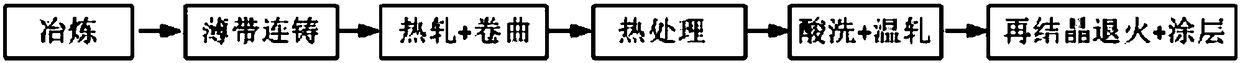

Preparation method of high grade non-oriented silicon steel based on thin-strip casting

A technology of oriented silicon steel and twin-roll thin strip continuous casting, which is applied in the metallurgical field to achieve the effects of reducing pinning, improving plate shape and reducing iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the preparation method of high-grade non-oriented silicon steel based on thin strip continuous casting is carried out according to the following steps:

[0027] In terms of weight percentage, the composition is: C 0.0035%, Si 2.6%, Mn0.15%, Al 0.45%, S 0.0027%, N 0.0030%, and the balance is Fe molten steel by using an intermediate frequency vacuum induction furnace to control molten steel pouring The temperature is 1590° C., and a 2.2 mm cast strip is obtained by using a twin-roll thin strip continuous caster. After the cast belt is taken out of the roll, it is crimped directly after being pressed by 12%, and the crimping temperature is 1150°C. Put the cast strip into a holding furnace at 1100°C for 10 minutes and then air-cool to room temperature. Then the cast strip was pickled and warm-rolled to 0.5mm with a reduction ratio of 75% and a warm-rolling temperature of 200°C. Then the warm-rolled sheet was annealed at 1100°C for 3 minutes, and the an...

Embodiment 2

[0029] In this embodiment, the preparation method of high-grade non-oriented silicon steel based on thin strip continuous casting is carried out according to the following steps:

[0030] In terms of weight percentage, the composition is: C 0.0037%, Si 3.0%, Mn0.35%, Al 0.72%, S 0.0025%, N 0.0027%, and the balance is Fe molten steel by using an intermediate frequency vacuum induction furnace to control molten steel pouring The temperature is 1550° C., and a 2.5 mm cast strip is obtained by using a twin-roll thin strip continuous caster. After the cast strip is taken out of the roll, it is directly crimped after being pressed by 15%, and the crimping temperature is 1070°C. Put the cast strip into a holding furnace at 1000°C for 20 minutes and then air-cool to room temperature. Then the cast strip was pickled and warm-rolled to 0.5mm with a reduction rate of 76% and a warm-rolling temperature of 320°C. Then the warm-rolled sheet is annealed at 950°C for 6 minutes, and the anne...

Embodiment 3

[0033] In this embodiment, the preparation method of high-grade non-oriented silicon steel based on thin strip continuous casting is carried out according to the following steps:

[0034] In terms of weight percentage, the composition is: C 0.0037%, Si 3.4%, Mn0.25%, Al 0.54%, S 0.0025%, N 0.0030%, and the balance is Fe molten steel by using an intermediate frequency vacuum induction furnace to control molten steel pouring The temperature was 1540° C., and a 3.0 mm cast strip was obtained by using a twin-roll thin strip continuous caster. After the casting belt is taken out of the roll, it is directly crimped after being pressed by 8%, and the crimping temperature is 1020°C. Put the cast strip into a holding furnace at 1000°C for 20 minutes and then air-cool to room temperature. Then the cast strip was pickled and warm-rolled to 0.5mm with a reduction ratio of 82% and a warm-rolling temperature of 450°C. Then the warm-rolled sheet is annealed at 1100°C for 2 minutes, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com