Coolant pump for an internal combustion engine

A technology for coolant pumps and internal combustion engines, applied in engine cooling, liquid cooling, pumps, etc., can solve the problems of impossible layout and installation, increased location requirements, increased installation costs, etc., and achieves simple installation, precise axial movement, and high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

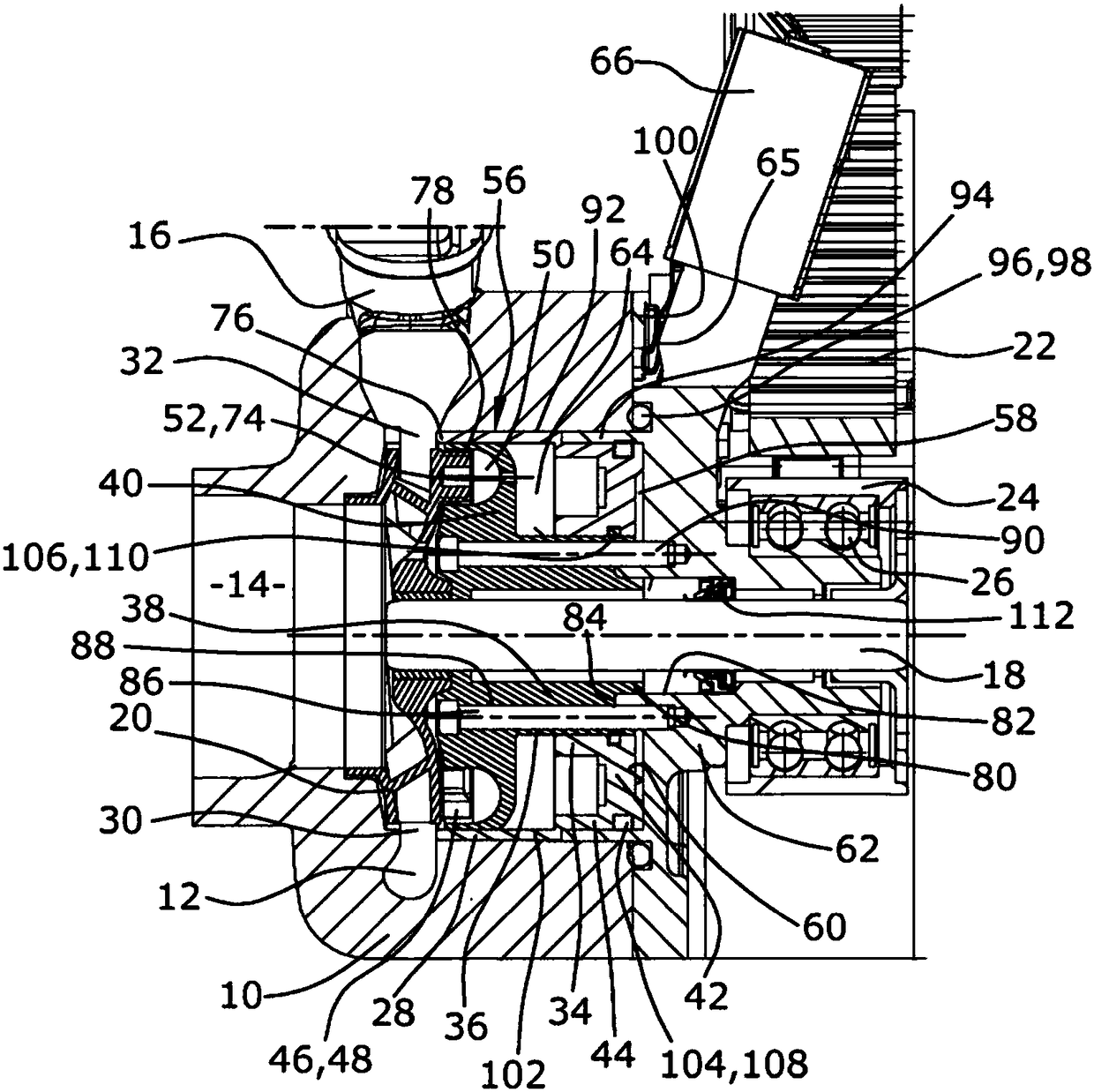

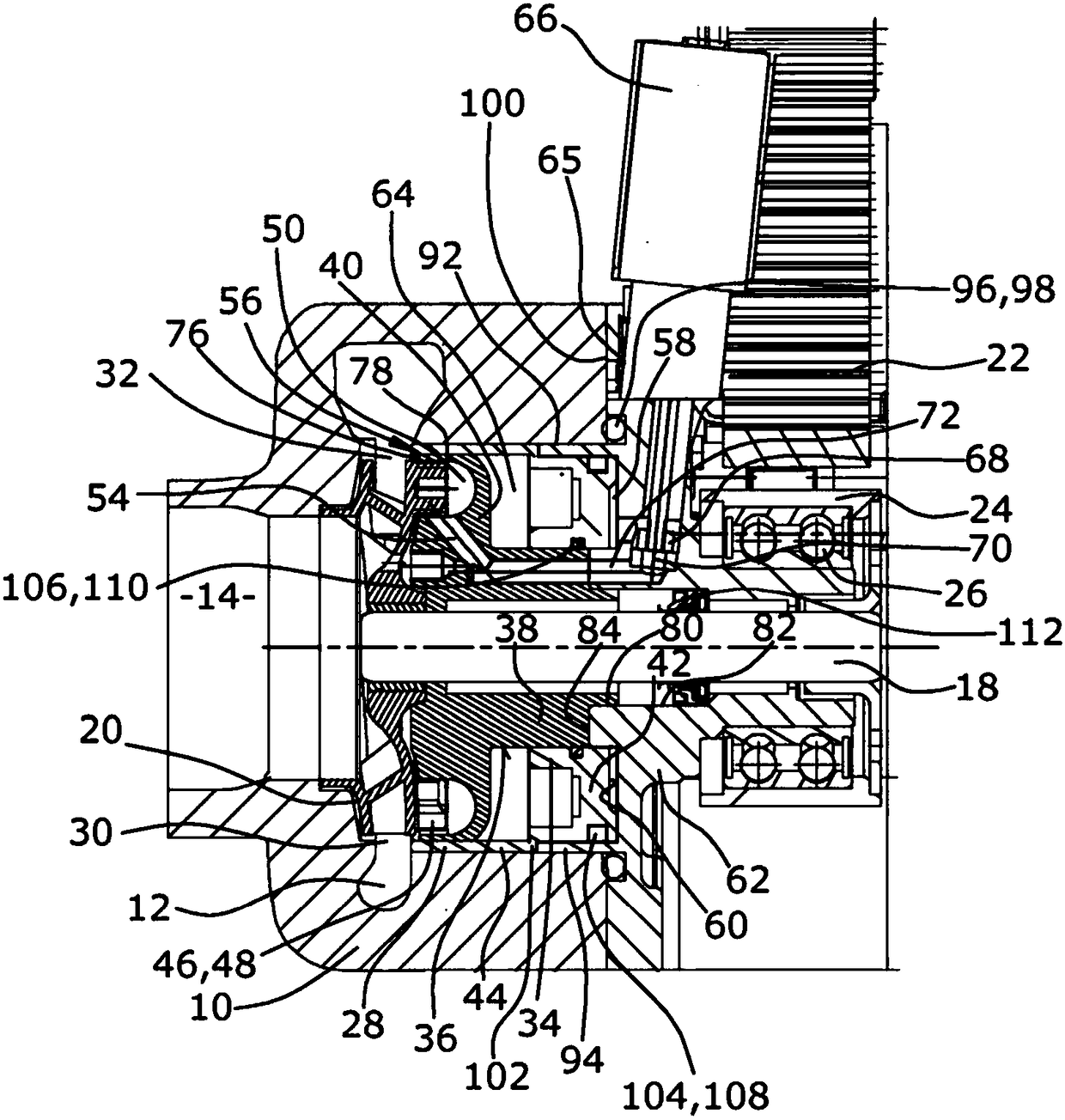

[0025] The coolant pump according to the invention comprises an outer housing 10 in which a helical delivery channel 12 is formed, in which cooling is sucked in via an axial pump inlet 14 also formed in the outer housing 10 The coolant is delivered via the delivery channel 12 into a tangential pump outlet 16 formed in the outer housing 10 and into the cooling circuit of the internal combustion engine. Furthermore, the housing 10 can be formed in particular by a cylinder crankcase which has a recess for receiving the remaining coolant pump.

[0026] For this, a coolant pump impeller 20 is fastened radially in the delivery channel 12 on the drive shaft 18 , said coolant pump impeller 20 is formed as a radial pump wheel, the rotation of which achieves the cooling of the coolant. Delivery in the delivery channel 12.

[0027] The drive of the turbine pump impeller 20 takes place via a drive belt 22 which drives a pulley 24 which is fastened on the axial end of the drive shaft 18 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com