Radial rolling bearing, in particular single-row spherical-roller bearing

一种球面滚子、滚动轴承的技术,应用在径向滚动轴承领域,能够解决刮擦、轴承轴向和径向承载能力小等问题,达到减小轴向结构空间、径向和轴向承载能力高、高轴向承载能力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

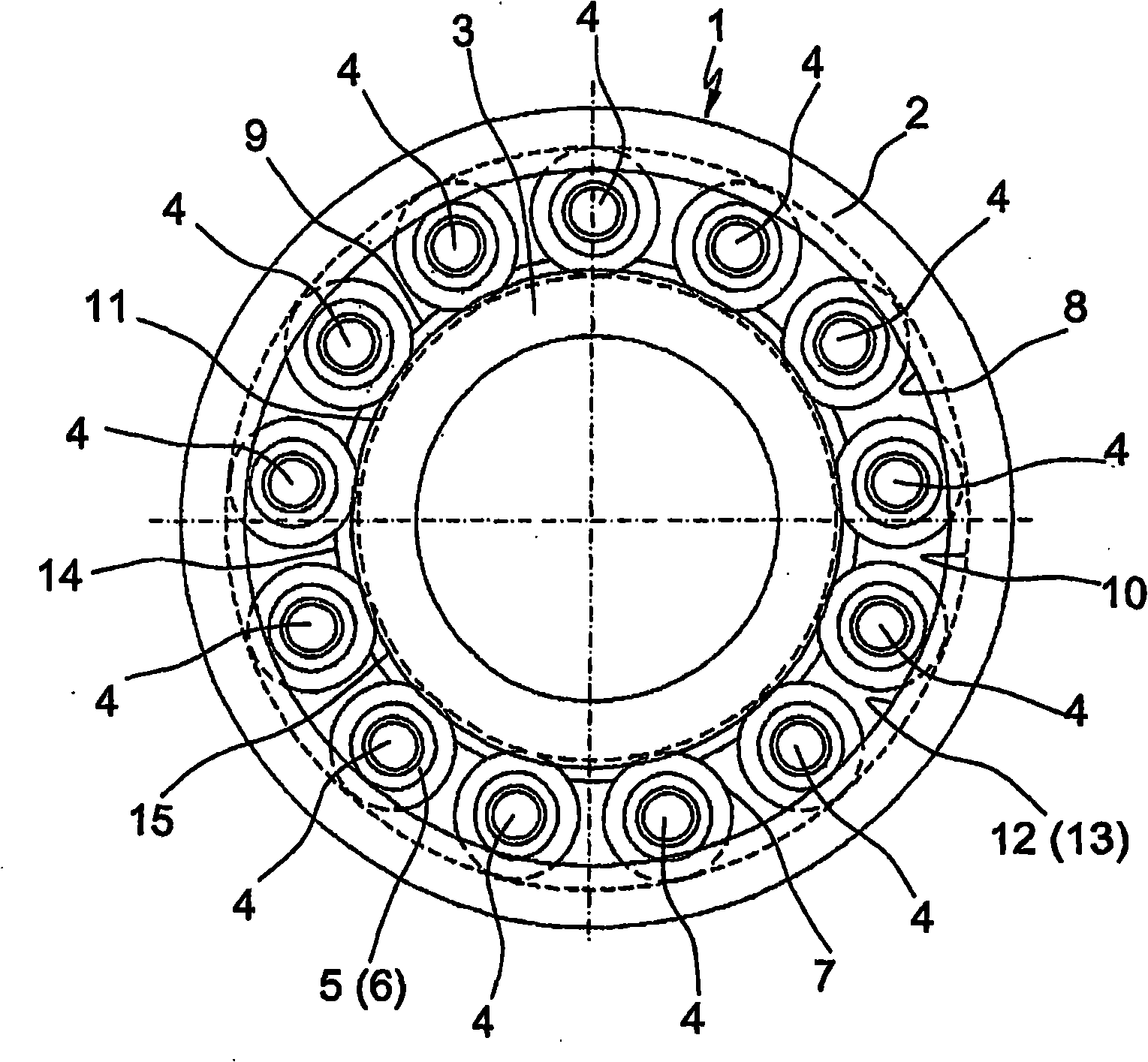

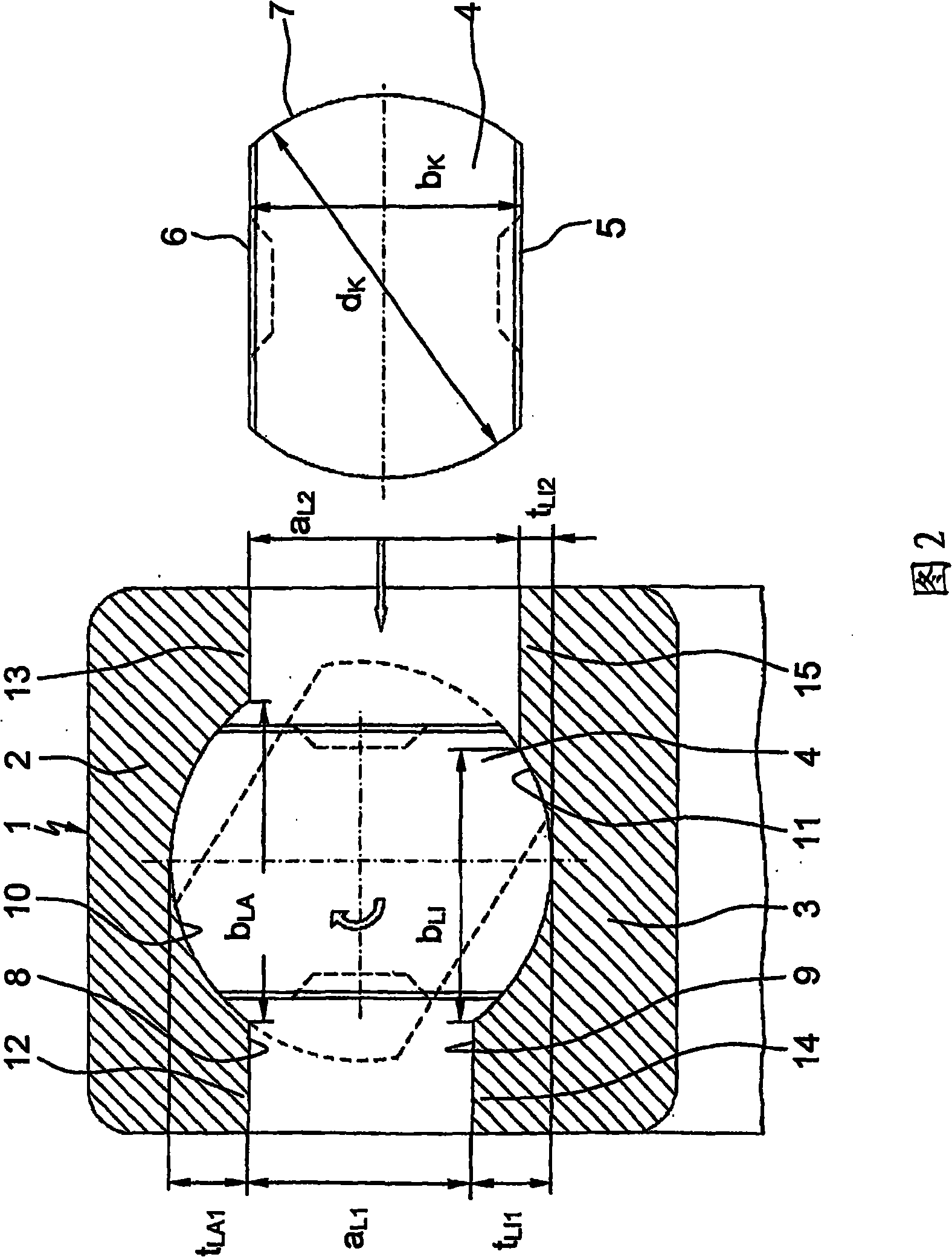

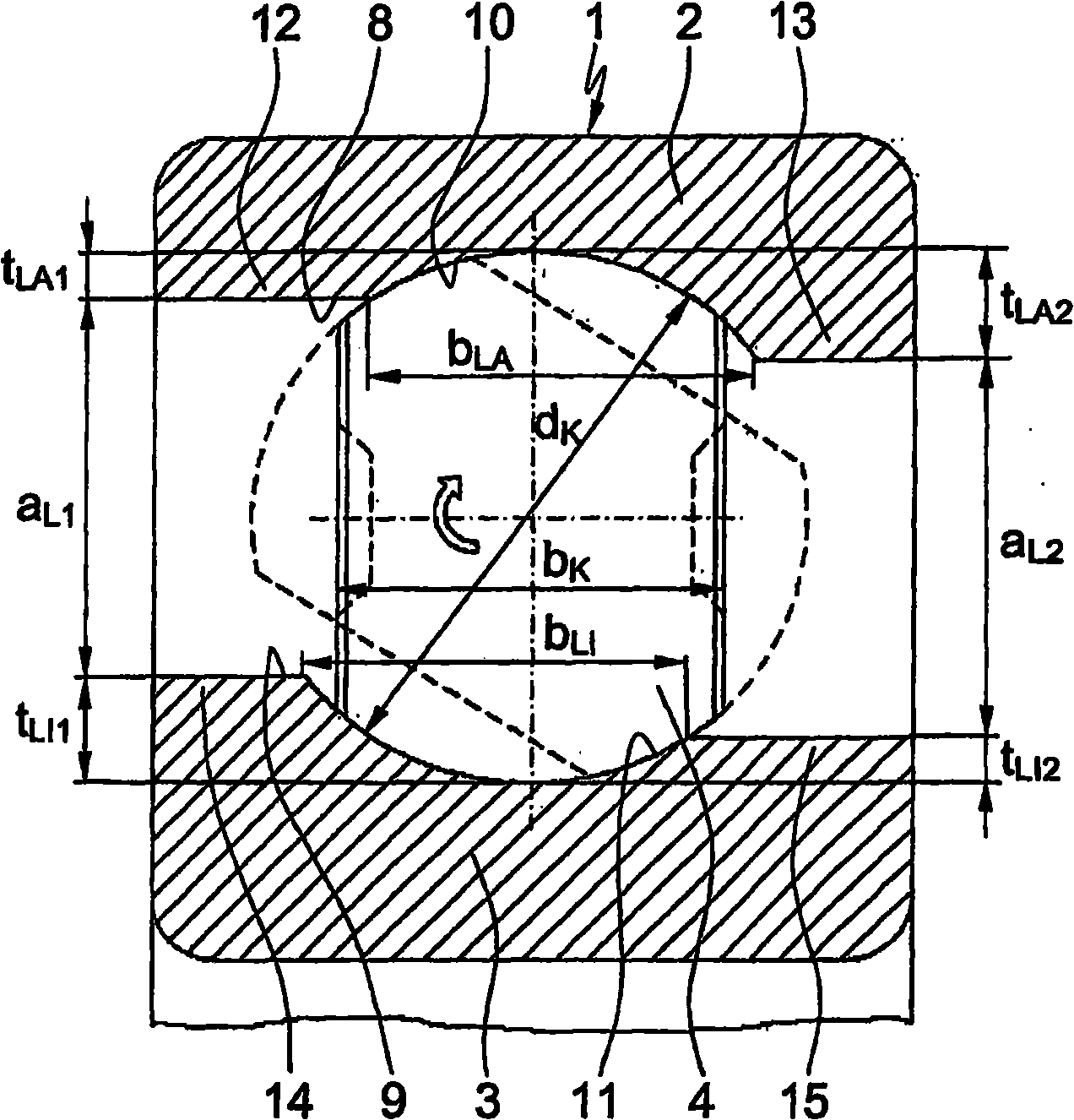

[0020] Depend on figure 1It can be clearly seen that the radial rolling bearing 1 designed as a single row spherical roller bearing is mainly composed of a bearing outer ring 2, a bearing inner ring 3 and many spherical rollers 4 arranged between the bearing rings 2 and 3, such as It can be seen in FIG. 2 that the spherical rollers each have two sides 5 , 6 that are symmetrically flattened from the spherical basic shape and are arranged parallel to one another and are kept at a uniform distance from one another in the circumferential direction by a bearing cage (not shown). These spherical rollers 4, as can also be clearly seen in FIG. 2, have a diameter d between their sides 5, 6 of their spherical basic shape k about 70% of the width of b k , and use its rolling surface 7 to roll in two grooved raceways 10, 11 processed on the inner side 8 of the bearing outer ring 2 and the outer side 9 of the bearing inner ring 3. These raceways respectively pass through two axial Edges ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com