulating coating comprises the following components in percentage by mass: 60%-75% of a main component, 0.01%-5% of a secondary component, 24%-34% of a nano solvent binding phase and 0.01%-5% of a coating stabilizing phase, wherein the main component comprises amorphous aluminum oxide, nano-scale rho-Al2O3, nano-scale gamma-Al2O3 and nano-scale alpha-Al2O3. The insulating coating prepared by the invention can be cured at normal temperaturefor 6-8 hours after being sprayed to an anode by a spraying machine, the anode coating can form a compact net-shaped structure at the working temperature of 500-800 DEG C, the long-term tolerable temperature is over 900 DEG C, and the physical and chemical properties are stable.

Owner:CENT SOUTH UNIV +1

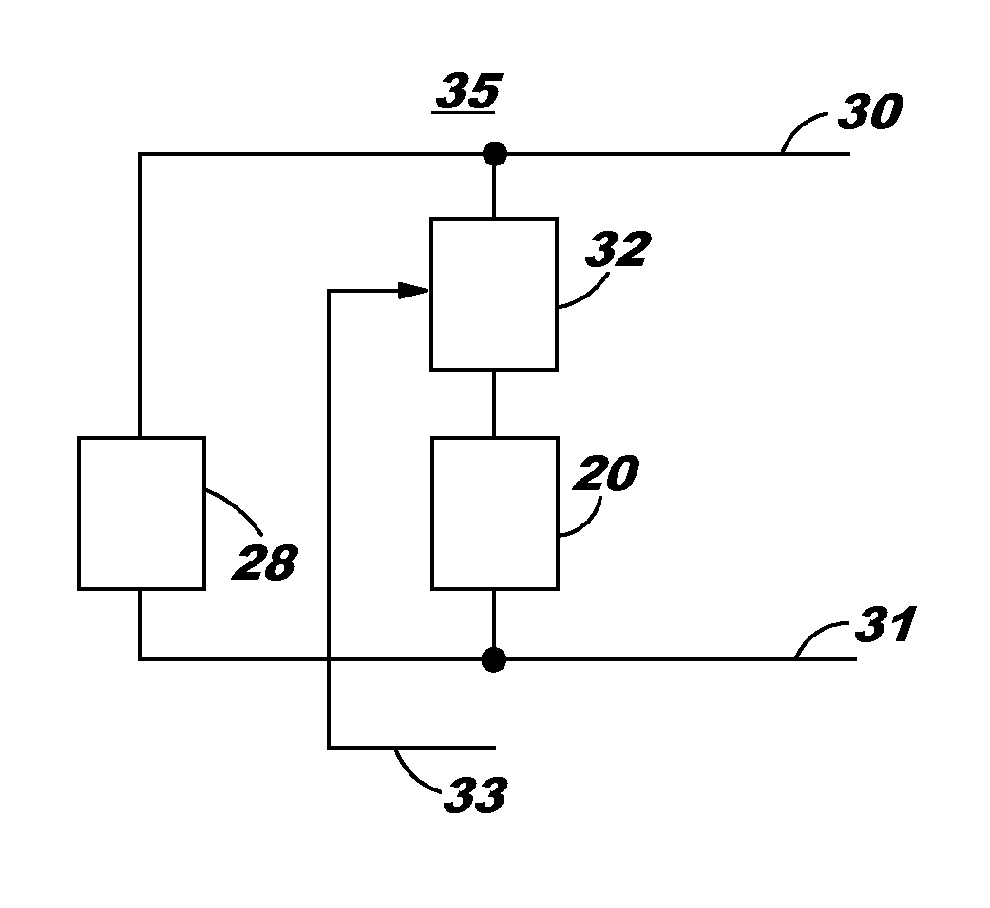

Energy storage systems and methods

ActiveUS9272627B2Minimize occurrenceReduce waste heatElectric signal transmission systemsBatteries circuit arrangementsElectrical batteryEngineering

In an energy storage system that includes a battery and an ultracapacitor, the state of charge (SOC) of the capacitor is the subject of a dynamic set-point. This dynamic set-point control is a function of the load regime to which the storage system is exposed, for example a hybrid automobile or electric automobile. The control may be based in part upon real-time fast Fourier transform analysis of load current, permitting real-time adjustment of control coefficients. In this way, it is possible to minimize the occurrence of the capacitor being fully charged at a time when it would be desired to be able to absorb high current, for example from regenerative braking. Likewise it is possible to minimize the occurrence of the capacitor being nearly discharged at a time when it would be desirable to have boost power available. A result is that even a relatively small ultracapacitor (having perhaps one two-hundredth the energy storage capacity of the battery) can permit greatly reducing waste heat dissipated in the battery, and can reduce otherwise unnecessary cycling of current into and out of the battery. This can extend battery life and battery performance.

Owner:UCAP POWER INC

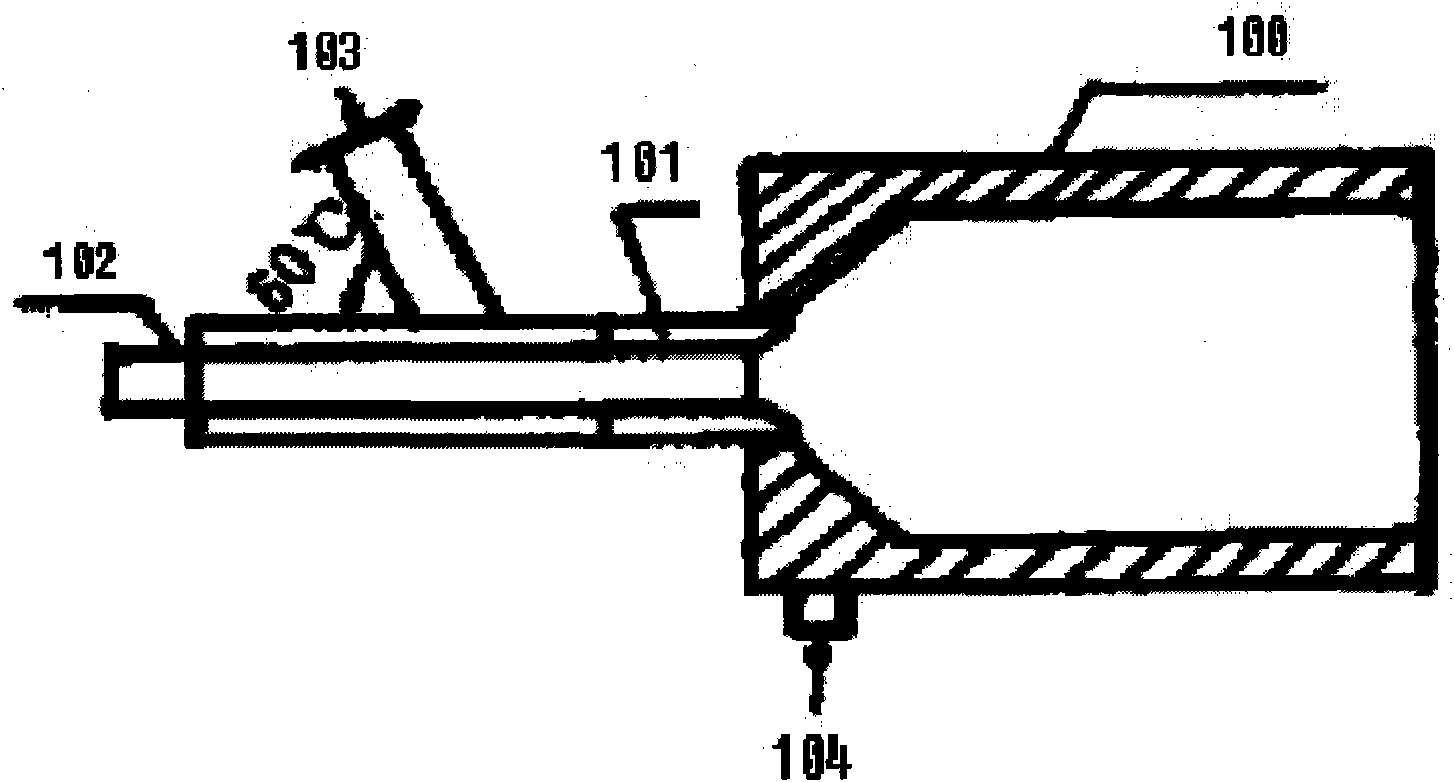

Oxygen-enriched burner

InactiveCN101556039ASave high-grade energySaving grade energyChemical industryDispersed particle separationCombustorFlue gas

The invention discloses an oxygen-enriched burner which comprises a burner communicated with a hearth and an oxygen-enriched gas generator that includes an air separator, an air inlet pipe, a nitrogen outlet pipe and an oxygen-enriched gas outlet pipe; wherein, the air inlet pipe, the nitrogen outlet pipe and the oxygen-enriched gas outlet pipe are respectively connected with three ports of the air separator; the burner comprises an inner bushing, a middle bushing, an outer bushing and a connecting pipe between the inner and the outer bushings, wherein, the inner bushing is arranged inside the middle bushing which is positioned inside the outer bushing, one end of the inner bushing is connected with one end of the outer bushing by the connecting pipe between the inner and the outer bushings, the other end of the inner bushing is communicated with an inlet of the hearth, and the other end of the outer bushing is an inlet of regenerative cycle flue gas; one end of the middle bushing is communicated with an inlet of the hearth, and the other end thereof is an inlet of coal dust and oxygen-enriched gas. The oxygen-enriched burner leads the oxygen-enriched gas and the coal dust to be fully and evenly mixed together, and improves the heat exchange efficiency of preheating the coal dust by back-flow gas, so as to overcome the defects of the existing oxygen-enriched combustion technology.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

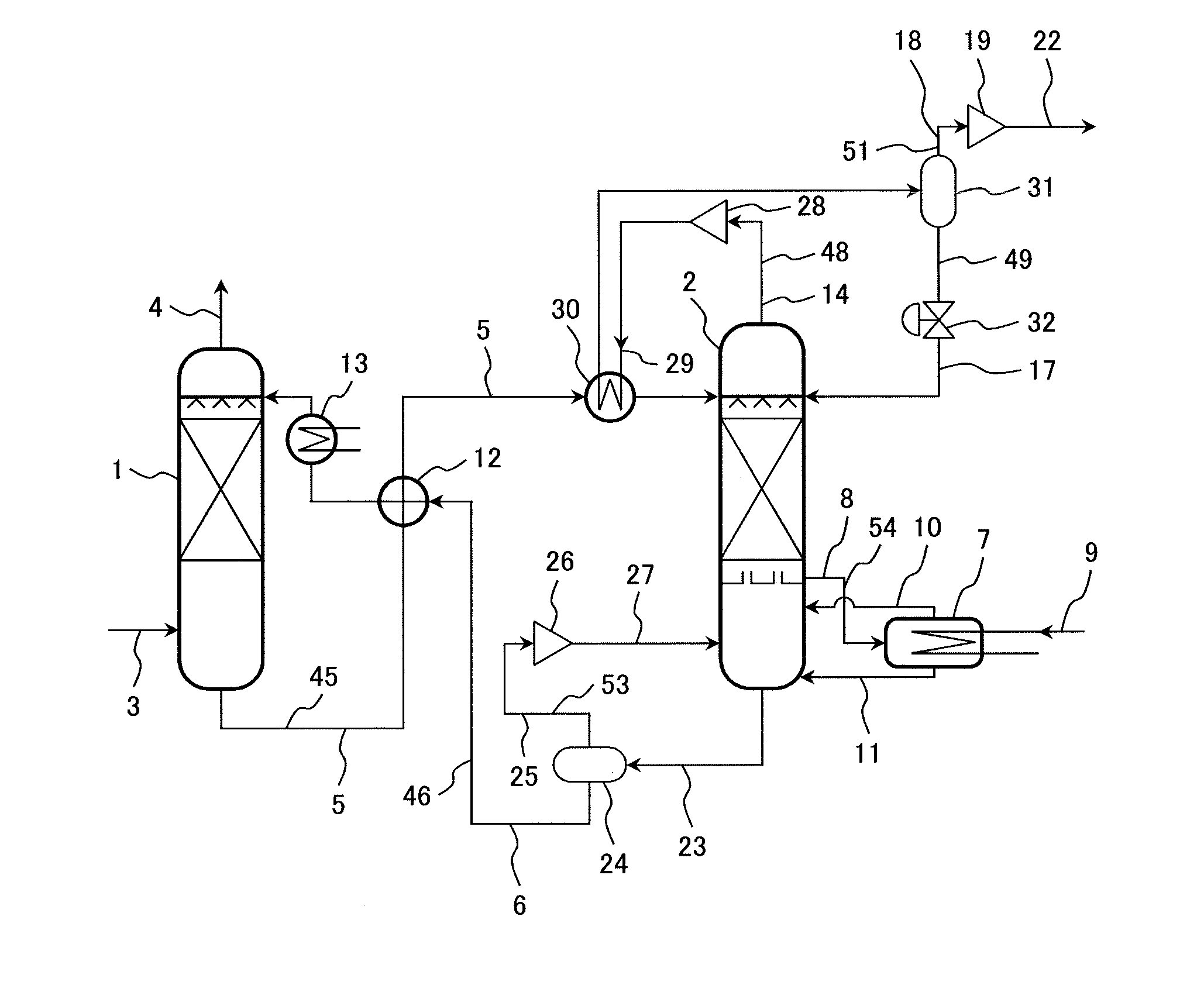

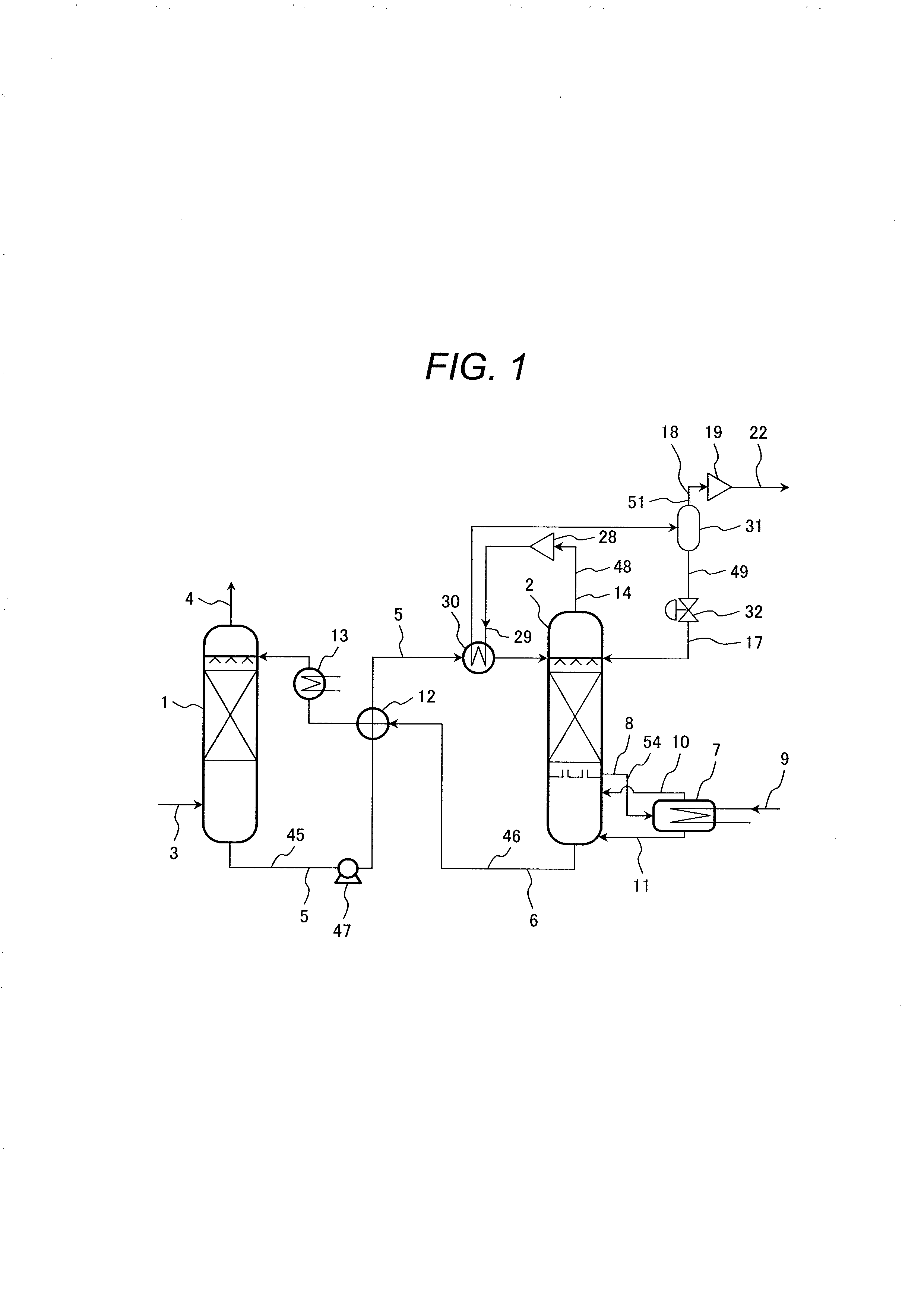

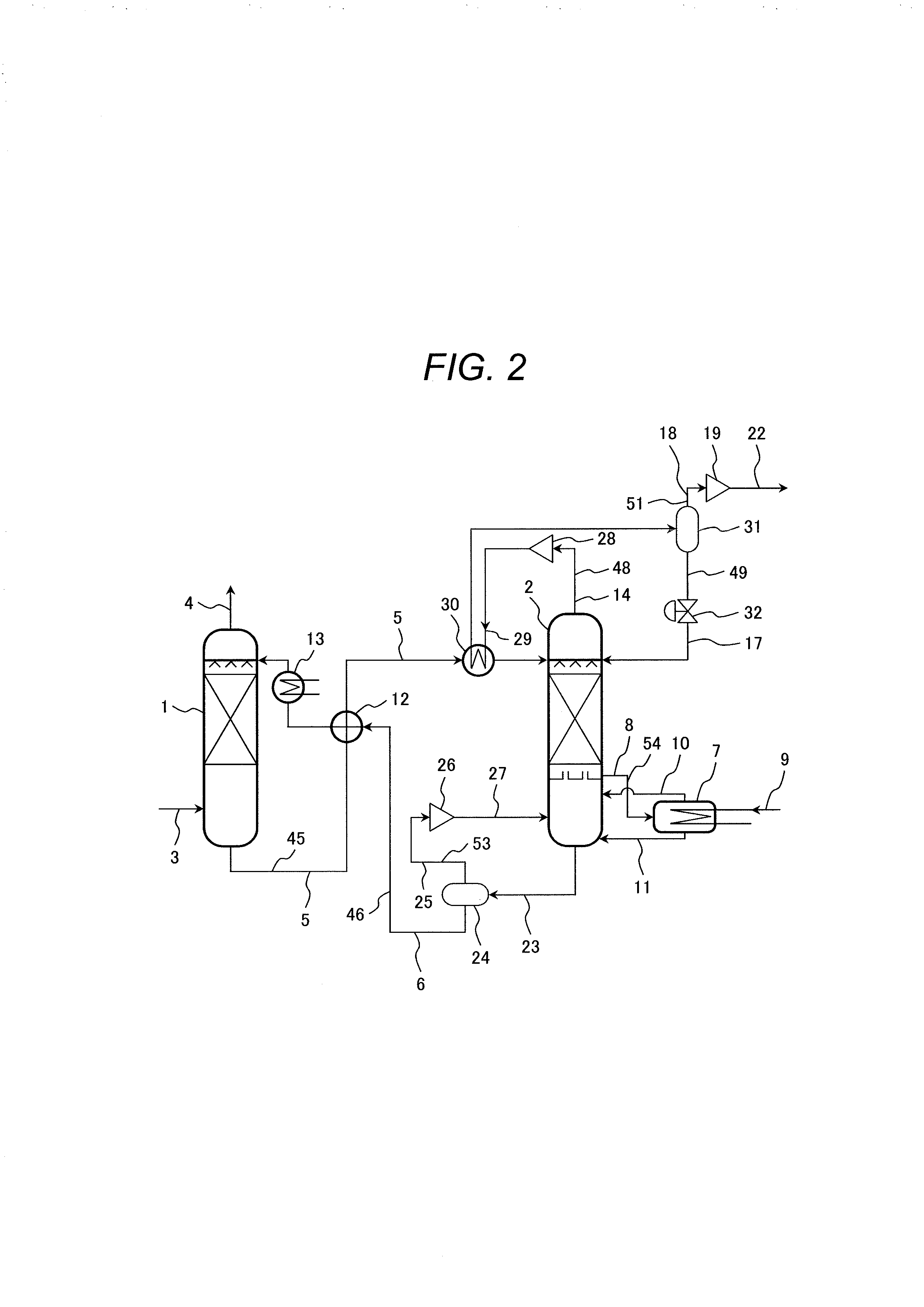

CO2 Capture System by Chemical Absorption

InactiveUS20130177481A1Increase energy efficiencyReduce cool exhaust heatGas treatmentLevel controlExhaust gasSolvent

The CO2 capture system by chemical absorption for removing CO2 from a combustion exhaust gas by a solvent, comprising: an absorber for absorbing CO2 by a solvent, a regenerator for heating a rich solvent absorbed CO2 thereby releasing CO2, a gas exhaust system for discharging gas from the regenerator, a gas compressor installed in the gas exhaust system, a heat exchanger disposed downstream of the gas compressor for exchanging heat between compressed gas and rich solvent to be supplied to the regenerator, a gas-liquid separator disposed downstream of the heat exchanger for separating gas from condensed water, a condensed water supply system for supplying condensed water from the gas-liquid separator to the regenerator, another gas exhaust system for discharging gas containing high-concentration CO2 from the gas-liquid separator, and a compressor disposed downstream of the gas-liquid separator in the another gas exhaust system for pressurizing the gas containing high-concentration CO2.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

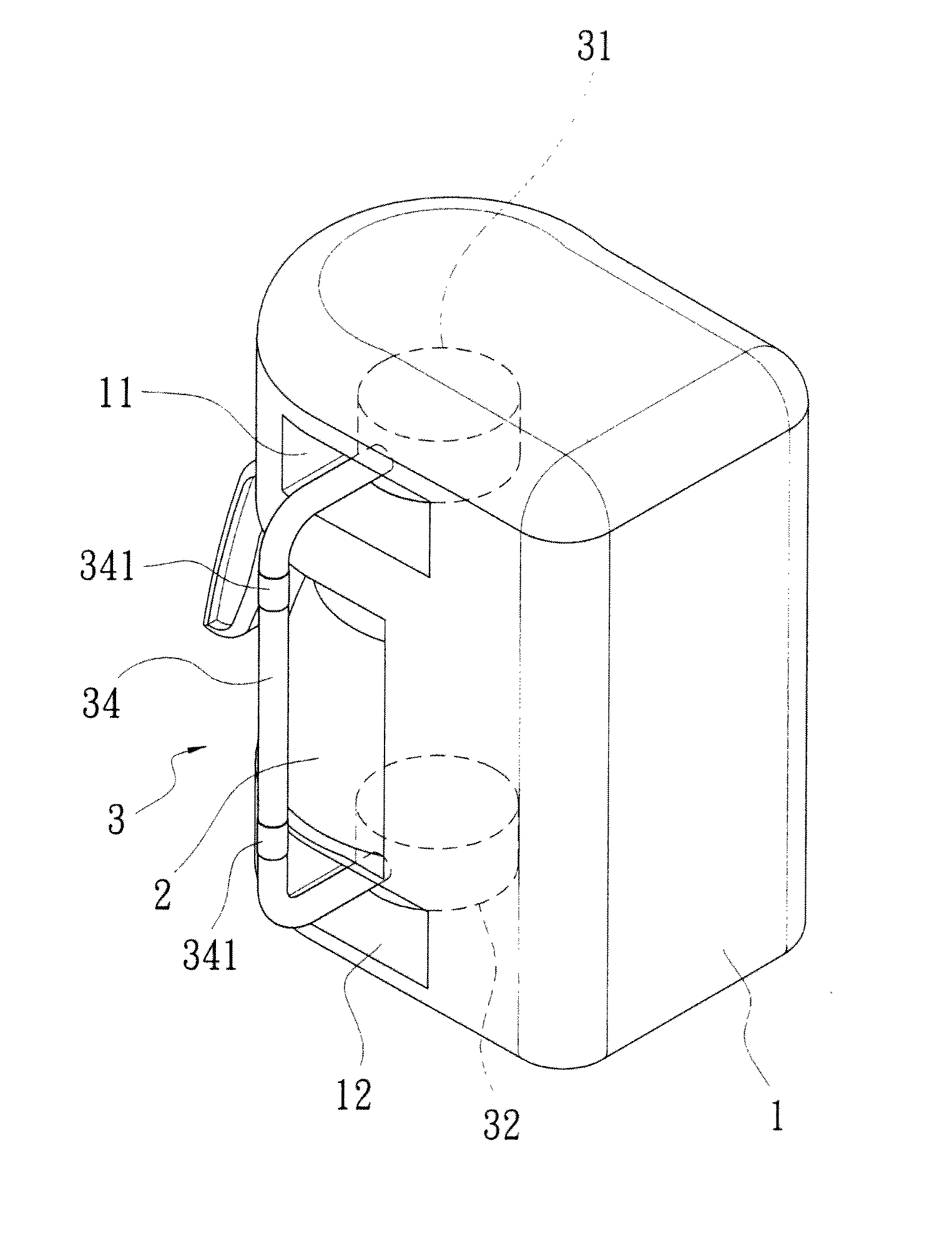

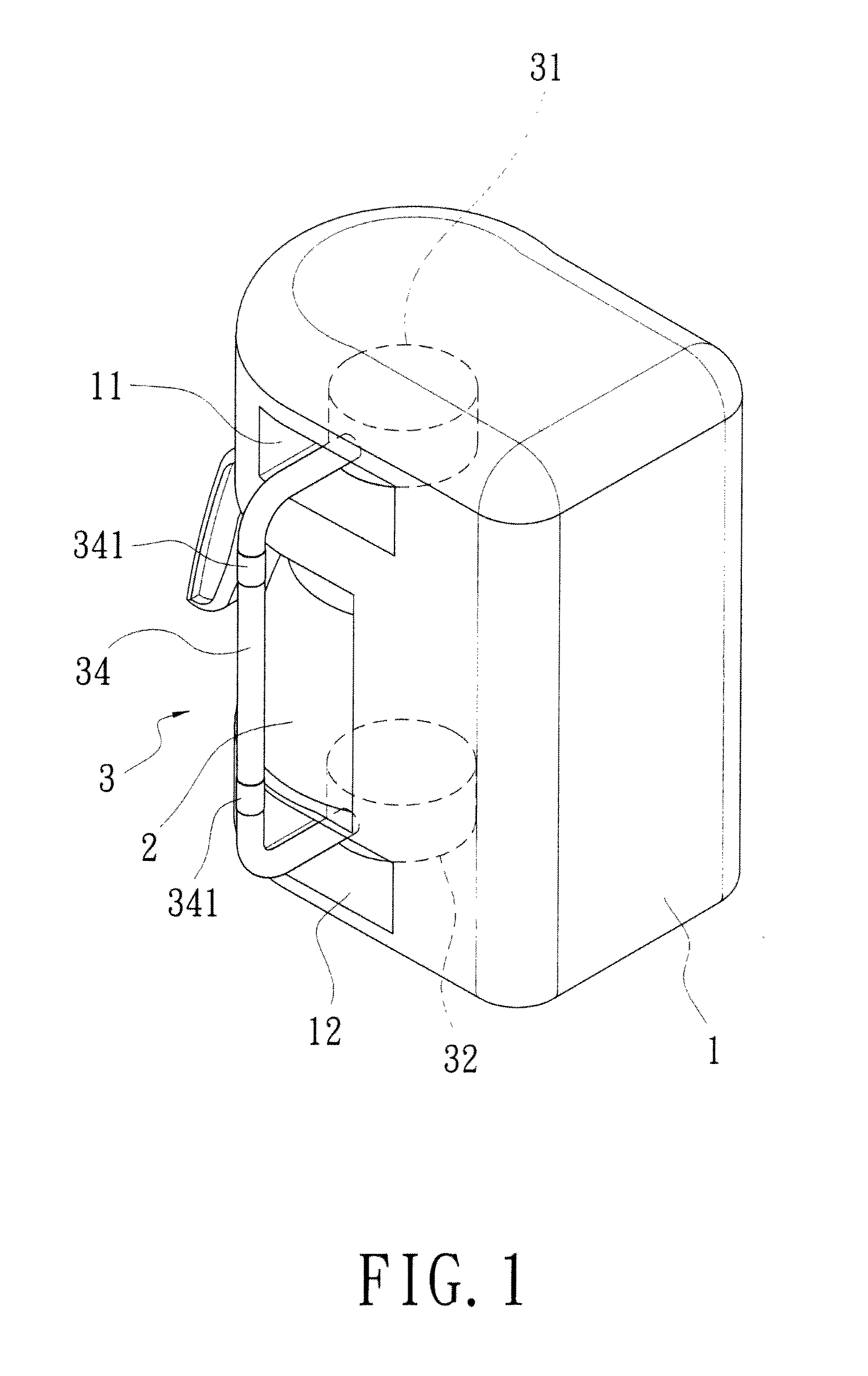

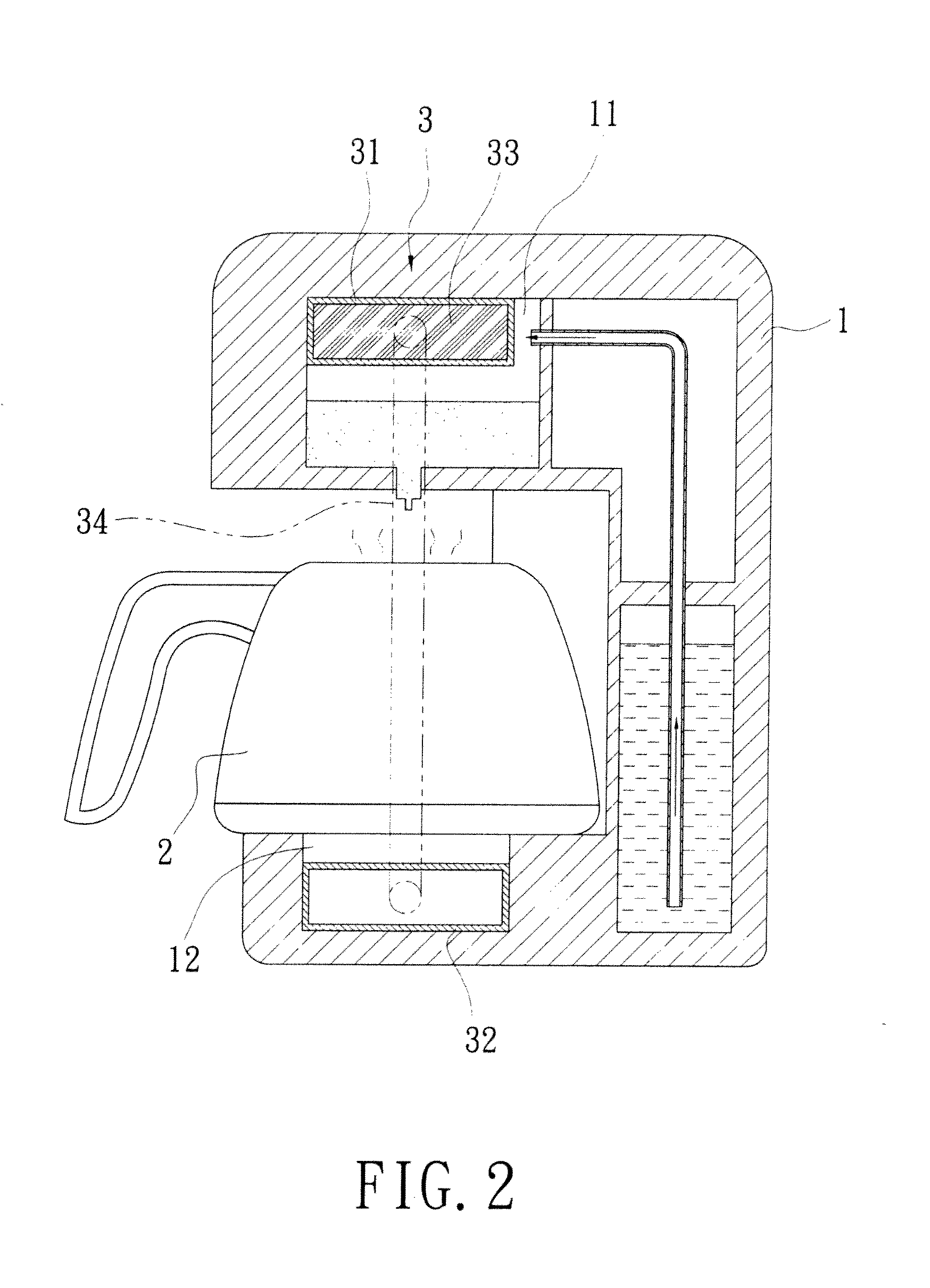

Energy-saving and heat preservation device

InactiveUS20120211483A1Reduce power consumptionImplement extensionsDomestic stoves or rangesElectrical heating fuelHeat conservationProcess engineering

An energy-saving and heat preservation device is mainly a heat preservation device for heating device and receptacle. Upper and lower receiving tanks opened to outside and opposite to upper and lower ends of a receptacle respectively are provided in the heating device, while a first and a second chambers opposite to each other are provided in the heat preservation device. Energy storage material, which is a coagulation type phase-change material, is received within the first chamber. A conduit is connected between the first and the second chambers to form an integral connection arrangement. Hence, waste heat generated in the heating process is collected and stored, and is used for heat preservation. Not only the exhausted waste heat, which later becomes heat load of air conditioning apparatus, can be reduced but also power consumption for heat preservation can be lowered.

Owner:SOUTHERN TAIWAN UNIVERSITY OF TECHNOLOGY

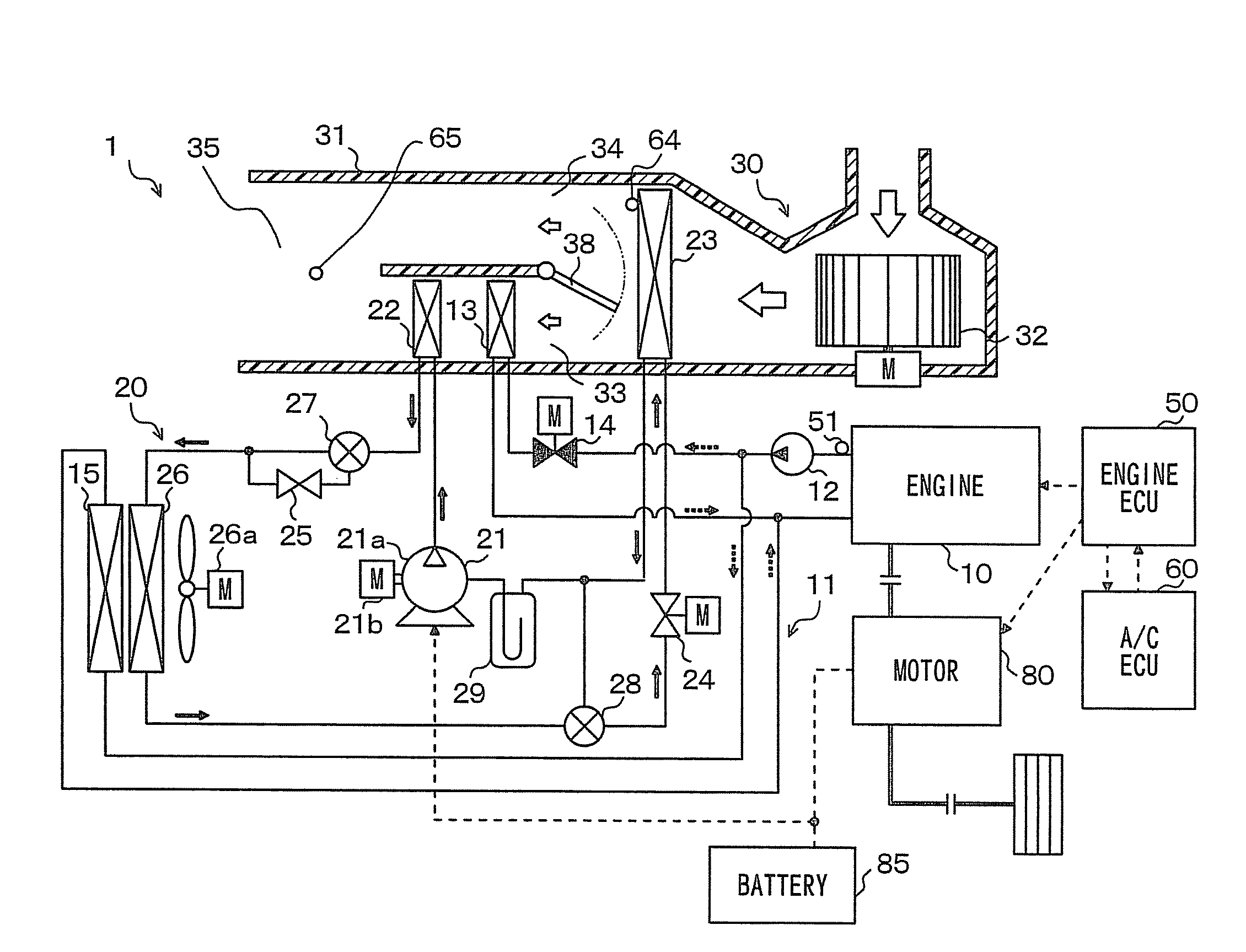

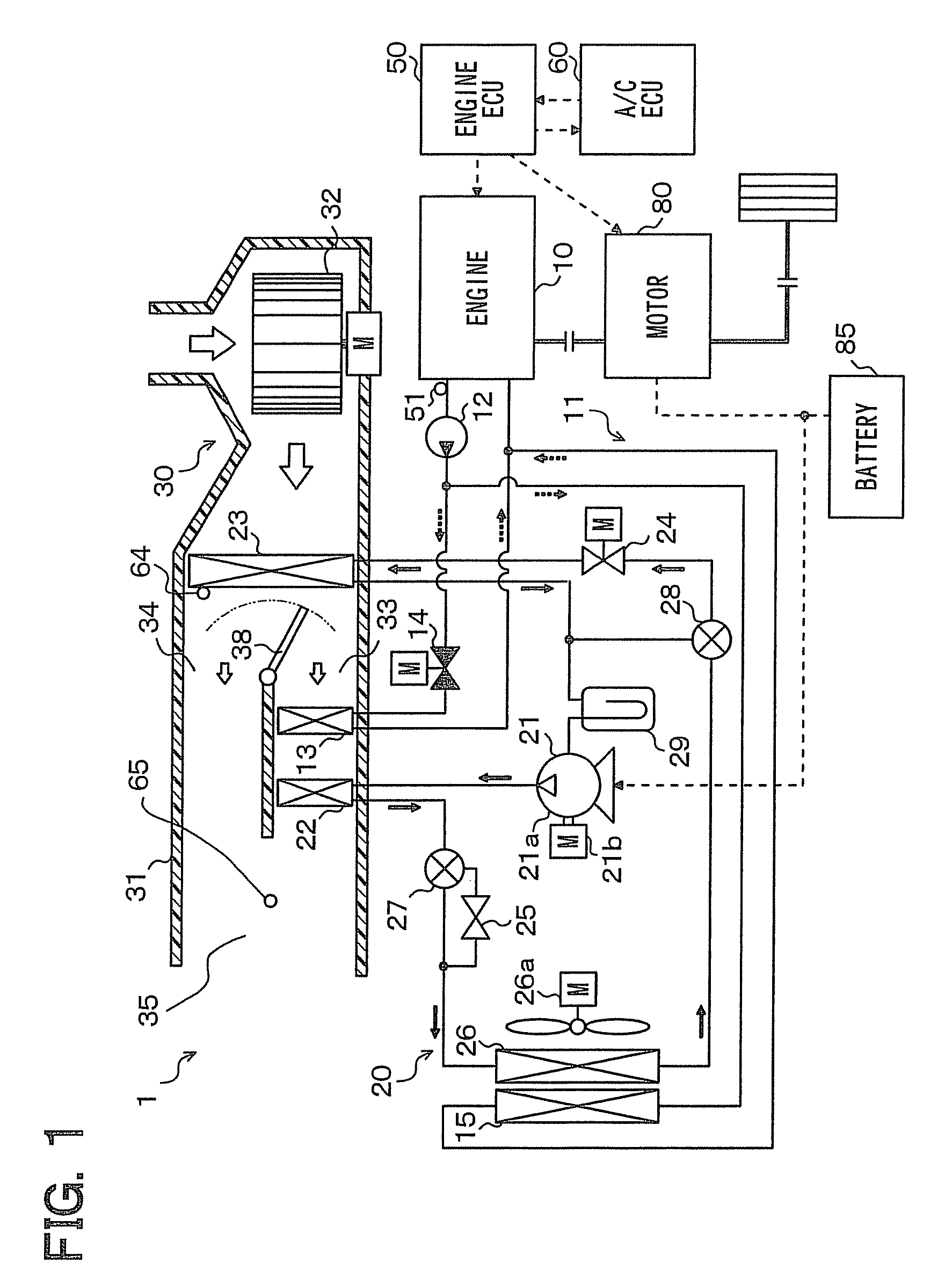

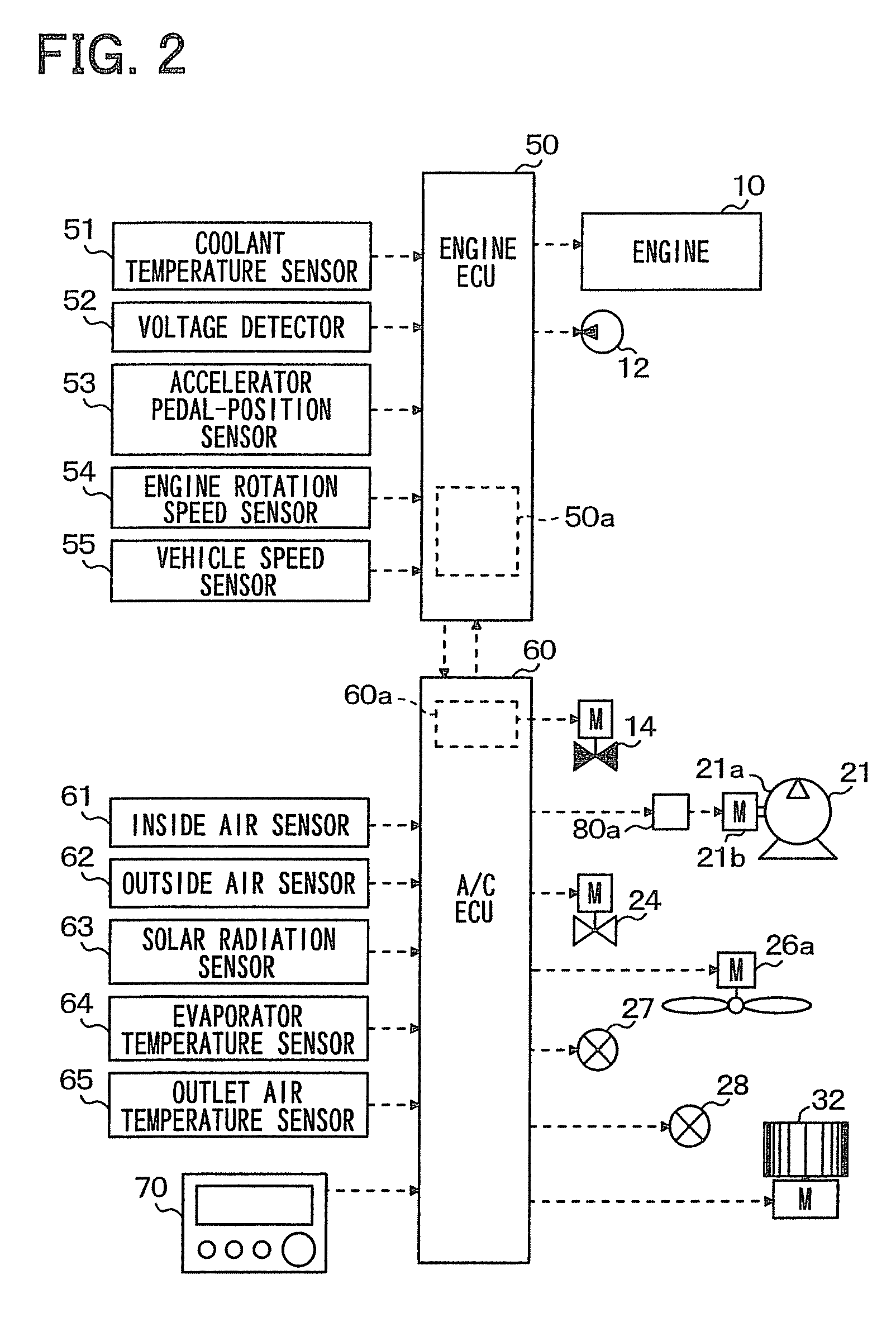

Air conditioner for vehicle

InactiveUS8688322B2Reduce the temperatureReduce frequencyAir-treating devicesDigital data processing detailsPower conditionerIn vehicle

An air conditioner for a vehicle in which an operational efficiency of an in-vehicle equipment is controlled, includes a first heating portion which heats air to be blown into a vehicle compartment by using heat medium, a second heating portion which heats the blown air by using heating energy outputted from the in-vehicle equipment, a determination portion which determines a target heat amount ratio that is a target value of a heating amount ratio of a second heat amount used in the second heating portion to a first heat amount used in the first heating portion, and a heating adjustment portion which adjusts at least one of the first and second heat amounts such that the heat amount ratio approaches the target heat amount ratio. The target heat amount ratio is increased in accordance with an increase of the operational efficiency.

Owner:DENSO CORP

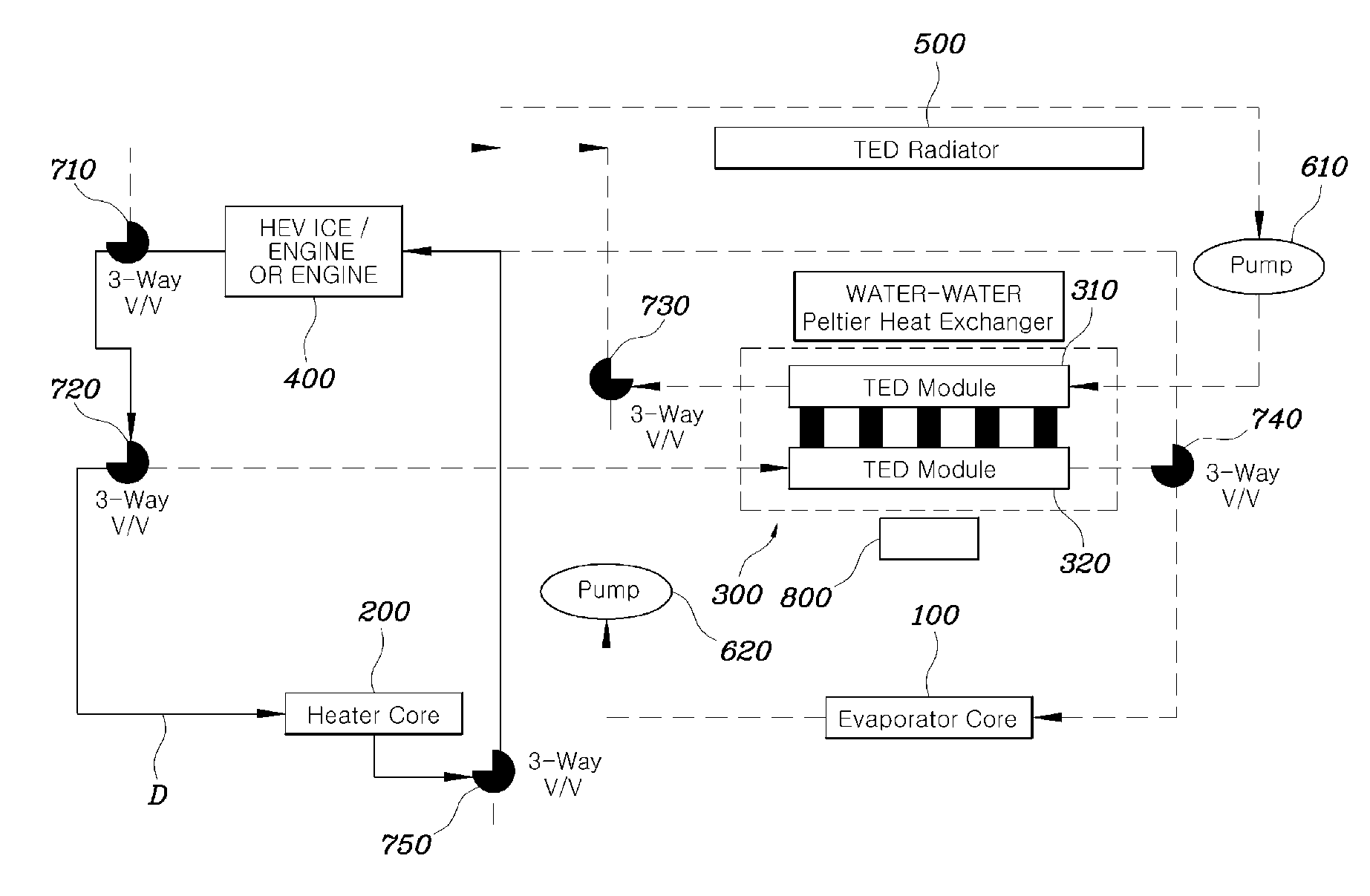

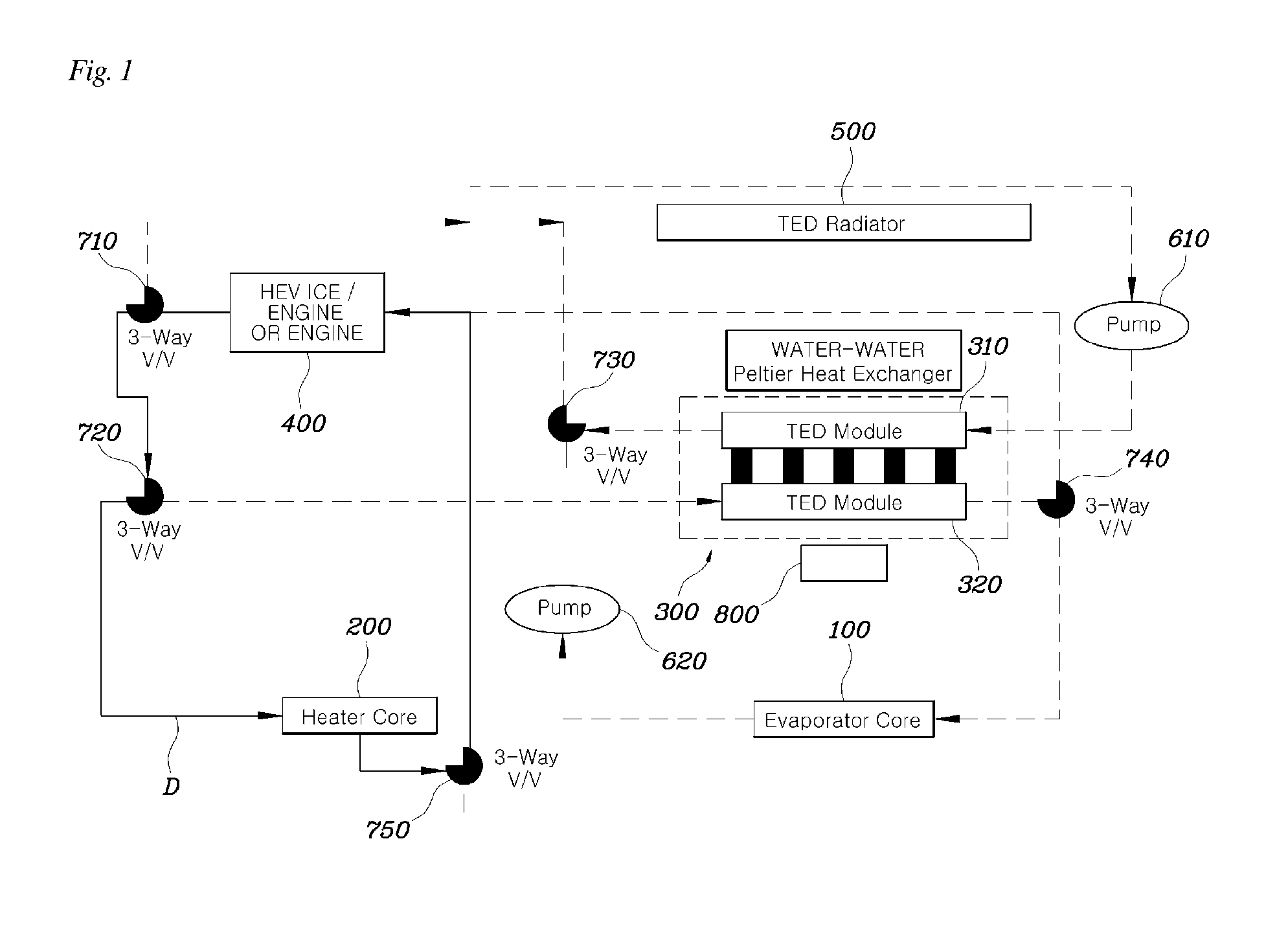

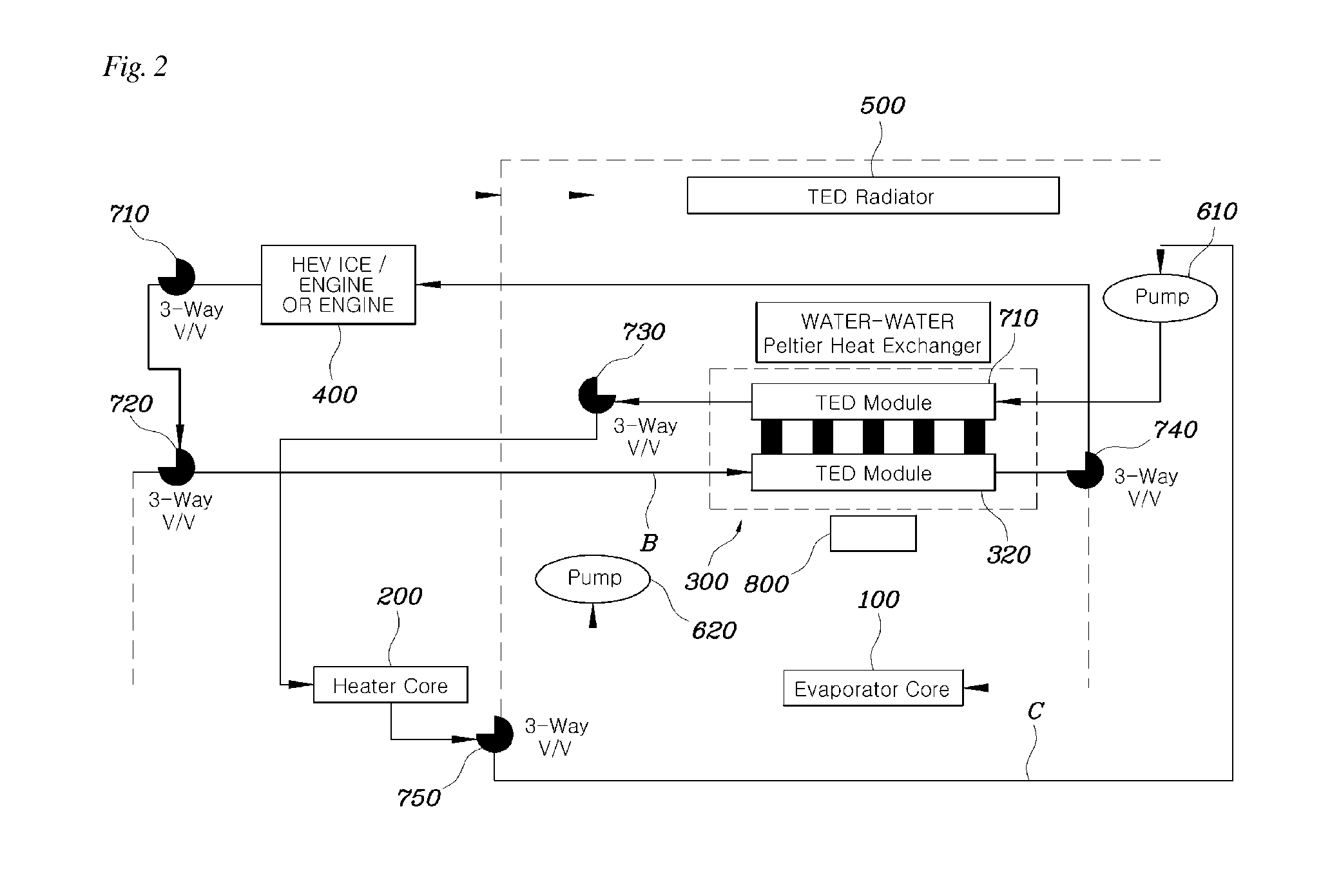

Air-conditioning apparatus for vehicle

ActiveUS20140165606A1Good thermal controlReduce waste heatVehicle heating/cooling devicesMachines using electric/magnetic effectsAir conditioningCooling channel

An air-conditioning apparatus for a vehicle, which includes an evaporator core and a heater core disposed on a ventilation channel overlapping each other, and thermoelectric device having a heat generating surface and a heat absorbing surface. A cooling line including a first cooling channel through which cooling water circulates around the heat absorbing surface and the evaporator core and a second cooling channel through which the cooling water circulates around the heat absorbing surface and an engine, and a heating line including a first heating channel through which the cooling water circulates around the heat generating surface and the heater core and a second heating channel through which the cooling water circulates around the engine and the heater core are also included. A controller controls concurrent circulation through the second cooling channel and the first heating channel or circulation through the second heating channel in a heating mode.

Owner:HYUNDAI MOTOR CO LTD +1

Green tea processing method

InactiveCN104621278AIncrease aromaGreat tastePre-extraction tea treatmentHigh temperature storageEmerald

The invention belongs to the technical field of processing of teas, and in particular relates to a green tea processing method. Green teas are prepared by sequentially spreading, removing green, refreshing breeze, cooling by spreading, primarily kneading, primarily drying, kneading again, shaping and showing tea hair of fresh teas. According to the invention, the teas are blown by cold wind before and after removing green; protein and saccharides in the teas are sufficiently decomposed in the spreading process before removing green; therefore, the contents and the concentrations of effective components in tea soup are ensured, and beneficial substances in the teas are promoted to dissolve out; by means of blowing cold wind after removing green, the temperature of the teas can be rapidly reduced; the teas are prevented from becoming yellow due to high-temperature storage; by adopting the kneading process for two times, cells in the teas are broken step by step after primarily kneading; therefore, the effective components are dissolved and leached easily in the brewing process; and the tea soup is kept emerald green in colour, strong in fragrance and high in soluble content.

Owner:HUNAN XIANGWEI TEA CO LTD

LED (light emitting diode) front car lamp

InactiveCN102392965AImprove lighting effectsImprove utilization efficiencyPoint-like light sourceLighting heating/cooling arrangementsLight energyFree form

The invention discloses an LED (light emitting diode) front car lamp, belonging to the field of illumination devices. The front car lamp comprises a lower beam lamp set, a higher beam lamp set, a PCB (printed circuit board) and a heat radiator, wherein the lower beam lamp set and the higher beam lamp set are installed on the PCB; the rear part of the PCB is provided with the heat radiator; the lower beam lamp set comprises an LED lamp and a lower beam cup; the higher beam lamp set comprises an LED lamp and a higher beam cup; the inner surfaces of the lower beam cup and the higher beam cup are mirror surfaces, and the mirror surfaces are divided into a plurality of irregular free-form surfaces axially; and the cup bodies of the lower beam cup and the higher beam cup are both divided into at least three sections axially, and each section is used for illuminating different areas. The lower beam cup and the higher beam cup of the front car lamp have high light efficiency, the amount of applied LEDs is less, and the heat radiation issue of the LED lamp is solved, thus the full LED of the front car lamp is realized; also the front car lamp provided by the invention is simple in structure, does not need excessive optical accessories the light energy loss is reduced, simultaneously the cost is lowered, and the front car lamp can be widely popularized and applied.

Owner:GUANGZHOU UNIVERSITY

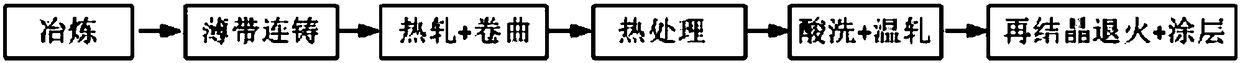

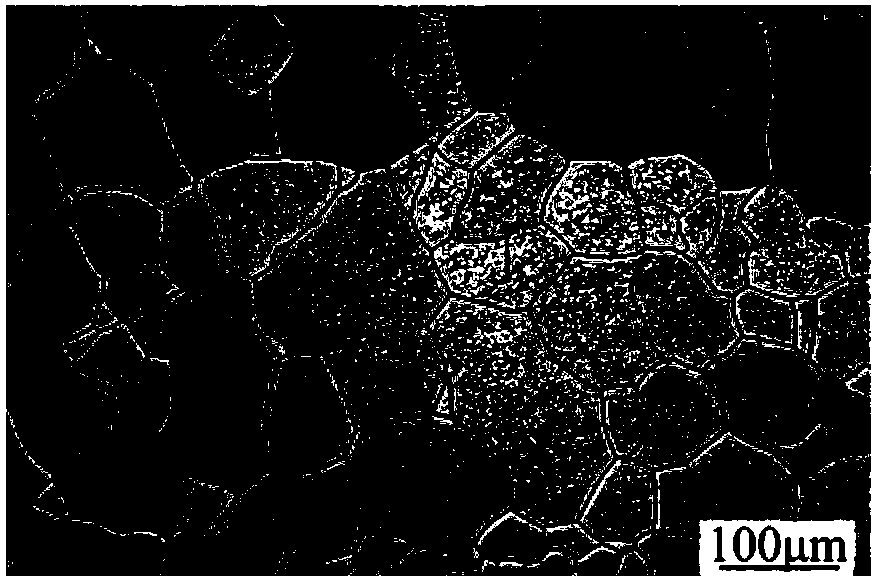

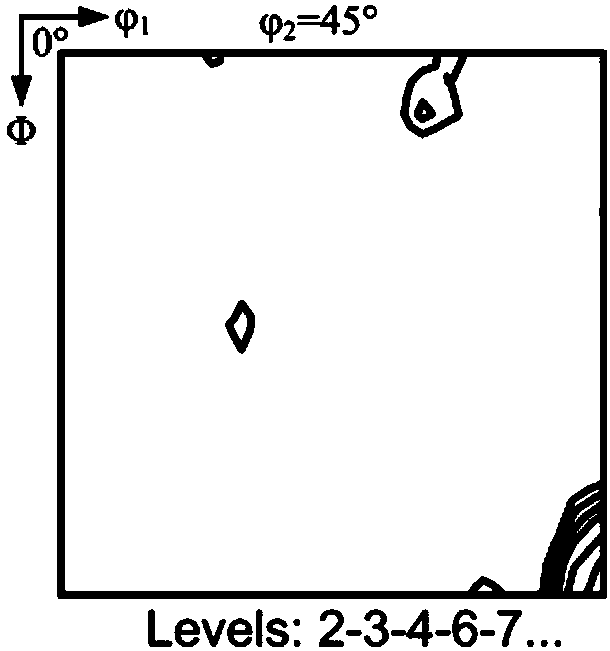

Preparation method of high grade non-oriented silicon steel based on thin-strip casting

The invention belongs to the technical field of metallurgy, and particularly relates to a preparation method of high grade non-oriented silicon steel based on thin-strip casting. The high grade non-oriented silicon steel is prepared from the following chemical components in percentage by weight: less than or equal to 0.004 percent of C, 2.6 to 3.4 percent of Si, 0.1 to 0.4 percent of Mn, 0.4 to 0.8 percent of Al, less than or equal to 0.003 percent of S, less than or equal to 0.003 percent of N and the balance of Fe. The preparation method comprises the following steps: preparing smelted molten steel into a casting strip of 2 to 3 mm through a thin-strip casting machine, and directly rolling at 1000 to 1150 DEG C after 8 to 15 percent of hot rolling; then keeping warm for 10 to 20 minutesat 1000 to 1100 DEG C; carrying out acid pickling and warm rolling, wherein the warm rolling temperature is 200 to 500 DEG C, and the rolling reduction is 70 to 85 percent; carrying out annealing andcoating treatment on a plate coil which is subjected to the warm rolling, thus preparing a non-oriented silicon steel sheet. According to the preparation method disclosed by the invention, the technology is simple, energy consumption and equipment investment are reduced, and meanwhile, an induction value of the high grade non-oriented silicon steel can be remarkably increased.

Owner:NORTHEASTERN UNIV

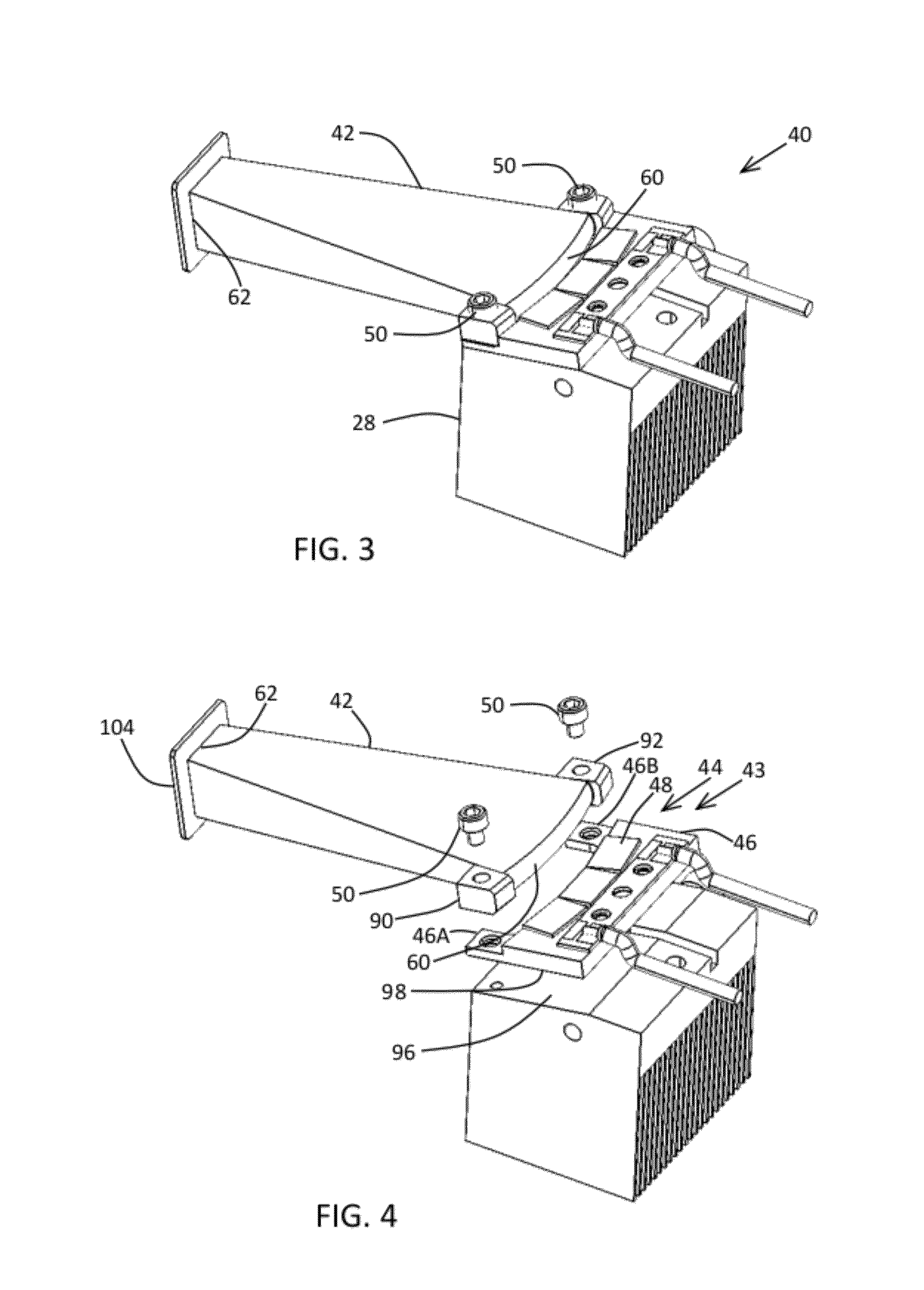

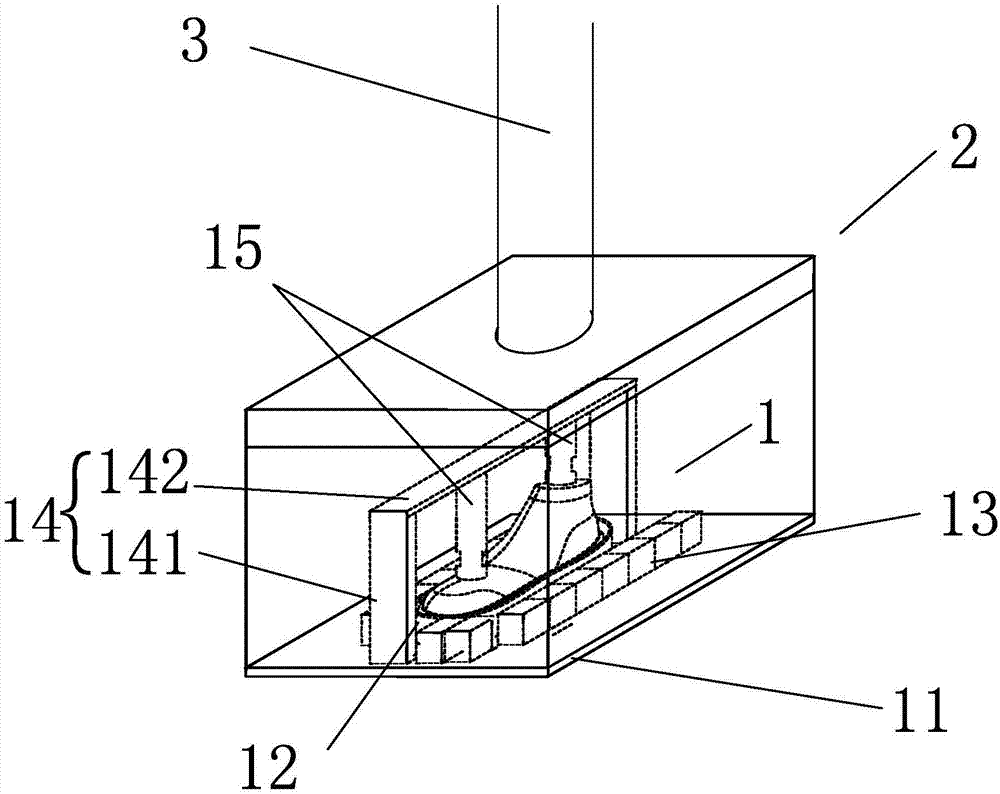

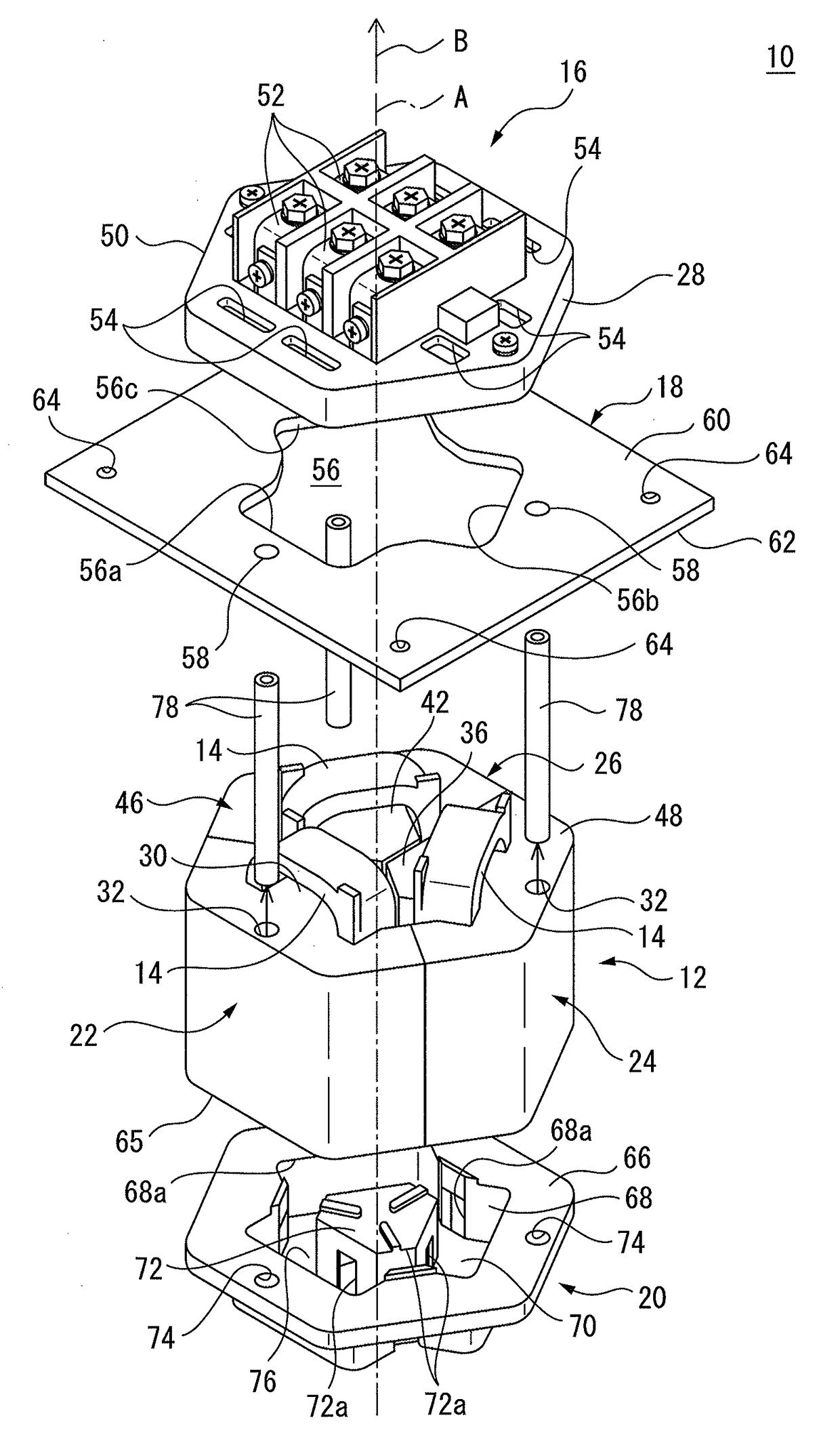

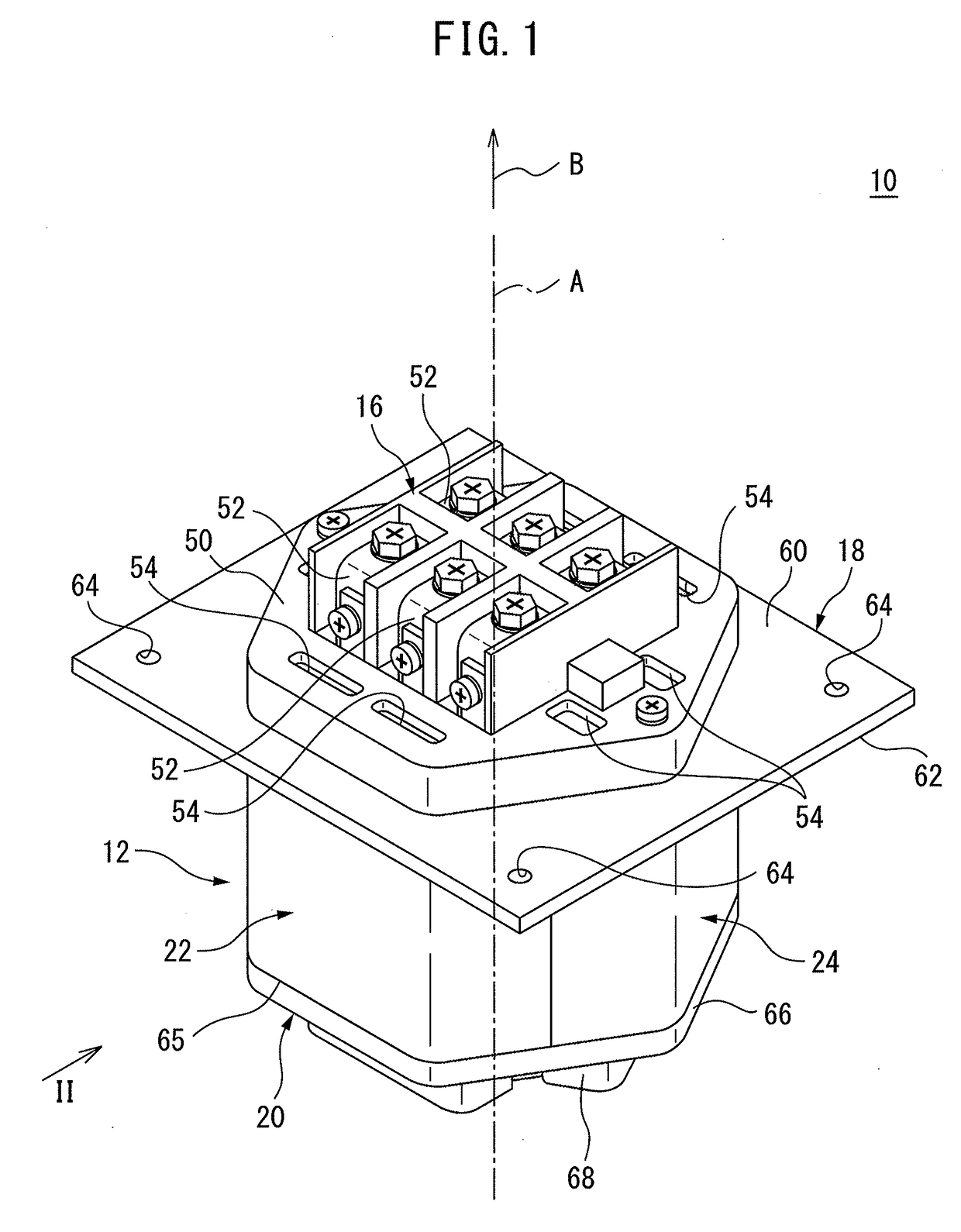

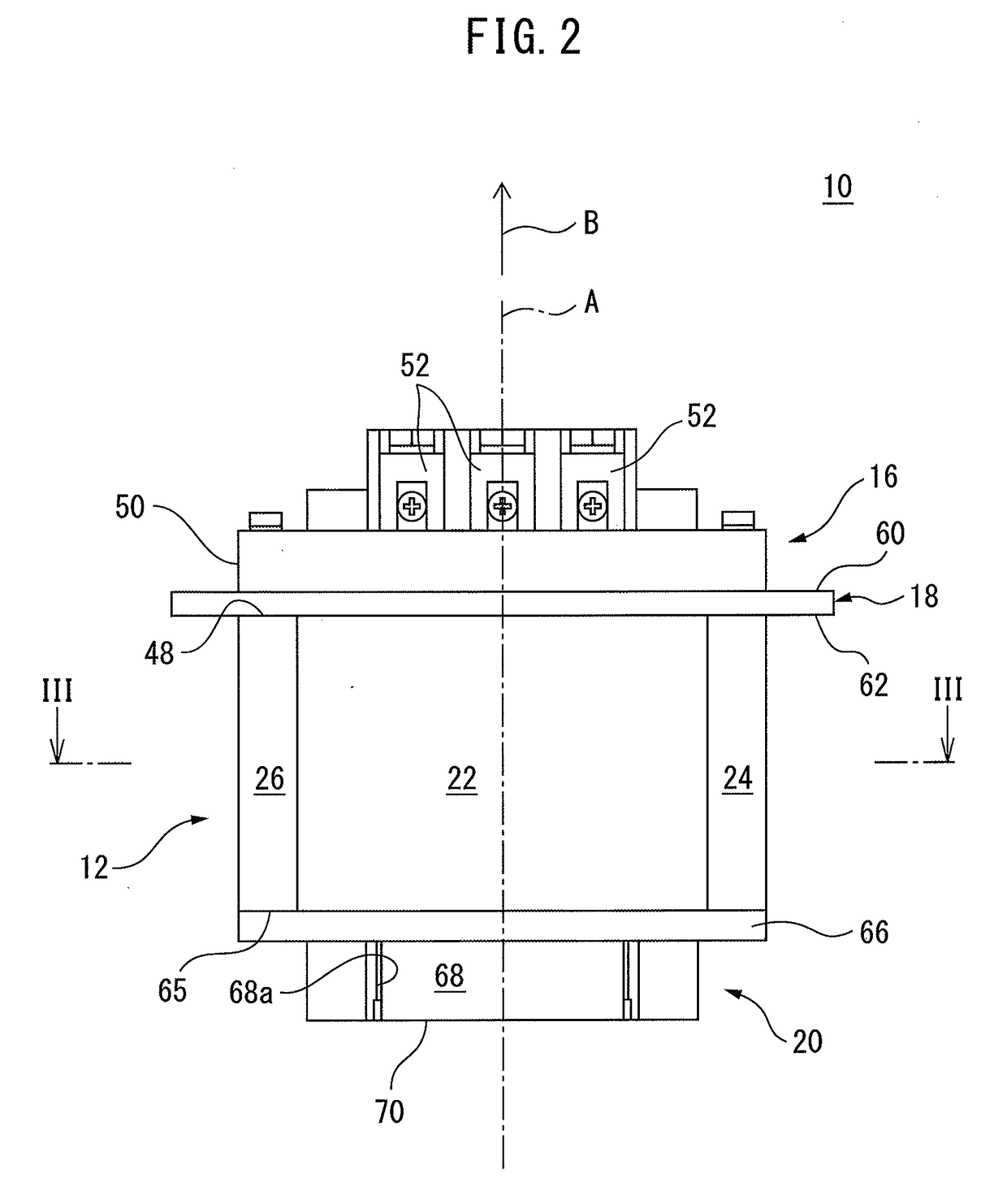

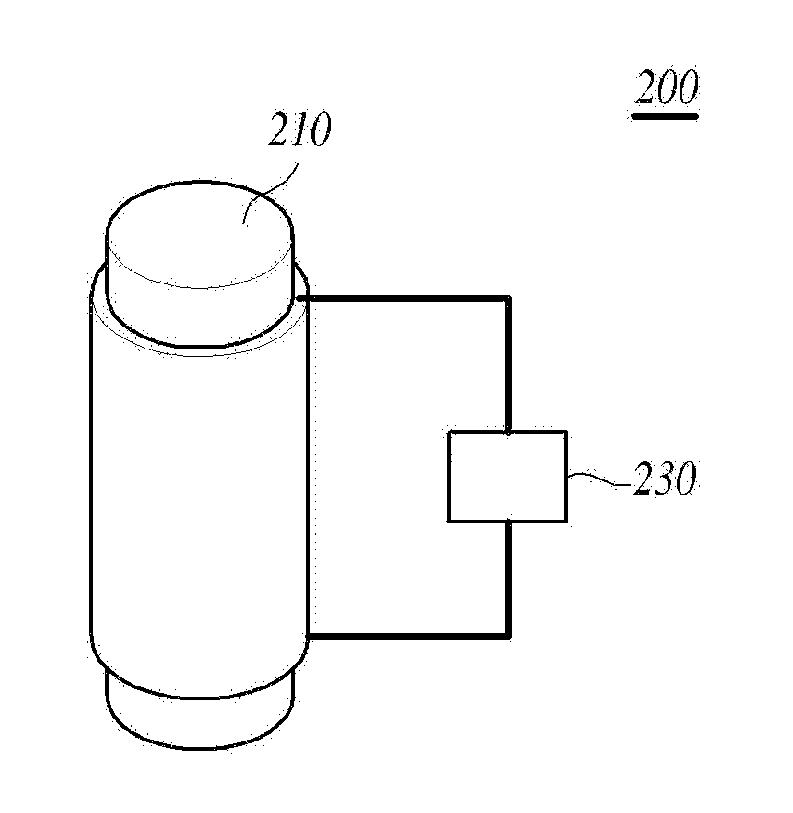

Reactor including tubular core, motor drive device, and amplifier device

ActiveUS20170372828A1Reduce waste heatTransformers/reacts mounting/support/suspensionDynamo-electric converter controlMotor driveAudio power amplifier

A reactor capable of eliminating a heat source provided within a power cabinet housing a motor drive device. The reactor includes a tubular core, a coil installed inside the core, a terminal which is provided at an axially first end of the core and which is connected to the coil, and an attachment flange which extends radially outside of the core and which is provided between the terminal and a second end of the core.

Owner:FANUC LTD

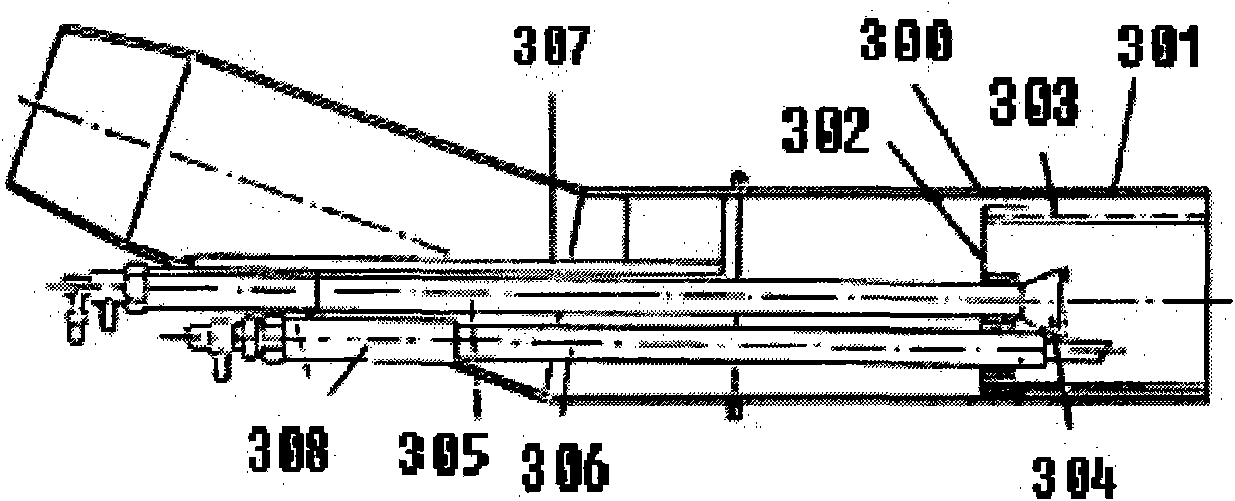

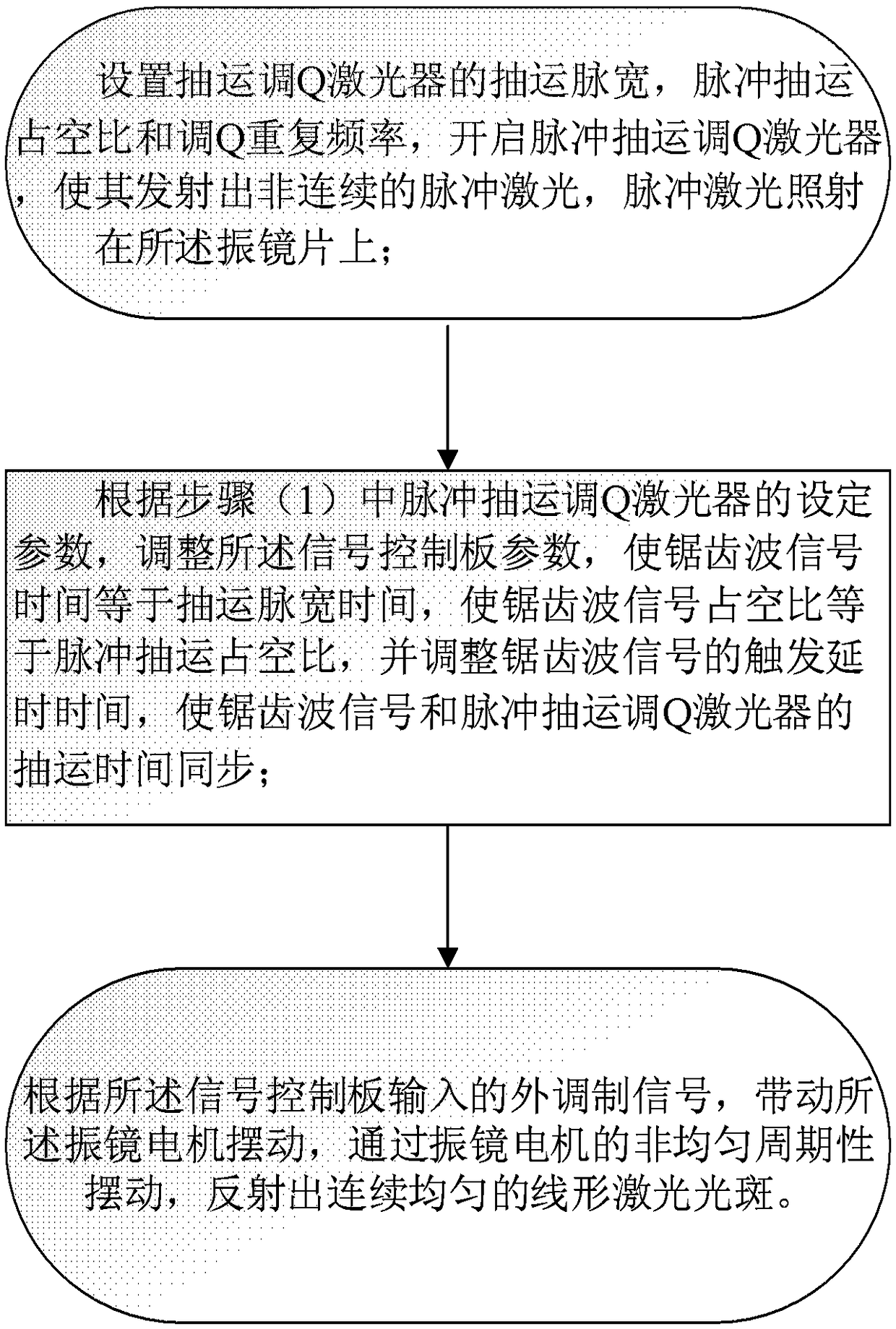

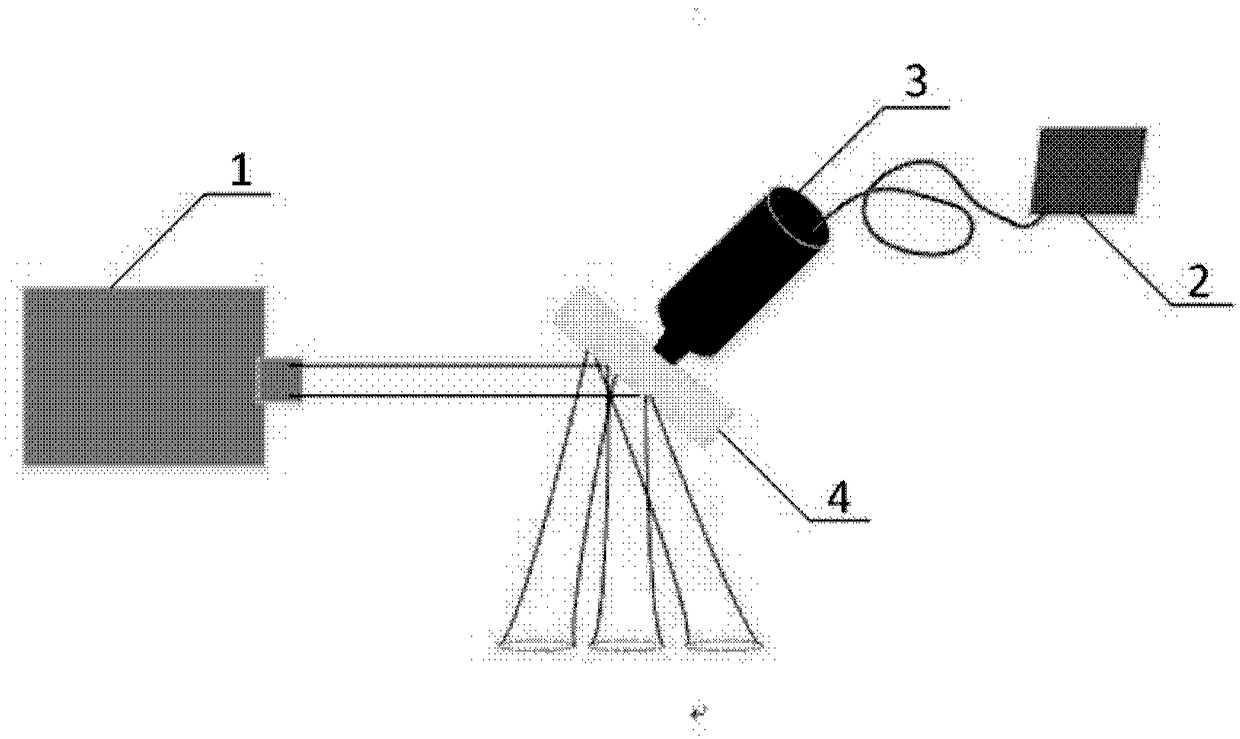

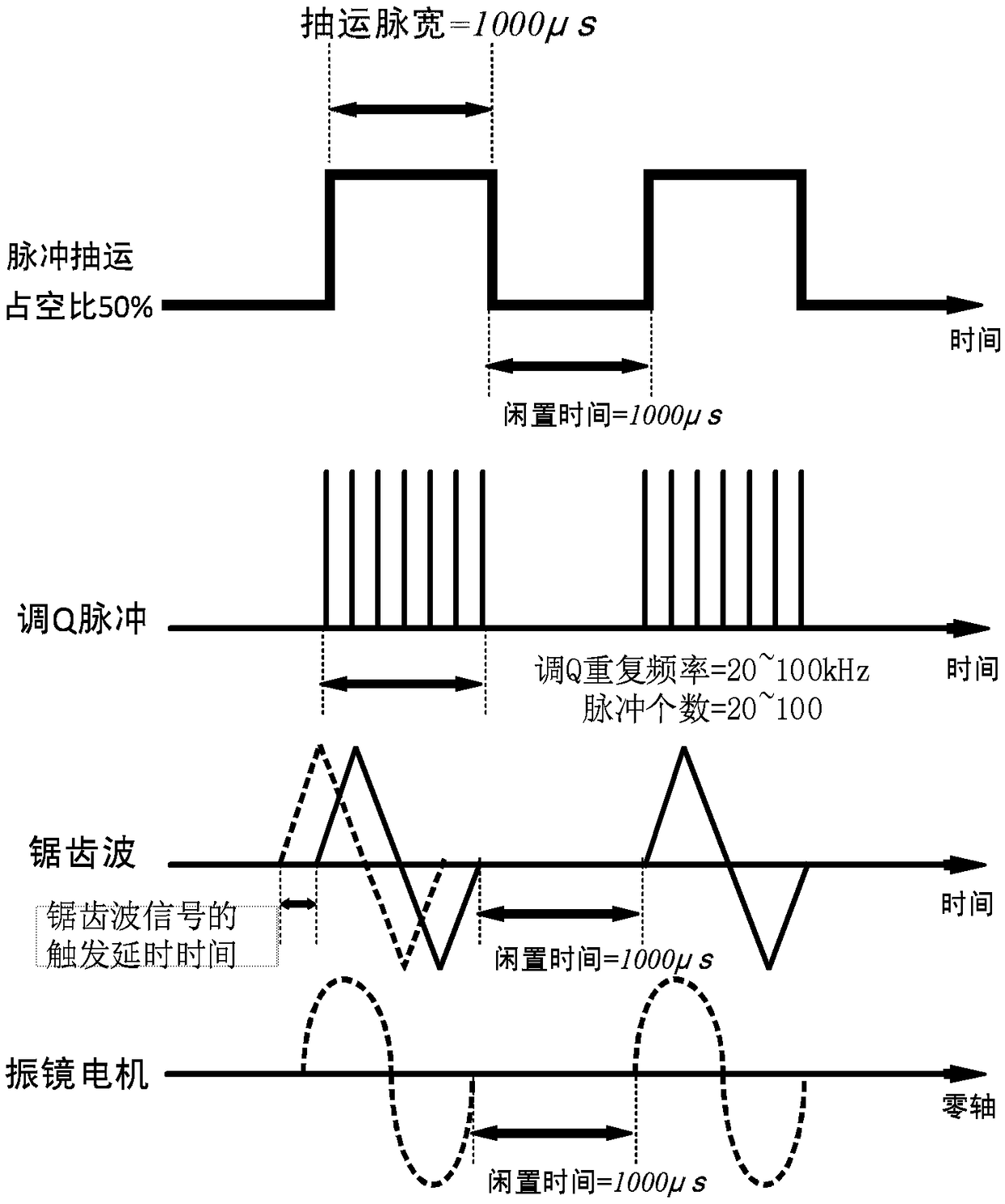

Scanning signal control method for pulse-pumping Q-switched laser cleaning

ActiveCN109226100AReduce waste heatImproved Thermal LensingCleaning processes and apparatusGalvanometerOptoelectronics

The invention discloses a scanning signal control method for pulse-pumping Q-switched laser cleaning. The method includes the following steps that parameters of a laser are set, and a pulse-pumping Q-switched laser is started, and emits discontinuous pulse laser; parameters of a signal control panel are adjusted, sawtooth signal time is equal to pulse width pumping time, the duty ratio of sawtoothsignals is equal to the pulse-pumping duty ratio, triggering delay time of the sawtooth signals is adjusted, and the pumping time of the sawtooth signals and the pumping time of the pulse-pumping Q-switched laser are synchronous; through non-uniform periodical swinging of a galvanometer motor, and continuous and even linear laser spots are output. By means of the scanning signal control method, the problem that due to a continuous-emitting discontinuous pulse emission mode of the pulse-pumping Q-switched laser, distribution of scanned spots is interrupted and discontinuous is solved, and application of laser cleaning of the light source is achieved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Infrared radiant emitter

ActiveUS10718527B2Efficiently projectedImproves rate and efficiencyDomestic stoves or rangesLighting and heating apparatusMaterials scienceInfrared emitter

An infrared heating apparatus includes an infrared emitter with a coiled resistive wire embedded in a ceramic refractory material so that a first portion of the resistive wire is exposed and a second portion of the resistive wire is enclosed by the ceramic refractory material, such that the first portion forms an array of arcs that protrude above the ceramic refractory material.

Owner:MASTEN JR JAMES WILLIAM

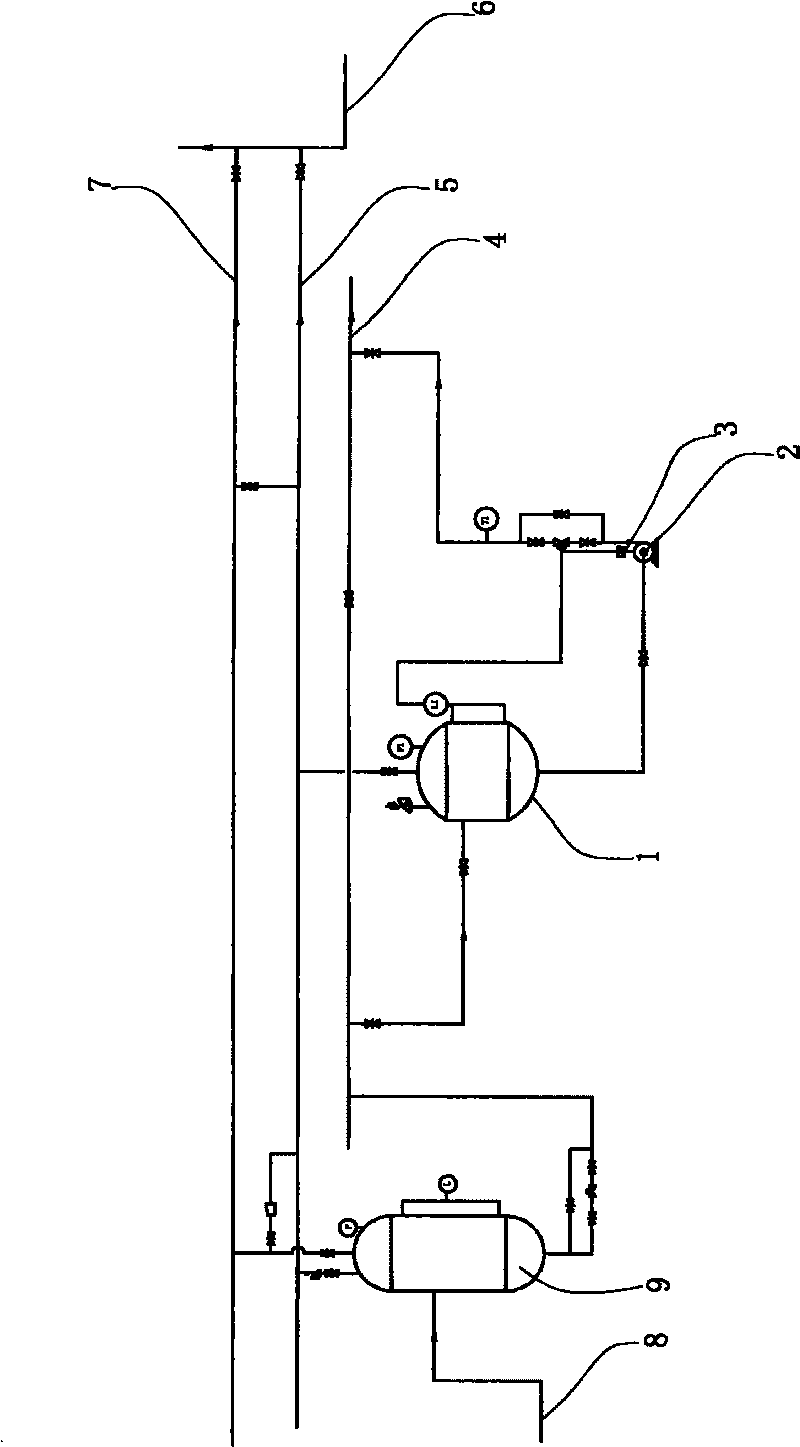

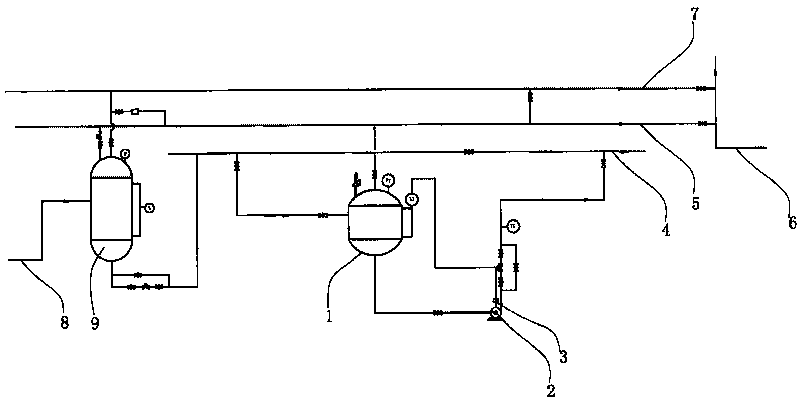

Method and device for recovering waste heat of steam condensate of calcination plant

InactiveCN101761913ATake advantage ofSave energyEnergy inputSteam generationSodium bicarbonateBoiler plant

The invention discloses a method for recovering waste heat of steam condensate of a calcination plant, which comprises the following steps: carrying out secondary flashing on the steam condensate from a secondary flashing tank in the sodium bicarbonate calcination process for preparing calcined soda by an ammonia-soda process; recovering and reutilizing the flashed steam; and adopting a device for recovering the steam condensate of the calcination plant. The device comprises a condensate backflow liquid collection tank, one side of the condensate backflow liquid collection tank is connected with the secondary flashing tank, the top end of the condensate backflow liquid collection tank is connected with a secondary flashing second steam pipe, the top end of the secondary flashing tank is connected with a secondary flashing first steam pipe, one side of the secondary flashing tank is connected with a primary flashing steam condensate inlet pipe, the secondary flashing second steam pipe and the secondary flashing first steam pipe are connected in parallel with the a distillation steam main pipe, the bottom end of the condensate backflow liquid collection tank is connected with a condensate pump, and the secondary flashing tank, the condensate backflow liquid collection tank and the condensate pump are simultaneously connected to a condensate pipe of a condensate heat removal electric boiler plant. Thus, the steam is fully utilized, and the energy sources are saved.

Owner:山东海天生物化工有限公司

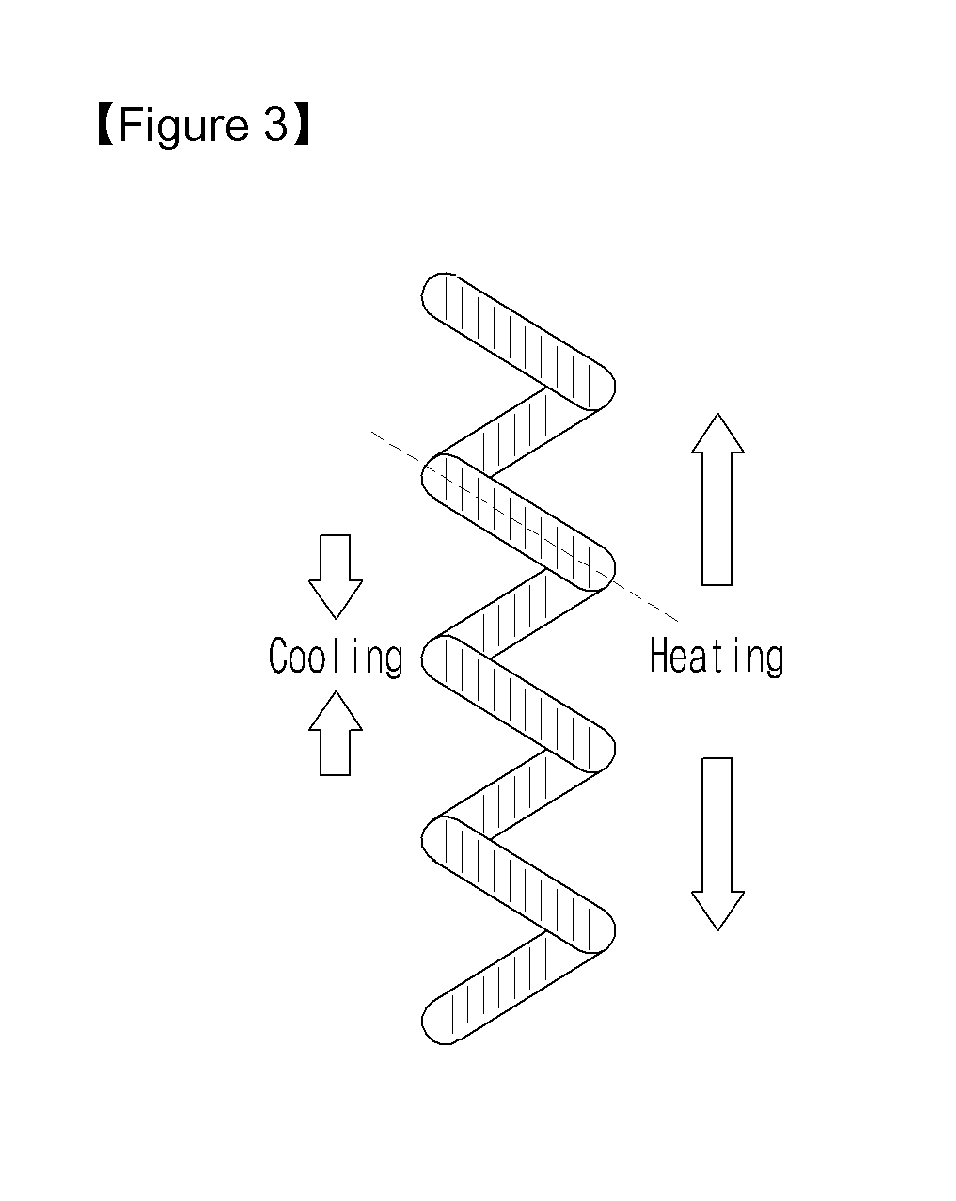

Soft actuator using thermoelectric effect

ActiveUS20180058429A1Reduce operation response timeControlled contractionThermoelectric device with peltier/seeback effectChiropractic devicesThermoelectric effectSoft actuator

The present invention relates to a soft actuator moving linearly against external stimuli whose expansion and contraction can be actively controlled, suggesting that the actuator of the invention overcomes the problems of the conventional soft actuators, The soft actuator of the present invention can be repetitively driven quickly and accurately by controlling heating and cooling by using thermoelectric effect and, the soft actuator of the present invention can realize bending, tensioning, compression, and rotational driving of a tubular device containing a driver.

Owner:DAEGU GYEONGBUK INST OF SCI & TECH

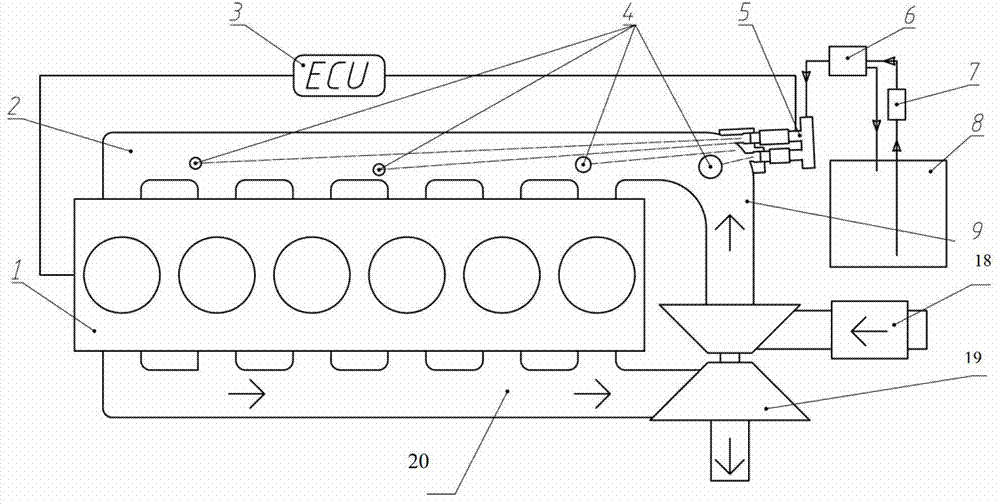

Penetration distance-composited alcohol spraying method and device

InactiveCN102953887AAlleviate heat load imbalanceReduce heat loadInternal combustion piston enginesCombustion-air/fuel-air treatmentCombustionAlcohol

The invention relates to methyl alcohol spraying method and a device in mixed combustion of diesel oil and alcohol, and in particular relates to a penetration distance-composited alcohol spraying method and device, which speed up the evaporation and gasification of methyl alcohol drops and improves the uniformity of the mixtures of methyl alcohol and air which enter cylinders. The invention adopts the following technical scheme that an elbow is arranged at the joint of an intake manifold and an intake pipe of an engine; two or more spray nozzles with different penetration distances for spraying alcohol are installed at the elbow; center lines of the spray orifices of the spray nozzles are parallel to the axis of the intake manifold or incline downward with respect to the axis of the intake manifold. The alcohol spraying method and the device realize at least two alcohol spraying penetration distances and enable the alcohol to land at different parts of the intake manifold of the engine after being sprayed out from the spray nozzles. The multi-penetration-distance alcohol spraying device enables the alcohol liquid to reach different parts of the intake manifold of the engine, reduces the thermal load of the engine, and reduces the waste heat brought away by the cooling water of the engine.

Owner:TIANJIN UNIV

Condensate water recovering device

InactiveCN103267275AReduce waste heatReduce recycling costsFeed water supplyStationary tubular conduit assembliesEnvironmental engineeringHeat pipe

The invention provides a condensate water recovering device. Two condensate water heat exchangers are adopted by a heat pipe vacuum treatment method so that heat exchanging and cooling of condensate water in the normal-pressure closed state can be carried out, waste of waste heat of the condensate water can be reduced, and recovering cost of the condensate water can be lowered.

Owner:刘成红

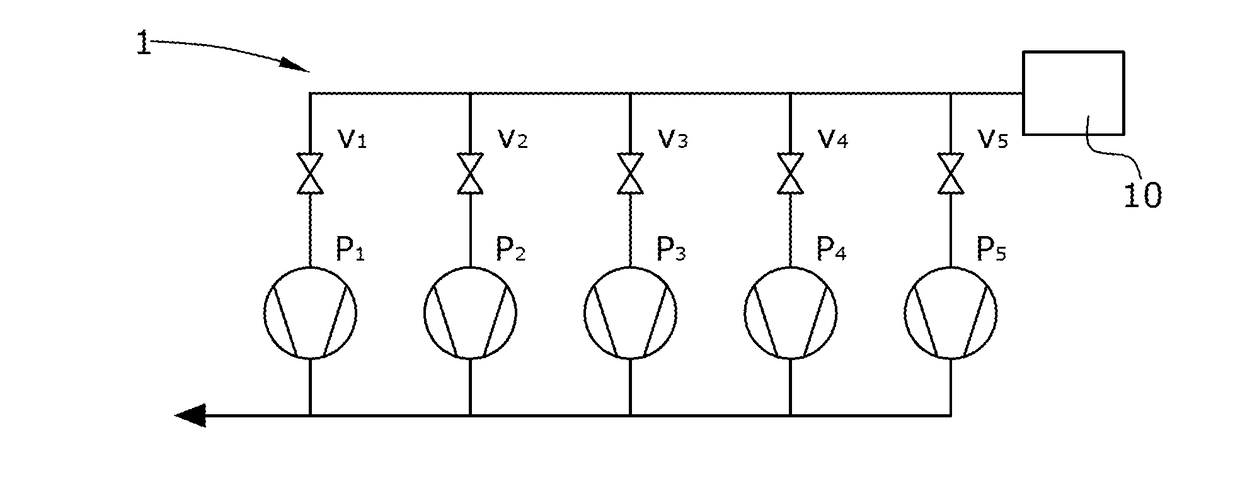

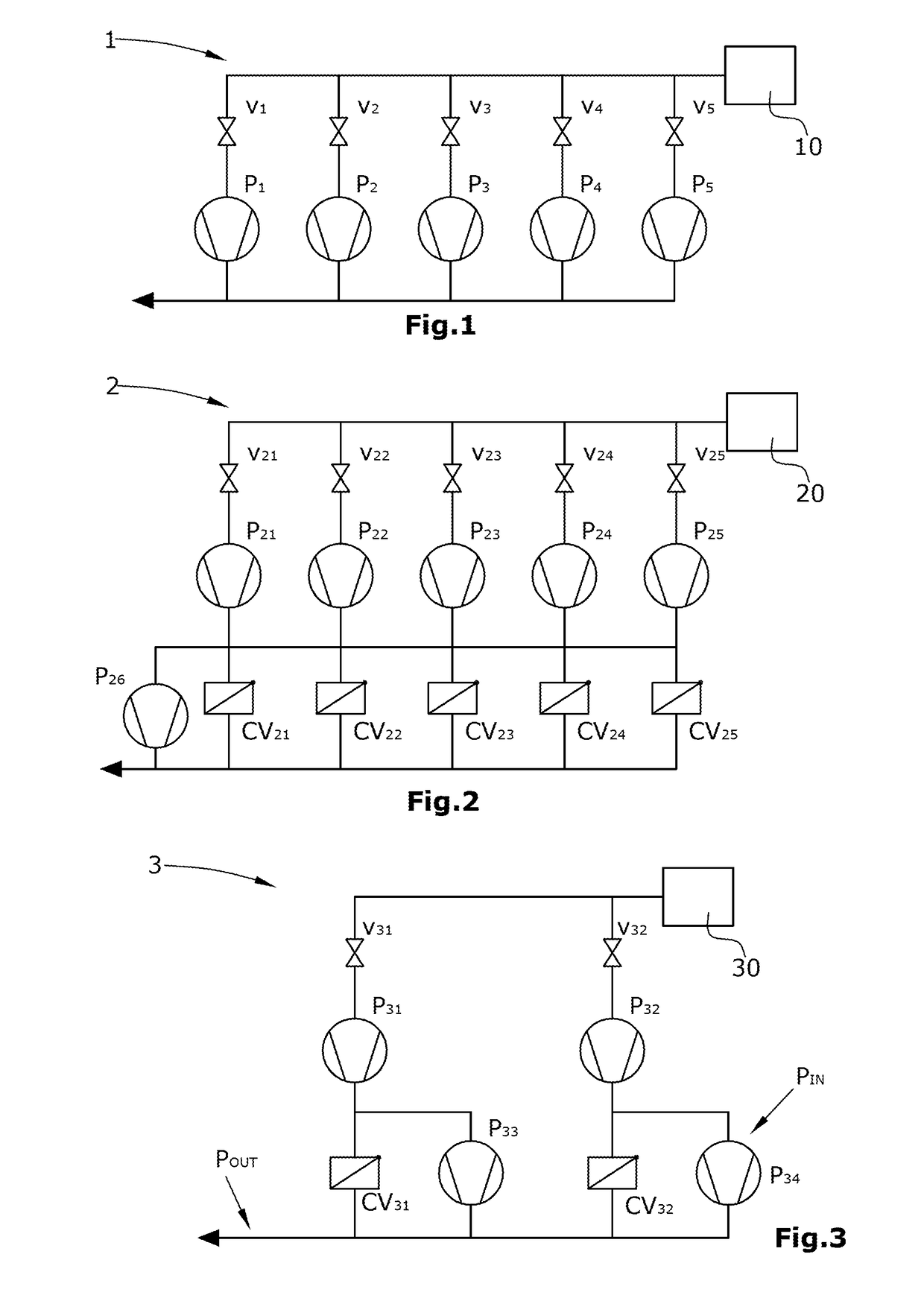

Vacuum pump system

InactiveUS20180112666A1Reduce sound levelReduce noiseRotary/oscillating piston combinations for elastic fluidsPump componentsVacuum pump

A vacuum pump system comprising a plurality of vacuum pumps which are connected to one another in parallel and are each connected on an inlet side to a chamber, having an outlet line which is connected on the outlet side of the vacuum pumps, and an intermediate line which connects the inlet side of at least one vacuum pump to the outlet line, wherein all the vacuum pumps are connected in parallel during a pumping-out period and at least one of the vacuum pumps is connected in parallel with the other vacuum pumps as a backing pump during an idle period.

Owner:LEYBOLD HERAEUS GMBH & CO KG

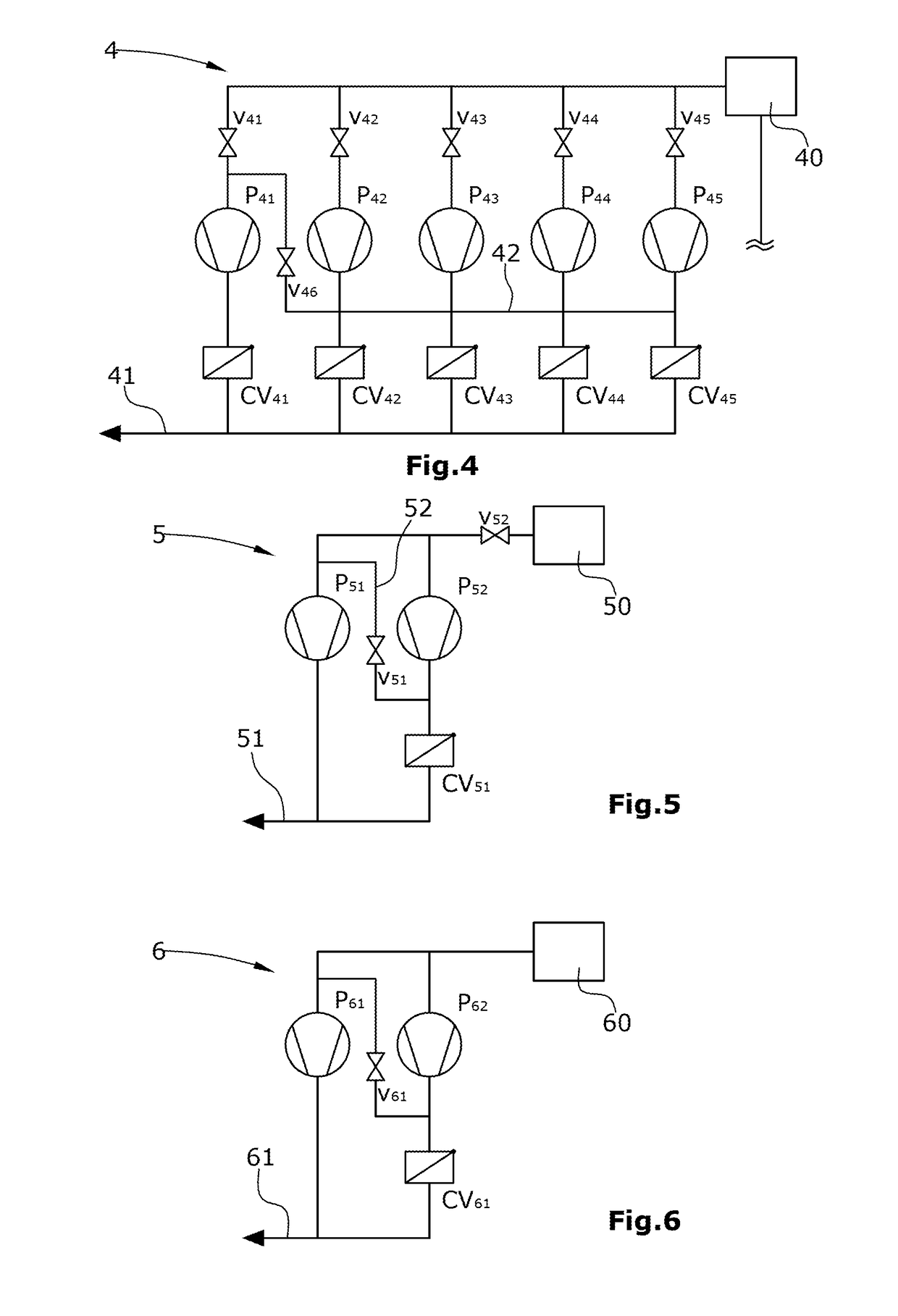

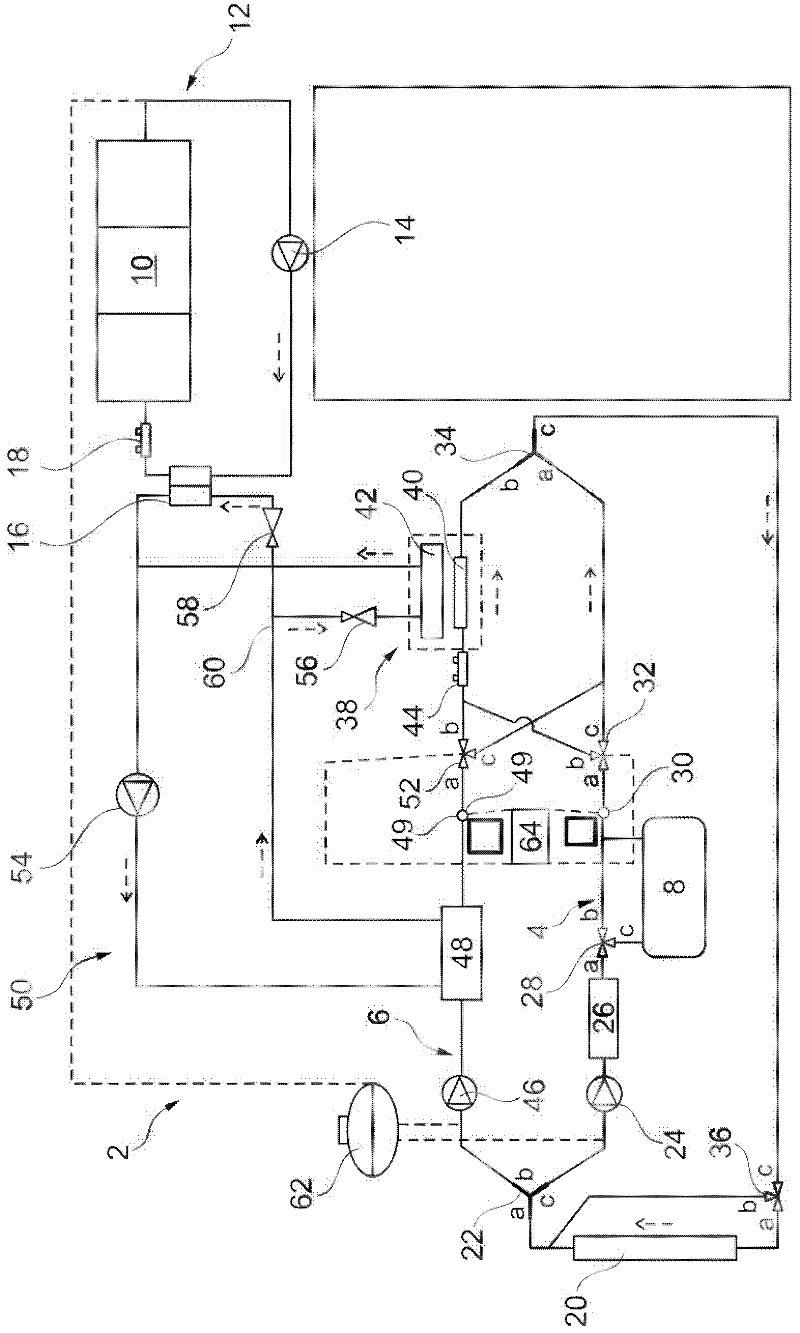

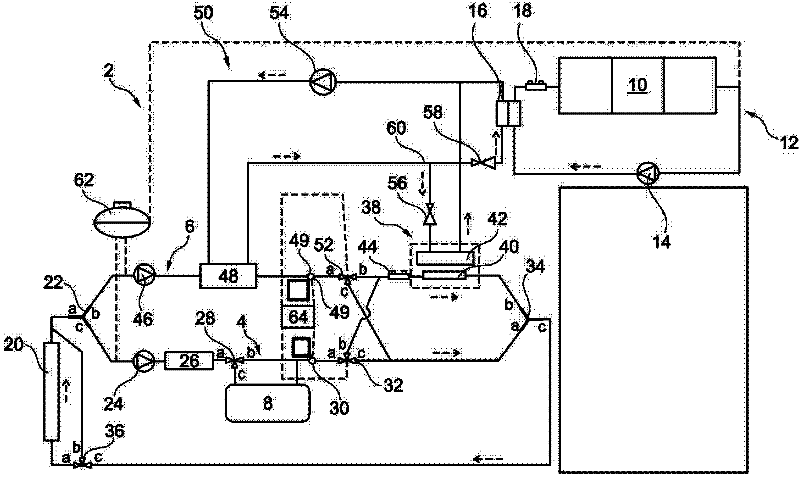

Air-conditioning system for an automobile and method for operating an air-conditioning system of an automobile

InactiveCN102452294AReduce waste heatReduce energy consumptionAir-treating devicesVehicle heating/cooling devicesAutomobile air conditioningCoolant temperature

An air-conditioning system (2, 102)is provided for an automobile comprising an interior air-conditioning module (38, 138), which can be connected in a heat-transporting manner to at least two coolant-carrying cooling circuits of the automobile via valves (32, 52, 132, 152)(e.g., controllable or adjustable valves). A controller (64, 164) is also provided that is configured to control the valves (32, 52, 132, 152)in such a manner that those cooling circuits (4, 6, 104, 106)having the higher coolant temperature can be connected in a heat-transporting manner to the interior air-conditioning module. A method is also provided for operating an air-conditioning system (2, 102).

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com