LED (light emitting diode) front car lamp

A technology for LED lights and headlights, which is applied to point light sources, lighting and heating equipment, fixed lighting devices, etc. High efficiency and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

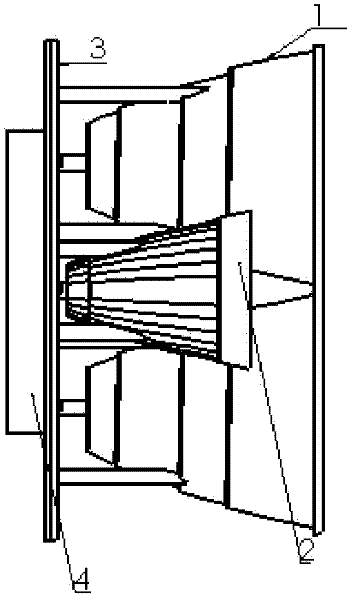

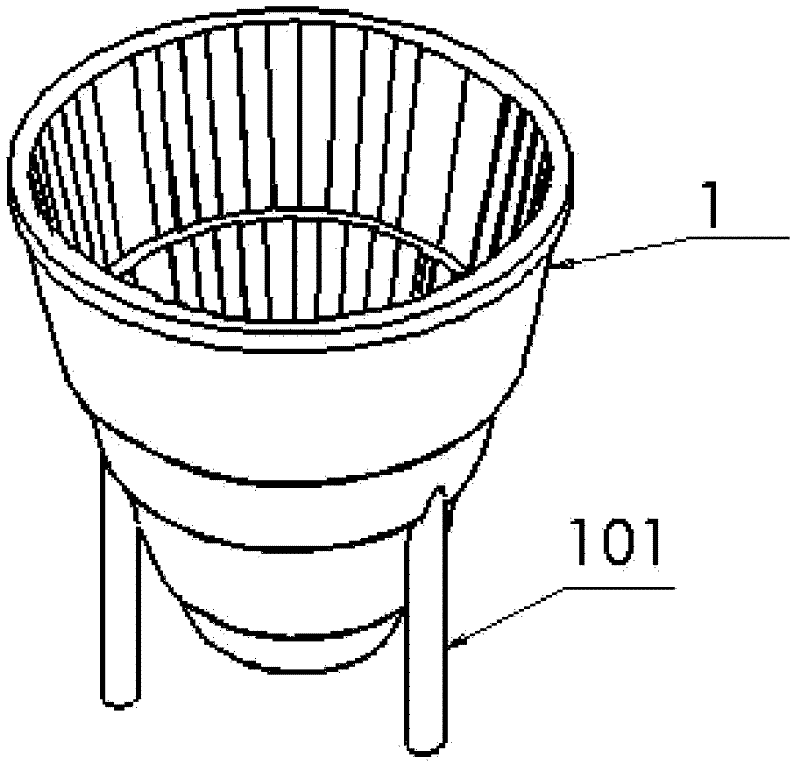

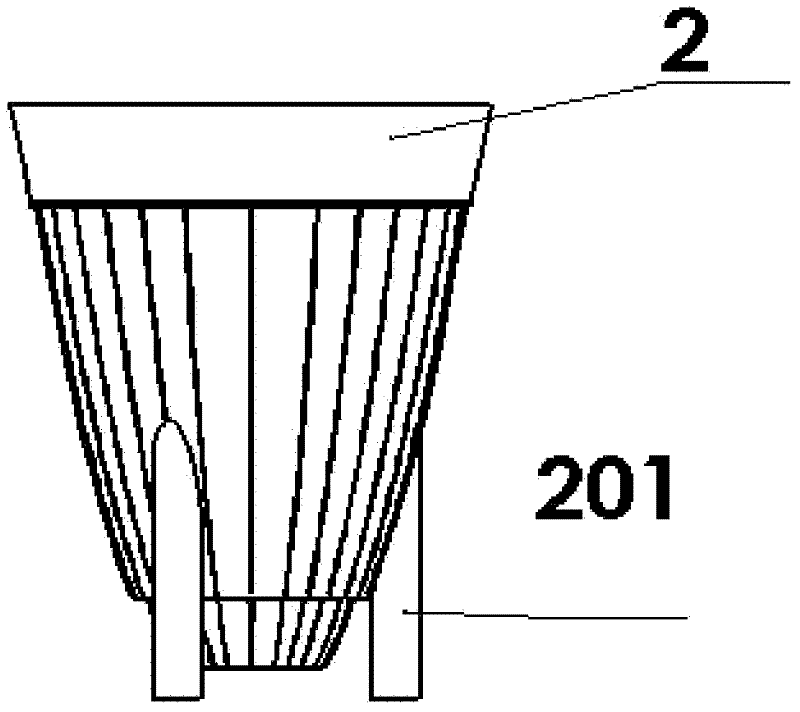

[0025] A kind of LED headlamp, comprises low beam lamp group 1, high beam lamp group 2, PCB board 3, radiator 4; Described low beam lamp group 1 and high beam lamp group 2 are installed on the PCB board 3, described A radiator 4 is installed at the rear of the PCB board 3; the low beam group 1 includes an LED lamp and a low beam cup; the high beam group 2 includes an LED lamp and a high beam cup; The inner surface of the optical cup and the high beam cup is a mirror surface, and the mirror surface is divided into several irregular free-form surfaces along the axial direction; the cup bodies of the low beam cup and the high beam cup are divided into at least 3 sections along the axial direction, and each section Different areas are illuminated to achieve a relatively uniform light spot and a clear cut-off line.

[0026] When the front lamp works, the waste heat emitted by the LED lamp is quickly transferred to the radiator 4 by the PCB board, so as to achieve the effect of heat...

Embodiment 2

[0028] A kind of LED headlamp, comprises low beam lamp group 1, high beam lamp group 2, PCB board 3, radiator 4; Described low beam lamp group 1 and high beam lamp group 2 are installed on the PCB board 3, described A radiator 4 is installed at the rear of the PCB board 3; the low beam group 1 includes an LED lamp and a low beam cup; the high beam group 2 includes an LED lamp and a high beam cup; The inner surface of the optical cup and the high beam cup is a mirror surface, and the mirror surface is divided into several irregular free-form surfaces along the axial direction; the cup bodies of the low beam cup and the high beam cup are divided into at least 3 sections along the axial direction, and each section Different areas are illuminated, and each segment illuminates different areas, so as to achieve a relatively uniform spot and a clear cut-off line.

[0029] The divergence angle of the cup body in the horizontal direction is 11°, and the divergence angle of each segment...

Embodiment 3

[0033] A kind of LED headlamp, comprises low beam lamp group 1, high beam lamp group 2, PCB board 3, radiator 4; Described low beam lamp group 1 and high beam lamp group 2 are installed on the PCB board 3, described The low beam lamp group 1 is connected with the PCB board through the positioning column one 101 provided on it and the positioning hole one 301 provided on the PCB board; the high beam lamp group 2 is connected with the PCB board through the positioning column two 201 provided on it and the PCB The positioning hole 301 provided on the board is connected with the PCB board; the heat sink 4 is installed at the rear of the PCB board 3; the PCB board 3 is connected with the positioning hole three 401 through the positioning hole two 302 provided thereon; The low beam group 1 includes an LED lamp and a low beam cup; the high beam group 2 includes an LED lamp and a high beam cup; the inner surface of the low beam cup and the high beam cup is a mirror surface, and the mir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com