Condensate water recovering device

A technology for recycling device and condensate water, which is applied in the directions of supplementary water supply, preheating, steam generation, etc., which can solve the problems of high equipment failure rate, waste of waste heat of condensate water, and lower grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to illustrate the present invention more clearly, an example is given for illustration, but the rights required by the present invention are not limited thereto:

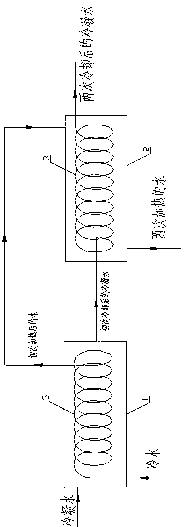

[0011] As shown in the figure, a condensed water recovery device is characterized by a condensed water heat exchanger (1), a condensed water heat exchanger (2), and a heat exchange tube (3).

[0012] The heat exchange tubes (3) in the condensed water heat exchanger (1) and the condensed water heat exchanger (2) are one or several types of composite tubes, coiled tubes or serpentine tubes.

[0013] The cold water entering the heat exchange tube (3) in the condensed water heat exchanger (1) is pushed in from the bottom.

[0014] Contains condensed water heat exchanger (1), condensed water heat exchanger (2), heat exchange tube (3), wherein the cold water enters the heat exchange tube (3) in the condensed water heat exchanger (1) and enters the condensed water The condensed water outside the heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com