Drive train for a motor vehicle, and method for operating a drive train

A technology for powertrain and motor vehicles, which is applied to the arrangement of multiple different prime movers of general power units, motor vehicles, power units, etc., can solve the problems of large structural space requirements of transmission output shafts, and reduce the structural space. , compact structure, high flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In the different figures, identical components are always provided with the same reference numerals and are therefore usually only mentioned and explained once in each case.

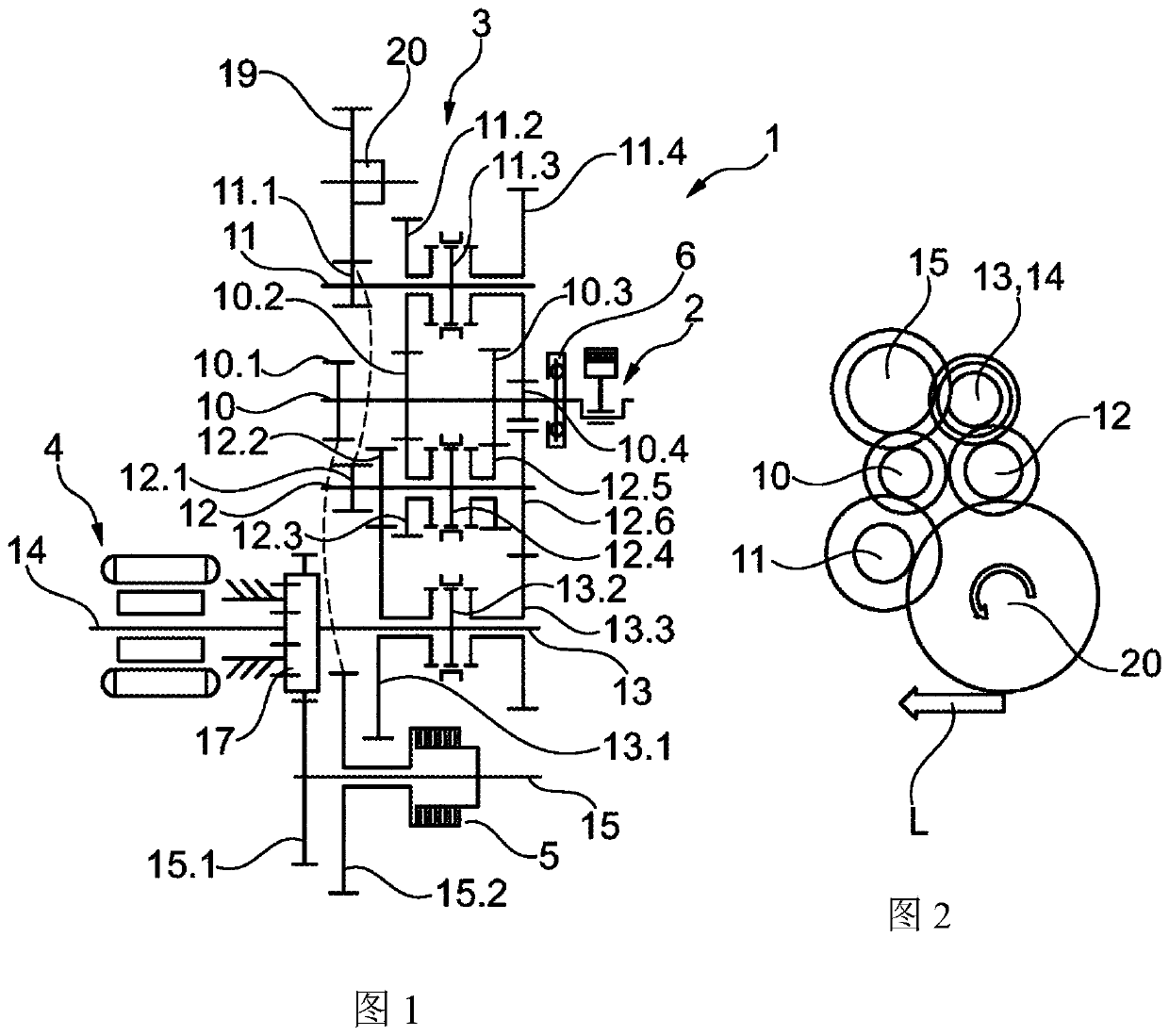

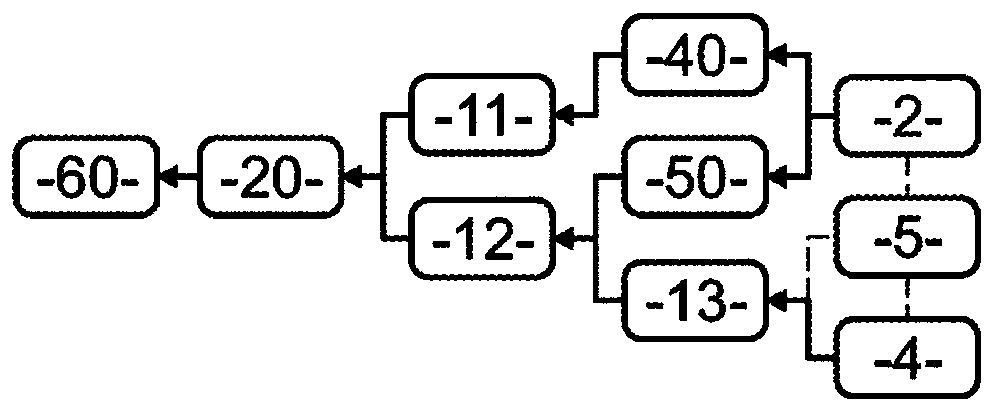

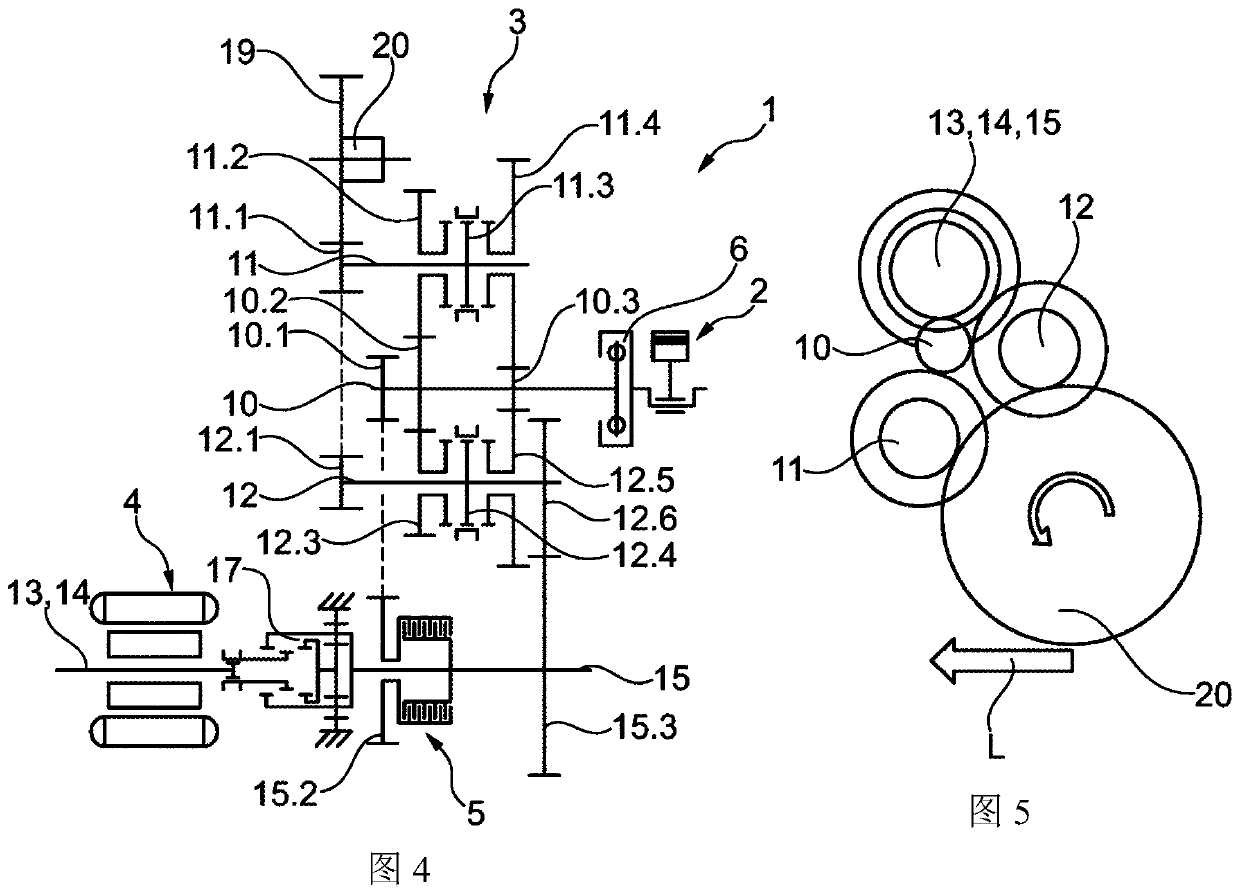

[0047] exist figure 1 In , a first embodiment of a powertrain system 1 is shown, which may be used in a hybrid motor vehicle. The drivetrain 1 has an internal combustion engine 2 , a transmission 3 , an electric machine 4 and a disconnect clutch 5 . As will be described further below, in the closed state of the separating clutch 5 a force transmission between the electric machine 4 and the internal combustion engine 2 can take place. In the disengaged state of the separating clutch 5 , the electric machine 4 and the internal combustion engine 2 are decoupled from each other.

[0048] The internal combustion engine 2 has an output shaft 2 . 1 , which is connected without a clutch to a first transmission input shaft 10 of the transmission 3 . This means that the output shaft 2.1 is permanently op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com