Shoe material thermal-laminating process, shoe material thermal-laminating device and production line thereof

A thermal bonding and shoe material technology, applied in footwear, bonding shoe parts, shoe-making machinery, etc., can solve problems such as affecting the efficiency of shoe sole material pasting, inability to use oven waste heat, uneven heat distribution, etc. Save labor costs, save heat dissipation time, and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

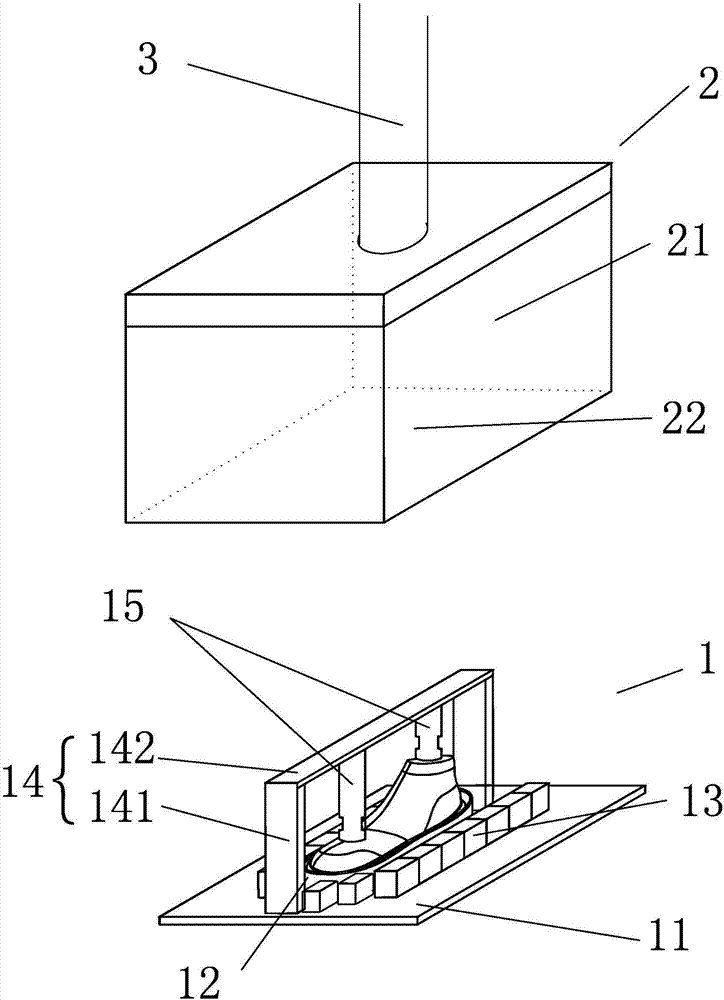

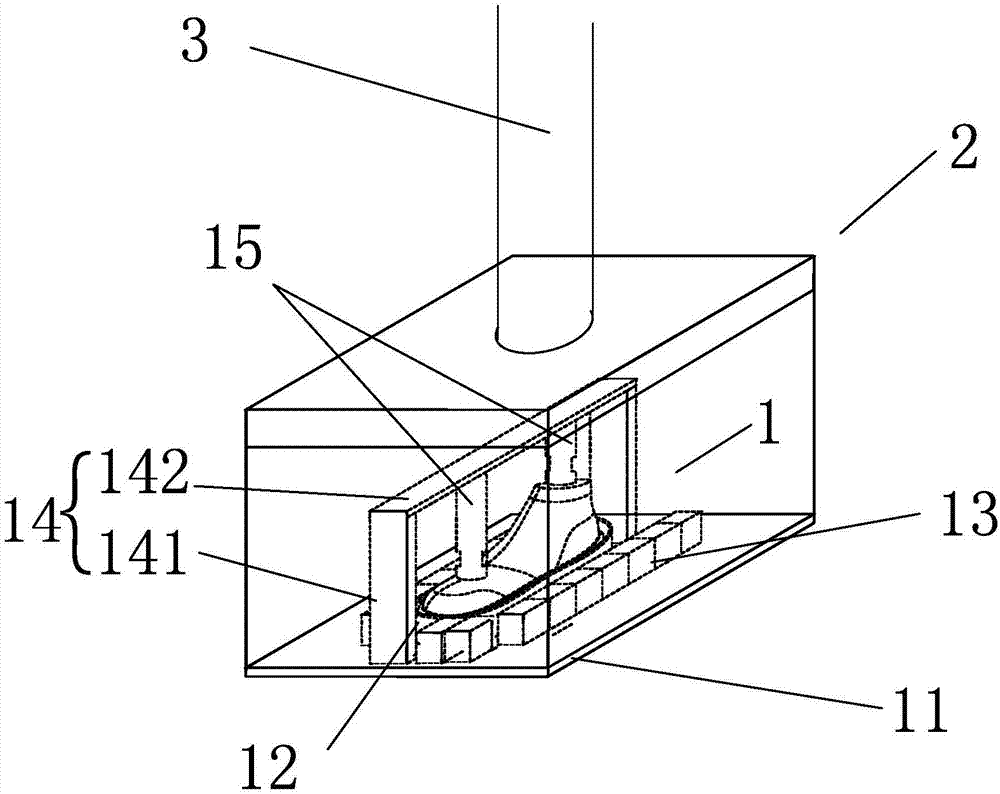

[0027] Embodiment 1: The present invention discloses a thermal lamination process for shoe materials, which includes the following steps:

[0028] Step 1: Prepare the shoe material to be processed. The shoe material to be processed includes the first shoe material and the second shoe material to be bonded, and the area to be bonded to the first shoe material and / or the area to be bonded to the second shoe material Carrying out the gluing treatment of applying the adhesive, the gluing treatment forms an adhesive layer, and the area to be bonded and / or the adhesive contains moisture;

[0029] Step 2: Correspondingly bonding the first shoe material obtained in step 1 and the area to be bonded of the second shoe material, and keeping the bonding, to obtain the shoe material bonding part;

[0030] Step 3: The shoe material bonding part of step 2 is subjected to microwave heating treatment through a microwave heating device, so that the first shoe material and the second shoe materi...

Embodiment approach 2

[0040] Embodiment 2: This embodiment is generally the same as Embodiment 1, except that the adhesive used in the gluing process in the first step is powder hot melt adhesive, and the pre-configured powder adsorbent and hardener are first (For example, add 4% hardener to the treatment agent and stir well) Evenly brush on the above-mentioned area to be bonded, remove the overflow part, and then evenly sprinkle TPU powder glue on the above-mentioned area to be bonded after treatment, Finally, it is sent to the oven for drying, and the temperature of the oven is controlled to be lower than the melting point of the powder glue. After drying, clean water is sprayed on the area to be bonded, and then steps 2 and 3 are performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com