A linked detection device for harmful particles of lubricating grease

A particle detection device and grease technology, which is applied to measurement devices, mechanical devices, instruments, etc., can solve the problems of low detection efficiency and laborious operation process, and achieve the effect of smooth movement, simple operation and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

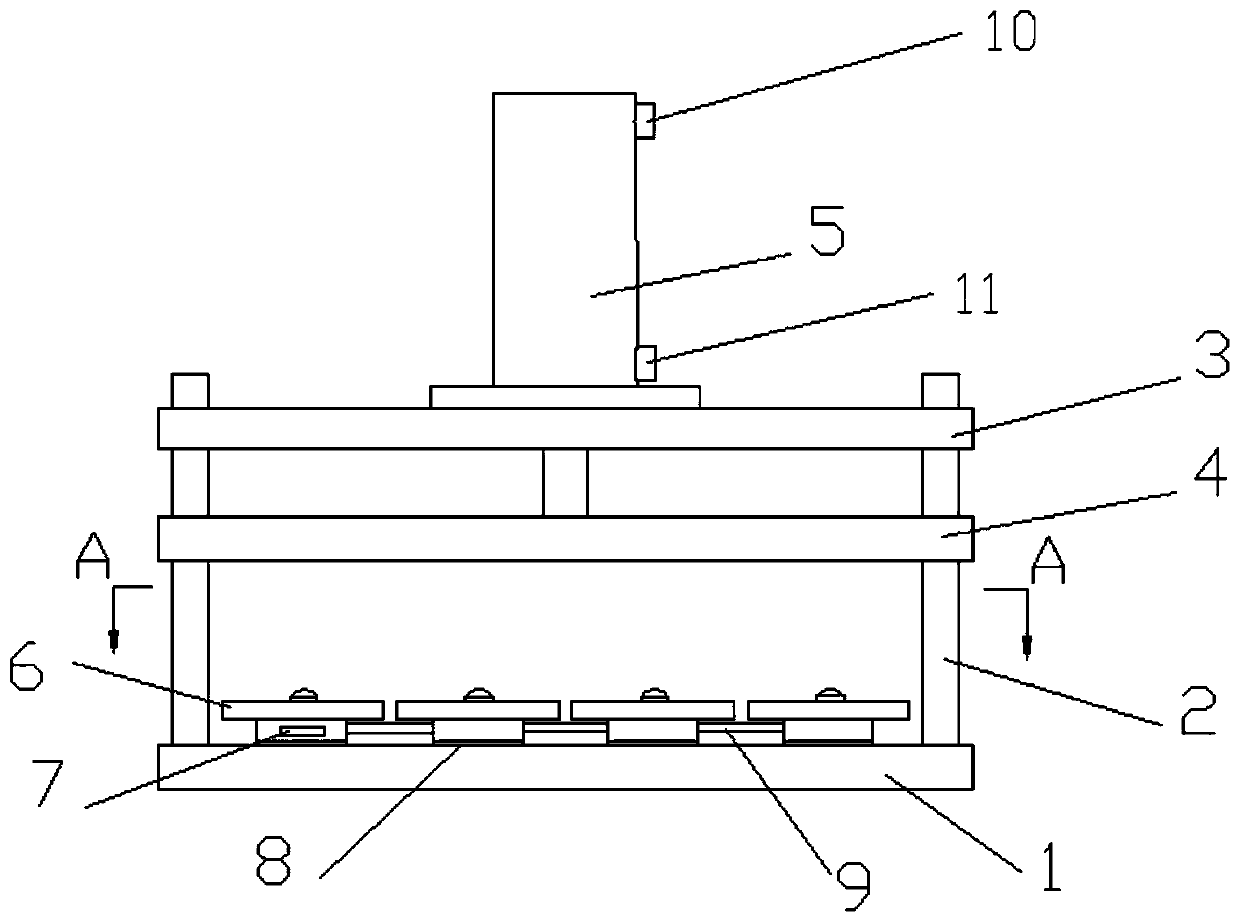

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

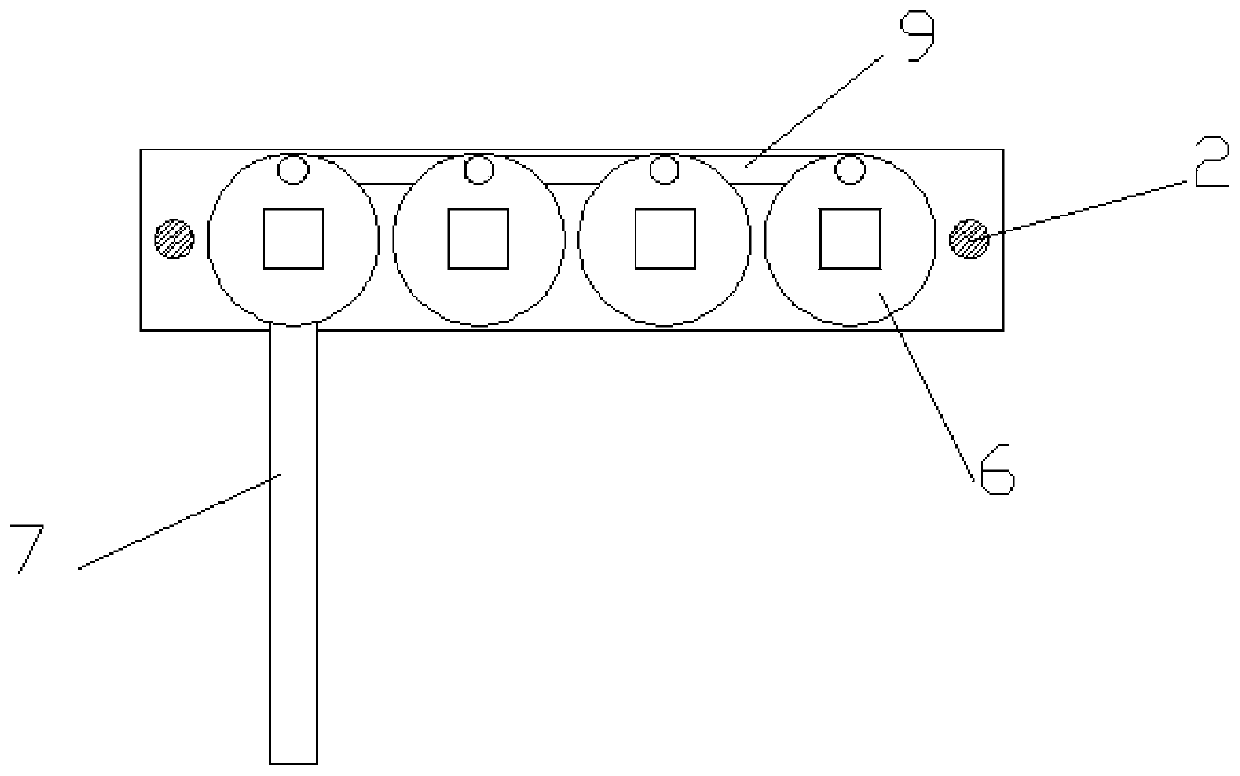

[0022] The invention relates to a detection device for harmful particles of lubricating grease in interlocking mode, which comprises a base, a column, a moving seat, a static seat, a hydraulic cylinder, a lower seat, a handle, a centripetal thrust bearing, an upper plate, and a lower plate. The two columns are symmetrically arranged at both ends of the base, and the two ends of the movable seat are slidingly fitted on the two columns. The movable seat can move along the axial direction of the column, and the static seat is fixed on the top of the two columns. The power mechanism is a hydraulic cylinder. The hydraulic cylinder is installed above the static seat, and the lower end of the piston rod of the hydraulic cylinder protrudes from the static seat, and the lower end of the piston rod is threadedly connected with the movable seat. 4 lower seats are evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com