Toothed wheel for use in a gear transmission, gear pairing of a gear transmission and gear transmission with such a gear pairing

A gear transmission and gear technology, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of inability to maintain meshing, dominant temperature changes, large operating temperature range, etc., to achieve smooth operation and simplified manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

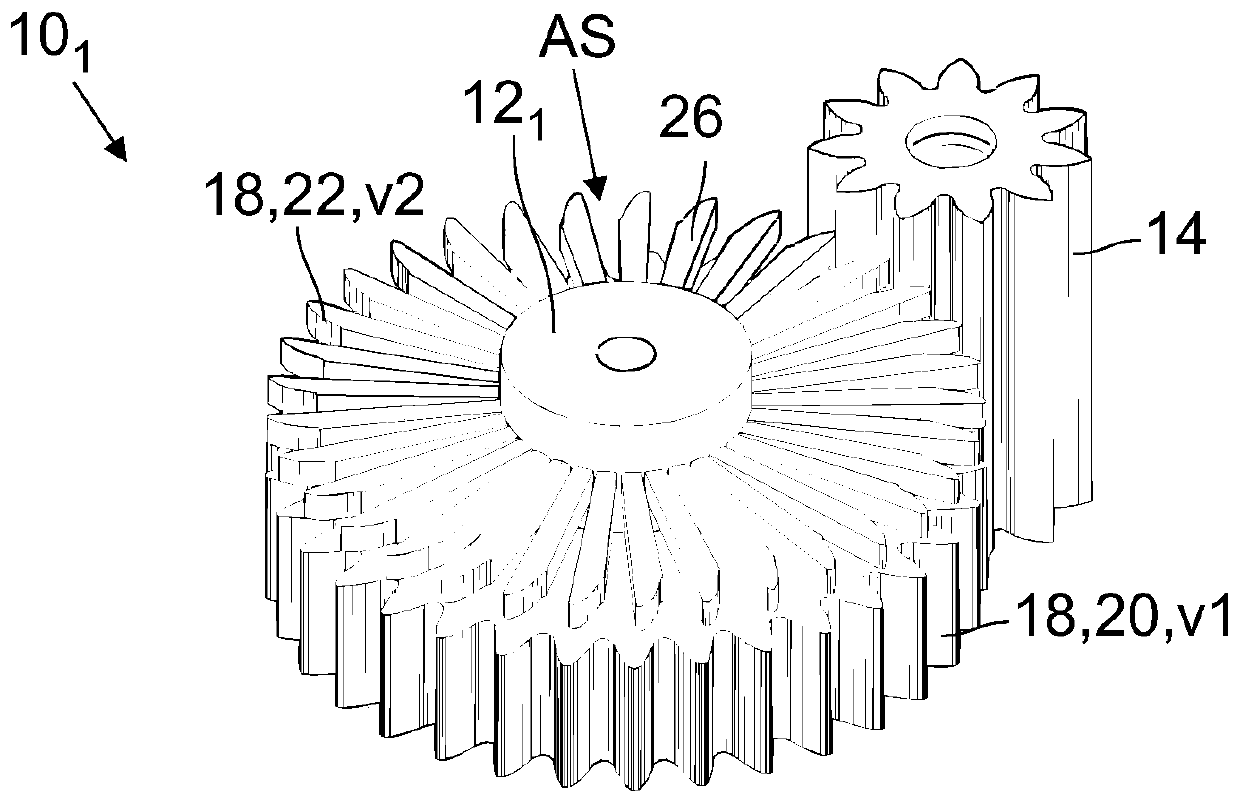

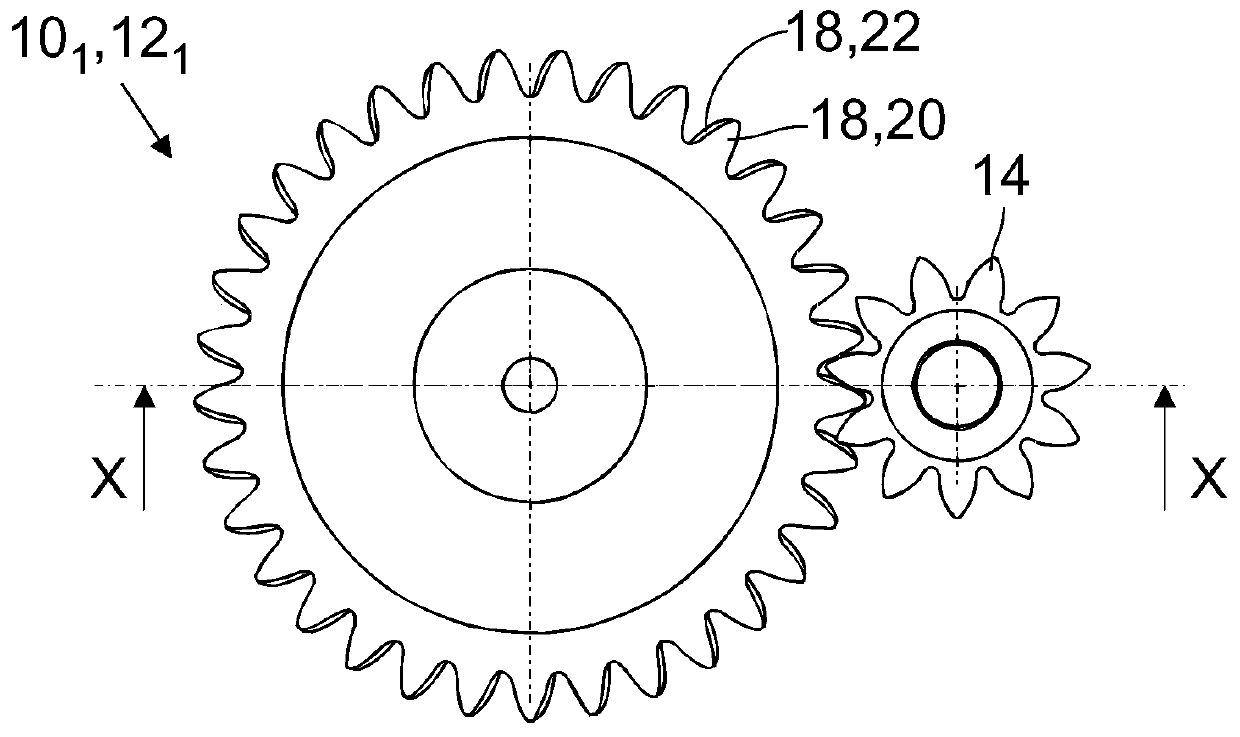

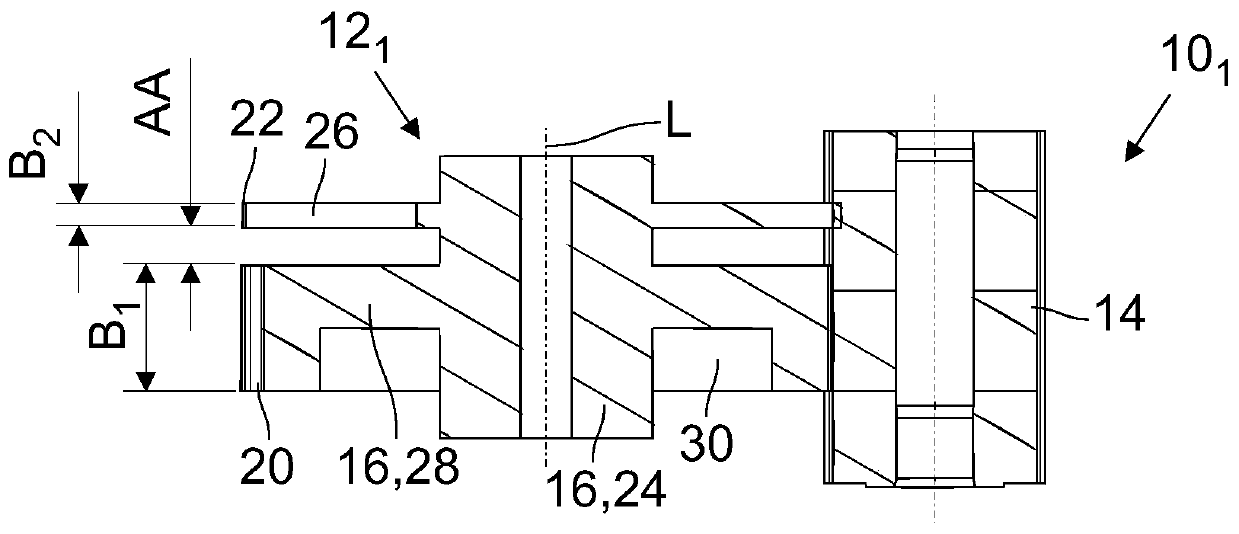

[0056] exist Figure 1A to Figure 1C A gear pair 10 according to the invention is shown in various views in 1 The first embodiment of . it's here, Figure 1A shows a perspective view, while Figure 1B shows a top view, and Figure 1C shows along the Figure 1B Cross-sectional view of section X-X defined in . gear pair 10 1 Comprising a gear 12 according to the invention according to the first embodiment 1 and another gear 14, wherein gear 12 1 and another gear 14 mesh with each other. In the first embodiment, the gear 12 1 And the further gear wheel 14 is embodied as a spur gear with spur toothing.

[0057] gear 12 1 With base body 16 (see Figure 1C ), the base body 16 forms the ring gear 18. The ring gear 18 includes a first plurality of teeth 20 and a second plurality of teeth 22 . In the first embodiment, the number of the first teeth 20 and the second teeth 22 is the same, but the numbers can also be different from each other (see FIGS. Figure 6 ). Not onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com