Hybrid Module

A hybrid module and clutch technology, which is applied to hybrid vehicles, power units, pneumatic power units, etc., can solve problems such as difficult use and inability to use hybrid modules, and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

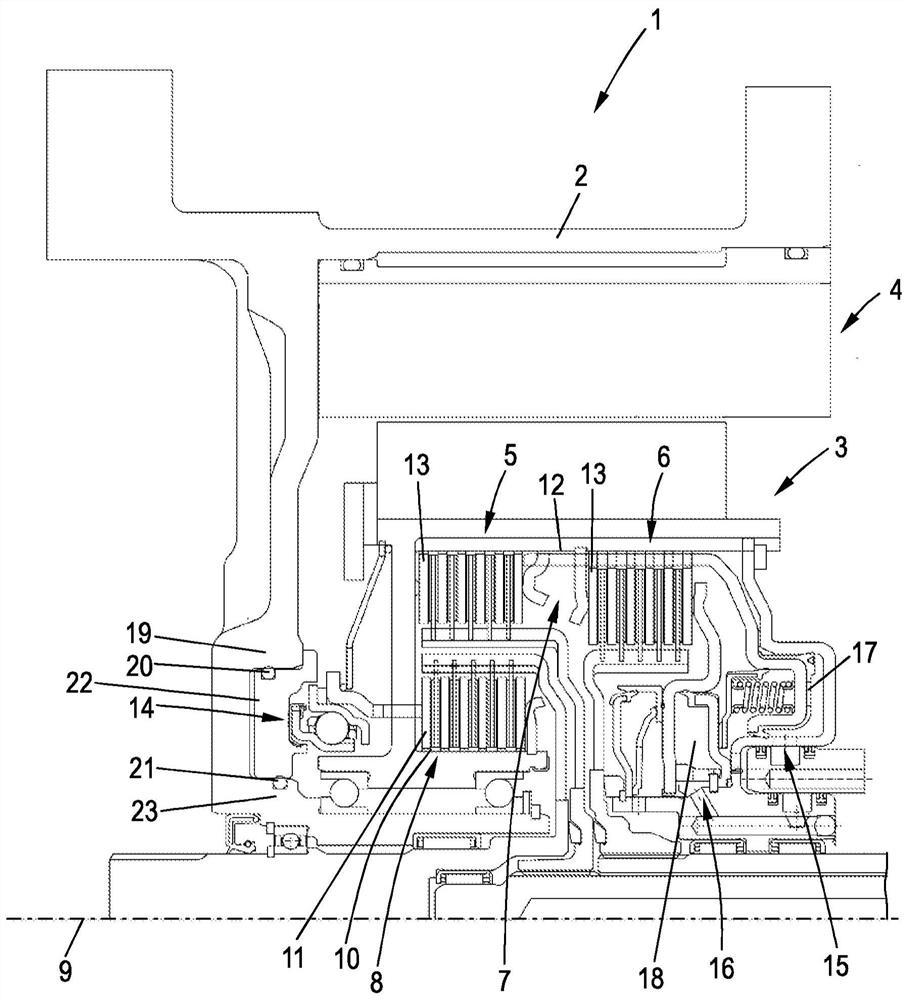

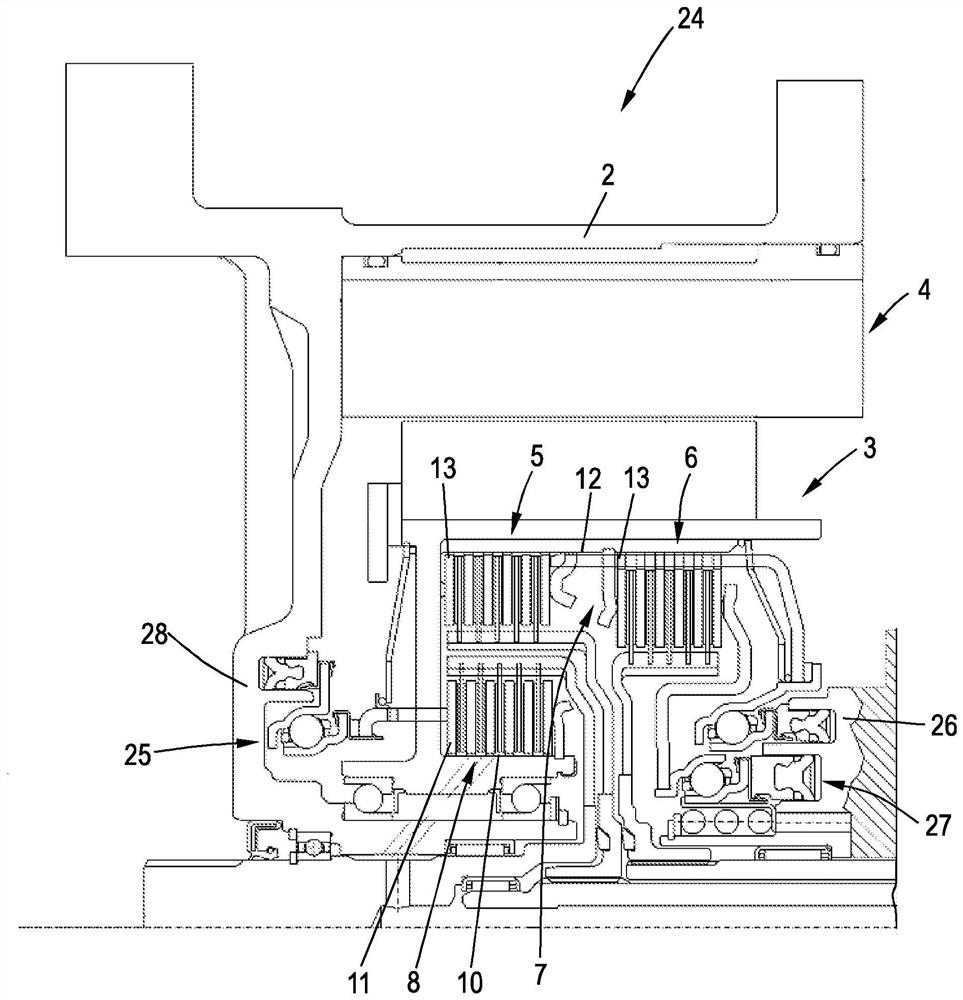

[0027] figure 1 Shown is a hybrid module 1 for a motor vehicle not further shown, comprising: an electric machine 4 with a stator 2 and a rotor 3 ; a dual clutch with a first and a second partial clutch 5 , 6 7, the double clutch is configured to connect the hybrid module 1 with the transmission of the motor vehicle (not shown) in a detachable manner; and a disconnect clutch 8 is configured to connect the internal combustion engine (not shown) of the motor vehicle to It can be connected with the hybrid module 1 in a detachable manner.

[0028] Obviously, the dual clutch 7 and the separating clutch 8 with their two partial clutches 5 , 6 are arranged not only radially but also axially within the rotor 3 . The first and second partial clutches 5 , 6 are arranged axially one behind the other, wherein the double clutch 7 is radially farther from the axis of rotation 9 of the rotor 3 than the separating clutch 8 . In other words, the separating clutch 8 is arranged radially close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com