Compact planetary gearbox

A transmission device and planetary gear technology, which is applied to gear transmission devices, transmission devices, transmission device parts, etc., can solve problems such as the need for axial structural space, and achieve the effect of saving structural space and reducing axial structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

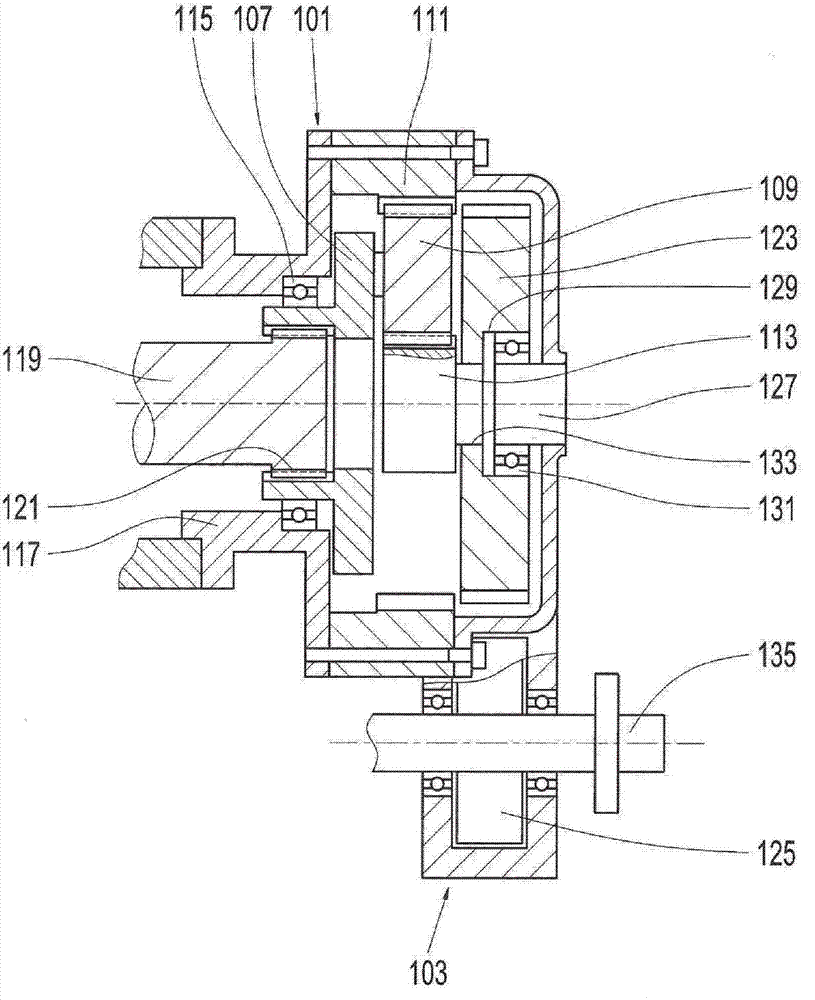

[0019] figure 1 The transmission shown has an input-side planetary gear stage 101 and an output-side spur gear stage 103 . The planetary gear stage 101 comprises a planet carrier 107 , planet gears 109 rotatably mounted in the planet carrier 107 , a stationary ring gear 111 and a rotatable sun gear 113 . The planetary gears 109 mesh with the ring gear 111 and the sun gear 113 .

[0020] The planet carrier 107 is rotatably mounted in the transmission housing 117 by means of exactly one bearing 115 . The ring gear 111 forms part of the transmission housing 117 and is screwed to another part of the transmission housing 117 . The bearing 115 is arranged offset with respect to the arms of the planet carrier 107 on the drive side, ie in the direction of the drive shaft 119 .

[0021] A drive torque is applied to the planet carrier 107 via the drive shaft 119 . For this purpose, the drive shaft 119 is connected to the planet carrier 107 in a rotationally fixed manner by means of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com