Air cylinder and punching machine using same

A punching machine and air cylinder technology, applied in the field of the air cylinder of the punching machine, can solve the problems of increasing production cost, affecting the processing time, and the stability of the axial movement of the cylinder is difficult to meet the requirements, so as to improve production efficiency, prevent chattering, The effect of precise axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

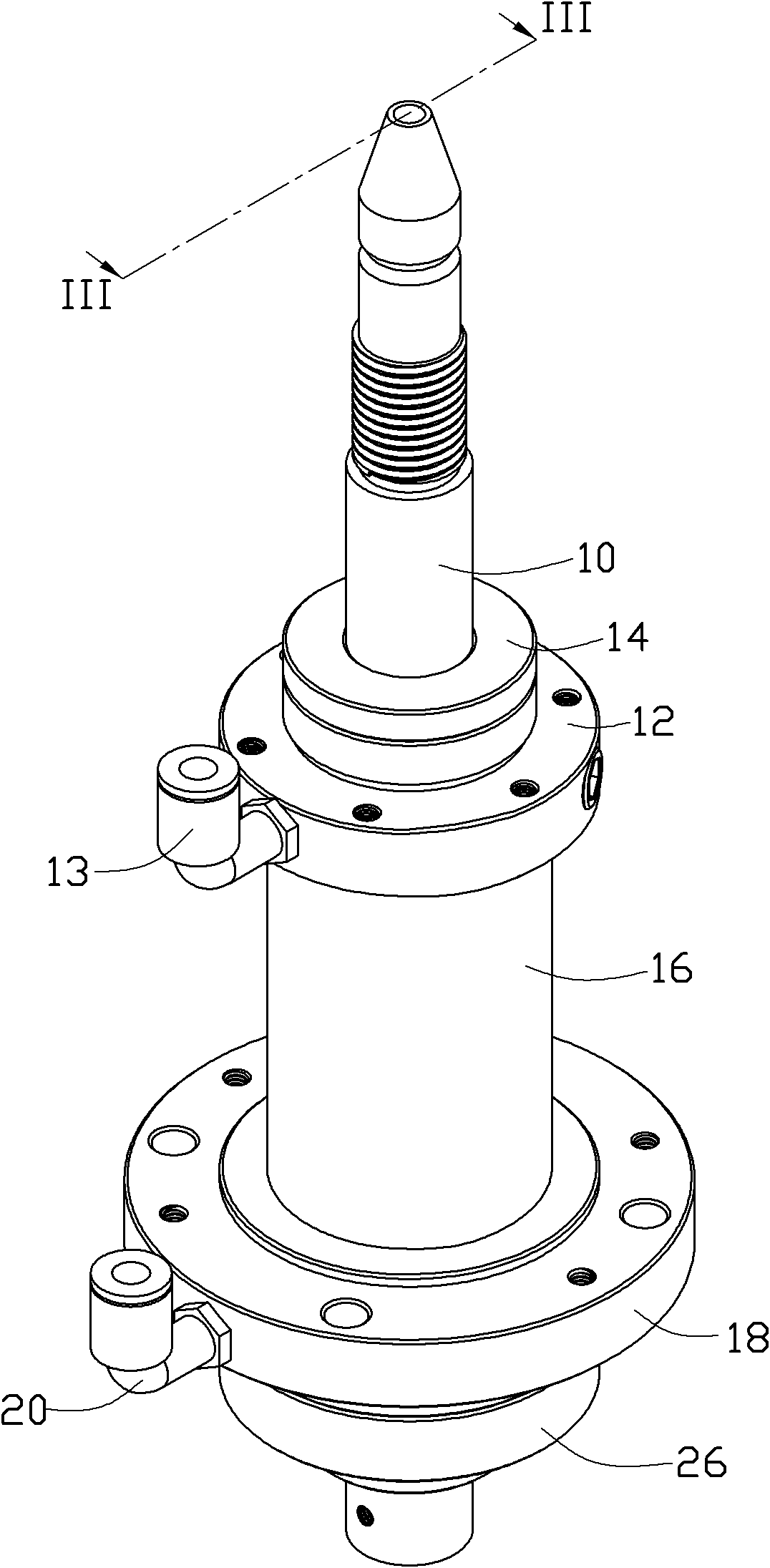

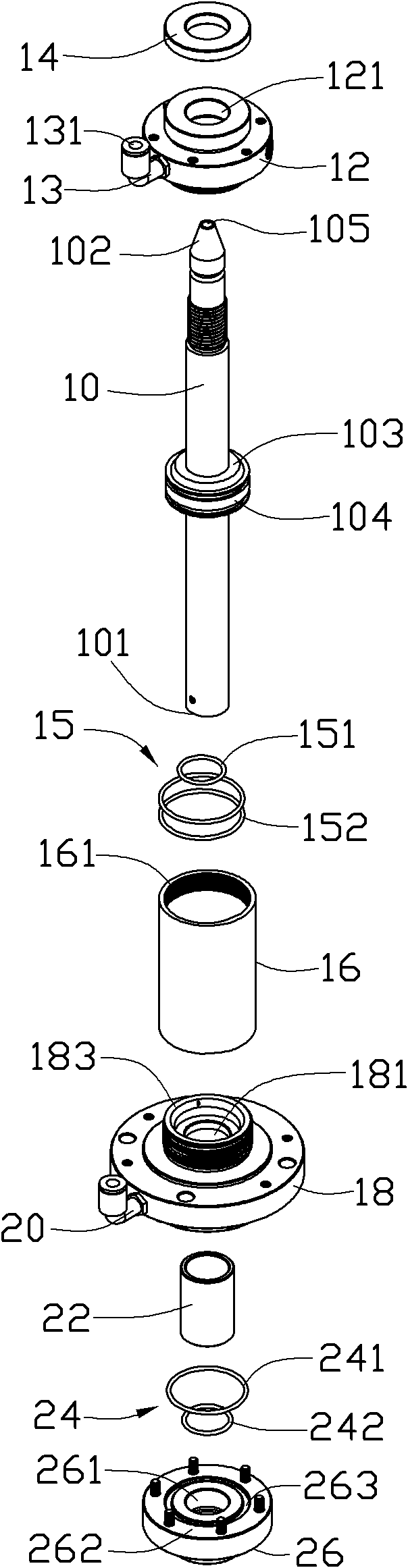

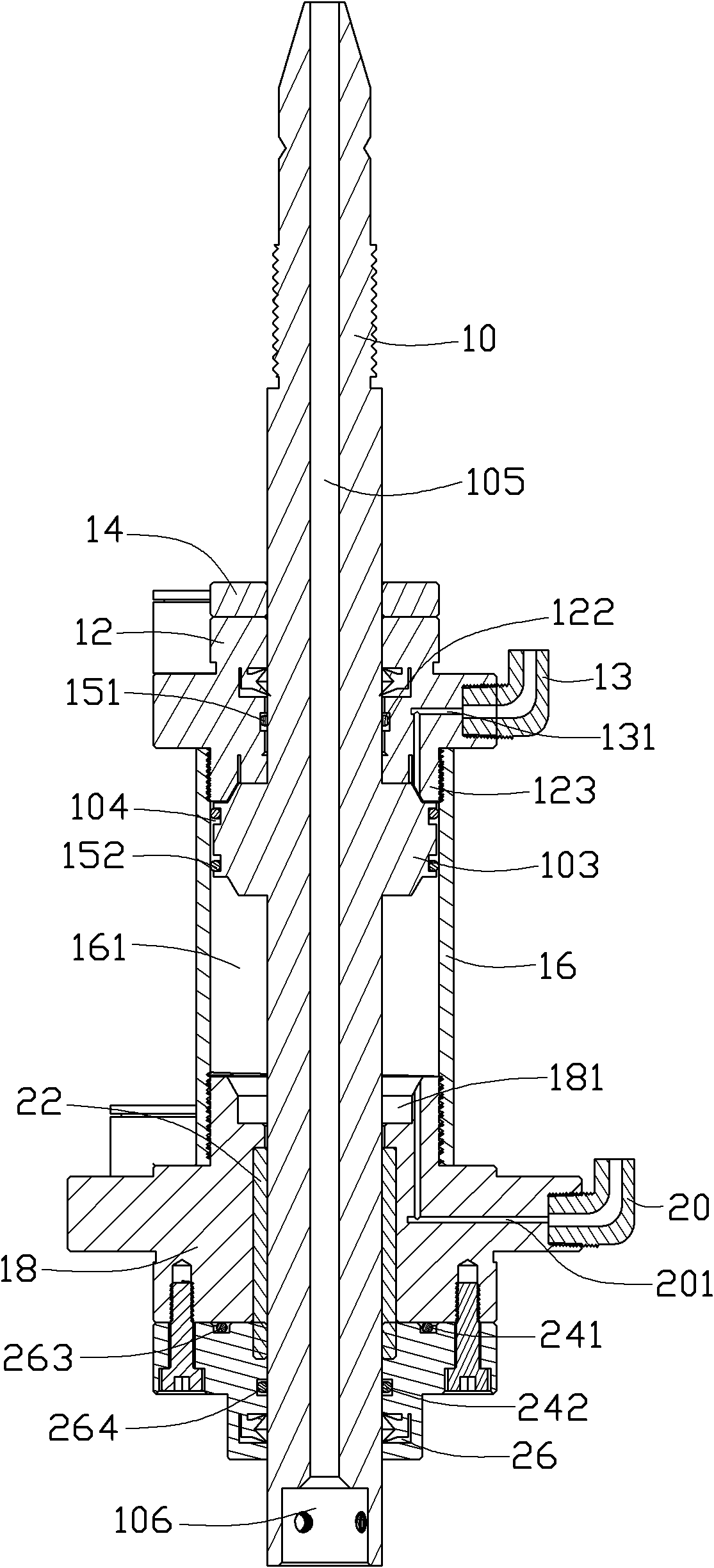

[0014] see figure 1 and figure 2 , the cylinder of the preferred embodiment of the present invention is used for the drive of the punching machine and removes waste materials, and it includes a piston rod 10, a rear end cover 12, a first joint 13, a buffer pad 14, a seal 15, a cylinder barrel 16, The front end cover 18 , the second joint 20 , the shaft sleeve 22 , the sealing member 24 and the fixing member 26 .

[0015] Please also refer to image 3 , the piston rod 10 is roughly a cylinder, which includes a front end 101 , a tail end 102 and a carrier 103 . The bearing body 103 is an annular disc located in the middle of the outer circle, which is larger than the diameter of the piston rod 10 . Two annular grooves 104 are recessed on the outer edge of the carrier 103 at intervals. A through hole 105 is defined along the axial direction of the piston rod 10 , passing through the front end 101 and the tail end 102 for removing waste materials. The front end 101 of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com