Fan mounted into a tube

A technology of fans and fan impellers, which is applied to parts of pumping devices for elastic fluids, pump devices, mechanical equipment, etc., can solve problems such as reducing fluid delivery efficiency, and achieve the effect of stabilizing flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

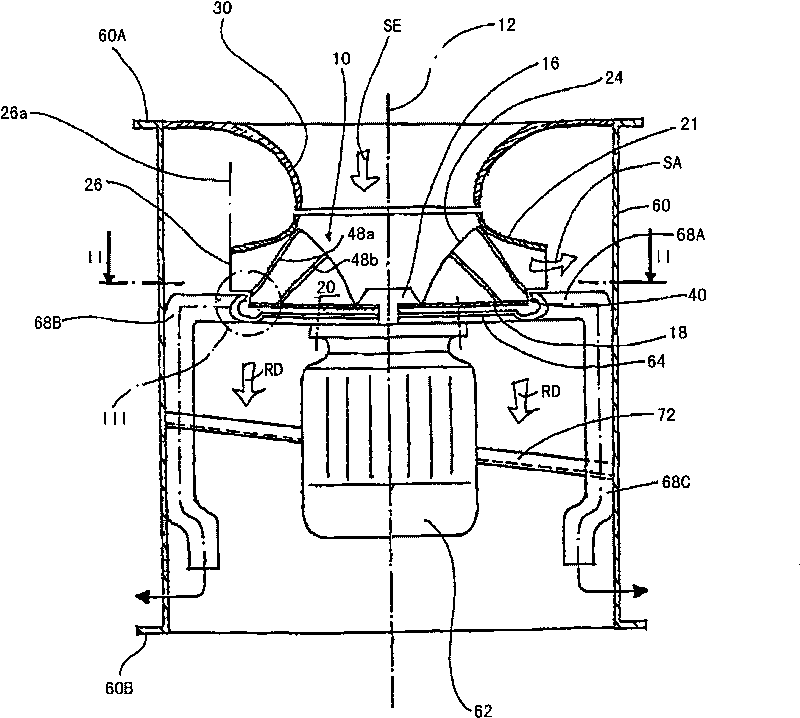

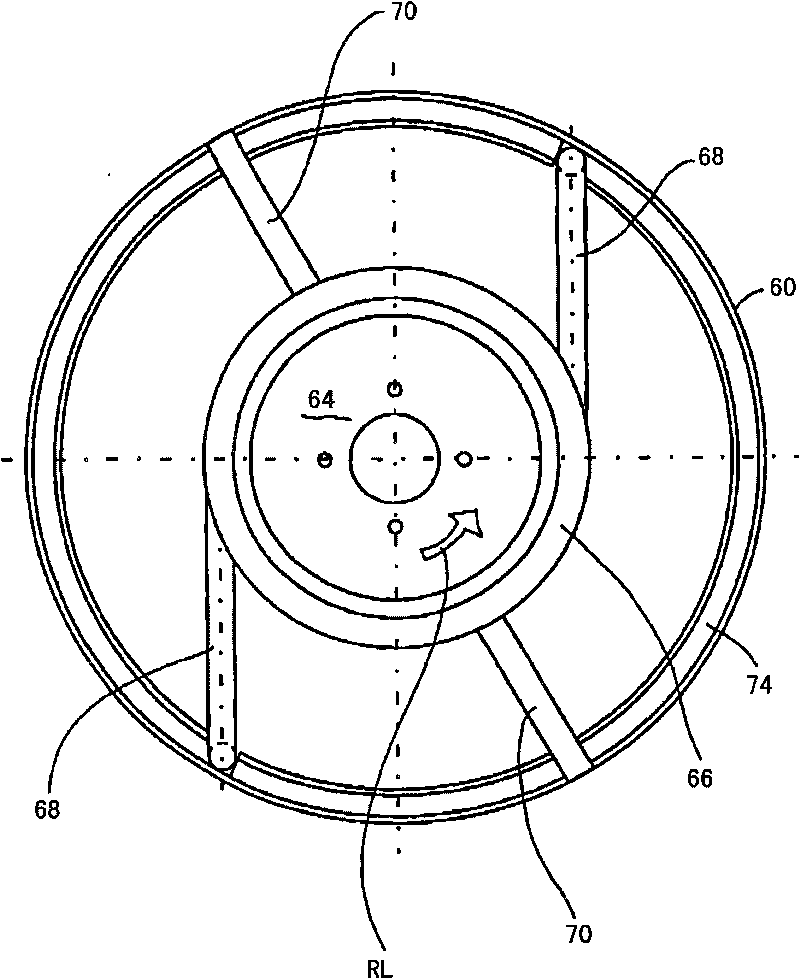

[0053] exist figure 1 The axis of the fan wheel arrangement installed in the pipe section 60 is designated with reference numeral 12 . The pipe section 60 is part of a pipe system for conveying a fluid or flow medium entrained with solid or liquid particles to be separated.

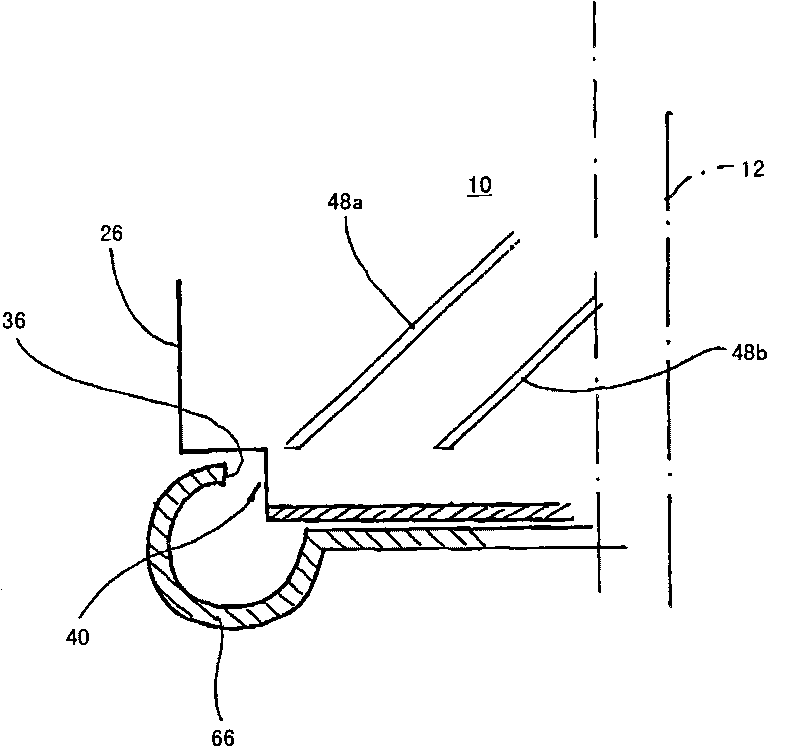

[0054] Specifically, an axial-inlet radial fan impeller is installed in the pipe section 60 , and the radial fan impeller is indicated by reference numeral 10 . The fan impeller should be capable of effectively conveying or pumping a gaseous flow medium entrained with abrasive particles (such as dust particles, water particles, snow flakes, fat particles and the like) from the surrounding environment. In addition, with figure 1 The fan wheel shown fulfills the task of largely separating the particles flowing past it. For this purpose, the following structure is provided:

[0055] The hub designated by reference numeral 16 is seated in a rotationally fixed manner on the drive shaft of a motor 62 , whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com