Patents

Literature

57results about How to "Increase drive torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

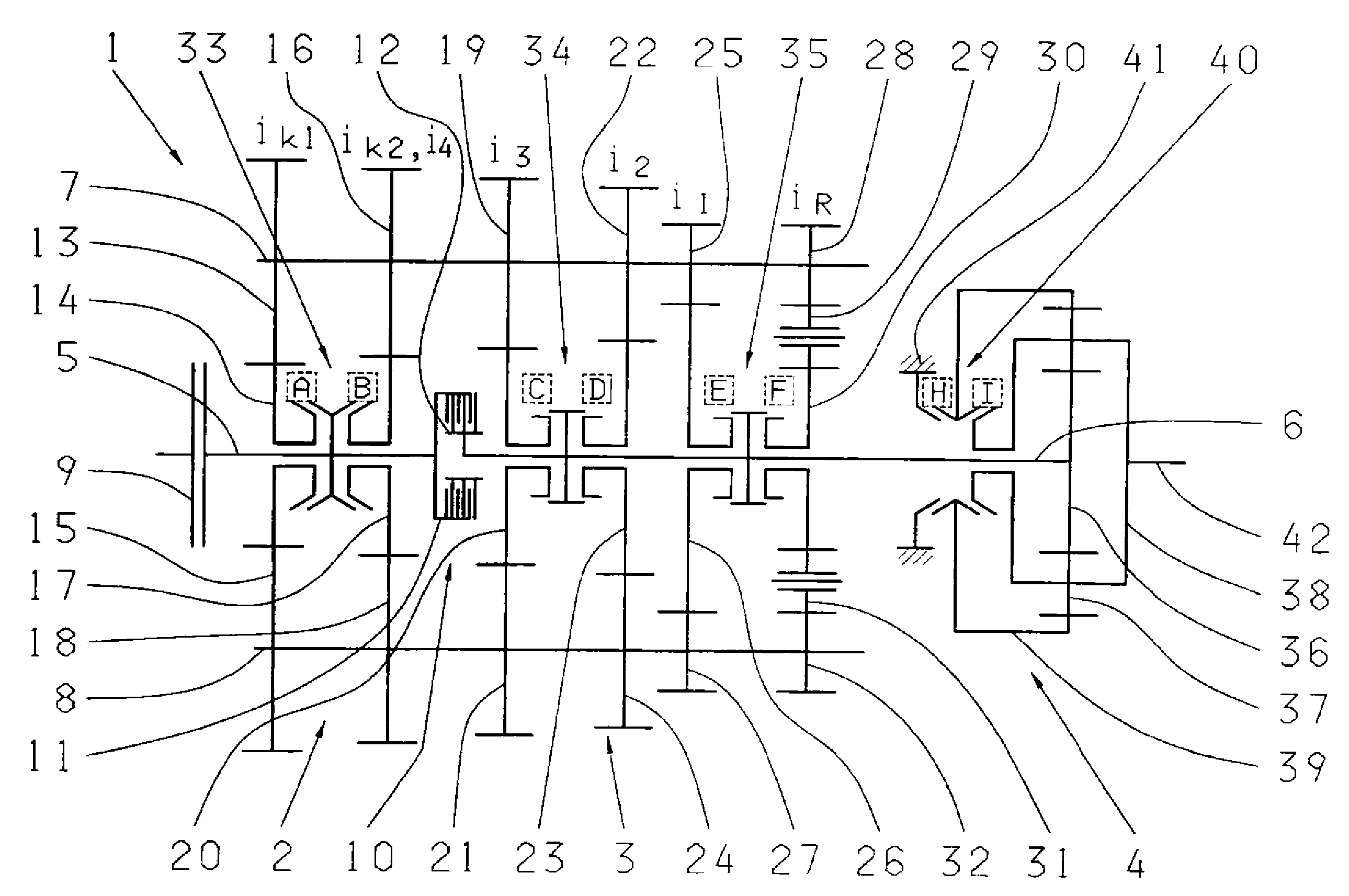

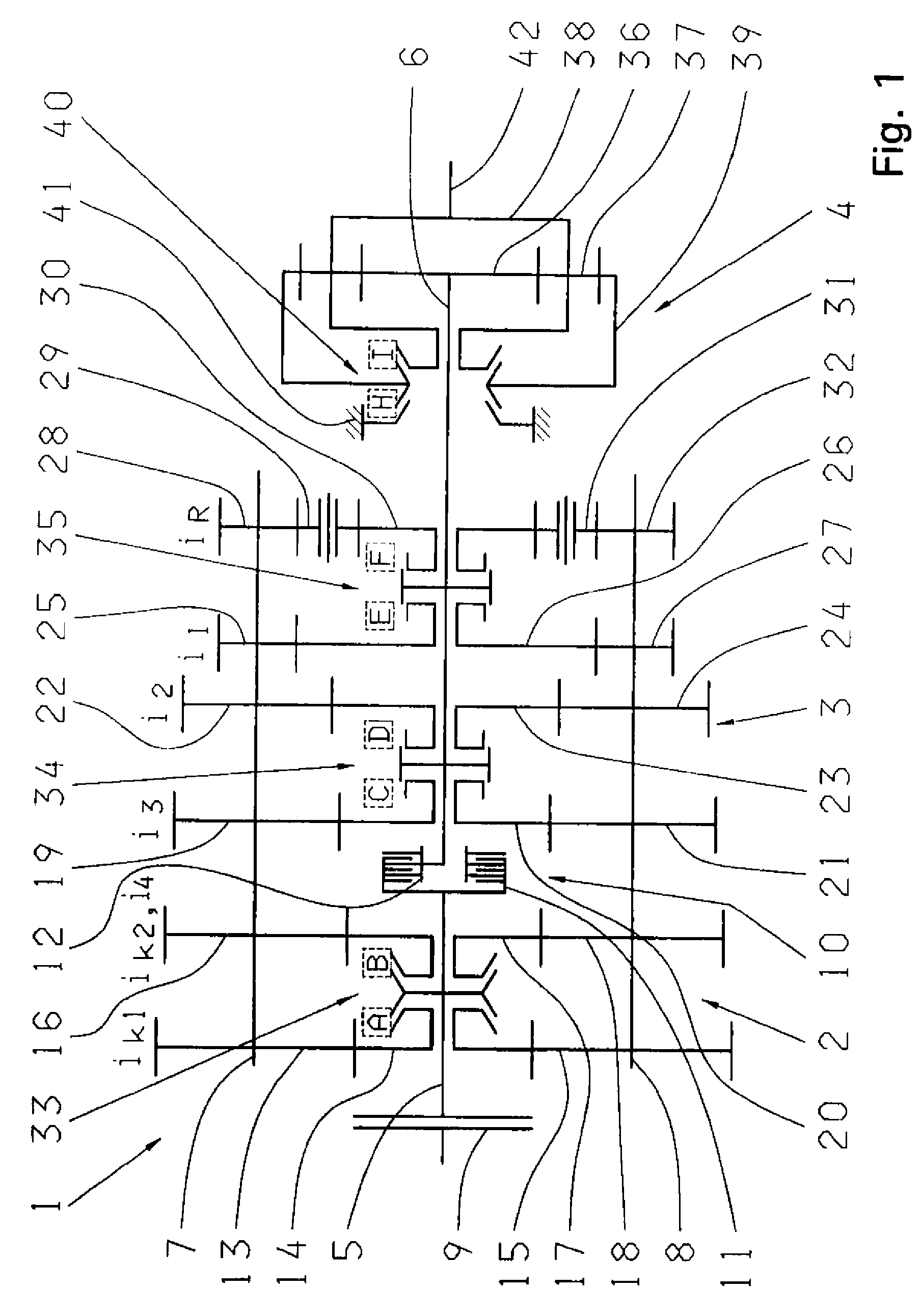

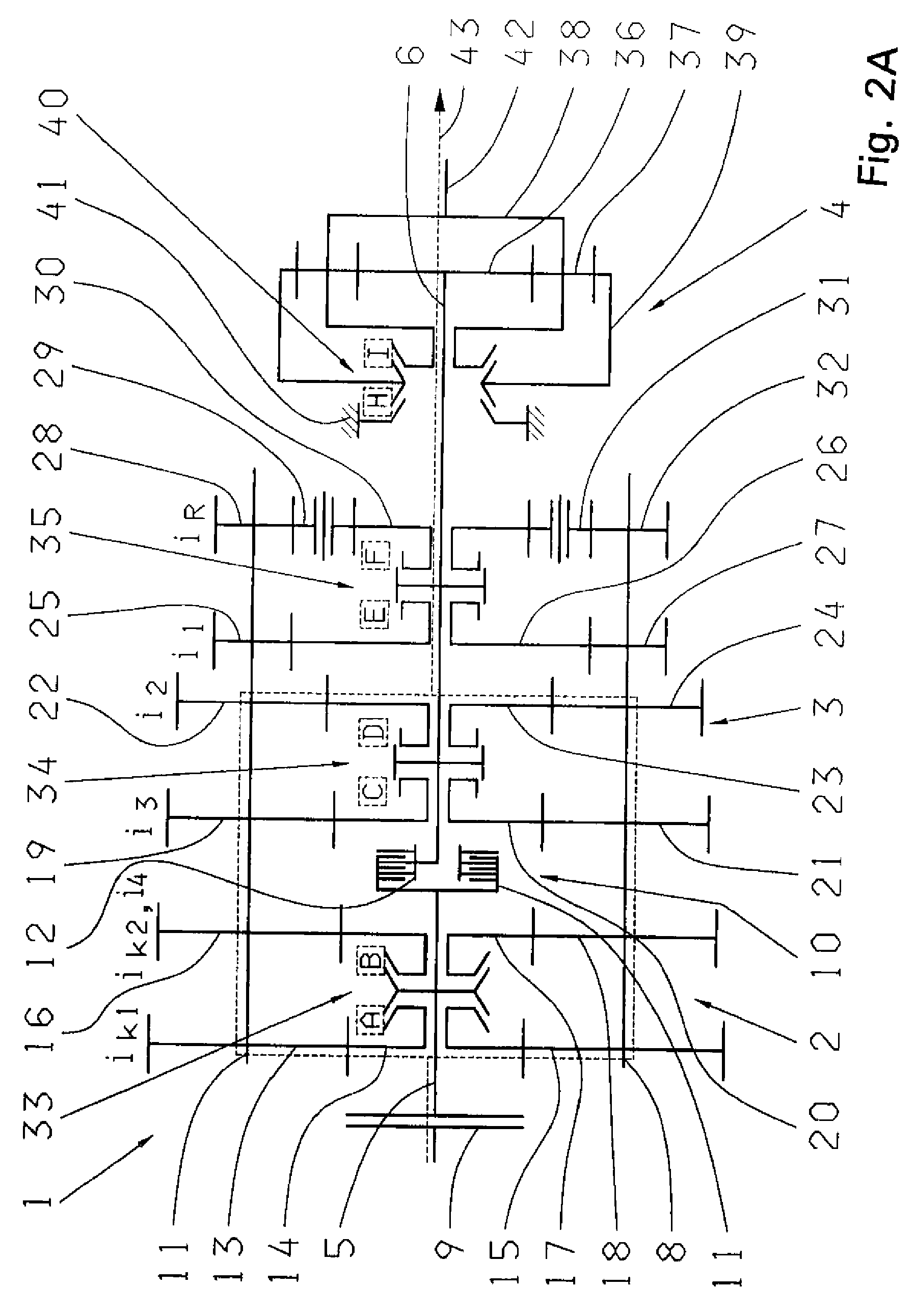

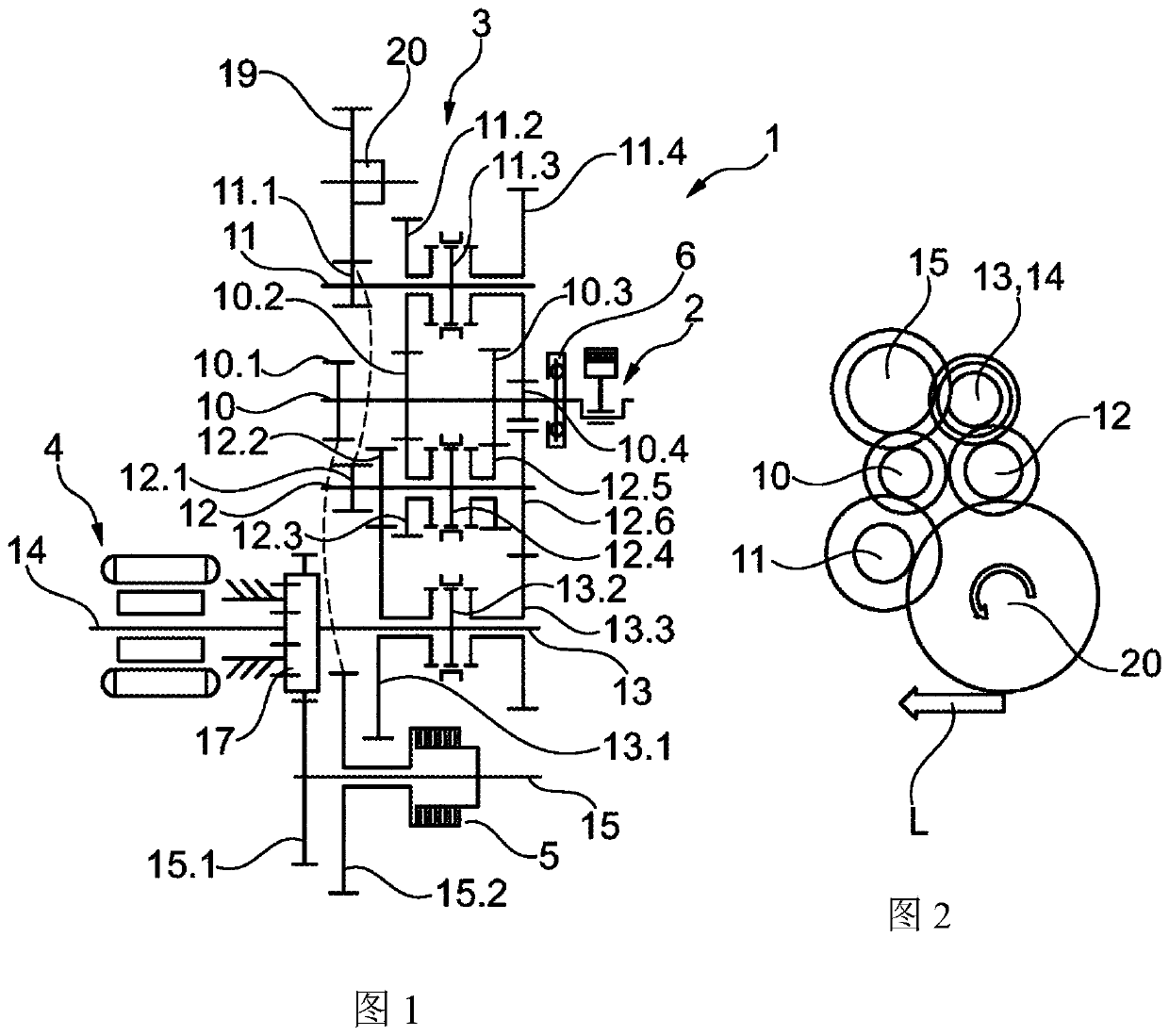

Multi-group transmission and method for changing gear in a multi-group transmission

ActiveUS20090107289A1Increase drive torqueTraction force interruptionToothed gearingsGearing controlEngineeringLoad shifting

An automated multi-group standard transmission, for a utility vehicle, and a process for changing gears in the multi-group transmission. The multi-group transmission includes at least two multi-speed transmission groups arranged one after the other, such that a multitude of gears can be shifted. A transmission input shaft that can be connected to an engine, via a startup element, is associated with a first transmission group and a second transmission main shaft is associated with a second transmission group. Load shifting mechanisms produce a temporary direct connection between the transmission input shaft and the transmission main shaft such that an intermediate gear can be shifted during a gear change from an original gear into a target gear. The load shifting mechanism enables gear changes that are virtually free of interruptions in load transfer during a gear change from a lower to a higher gear, thus increasing a high operational comfort.

Owner:ZF FRIEDRICHSHAFEN AG

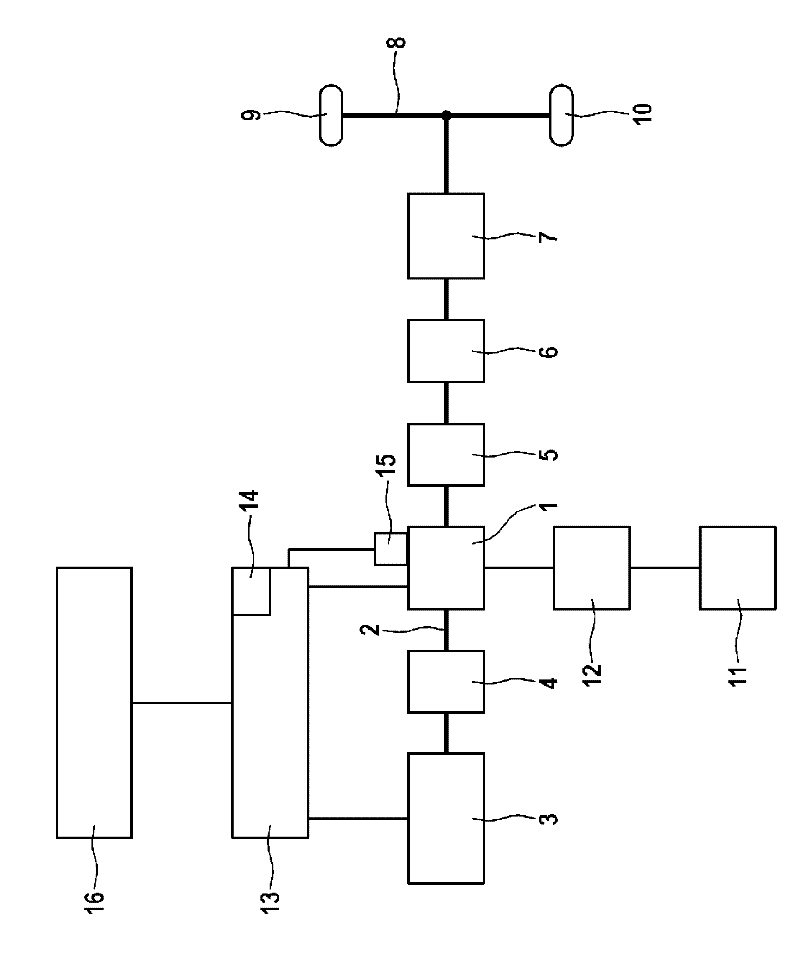

Method and device for adapting and/or diagnosing an internal combustion engine disposed in a hybrid vehicle

InactiveCN102470858AIncrease speedIncrease powerGas pressure propulsion mountingElectric machinesOperating pointExternal combustion engine

The invention relates to a method for adapting and / or diagnosing an internal combustion engine (3) disposed in a hybrid vehicle, forming a drive unit (1, 3) with at least one secondary machine (1). In order to allow a more rapid and simple adaptation and / or diagnostic method of the internal combustion engine (3), a positive or negative drive torque is applied to the internal combustion engine (3) by the secondary machine (1) for setting various operating modes of the internal combustion engine (3), and at least one operating parameter of the internal combustion engine (3) is determined at a set operating point.

Owner:ROBERT BOSCH GMBH

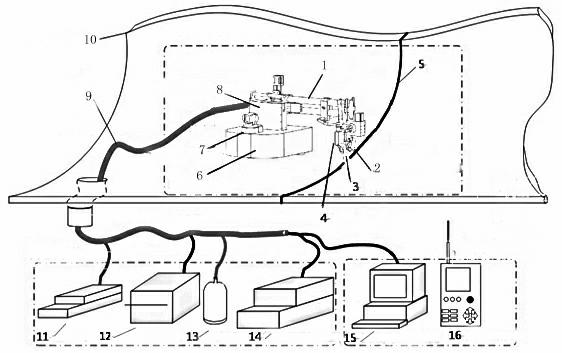

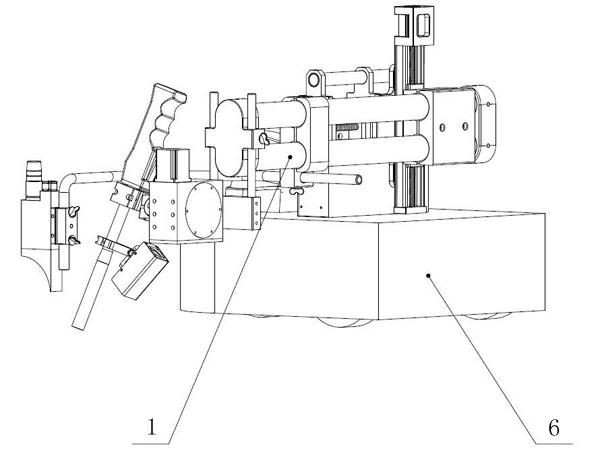

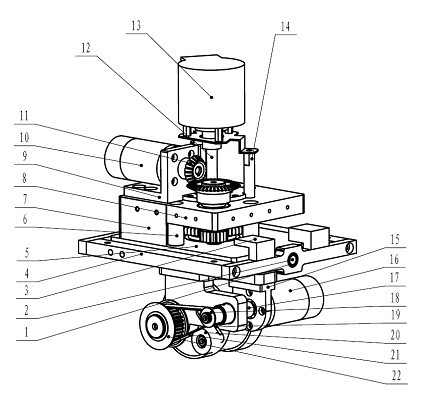

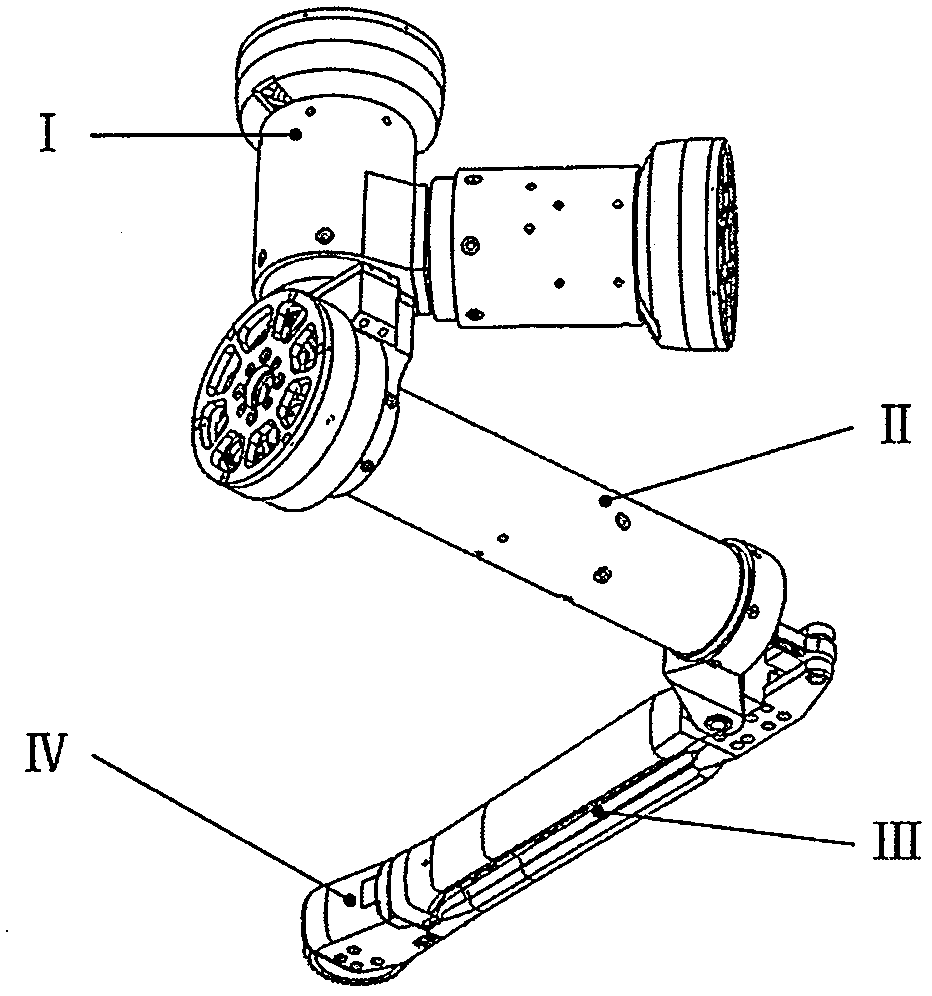

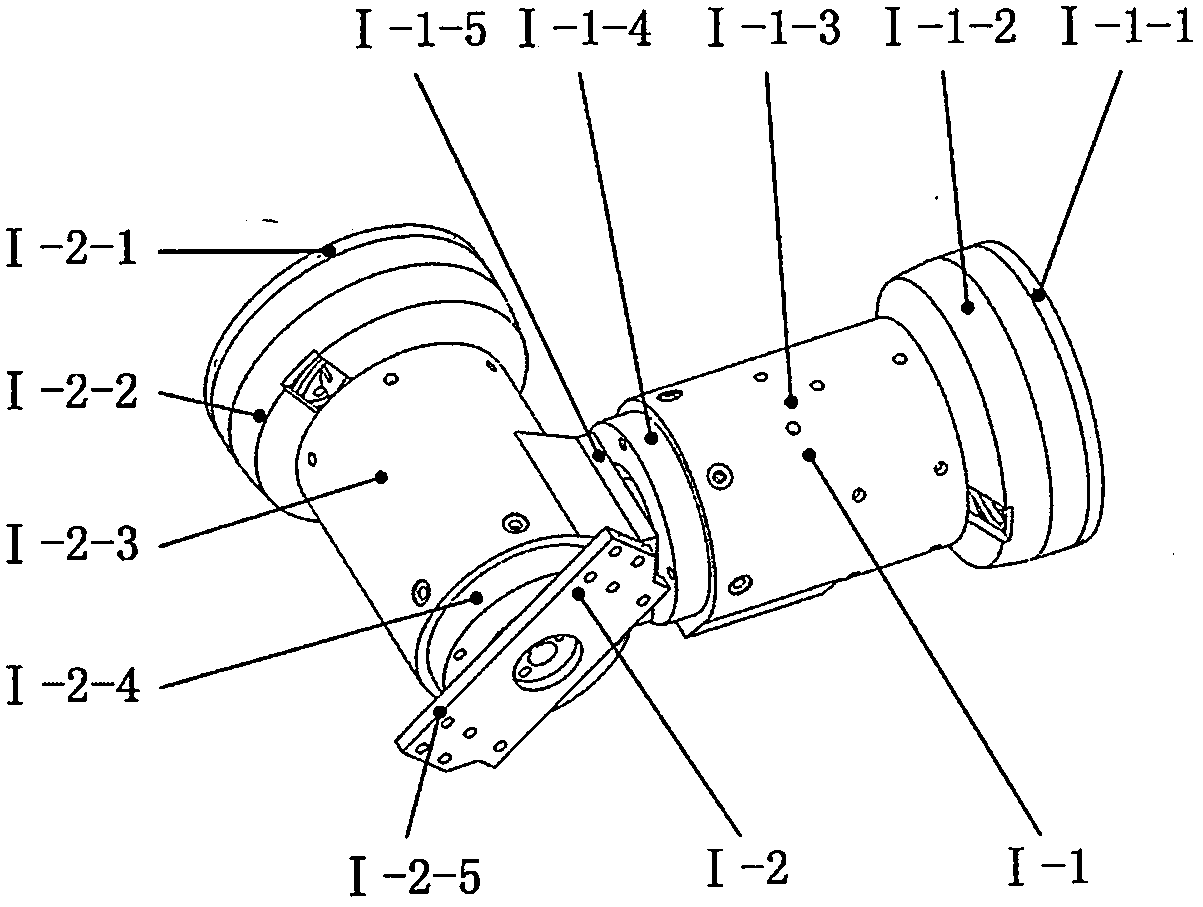

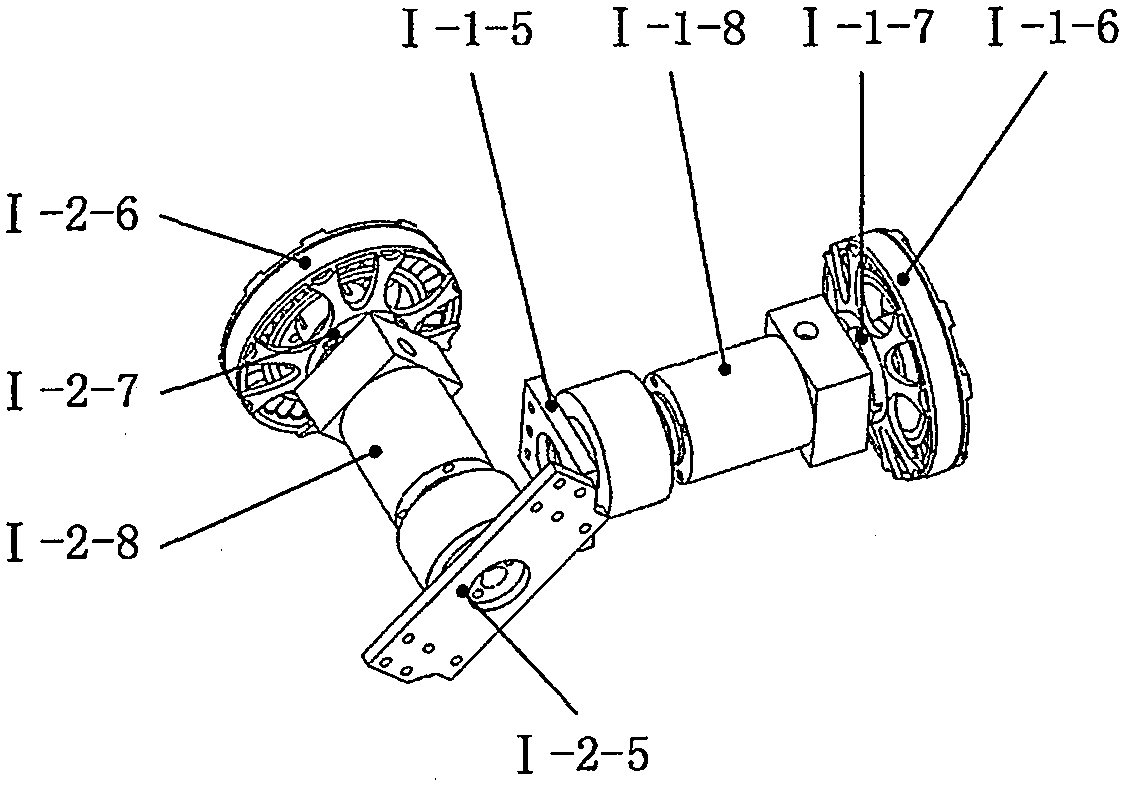

Autonomous mobile robot system for metal-inert-gas (MIG)/metal-active-gas (MAG) multilayer multipass welding of large thick plate

ActiveCN102689083AImprove performanceWith environmental monitoringElectrode supporting devicesDrive wheelShielding gas

The invention belongs to the technical field of welding of robots, and in particular relates to an autonomous mobile robot system for metal-inert-gas (MIG) / metal-active-gas (MAG) multilayer multipass welding of a large thick plate. The system comprises a robot body, a control system and an MIG / MAG welding system, wherein the robot body comprises a crawling mechanism and an operating mechanism; the control system comprises a sensing system, a robot body control box and a robot master control system; the MIG / MAG welding system comprises an MIG / MAG welding gun, an MIG / MAG welding power supply, a wire feeding machine, shielding gas and a weld cooling system; and the robot body, the control system and the MIG / MAG welding system are connected with one another through cables. The system has the advantages that a contact type magnet-wheel adsorption and non-contact type clearance adsorption composite mode and a three-wheel full-drive wheel type movement mode are used by the crawling mechanism, so that a robot can autonomously and flexibly move at all positions on the surface of an operating object, can be reliably adsorbed and can perform all-position welding operation, and the system is high in comprehensive performance.

Owner:DONGFANG ELECTRIC CORP LTD

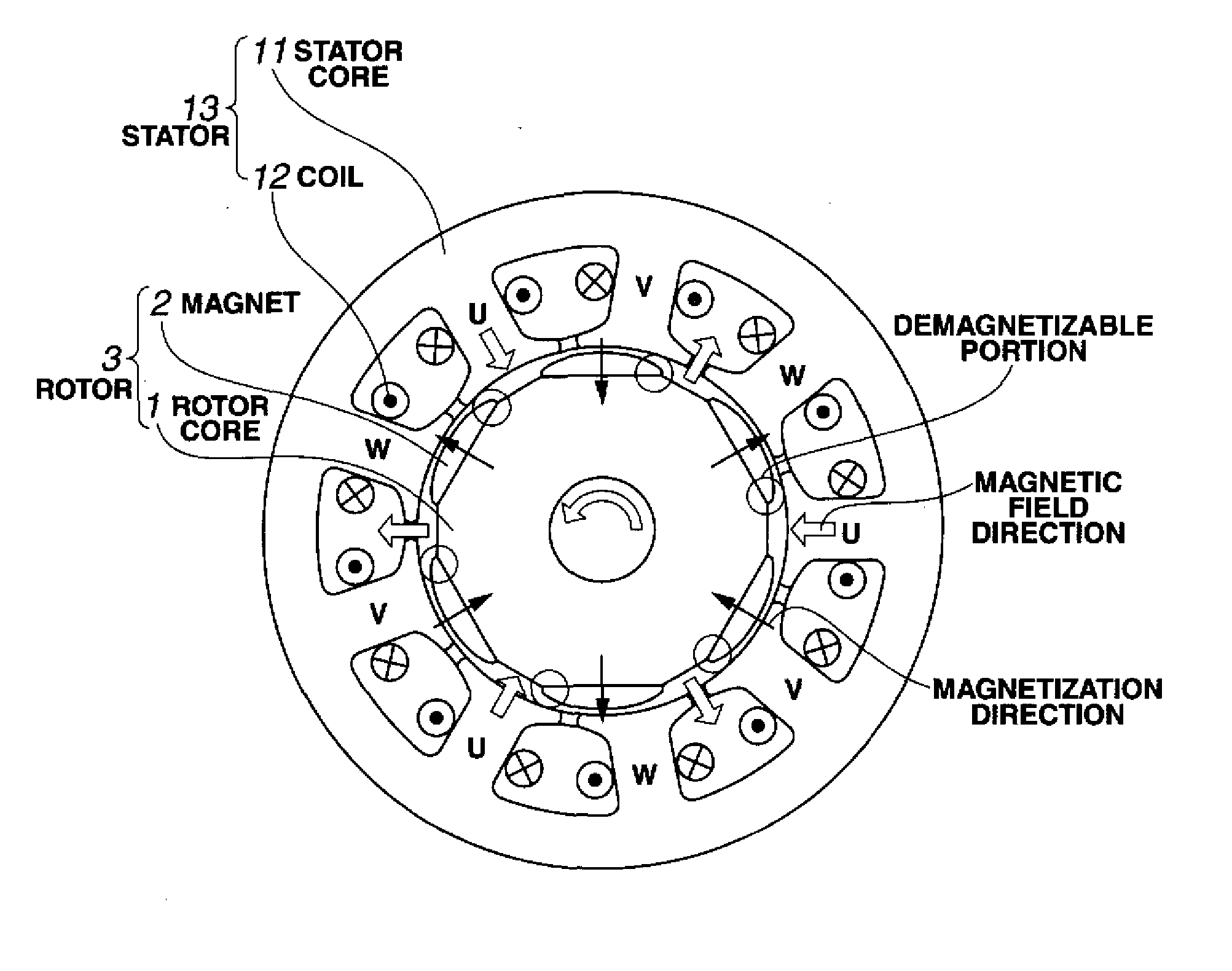

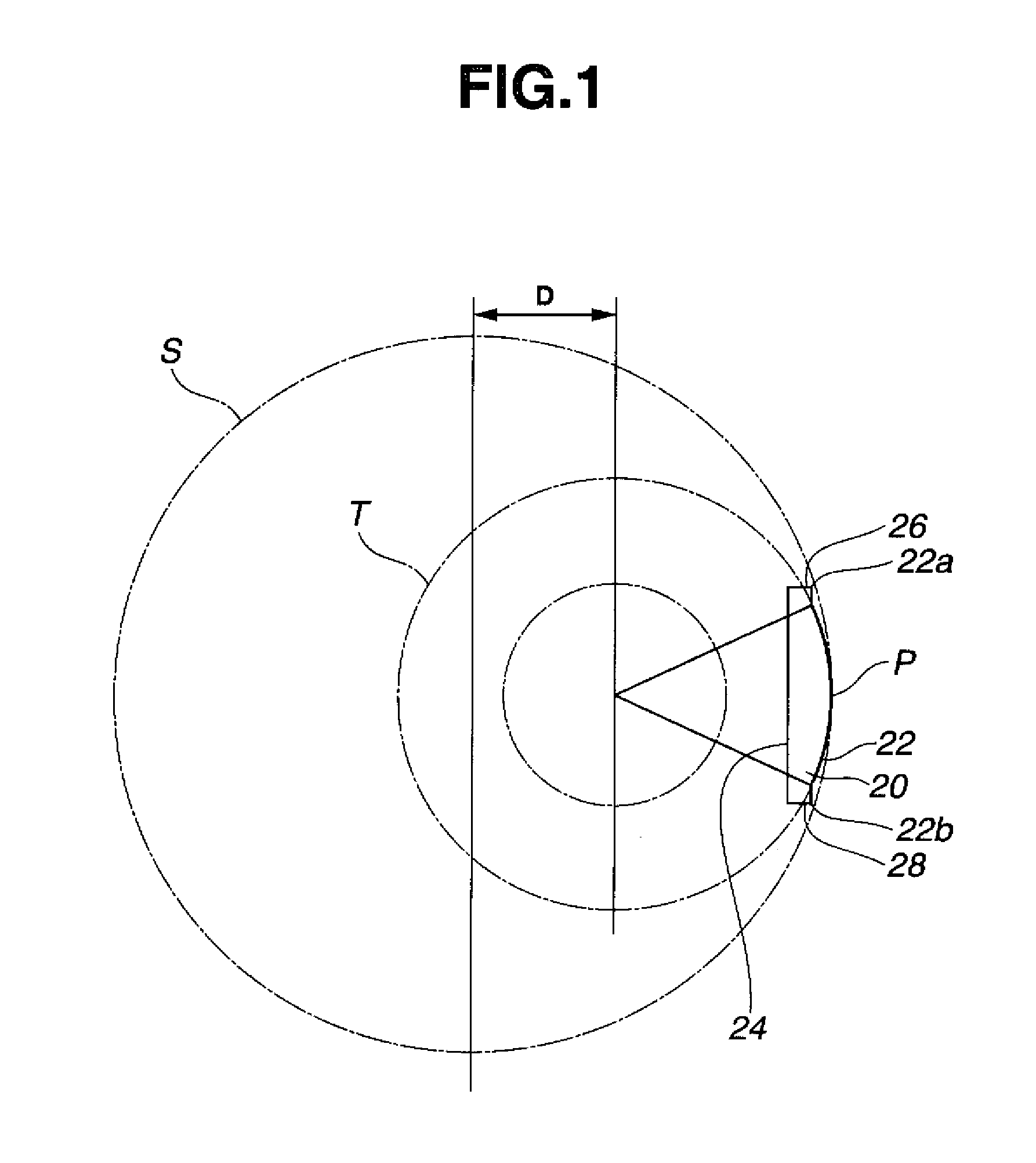

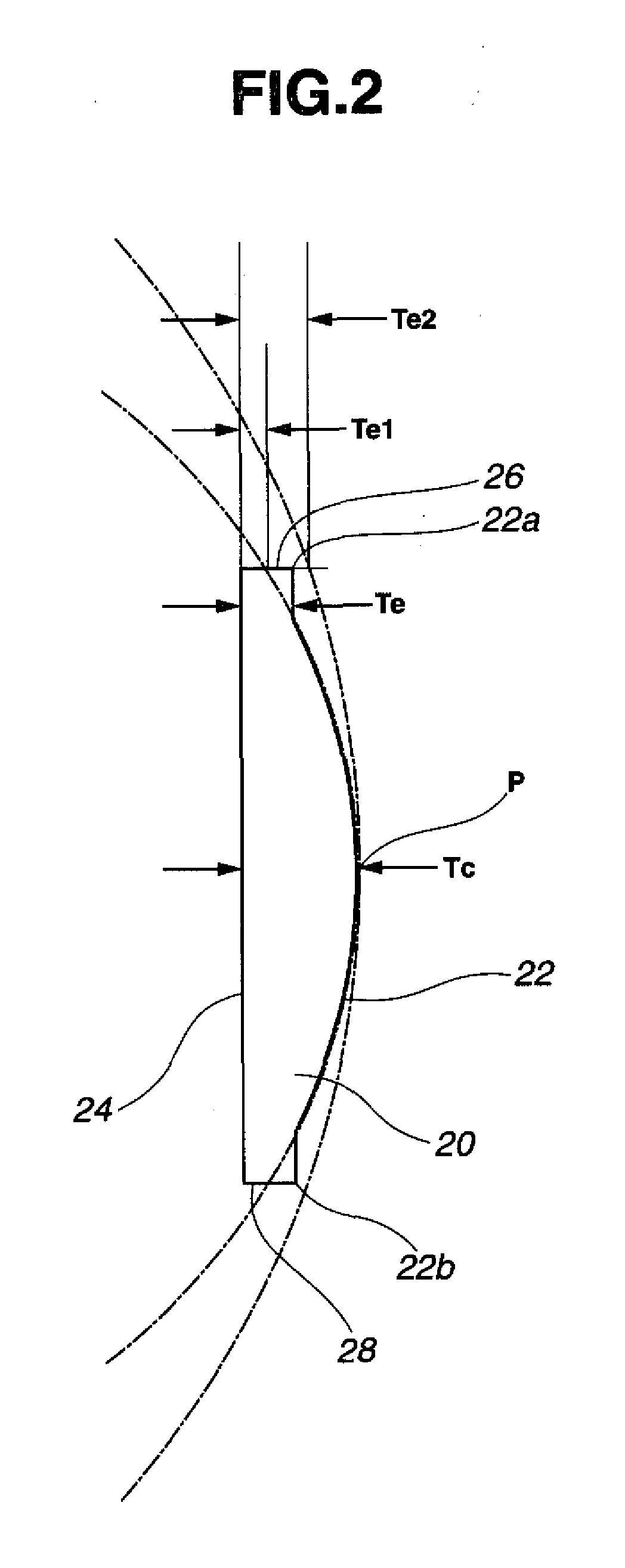

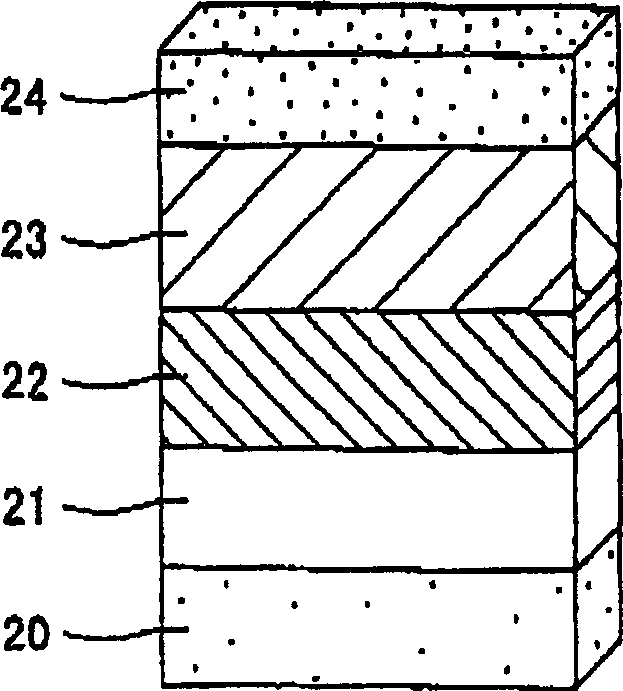

Permanent magnet and permanent magnet rotating machine

ActiveUS20080055032A1Reduce torqueReduce demagnetizationMagnetic circuit rotating partsPermanent magnetsMagnetCentral region

Owner:SHIN ETSU CHEM IND CO LTD

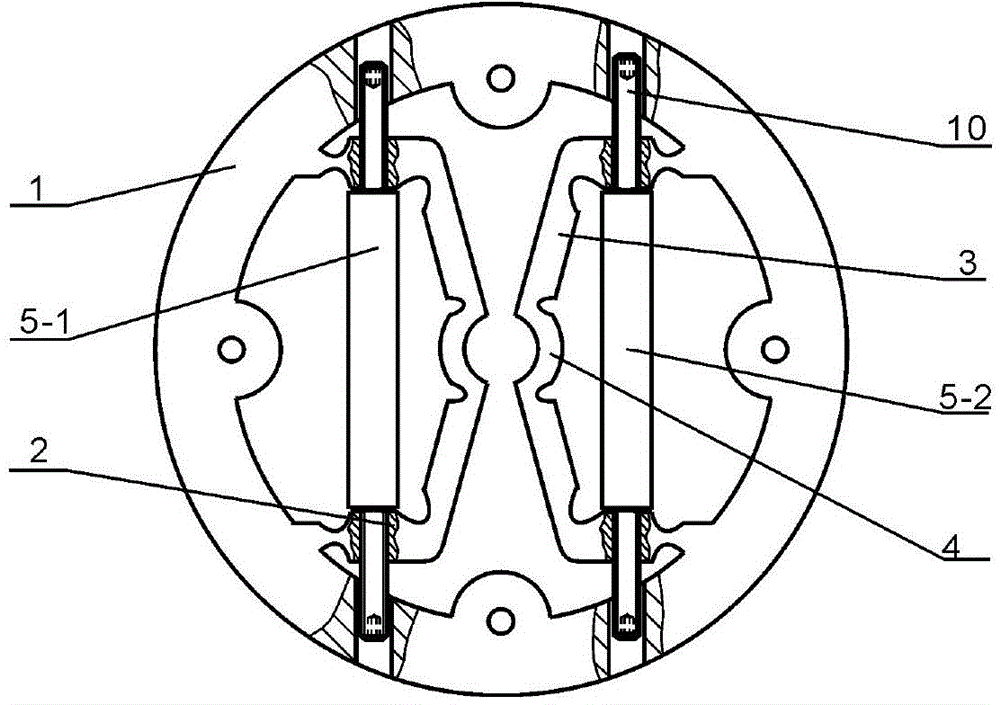

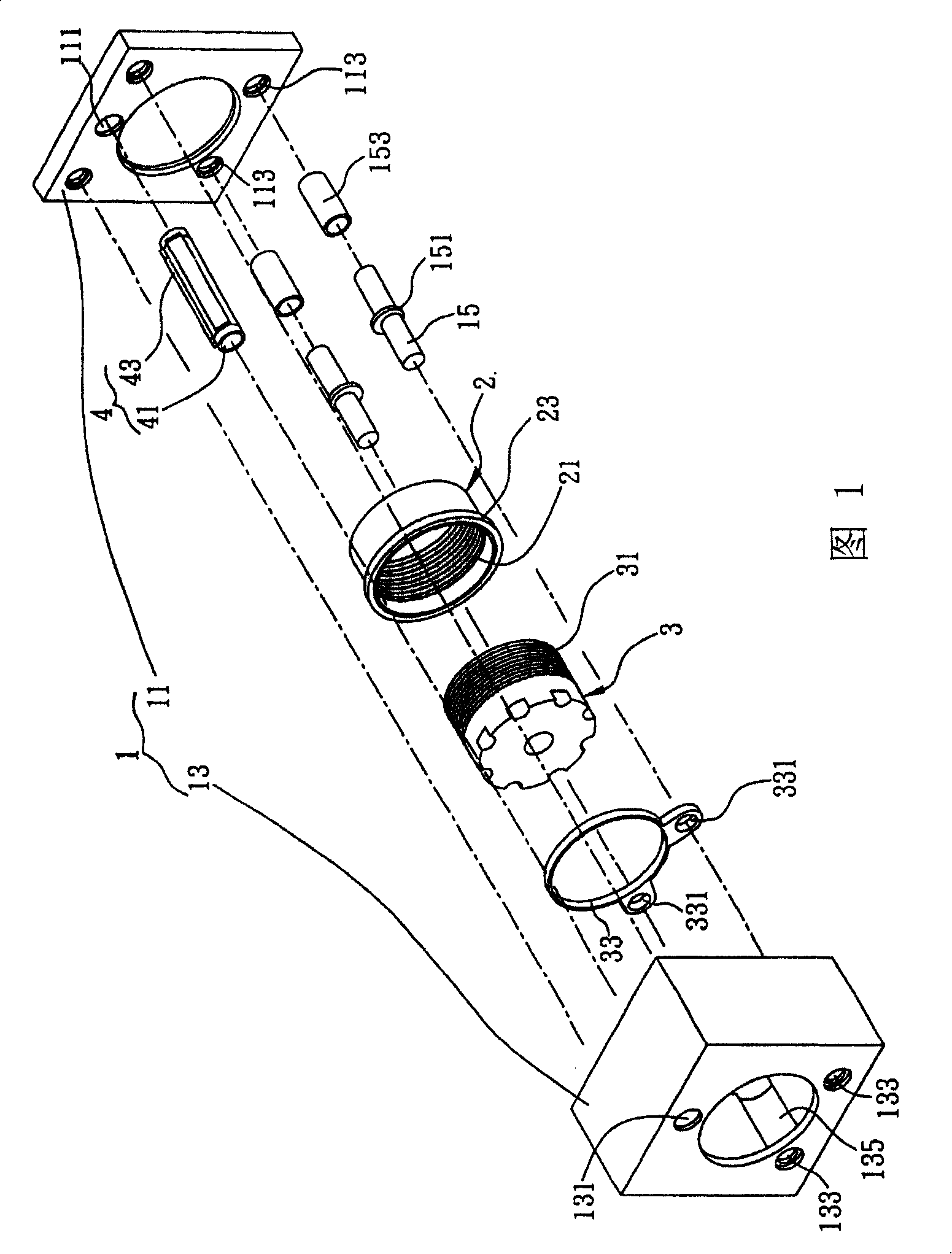

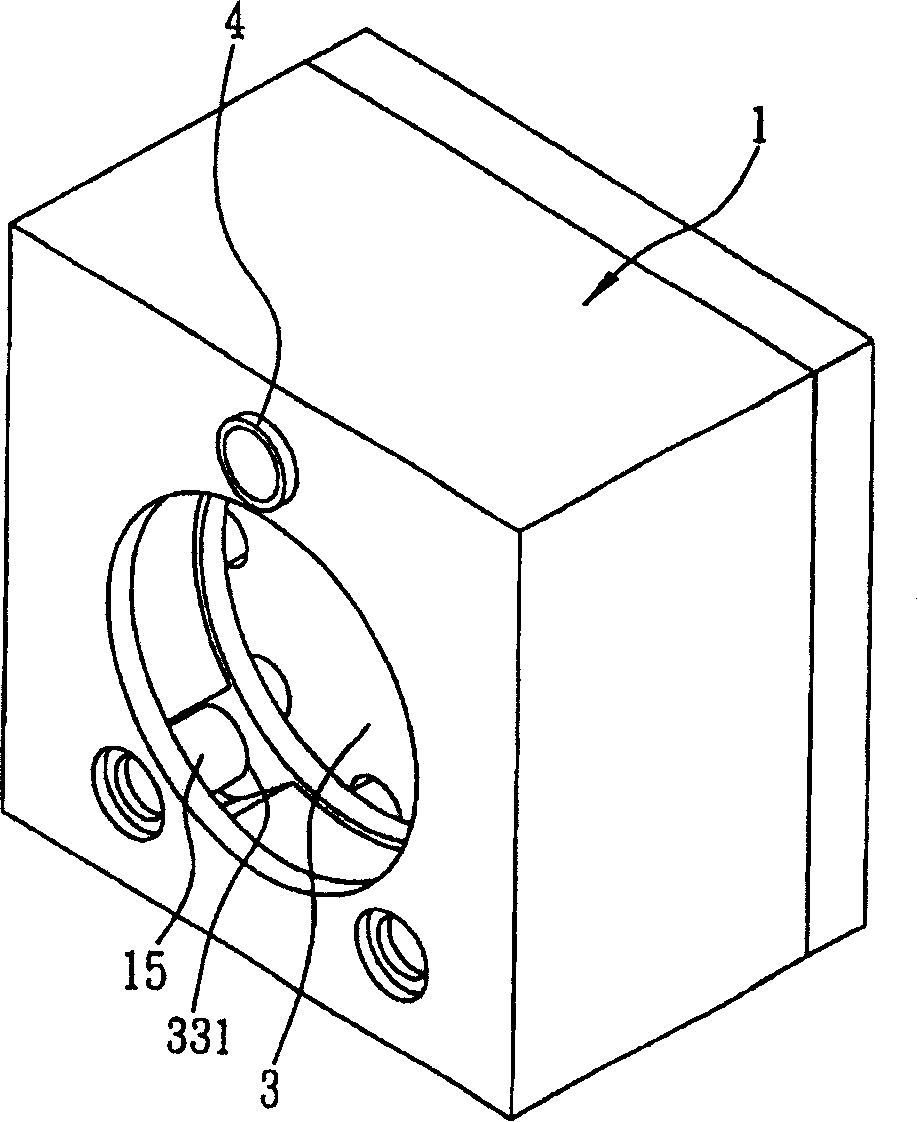

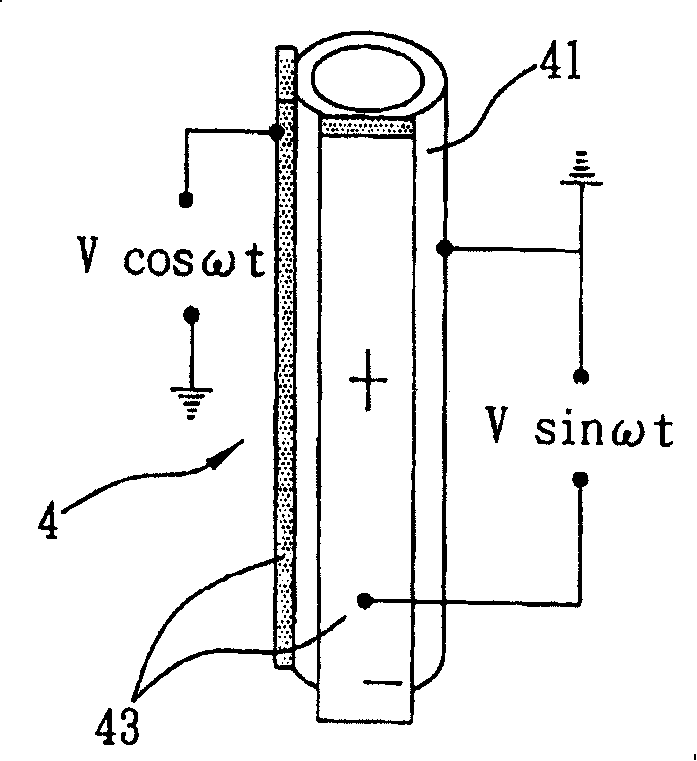

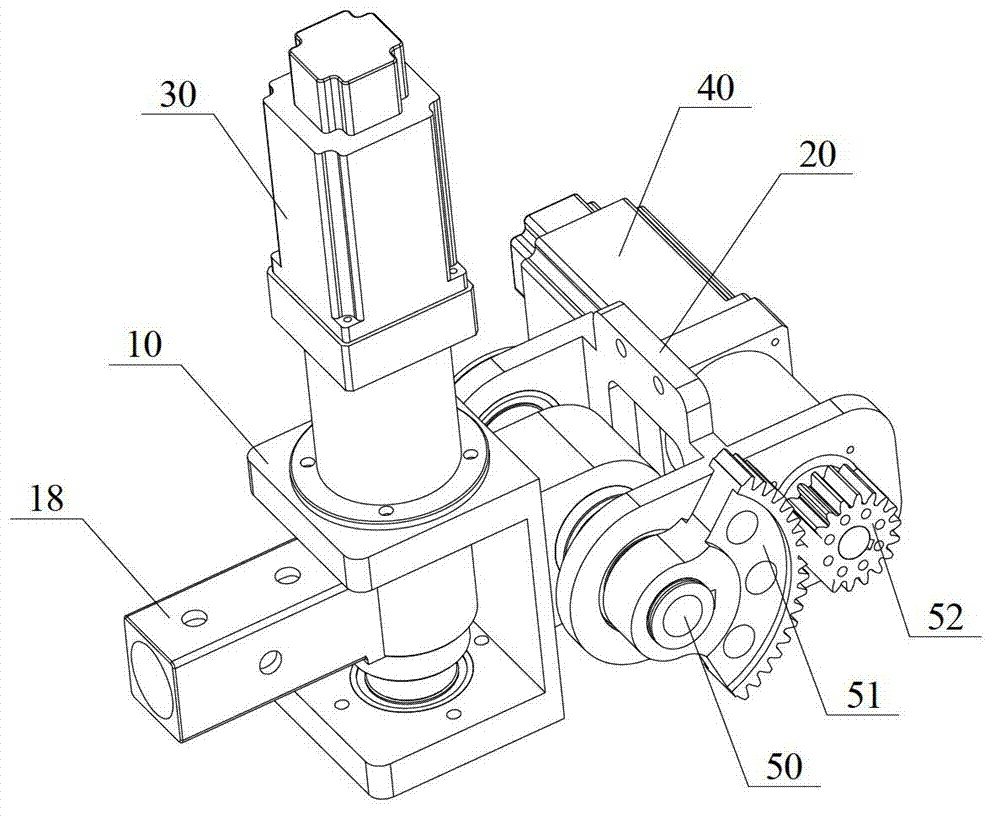

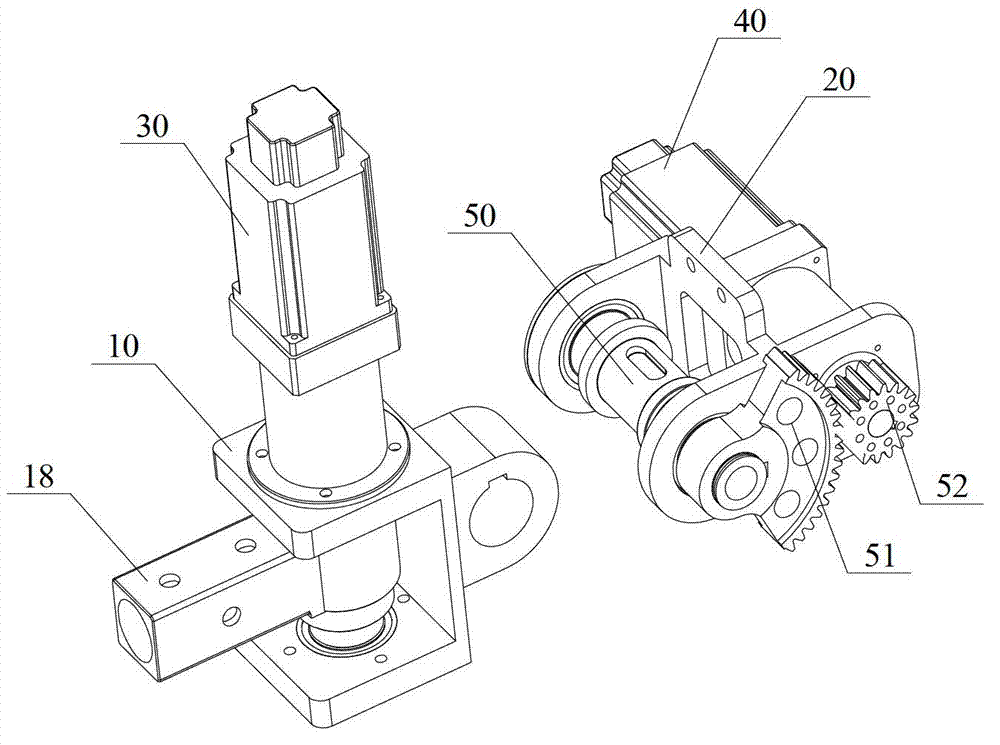

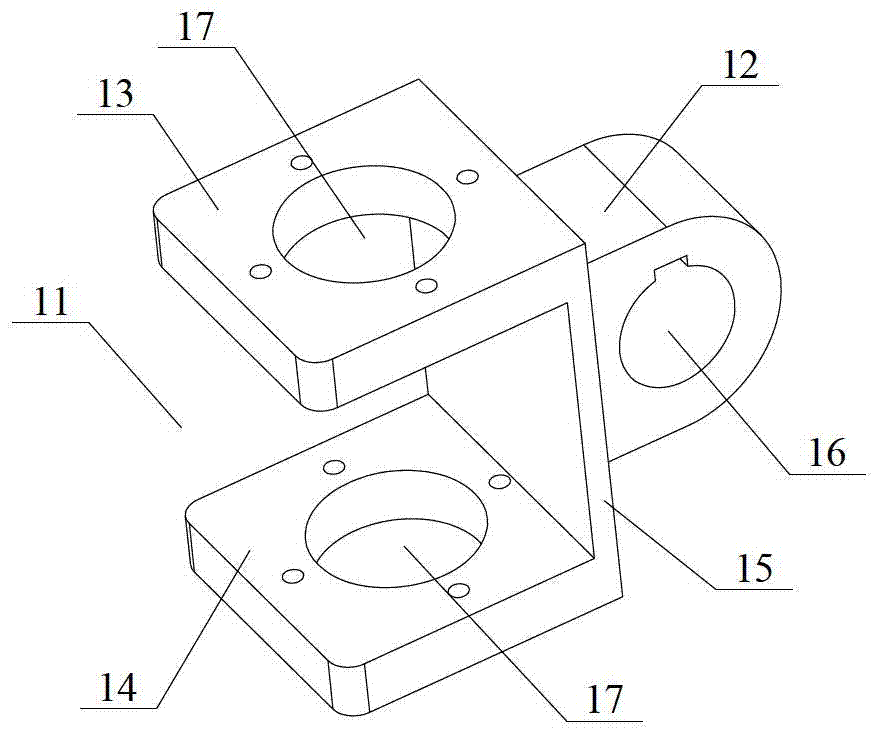

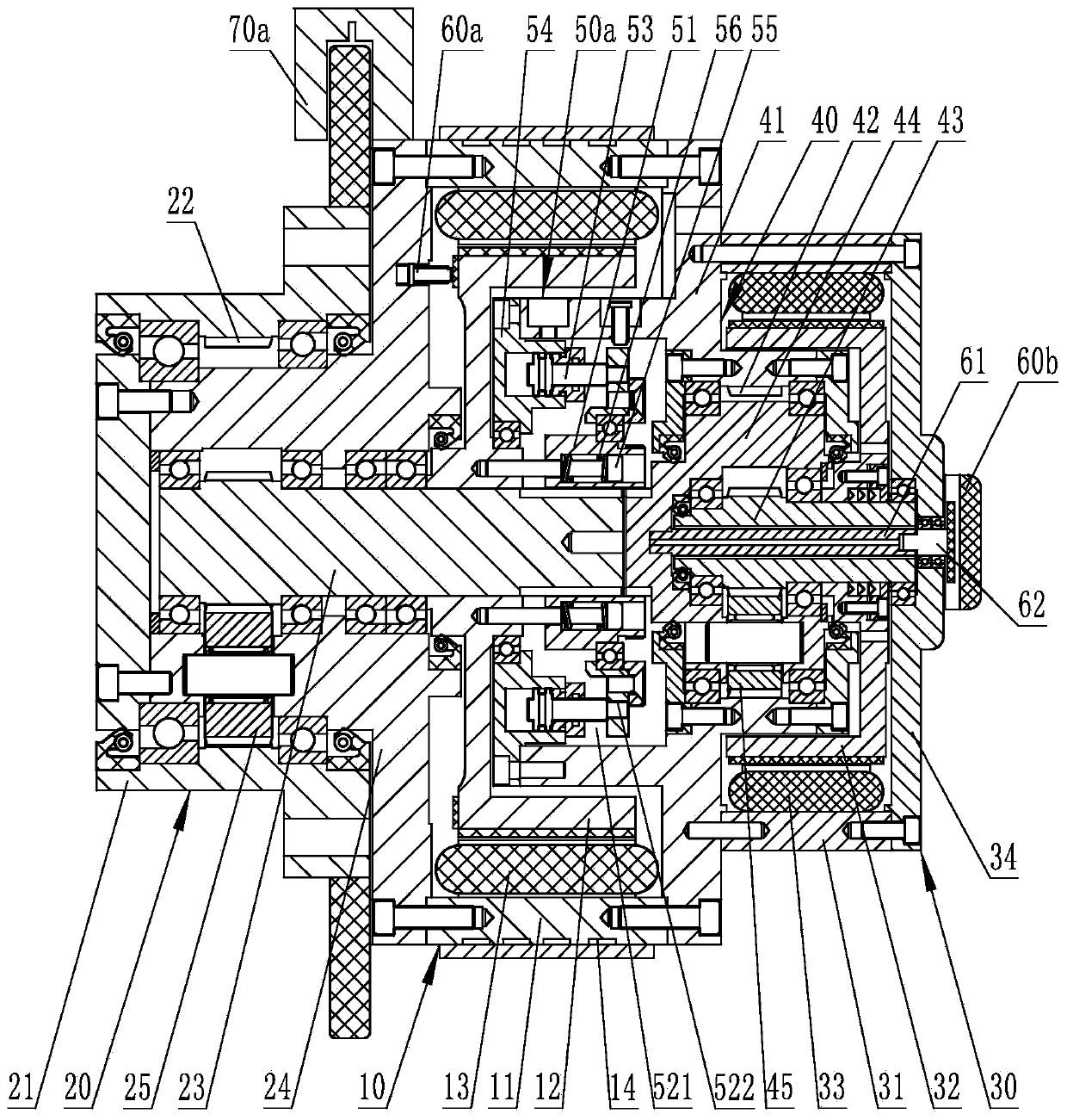

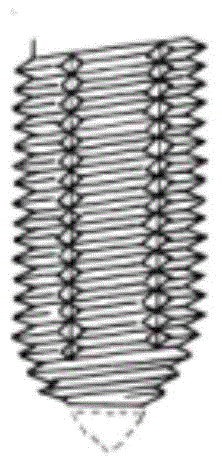

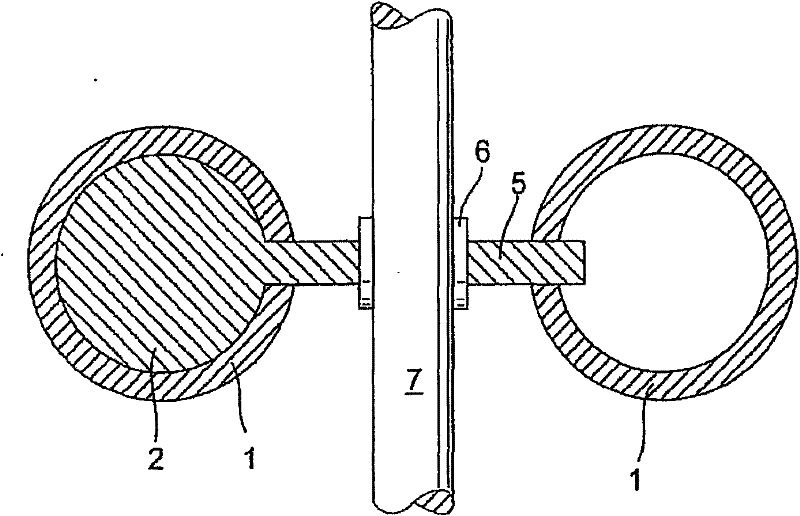

Walking piezoelectric rotary motor

ActiveCN104578901ALarge torsional displacementIncrease drive torquePiezoelectric/electrostriction/magnetostriction machinesActuatorControl theory

The invention discloses a walking piezoelectric rotary motor. A coaxial structure formed by a piezoelectric torsional actuator, two piezoelectric clamping bearing driver modules, two sleeves and a rotating shaft is adopted, wherein the two sleeves are fixed on the two ends of the piezoelectric torsional actuator respectively through adhesion, and two piezoelectric clamping bearing driver modules are fixedly connected with the two sleeves respectively through screws; each piezoelectric clamping bearing driver module is composed of a bearing unit and a piezoelectric stack, set pre-clamp force is applied to the rotating shaft through a bearing ring, and clamping movement is achieved through driving the bearing ring with the piezoelectric stack; step motion of the rotating shaft is achieved through controlling the timing sequence of the torsional movement of the piezoelectric torsional actuator and clamping movement of the two piezoelectric clamping bearing driver modules. According to the walking piezoelectric rotary motor, the layout of the structure is symmetrical, the structure is compact, micromation is applicable, and the operating efficiency and stability can be effectively improved.

Owner:HEFEI UNIV OF TECH

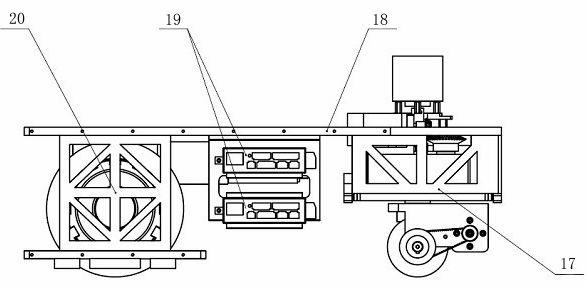

Driving and steering integrated magnetic wheel device for magnetic adsorption wall-climbing robot

The invention belongs to the technical field of robot welding and in particular relates to a driving and steering integrated magnetic wheel device for a magnetic adsorption wall-climbing robot. The driving and steering integrated magnetic wheel device comprises a vehicle body fixed framework, a rotating table framework, a steering and driving mechanism, a wheel driving mechanism and rolling wheels, wherein a passive side-tipping rotating structure is arranged between the vehicle body fixed framework and the steering table framework, and an independent steering structure is arranged between the rotating table framework and a magnetic wheel; and the side-tipping rotating structure comprises a side-tipping rotating shaft mounted before and after the rotating table framework and a self-lubricating sliding bearing mounted at the vehicle body fixed framework. Compared with the prior art, the driving and steering integrated magnetic wheel device disclosed by the invention has the following advantages that the transmission between a driving speed reduction motor and a wheel shaft is realized through a synchronous belt, a larger mounting space can be obtained by regulating the transmission center-to-center distance, and the driving speed reduction motor with higher power is mounted so as to improve driving moment. The independent steering freedom degree is arranged, and the steering axial line is perpendicular to the wheel axial line, so that independent steering of the wheels can be realized, and the flexibility in motion of the wall-climbing robot can be improved.

Owner:DONGFANG ELECTRIC CORP LTD

Unfolding mechanism for foldable double wing boards of aircraft

The invention discloses an unfolding mechanism for a foldable double wing boards of an aircraft, comprising a fuel gas action device, a linear guiderail, a slider, connection rods and rockers. The linear guiderail is located on a perpendicular bisector of a rotation shaft connecting line of two wing boards and fixed on the aircraft body through a lower bracket; the slider is articulated with one ends of two connection rods; the fuel gas action device drives the slider to move linearly along the linear guiderail; the other ends of the two connection rods are respectively articulated with one end of one rocker; the other end of each rocker is articulated with a wing board rotation shaft fixed on a wing board bracket; under the push of the connection rods, the rockers rotate around the wing board rotation shaft fixed on the wing board bracket; one rocker is fixedly connected with a wing board shaft sleeve; and the rockers drive the wing board to rotate when rotating around the wing boardrotation shaft. The unfolding mechanism of the invention greatly improves the unfolding driving capability of the wing board and does not generate impact to the wing board bracket.

Owner:中国航天科工集团第二研究院二一〇所

Automatic focusing optical lens module

The invention comprises a base with a holding space, a sleeve barrel located in the holding space, a lens connected to the sleeve barrel, and a piezoelectric assembly secured in the holding space and used for driving the sleeve barrel to rotate. Between the base and the lens there are a first and second guiding units used for driving the lens to focus after rotating the sleeve barrel.

Owner:IND TECH RES INST

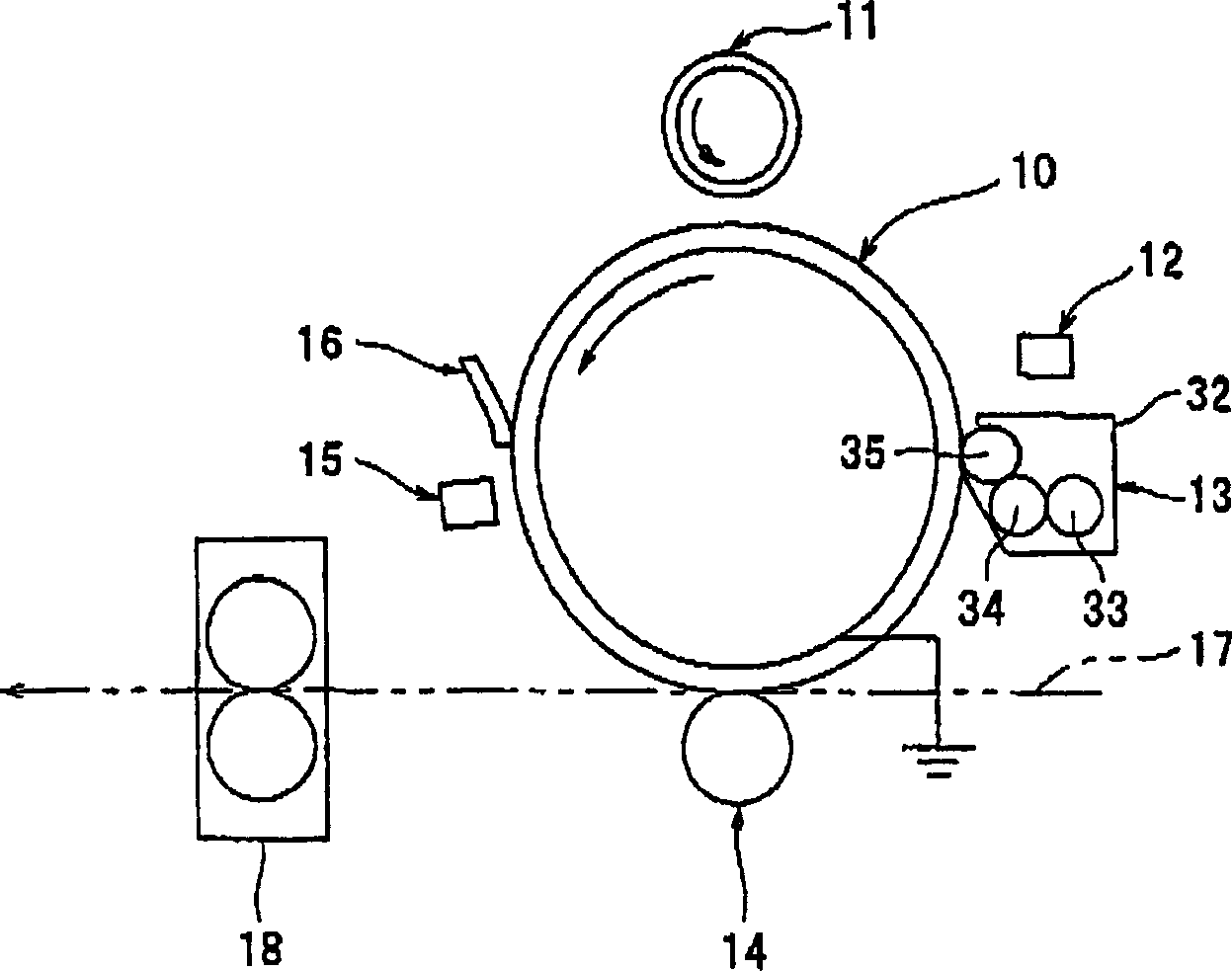

Cleaning device, process cartridge, and image forming apparatus

ActiveCN1770041ANo reduction in contact widthIncrease line pressureElectrography/magnetographyBand shapeImage formation

In cleaning devices, process cartridges and image forming devices, a cleaning structure with low linear pressure and high surface pressure can be obtained by specifying the material, shape and support structure of the cleaning blade. Press the front end corners of the elastic cleaning blade (38) supported by the so-called sheet holder, that is, the supporting member (37), on the roller-shaped and belt-shaped image carrier (10), and remove the residue remaining on the image carrier after image transfer. body toner. In such a cleaning device (16), the angle (θ) forming the front end corner line portion (36) of the cleaning blade is formed as an obtuse angle, and the front end corner line portion is formed at a surface pressure greater than or equal to 2.0 g / mm2. Press on the image carrier. The so-called surface pressure refers to the value obtained by dividing the total load applied to the cleaning blade by the contact area of the cleaning blade with respect to the member to be cleaned.

Owner:RICOH KK

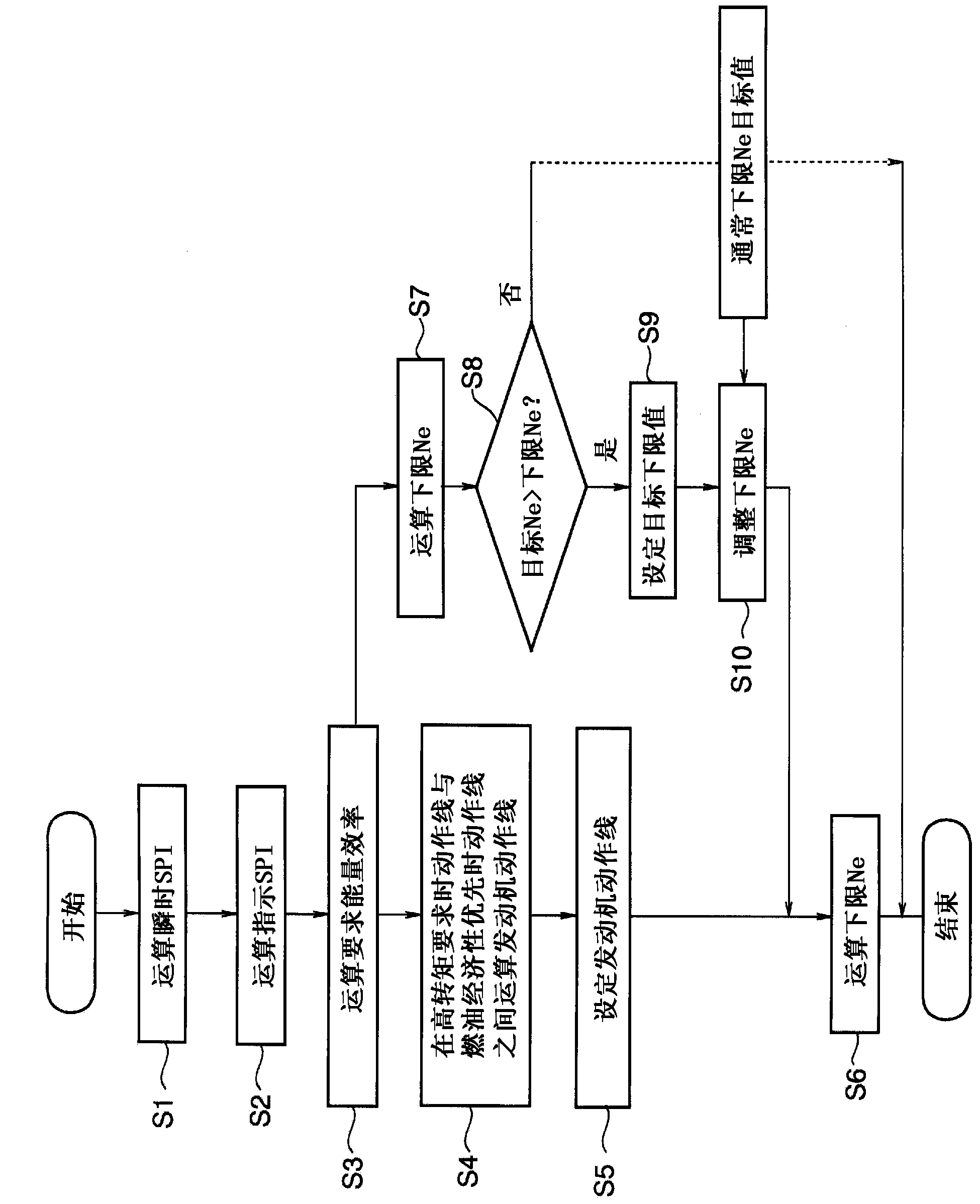

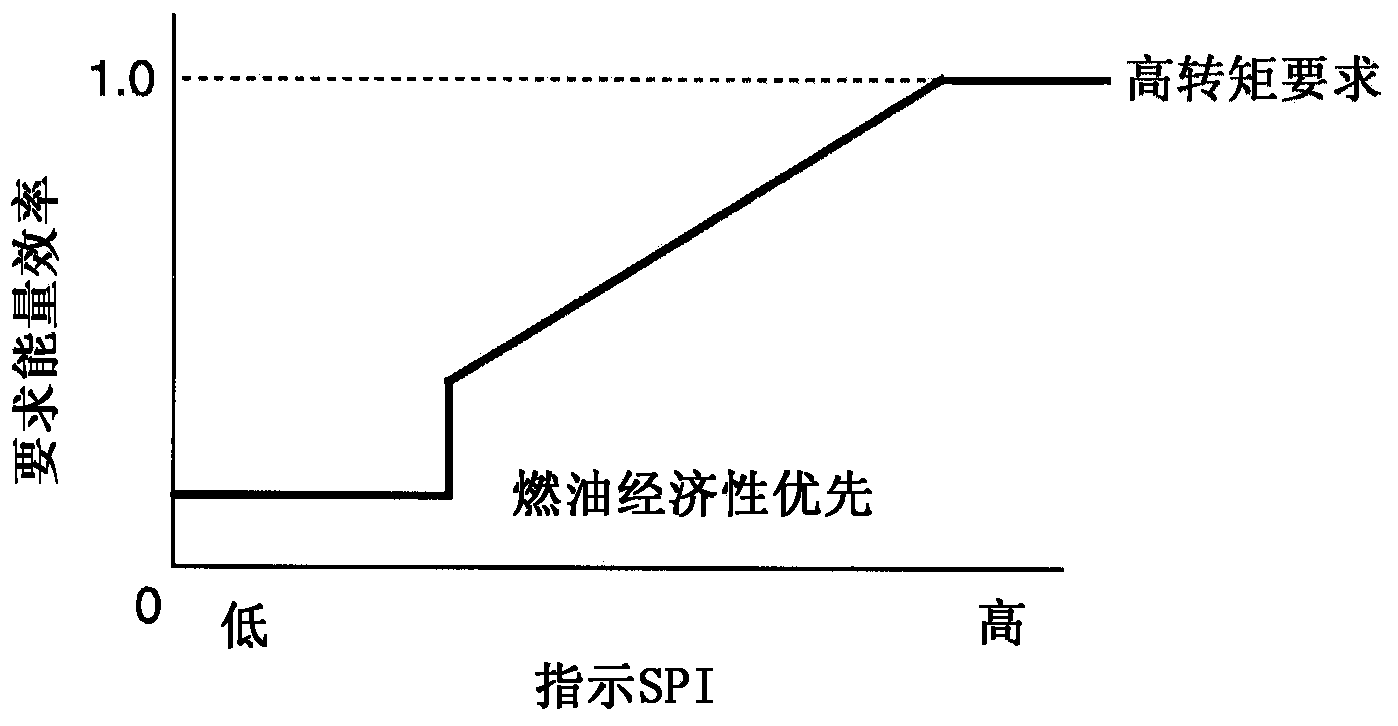

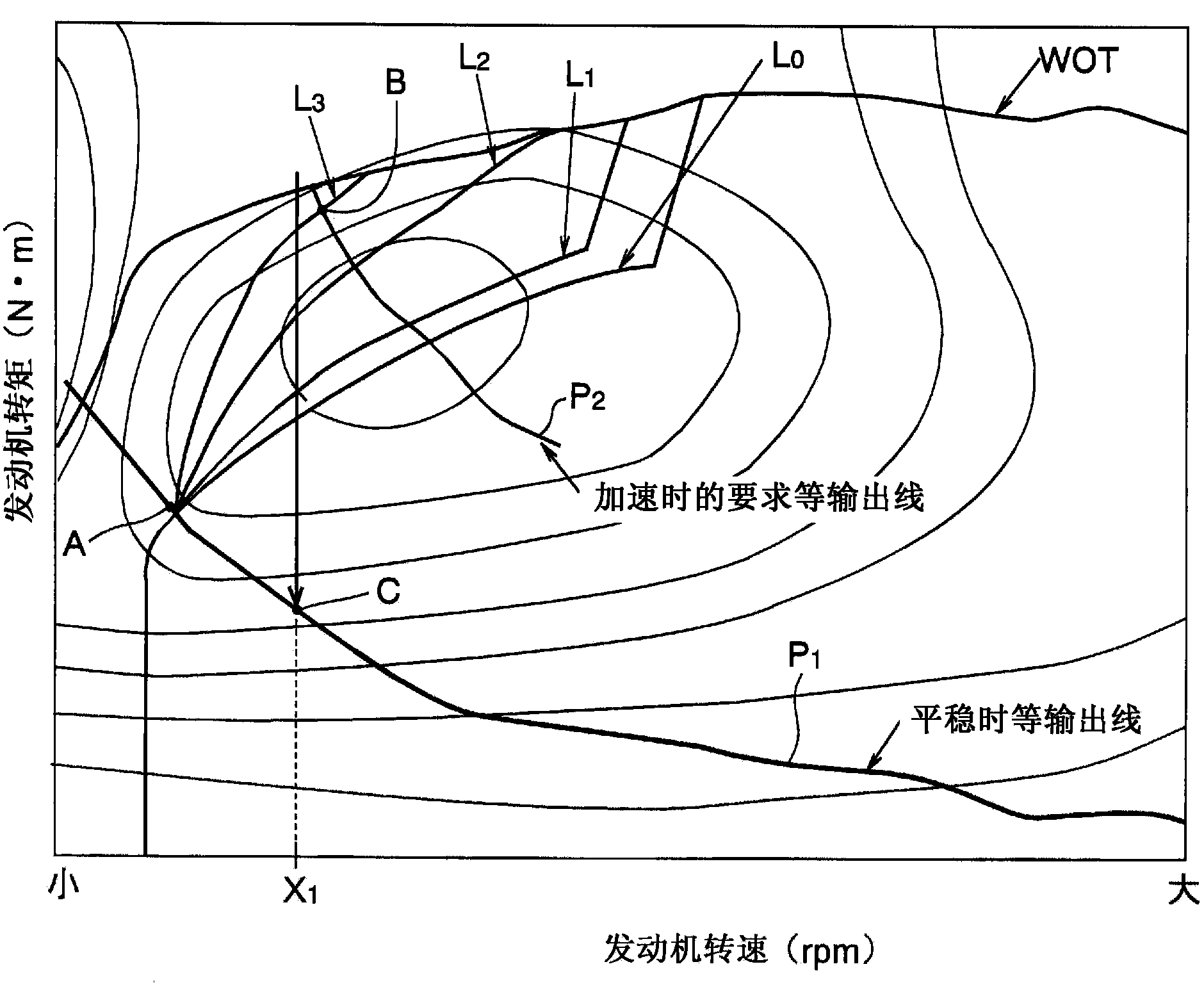

Vehicle driving force control device

InactiveCN103814201AIncrease speedIncrease drive torqueHybrid vehiclesElectrical controlLower limitDriver/operator

A vehicle driving force control device that is capable of selecting a first mode and a second mode with regard to a target rotational speed of an engine serving as a driving force source, said first mode setting the rotational speed such that a target output can be achieved with an optimal fuel consumption, and said second mode setting the rotational speed of the engine lower than the rotational speed for achieving the target output with the optimal fuel consumption, and selectively setting either the first mode or the second mode on the basis of an index which represents a driver's intent of driving, which is configured such that the vehicle driving force control device sets a lower limit on the rotational speed according to the index while the second mode is selected, and restricts the lower limit value of the target rotational speed to the lower limit rotational speed when the target rotational speed of the engine has exceeded the lower limit on the rotational speed while the second mode is selected.

Owner:TOYOTA JIDOSHA KK

Mechanical joint and neck and tail structures of bionic mechanical dinosaur

InactiveCN102830716ACompact structureIncrease drive torqueControl using feedbackMotor shaftSacroiliac joint

The invention discloses a mechanical joint which comprises a first support and a second support. A first motor and a rotary shaft are fixedly disposed on the first support. The first motor is perpendicular to the axis of the rotary shaft. A second motor is fixedly disposed on the second support. The first motor and the second motor are direct current servo reduction motors. The axis of the first motor is perpendicular to that of the second motor. The second motor is parallel with the axis of the rotary shaft. The rotary shaft is rotatably disposed on the second support. A first gear is fixedly disposed on the rotary shaft. A second gear is disposed on a motor shaft of the second motor. The first gear is meshed with the second gear. The mechanical joint has a similar function to a globe joint and is compact and simple in structure. A sector spur gear reduction mechanism is added to the vertical joint, so that driving torque of the motor in the vertical direction is increased. On the basis, the invention further provides neck and tail structures of a bionic mechanical dinosaur.

Owner:ZHONGKE YUBO BEIJING CULTURE

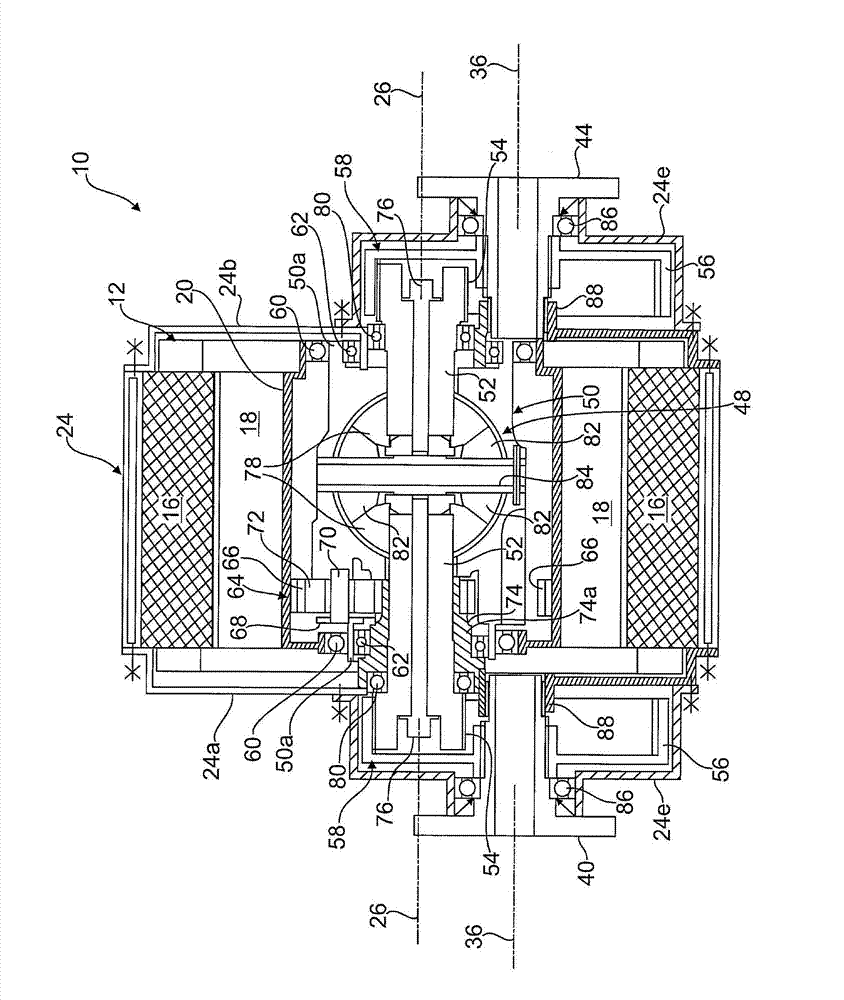

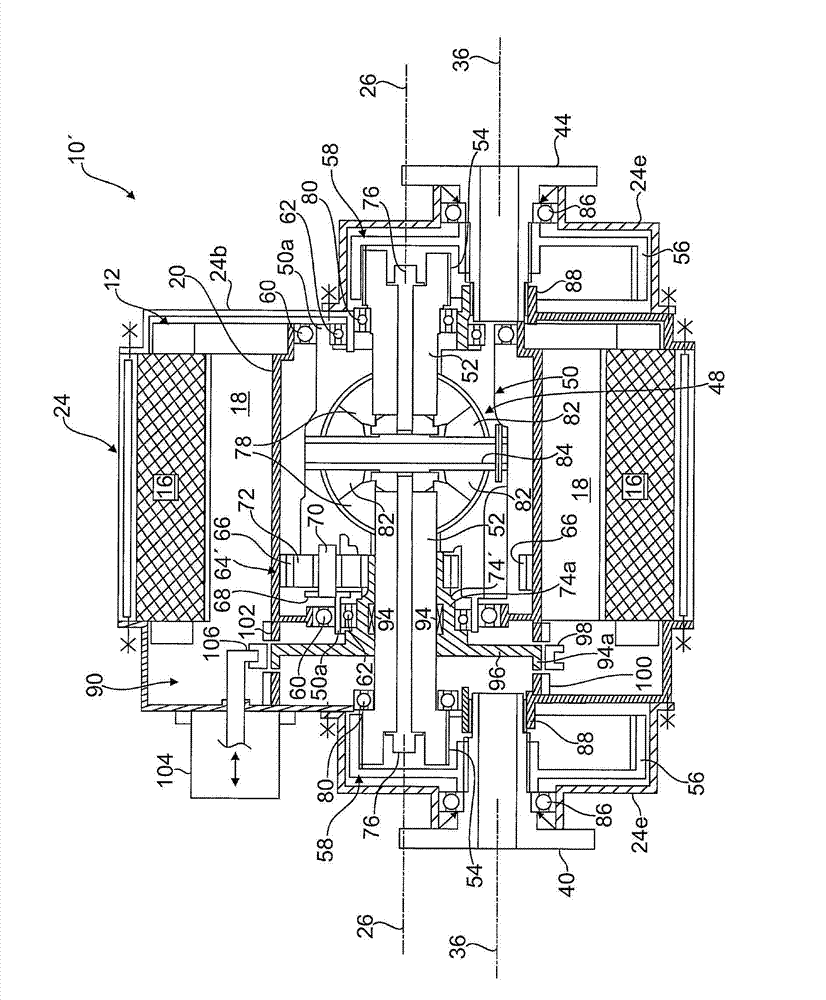

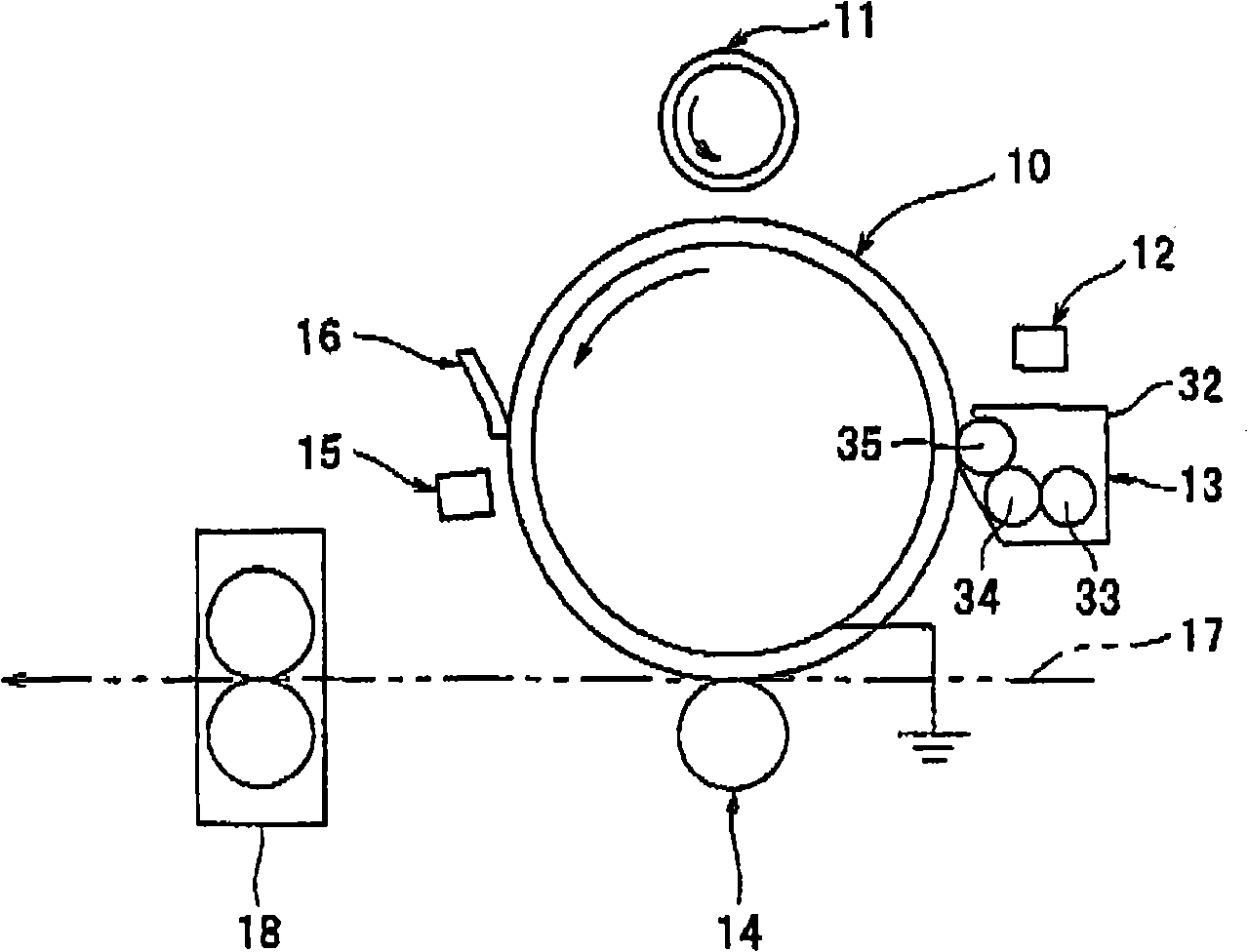

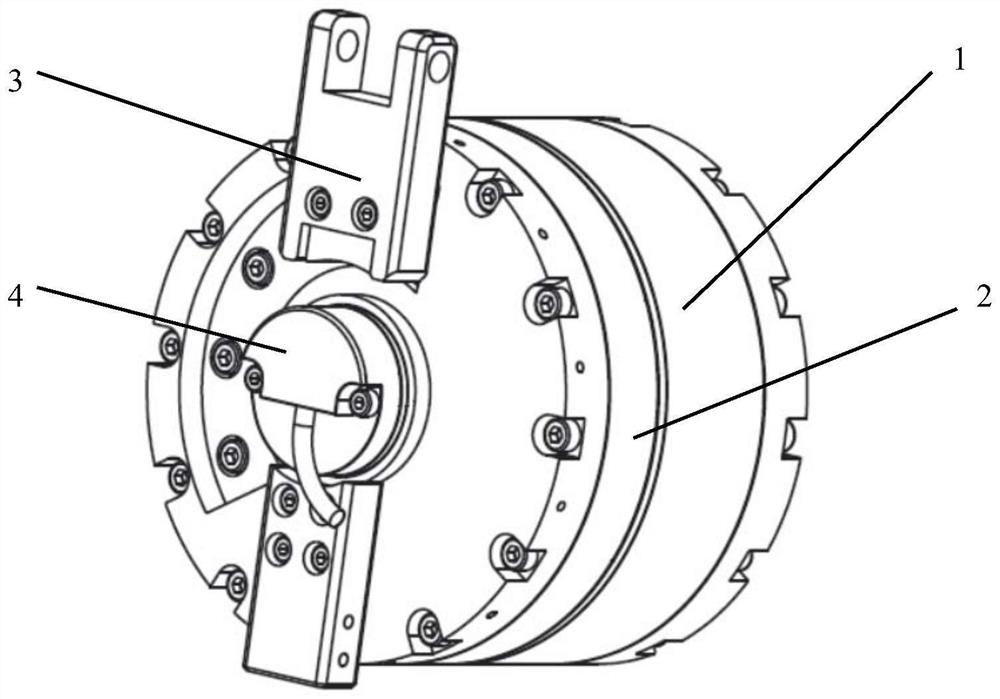

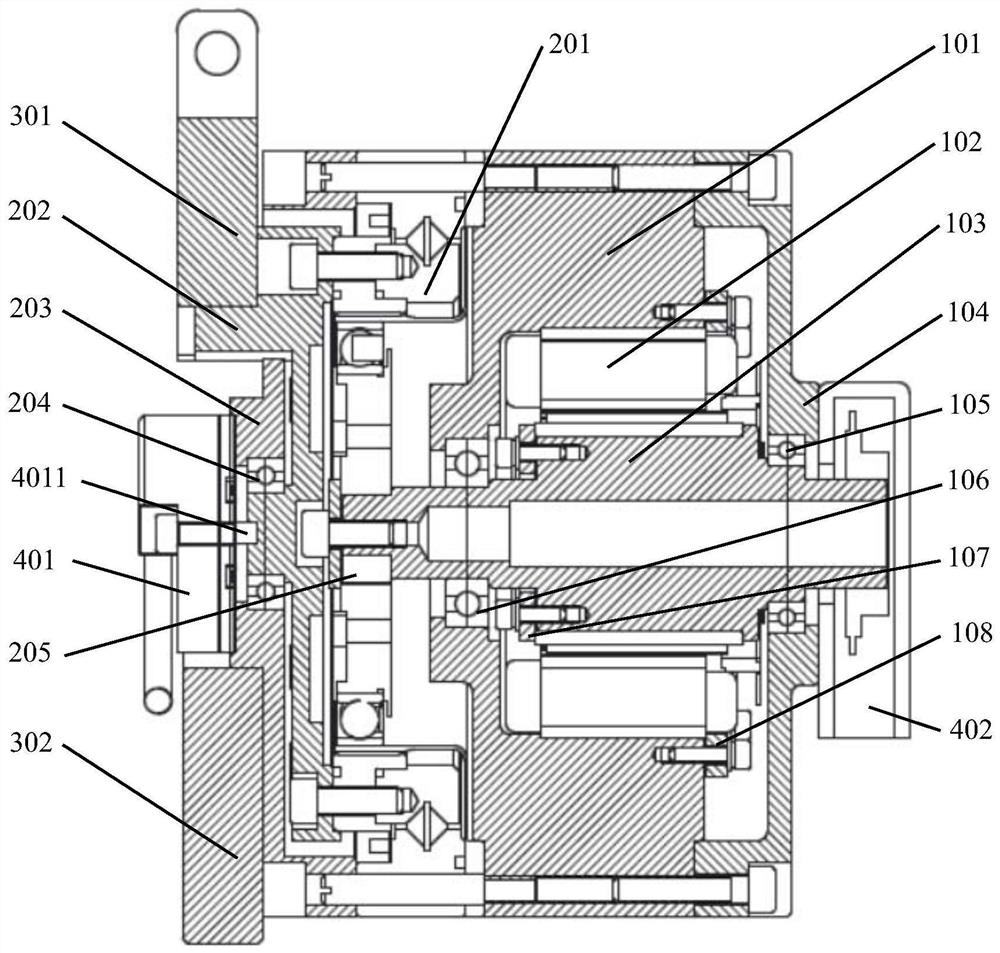

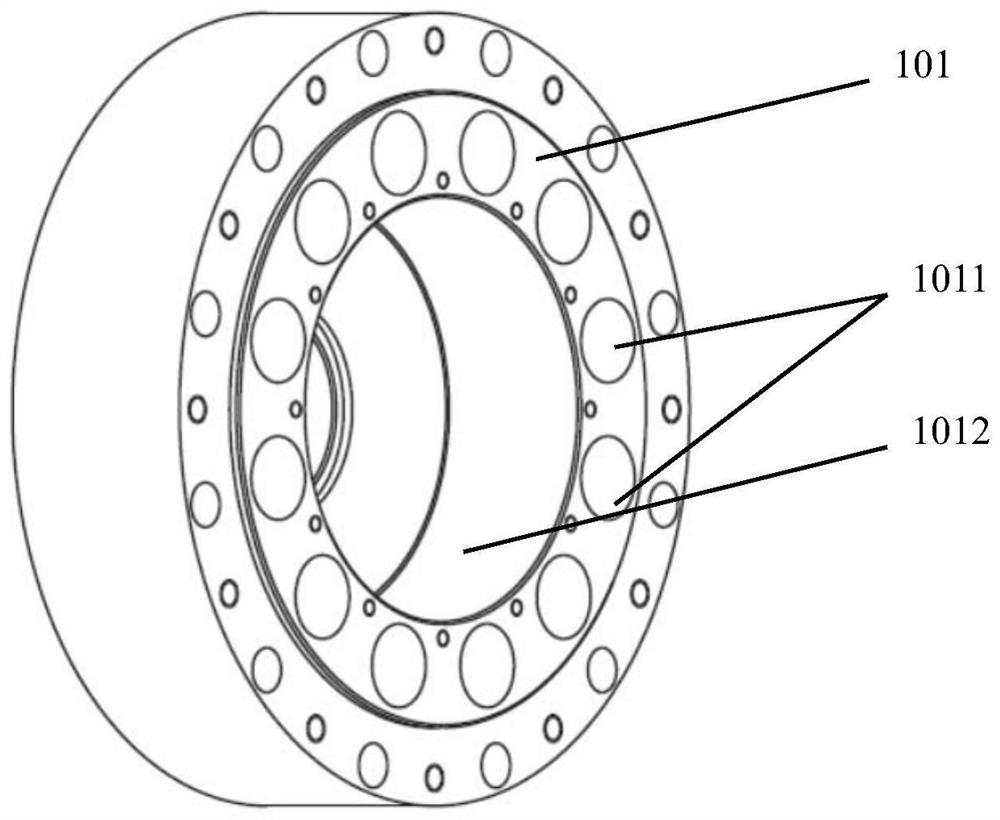

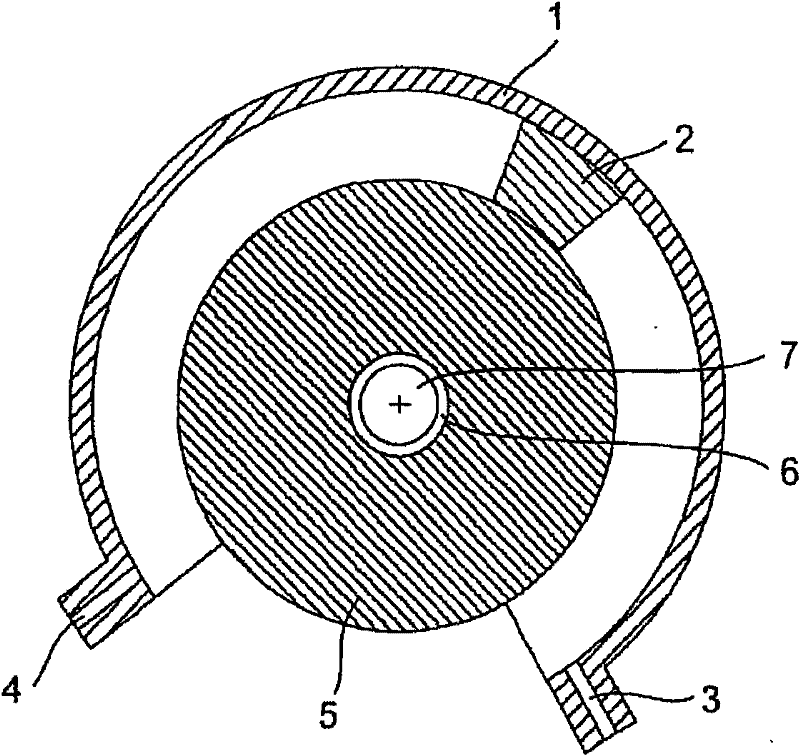

Driving device

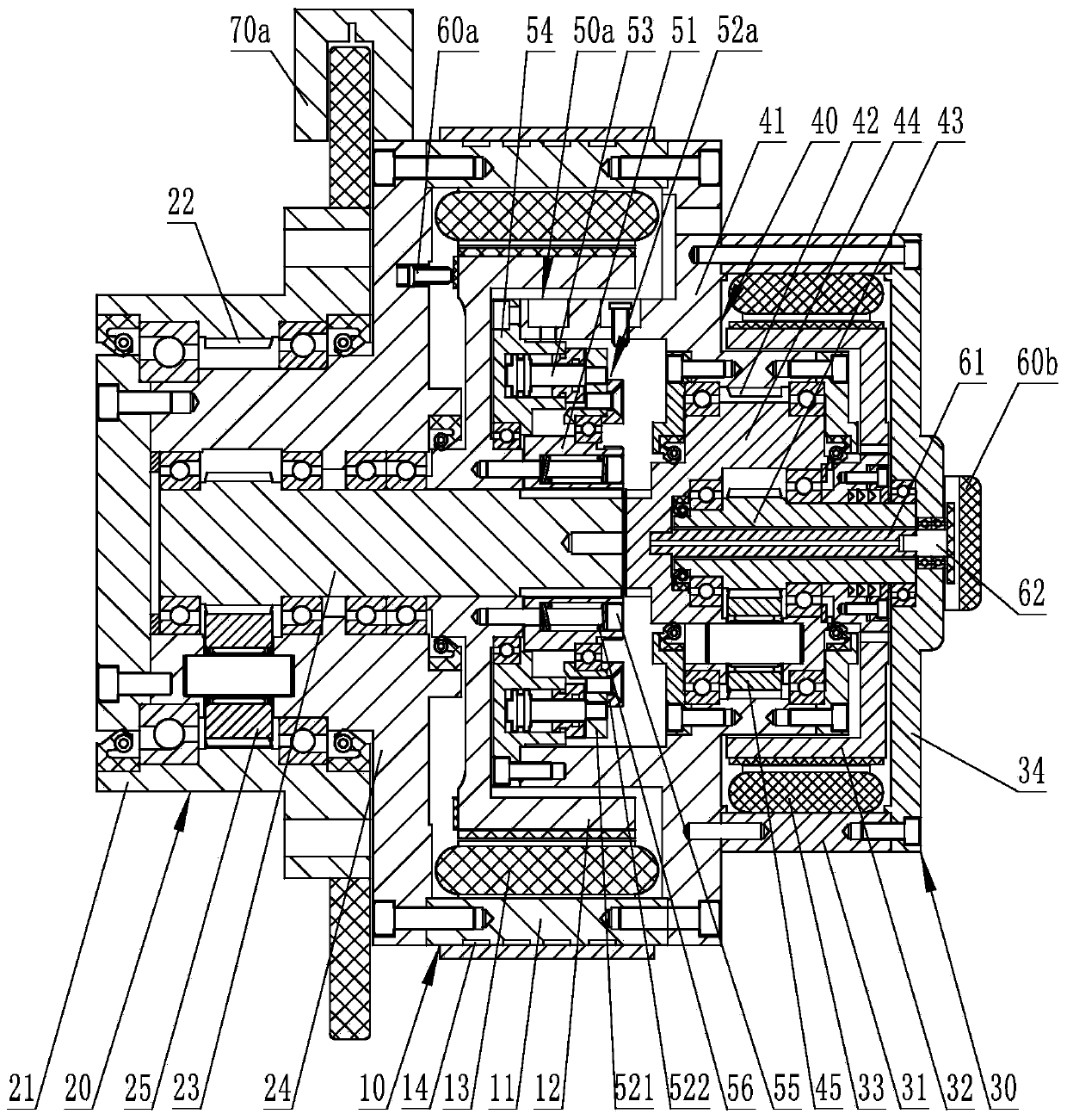

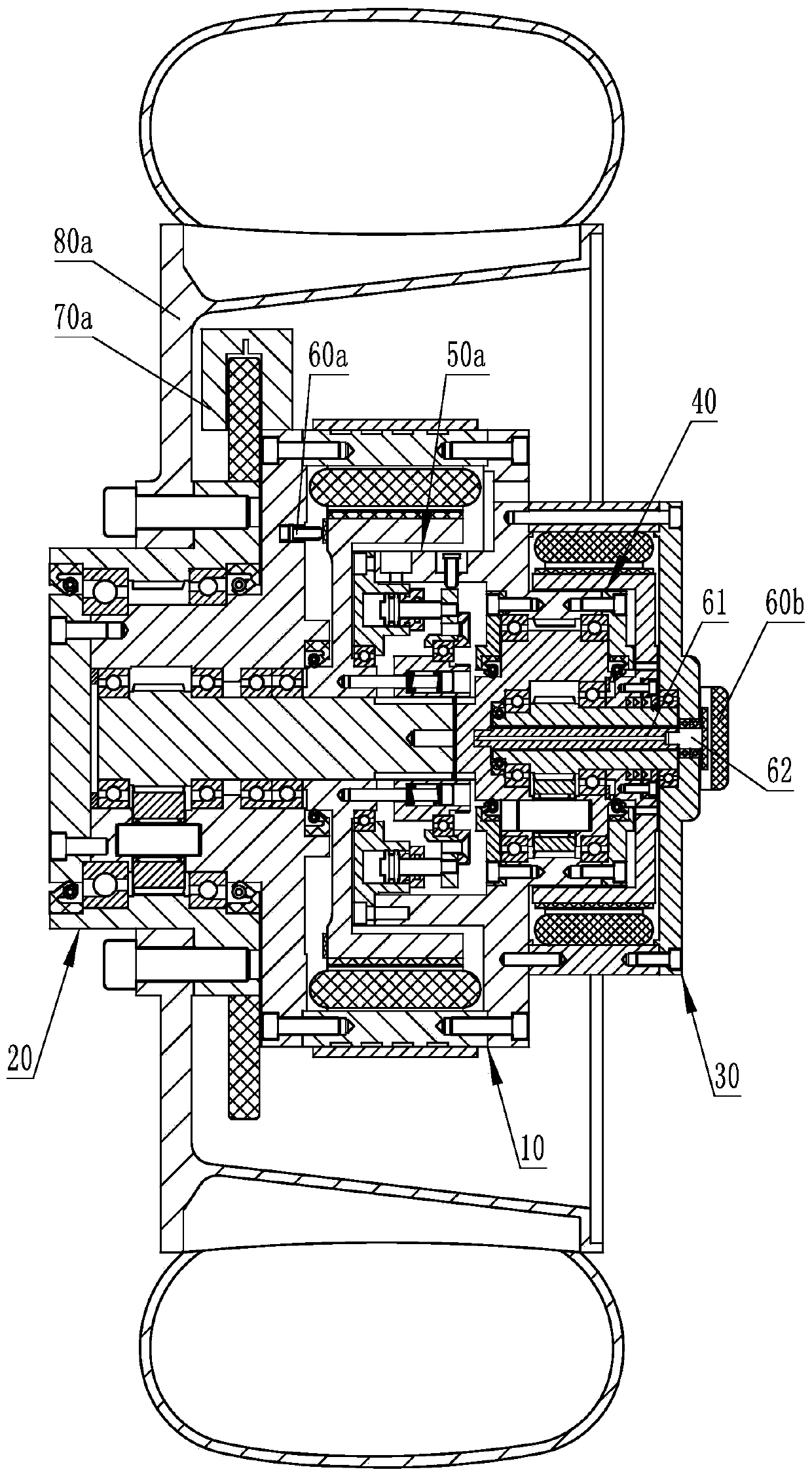

ActiveCN102774281AIncrease drive torqueCompact structureDifferential gearingsMotor depositionElectric machineControl theory

The invention relates to a driving device, used for a wheel of a motor vehicle having the aid of a motor and driven by a differential mechanism; wherein the motor possessing rotors and a stator drives the input element of the differential mechanism, and the output element of the differential mechanism is outputted to the wheel of the motor vehicle via an output shaft. In order to realize a structure which is compact in structure and favorable in gear ratio, the driving device is provided. The annular rotors (18) of the motor (12) are outputted to the input element (50) of the differential mechanism (48) via variable-speed control mechanisms (64, 64'), and the variable-speed control mechanisms (64, 64') and the differential mechanism (48) are integrated in the rotors (18, 20).

Owner:AUDI AG

Cleaning device, process cartridge, and image forming apparatus

ActiveCN101339396ANo reduction in contact widthIncrease line pressureElectrographic process apparatusBand shapeImage transfer

A low linear pressure and high surface pressure cleaning structure by specifying the material, shape and support structure of a cleaning blade in a cleaning device, a process cartridge and an image forming apparatus is obtained. A tip portion of an elastic cleaning blade 38 supported by a support member 37 which is a so-called blade holder is pressed against a drum-shaped or belt-like image bearing member 10 to remove a residual toner remaining on the image bearing member after image transfer. In such a cleaning device 16, an angle [theta] forming a front edge portion 36 of the cleaning blade is made obtuse and the front edge portion is pressed against the image bearing member at a surface pressure of 2.0g / mm<2> or larger. The surface pressure is a value given by dividing total load applied on the cleaning blade by a contact area of the cleaning blade to the image bearing member.

Owner:RICOH KK

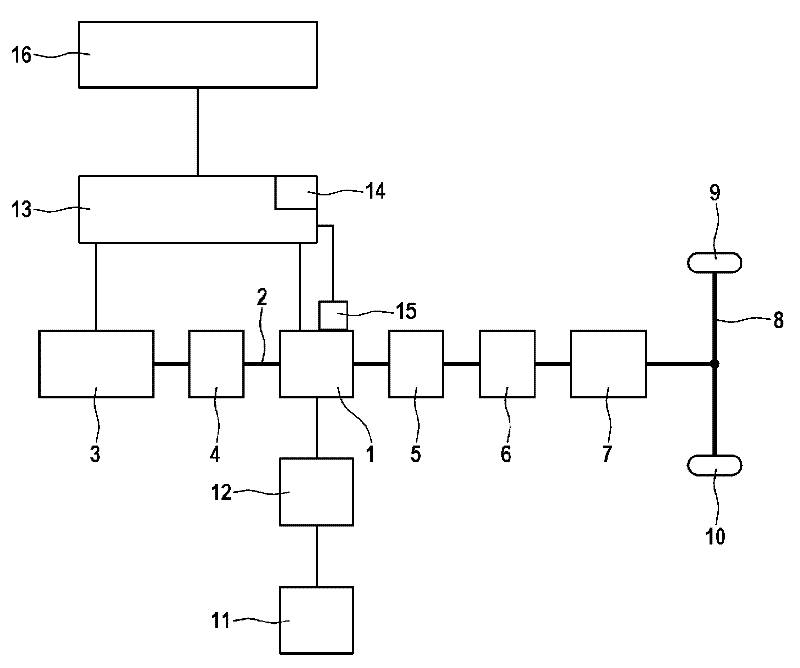

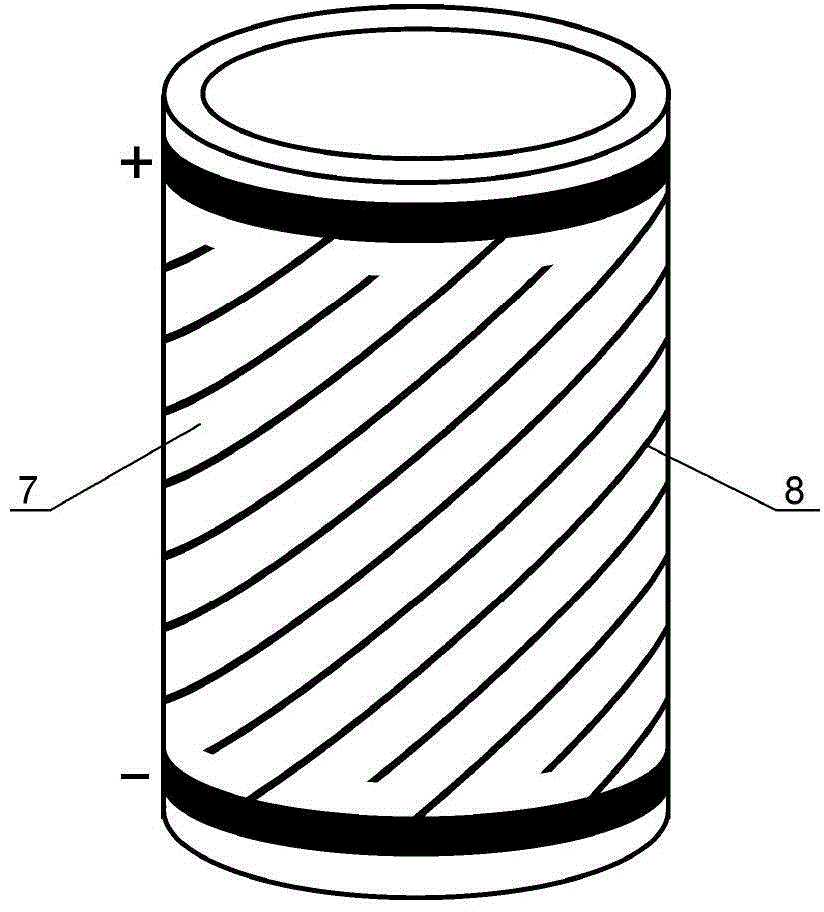

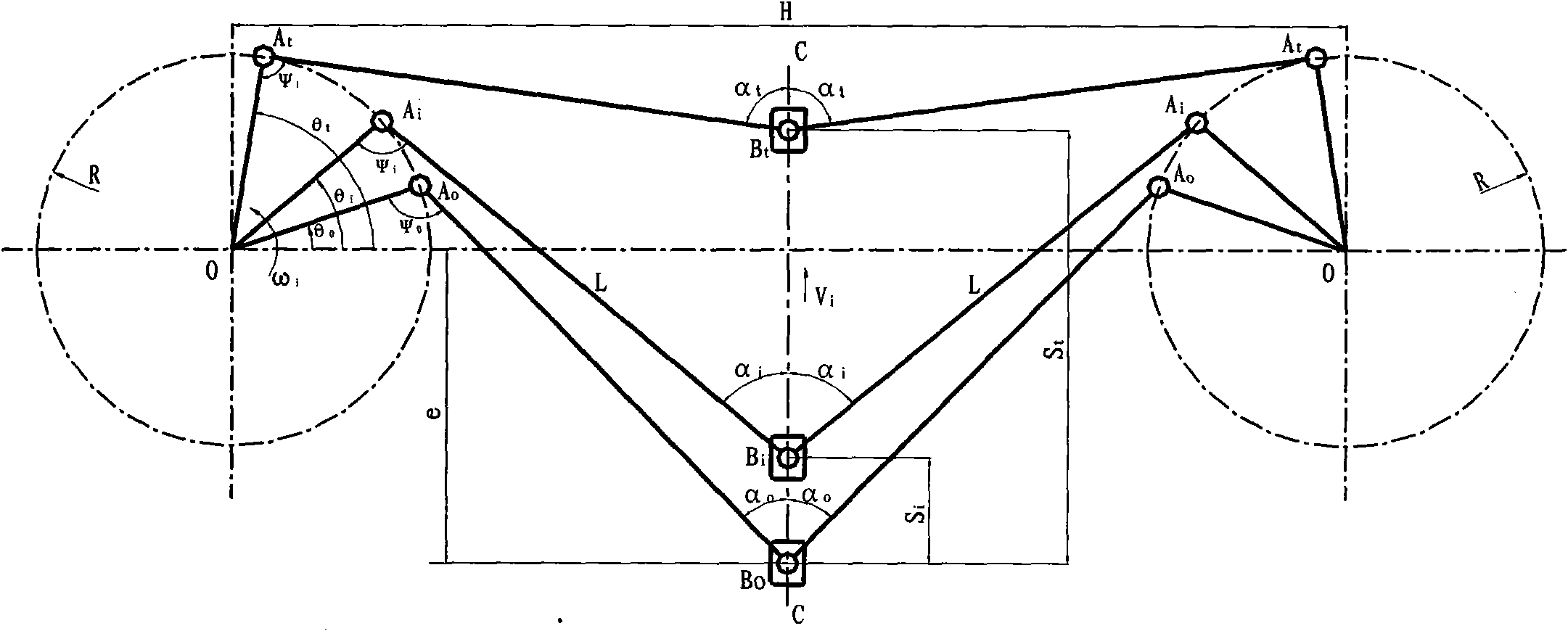

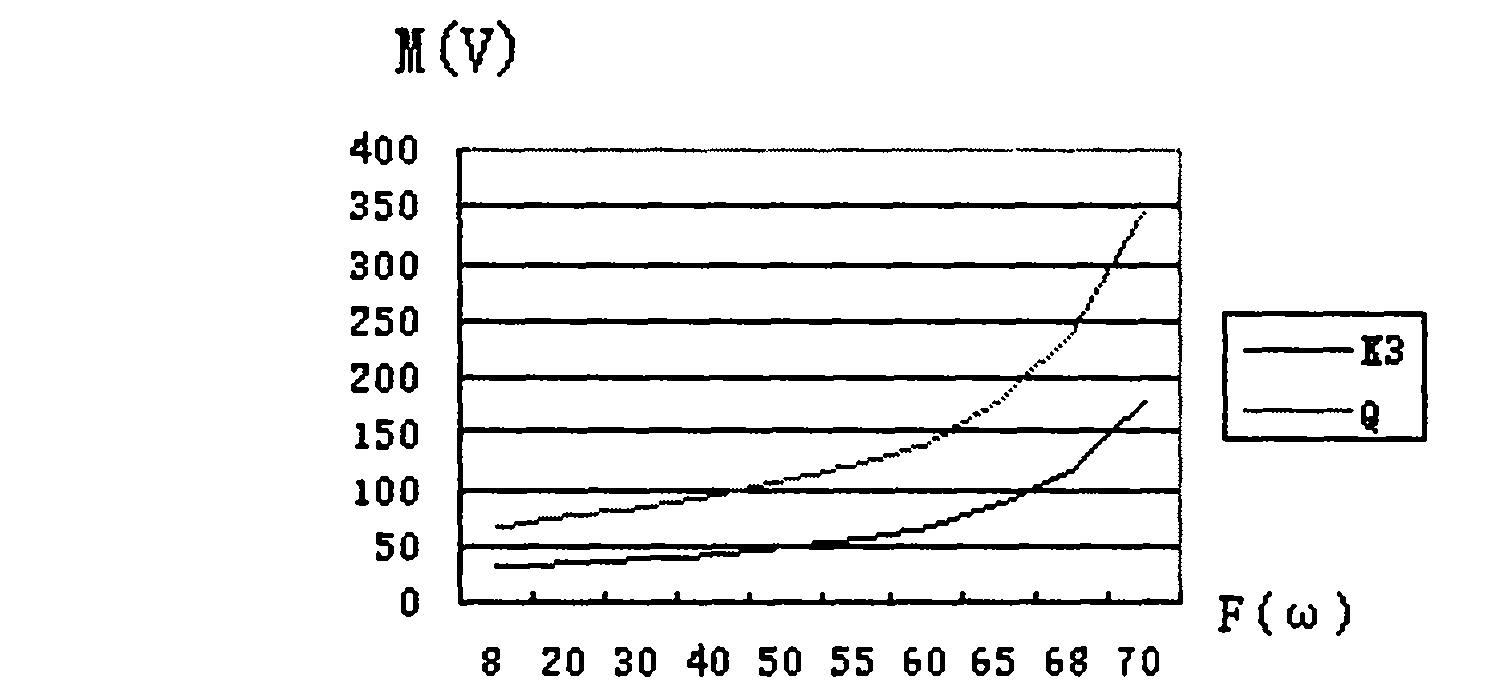

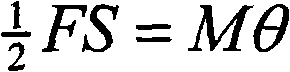

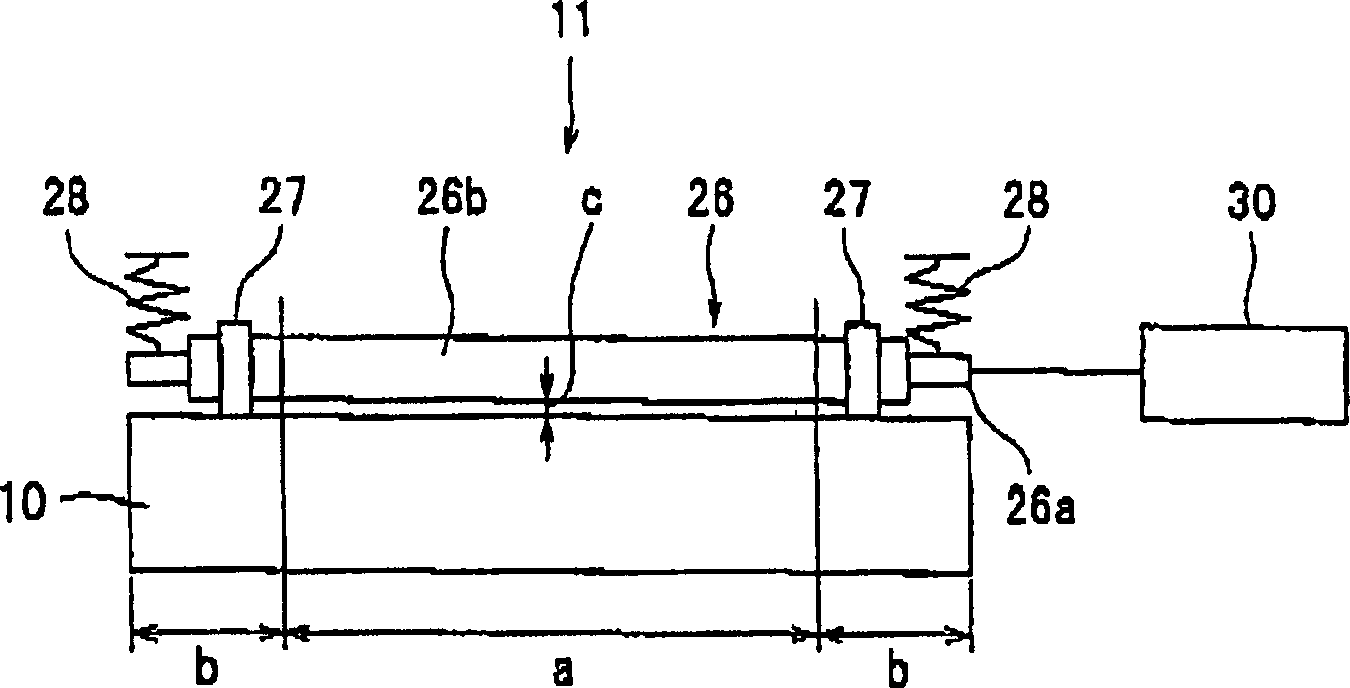

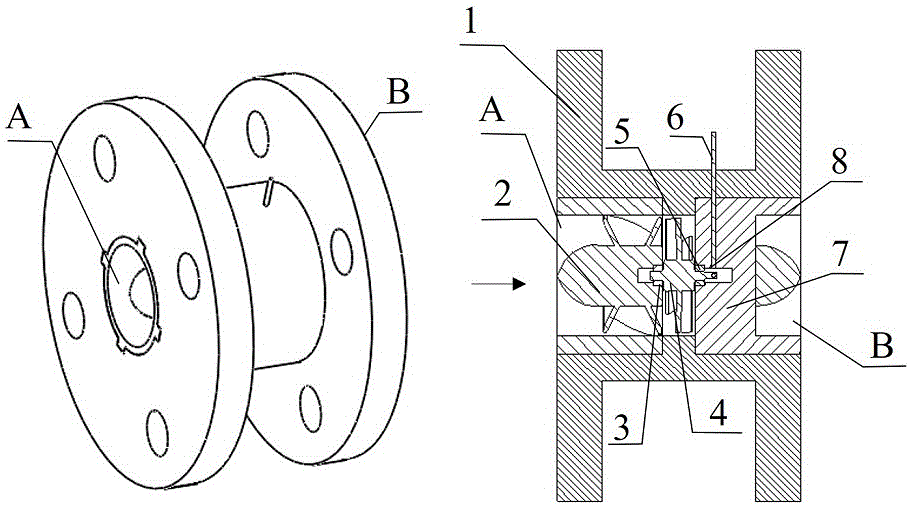

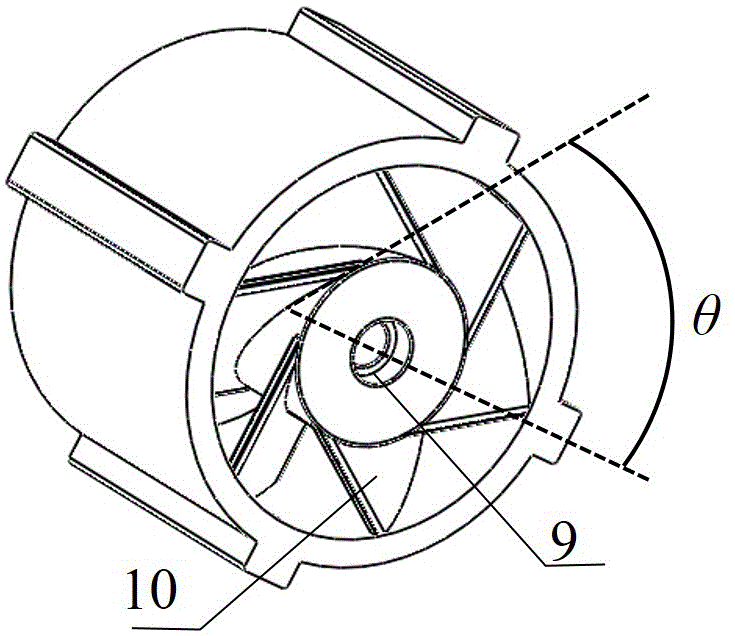

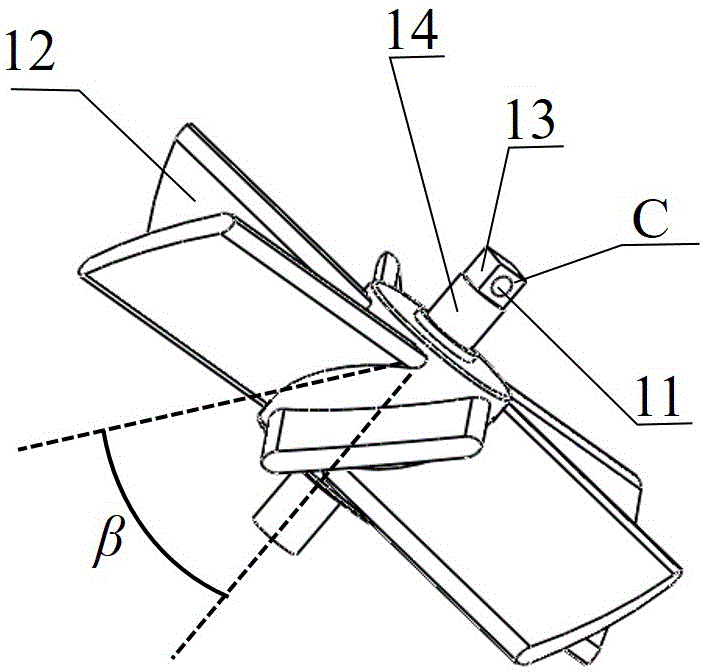

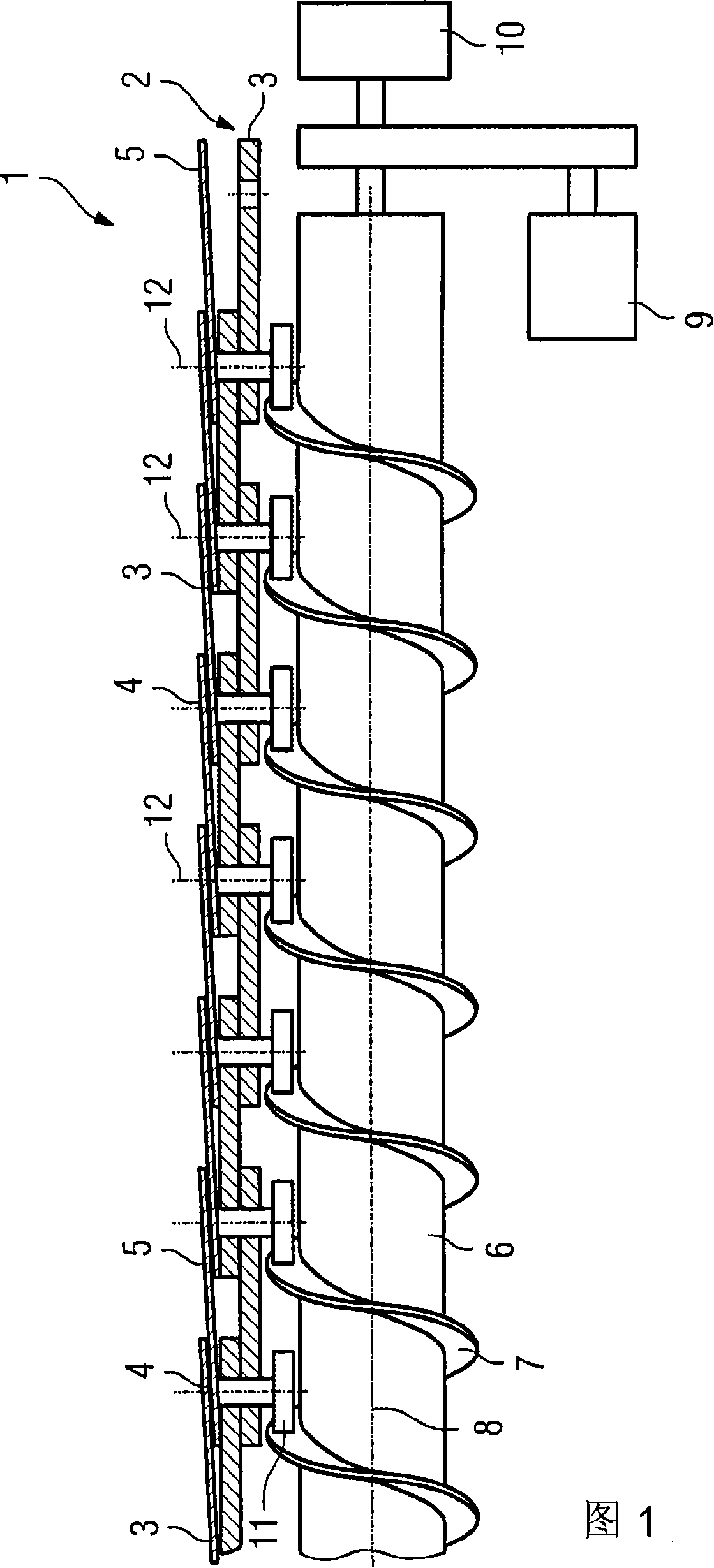

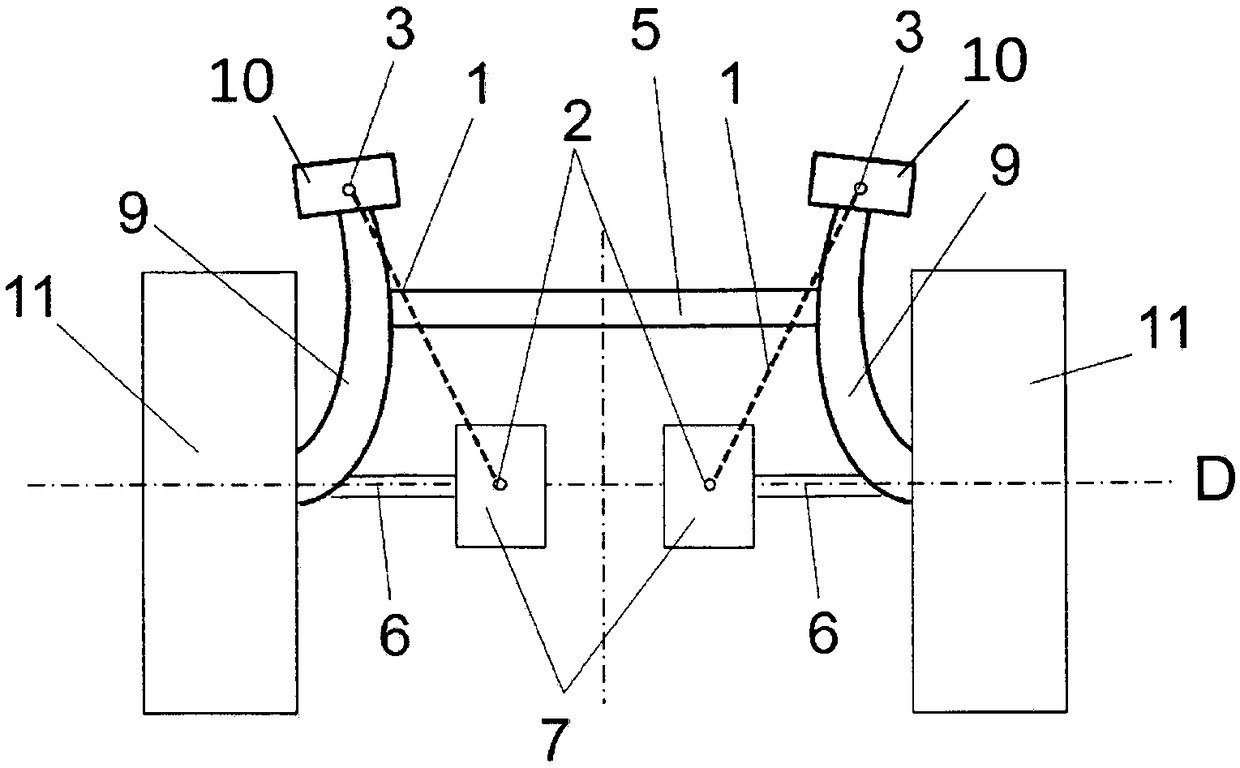

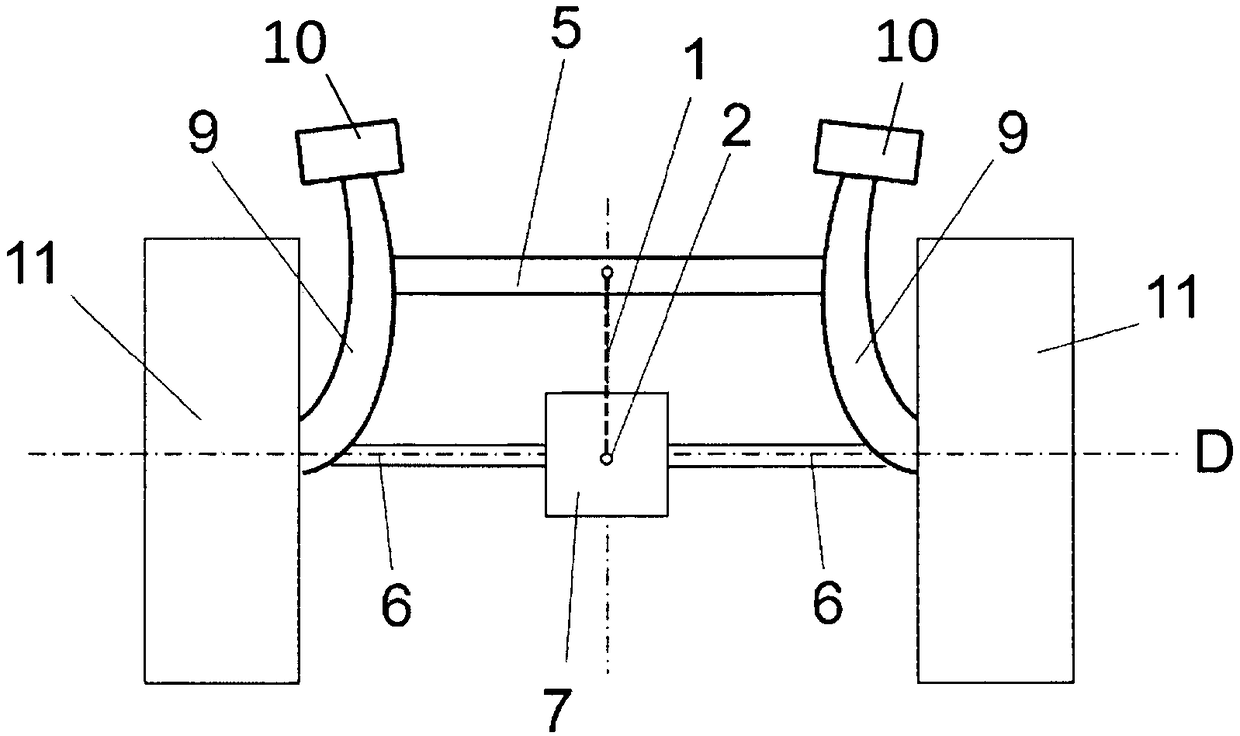

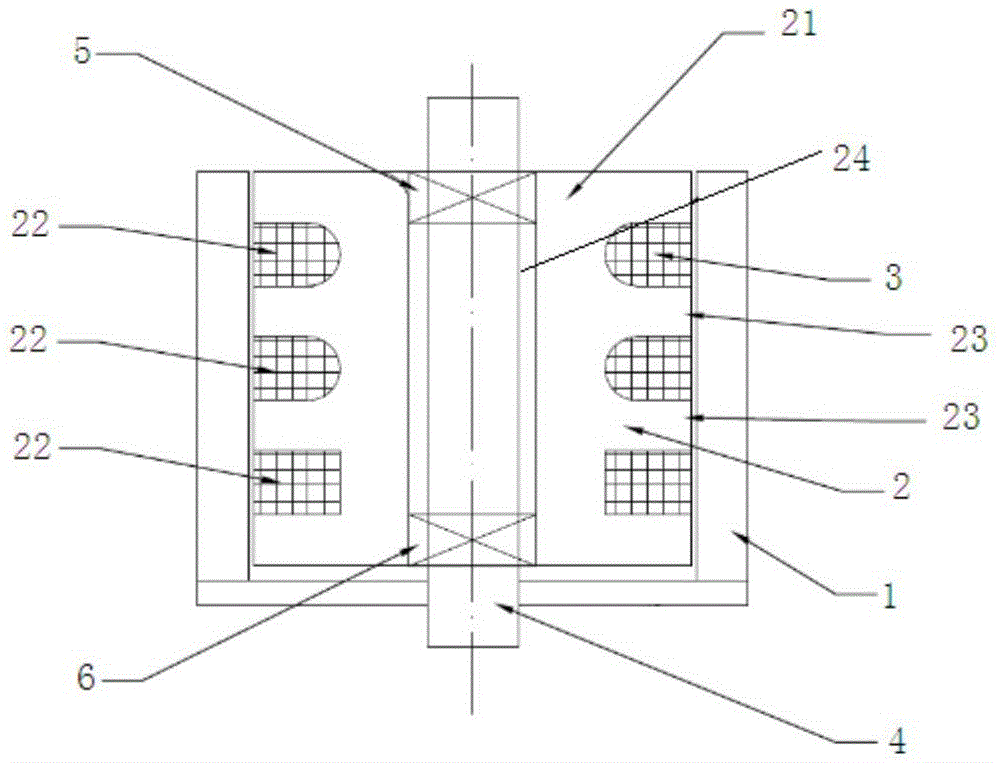

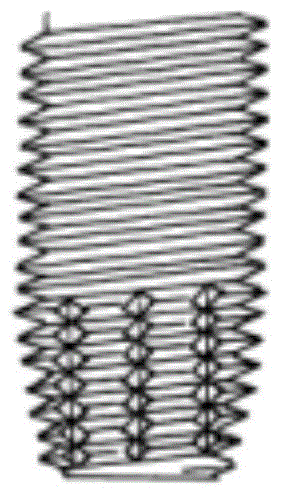

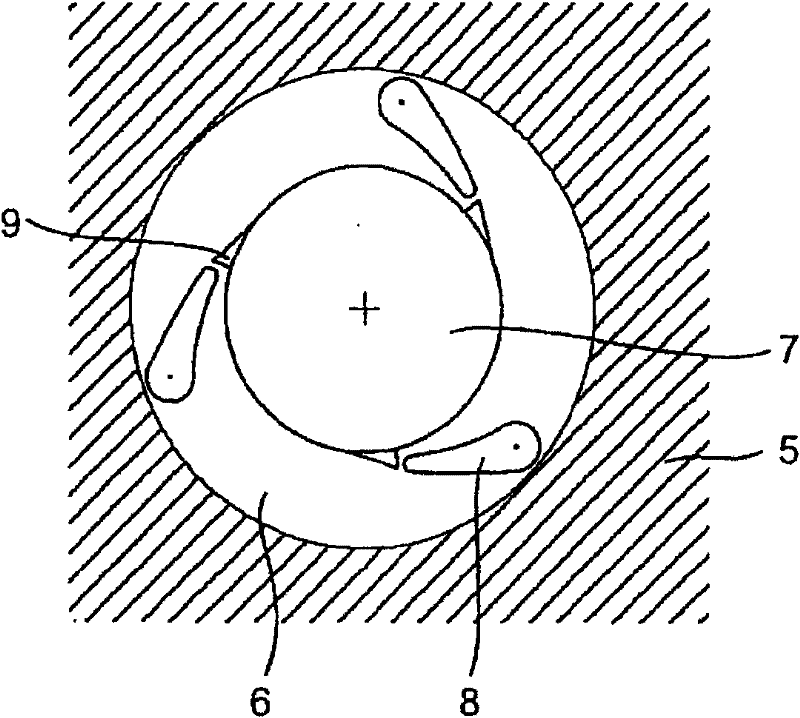

Improved optical fiber turbine flowmeter

ActiveCN105841755AIncrease drive torqueIncrease the turndown ratioVolume/mass flow by mechanical effectsImpulse frequencyTurbine blade

The invention provides an improved optical fiber turbine flowmeter. The improved optical fiber turbine flowmeter is composed of a shell (1), a front flow guide element (2), a fore bearing (3), a rotating turbine (4), a rear bearing (5), optical fiber (6) and a rear flow guide element (7). The helix angle beta of rotating turbine blades (12) of the turbine flowmeter is designed to be 45 degrees, and the helix angle beta of front flow guide element blades (10) is designed to be 45 degrees, so that driving moment of the rotating turbine (4) is effectively increased, the starting flow rate is reduced, the range ratio is increased, and sensitivity is improved. In addition, the optical fiber (6) is sealed in rear flow guide element blades (16), an optical fiber probe end face (8) is effectively prevented from being polluted by fluid, and therefore the flowmeter can operate reliably for a long time. Flattening, silver film plating and trepanning are conducted in a 2mm region at the tail end a rotating shaft (14) to obtain a through hole (11) and a silver film plated surface (13) of the rotating shaft, different reflection rates are provided, rotating speed signals are converted into optical signals of pulse changes, and the rotating speed of the turbine is measured by measuring the reflected light impulse frequency.

Owner:NORTHEASTERN UNIV +2

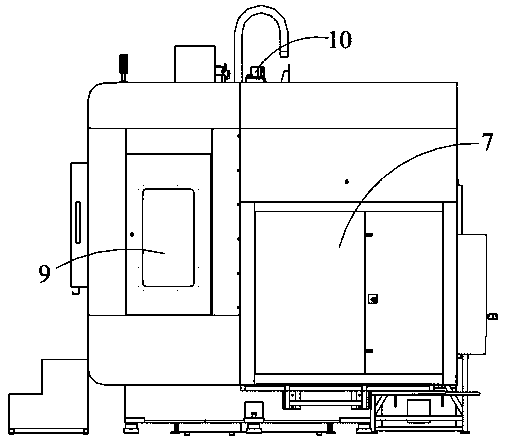

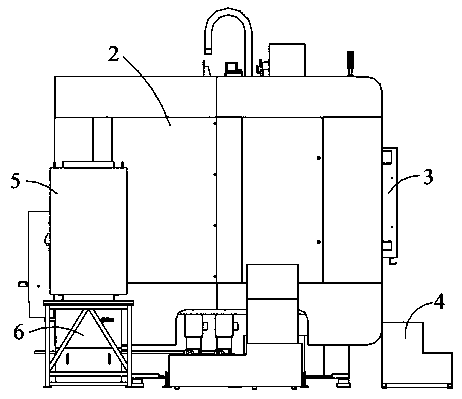

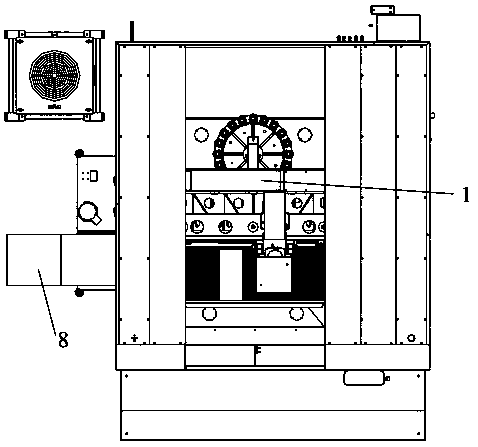

Nine-axis control five-axis linkage bridge type machining center and turning-milling combined machining center

PendingCN109940395AImprove dynamic response performanceIncrease drive torqueOther manufacturing equipments/toolsLarge fixed membersRotational axisBridge type

The invention relates to a nine-axis control five-axis linkage bridge type machining center and a turning-milling combined machining center. The nine-axis control five-axis linkage bridge type machining center comprises a numerical control system, a Y-axis feeding mechanism, an X-axis feeding mechanism, a Z-axis feeding mechanism, a main axis and a direct-drive A-C cradle type rotary table, an electric spindle mechanism and a servo tool magazine mechanism, wherein the Y-axis feeding mechanism comprises a Y1 axis and a Y2 axis, and is connected with the X-axis feeding mechanism and the Z-axis feeding mechanism to form four linear feeding coordinate axes; the direct-drive A-C cradle type rotary table comprises an A1 axis, an A2 axis and a C axis, so that three rotating coordinate axes are formed; the main axis mechanism is the electric spindle mechanism; and the servo tool magazine mechanism serves as a rotating axis, namely a W axis, of a tool magazine

Owner:JIANGSU SHINRI HEAVY IND SCI & TECH

Drive for a conveyor, in particular a baggage conveyor at an airport facility

The present invention relates to a drive for a conveyor in particular for a baggage conveyor, which is provided with flat shape brackets (5) overlap jointed with each other and fixed on a continuous rounding and articulated guide chain (2). In order to construct the drive in simply, effective and high effective way, the drive is provided with at least one rotatably driven worm (6) with spiral shape teeth parallel to the conveying direction. The worm is cooperated with a follower (11) which is embedded in the tooth part (7) of the worm (6) and arranged on the guide chain (2) in a way of worm gear worm wheel when the worm is driven to rotate around the longitudinal axis (8).

Owner:SIEMENS AG

Mechanical limiting exoskeleton robot joint

InactiveCN112405599ALimit the range of rotationImprove securityProgramme-controlled manipulatorJointsExoskeleton robotReduction drive

The invention discloses a mechanical limiting exoskeleton robot joint. The joint comprises a driving mechanism, a speed reducing mechanism, an executing mechanism and a feedback mechanism, and the exoskeleton robot joint can be driven to rotate at one degree of freedom. The driving mechanism is composed of a motor base, a motor, a rotating shaft, a rear end cover, a bearing, a stator check ring and a rotor check ring. The speed reducing mechanism is composed of a speed reducer, an output flange and a front end cover. The executing mechanism is composed of an upper connecting plate and a lowerconnecting plate. The feedback mechanism is composed of an absolute value encoder and a relative value encoder. A fan-shaped groove with the angle ranging from -6 degrees to 120 degrees is formed in the middle of the front end cover, a boss is designed for the output flange, the boss of the output flange is located in the fan-shaped groove of the front end cover after assembly and can move along the fan-shaped groove, therefore the relative rotation relation between the upper connecting plate and the lower connecting plate is converted into relative rotation between the front end cover and theoutput flange, and mechanical limiting is achieved. Hard limiting of the joint rotation angle is achieved through a mechanical structure, and the working safety and reliability of a robot are improved.

Owner:BEIJING AEROSPACE GUANGHUA ELECTRONIC TECH CO LTD

Vehicle torsion beam axle

ActiveCN108602410AEliminate trade-offsDetermine the spacing multipleElectric propulsion mountingInterconnection systemsRotational freedomEngineering

The invention relates to a vehicle torsion beam axle comprising two longitudinal links, a transverse profiled element that connects the longitudinal links, and a drive unit which drives, via an inputshaft, at least one of the wheels guided by the torsion beam axle and which is mounted in the immediate vicinity of the common axis of rotation of the wheels in the design position. The drive unit ismounted on the vehicle body in such a way as to be rotatable about an axis running parallel to the common axis of rotation of the wheels, and said degree of rotational freedom is aided by a pivoted support.

Owner:BAYERISCHE MOTOREN WERKE AG

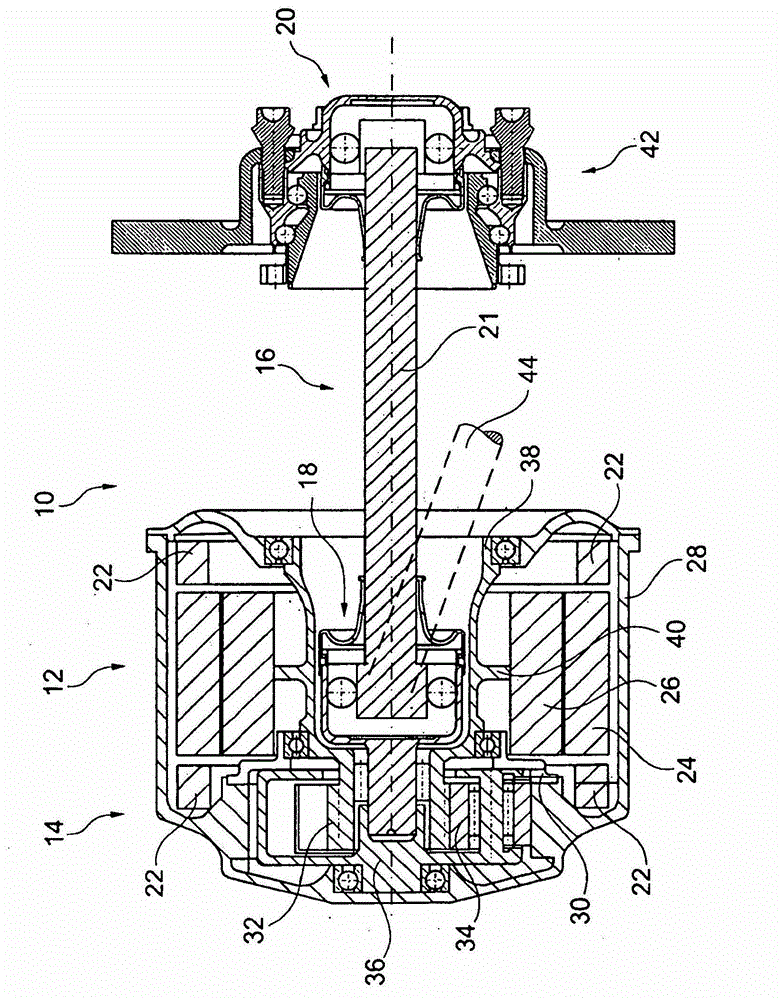

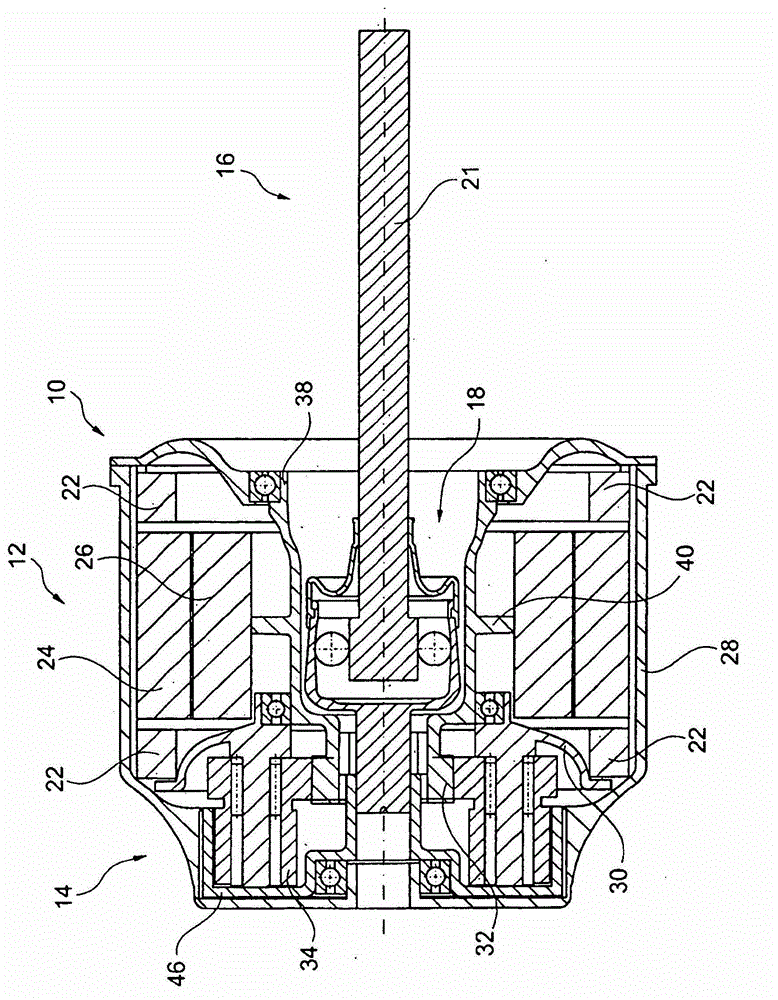

Wheel drive for a vehicle

ActiveCN102802990AOptimize space utilizationAvoid unused free spaceSpeed controllerElectric devicesElectric driveWheel drive

The invention relates to a wheel drive for driving a wheel of a vehicle, comprising an electric drive motor for generating a drive torque, a gear box for increasing the drive torque, and an articulated shaft having at least one joint for transferring the increased drive torque to the wheel. The electric drive motor is designed to surround the articulated shaft. The invention also relates to a vehicle comprising the wheel drive.

Owner:BAYERISCHE MOTOREN WERKE AG

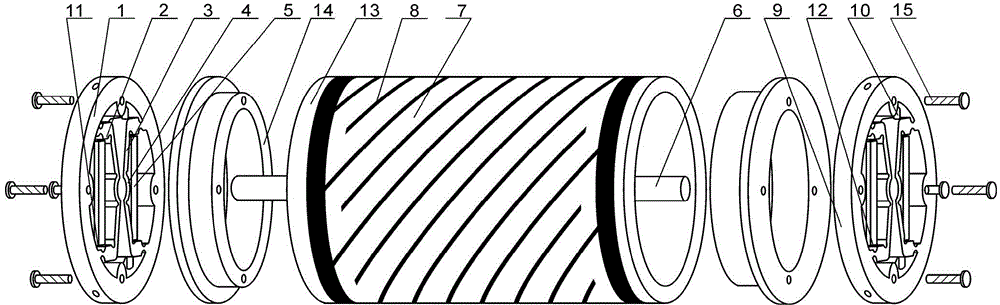

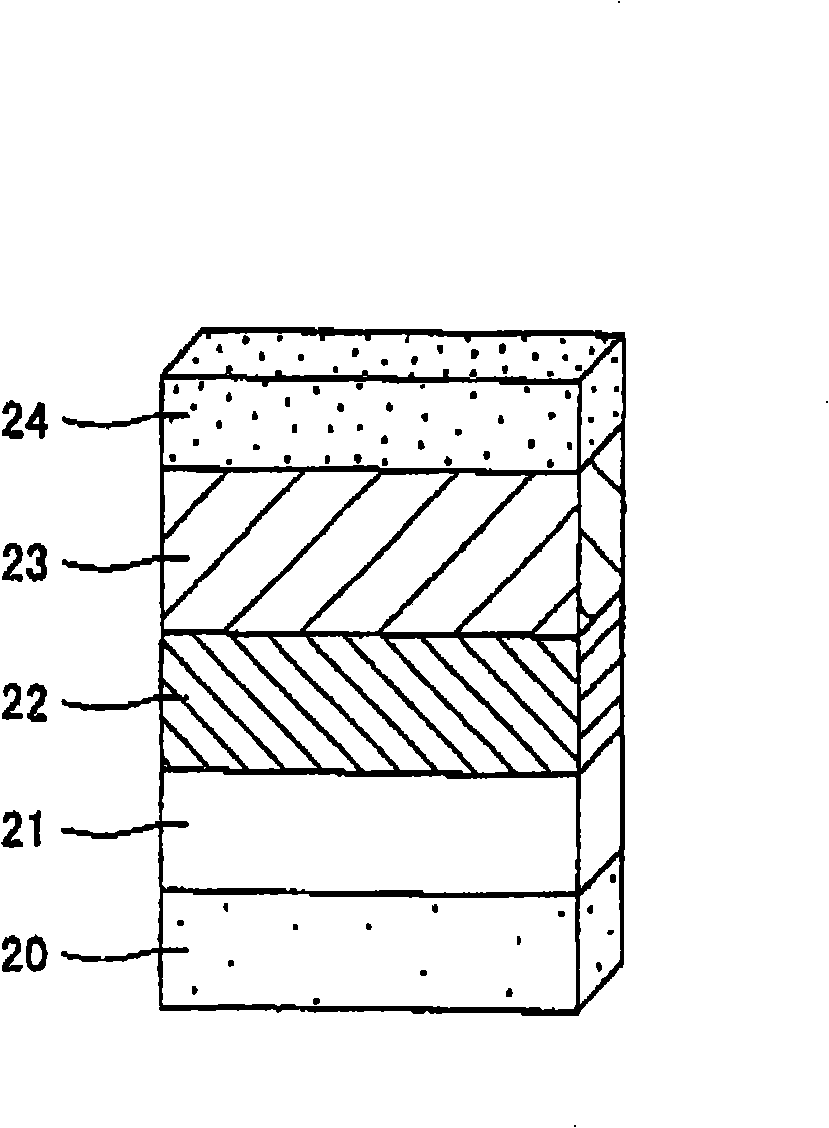

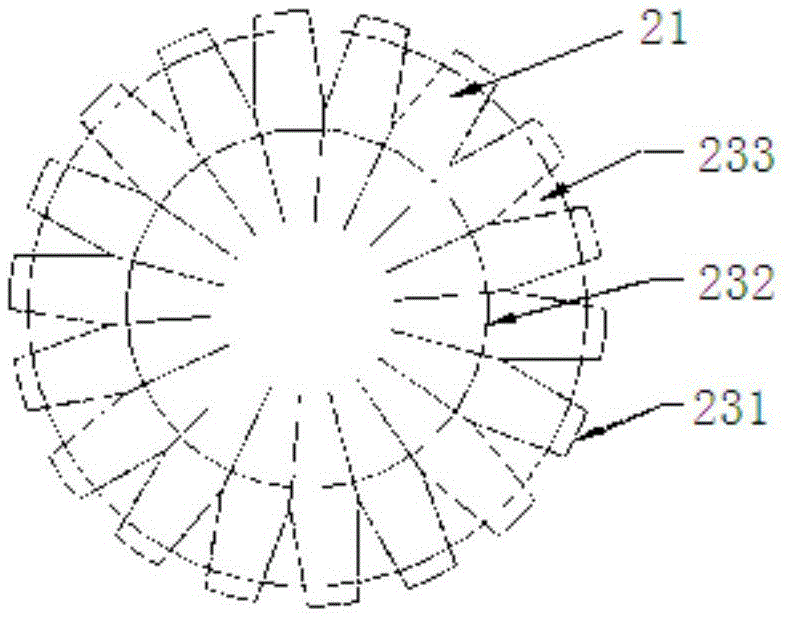

High-power density electric vehicle motor

InactiveCN105553207AImprove electricity efficiencyCompact structureMagnetic circuit rotating partsElectric machinesFully developedElectric machine

The invention relates to a high-power density electric vehicle motor, which comprises a rotor and a stator, wherein the stator is located in the rotor; a plurality of stator slots which are evenly distributed up and down are arranged in a circular region of the stator; an annular coil is arranged in each stator slot; the regions between the adjacent stator slots are magnetic-conducting regions; each magnetic-conducting region comprises magnetic poles, a winding slot bottom and annular windings; the magnetic poles are distributed in a straight line; the rotor comprises permanent magnets and inclined magnetizers; the permanent magnets are evenly arranged obliquely; the inclined magnetizers and the permanent magnets are correspondingly distributed; a small through hole or no through hole is formed in the center of the stator; and the structure of each stator slot is in a round shape or a roundish shape or a square shape with a round angle. The high-power density electric vehicle motor can improve the power density of the motor, especially can improve the torque density of the motor, and can fully develop the magnetic permeability and the frequency performance of a permeability magnetic material in structure.

Owner:WANXIANG QIANCHAO TRANSMISSION SHAFT +1

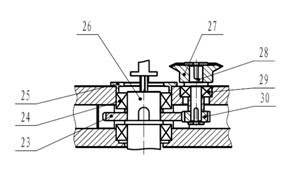

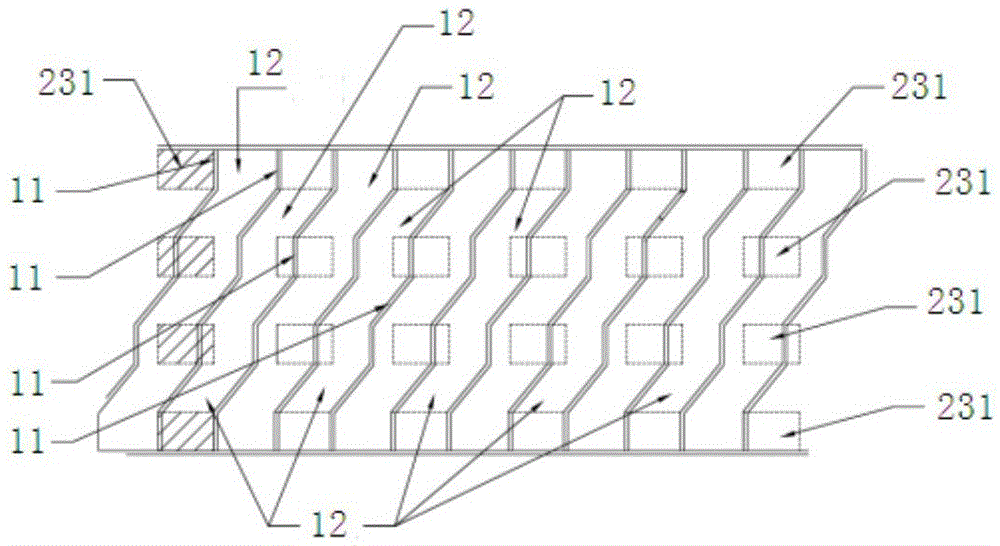

Dual-motor driving device of electric automobile

PendingCN111497596AIncrease drive torqueSolve the problem of high power consumptionElectric machinesMotor depositionElectric machineryElectric vehicle

The invention belongs to the technical field of electric vehicles, especially relating to a double-motor driving device of an electric automobile which comprises a first planetary speed reducing mechanism, a first inner rotor motor, a second planetary speed reducing mechanism and a second inner rotor motor which are arranged in sequence. A first rotor is fixed to a first sun wheel shaft. A first planet carrier or a first shell is fixedly connected with a first stator. A second shell is fixedly connected with the first stator, the second stator is fixedly connected with the second shell and thefirst stator, and the second rotor is fixed to the second sun wheel shaft. The clutch mechanism is arranged between the first sun gear shaft and the second planet carrier, the first detection feedback structure is arranged corresponding to the first sun gear shaft, and the second detection feedback structure is arranged corresponding to the second planet carrier. Synchronous connection between afirst planet speed reducing mechanism and a second planet speed reducing mechanism can be achieved, running is stable, the blocking phenomenon is avoided, and the problems that power is insufficient during starting and low-speed climbing, and power consumption is large during high-speed running are solved.

Owner:山东宏泰机械科技股份有限公司

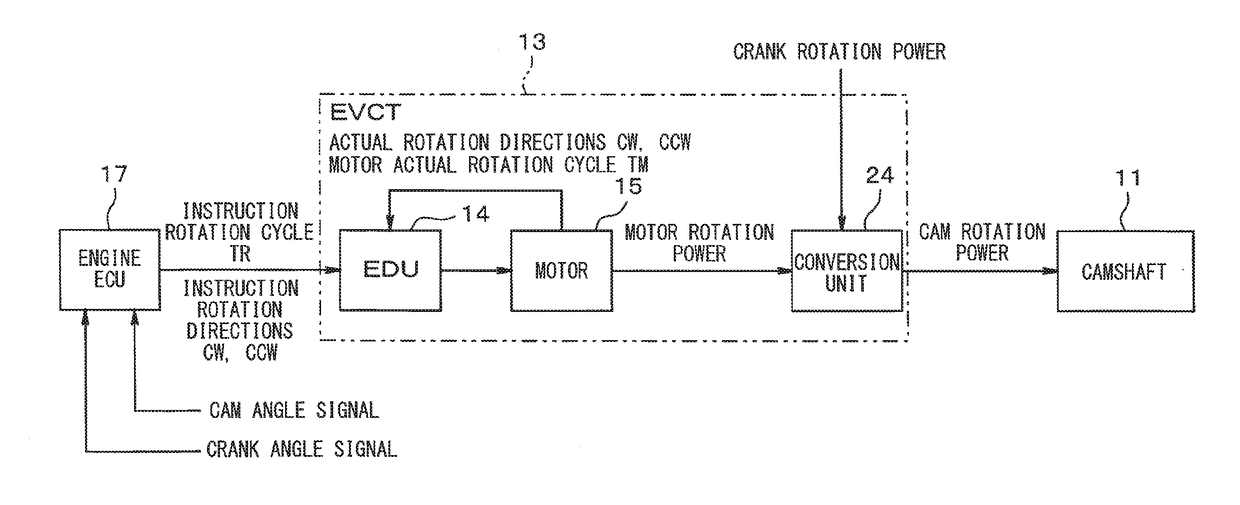

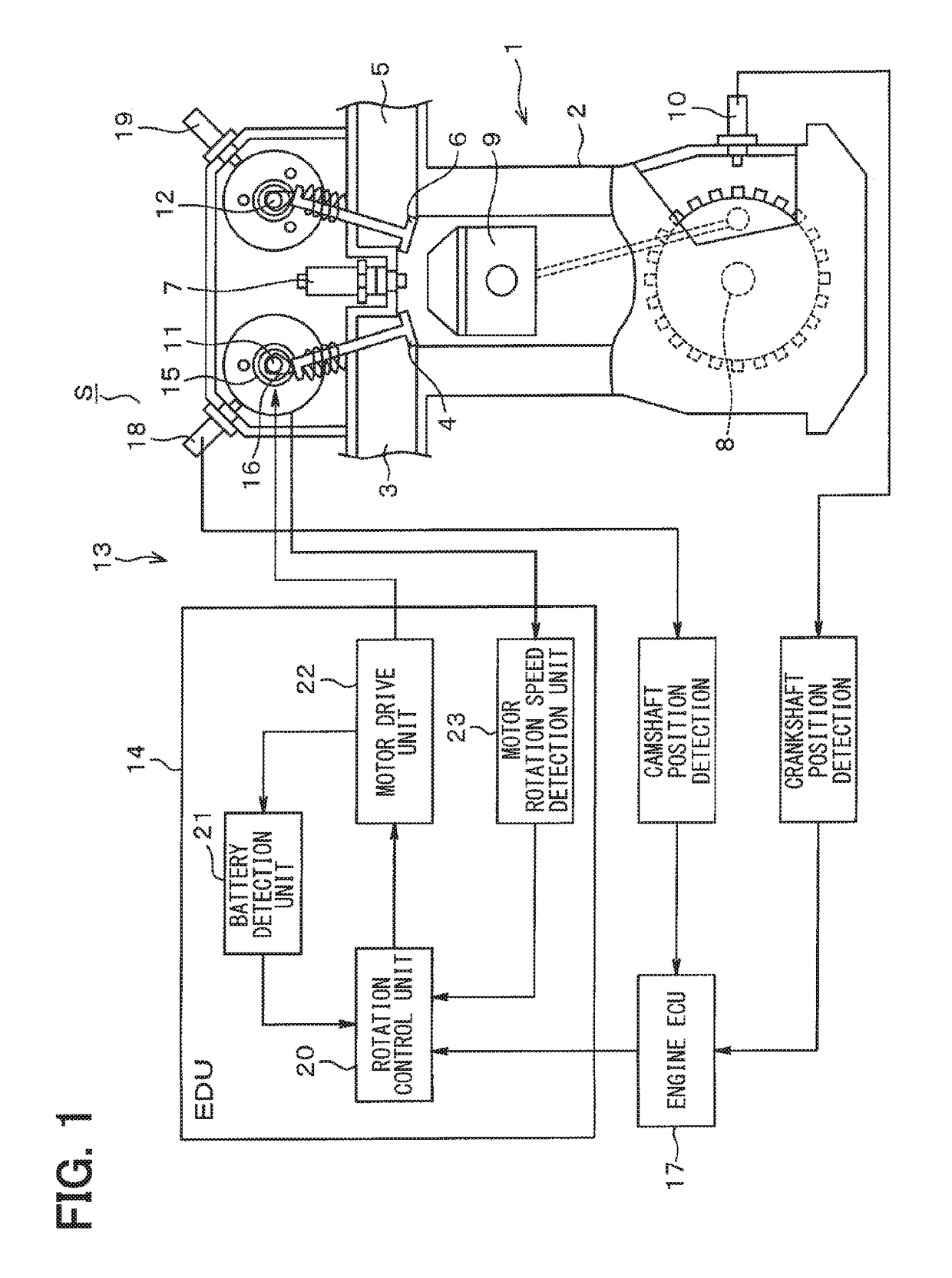

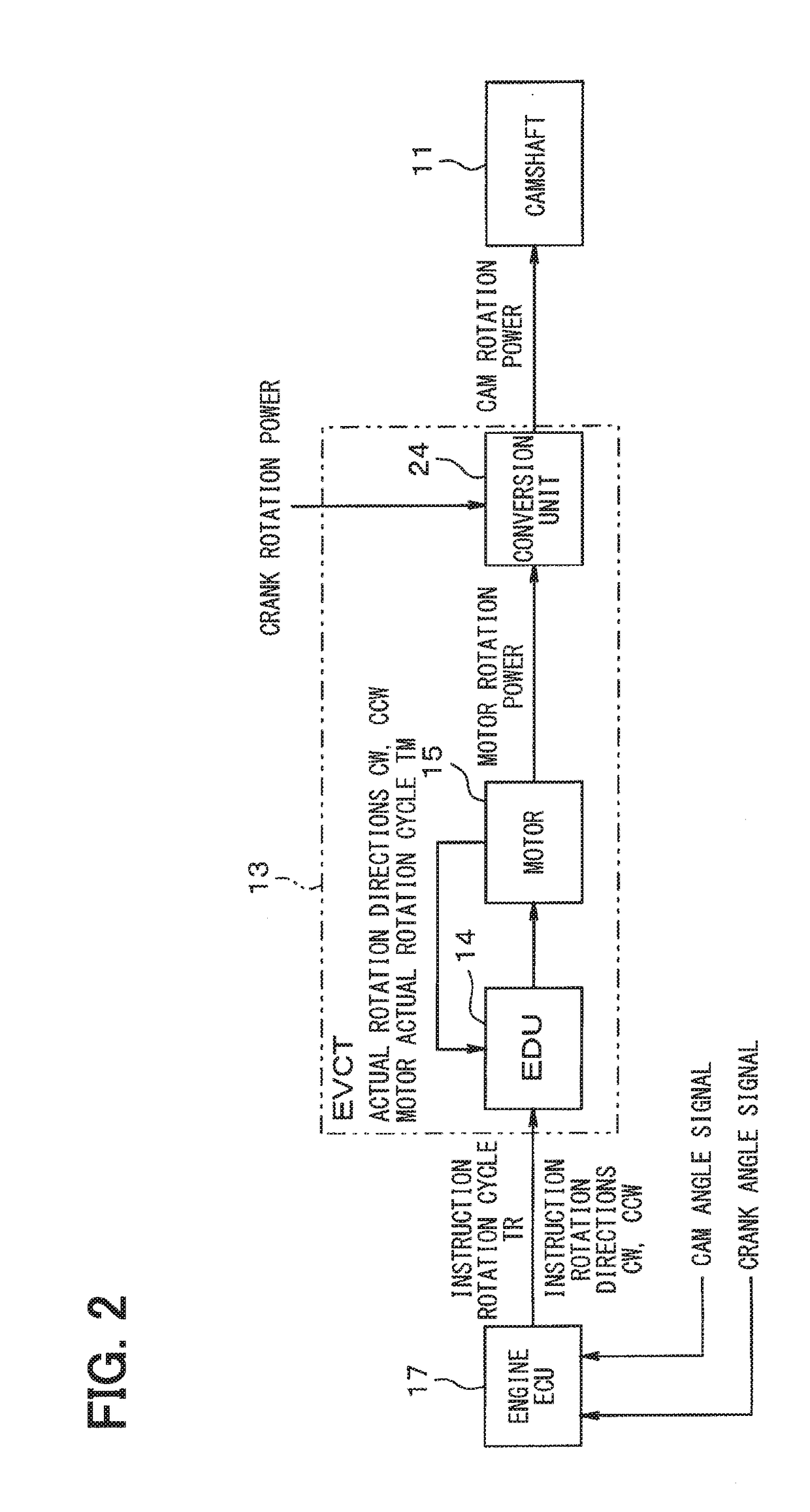

Motor drive device for controlling valve timing of internal combustion engine

InactiveUS20180066549A1Reduce vibrationIncrease drive torqueElectric motor controlSingle motor speed/torque controlMotor driveExternal combustion engine

A motor drive device for valve timing control of an internal combustion engine includes: a motor drive unit that controls a phase of a camshaft to drive a motor for controlling opening and closing operation of a valve; and a determination unit that determines whether a timing is to start up the motor or to normally drive the motor. The motor drive unit drives the motor with an advance angle when it is determined that the timing is to normally drive the motor by the determination unit, and the motor drive unit normally drives the motor without the advance angle when it is determined that the timing is to start up the motor.

Owner:DENSO CORP

A bionic quadruped robot leg mechanism

InactiveCN107128394BThe transmission is compactLarge angle of joint movementVehiclesFiberCarbon fibers

Owner:SHANGHAI UNIV

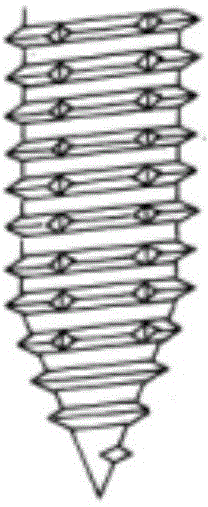

Self-tapping screw with sawtooth threads

InactiveCN104533916AIncreased cutting functionIncrease drive torqueScrewsEngineeringNational standard

Disclosed is a self-tapping screw with sawtooth threads. The end of a screw rod is a transition threaded area and is in the shape that the outer diameter is reduced and a circular truncated cone or a cone is extended. At least two to five circles or all of threads on the rod body or transition threaded area of the screw rod are sawtooth threads. The self-tapping screw can be easily screwed into an aluminum plate with the thickness of 4 mm and 1 mm, and tapping does not need to be carried out in advance, which the national-standard self-tapping screw pitch cannot easily complete.

Owner:WUXI YUXING BUILDING HARDWARE

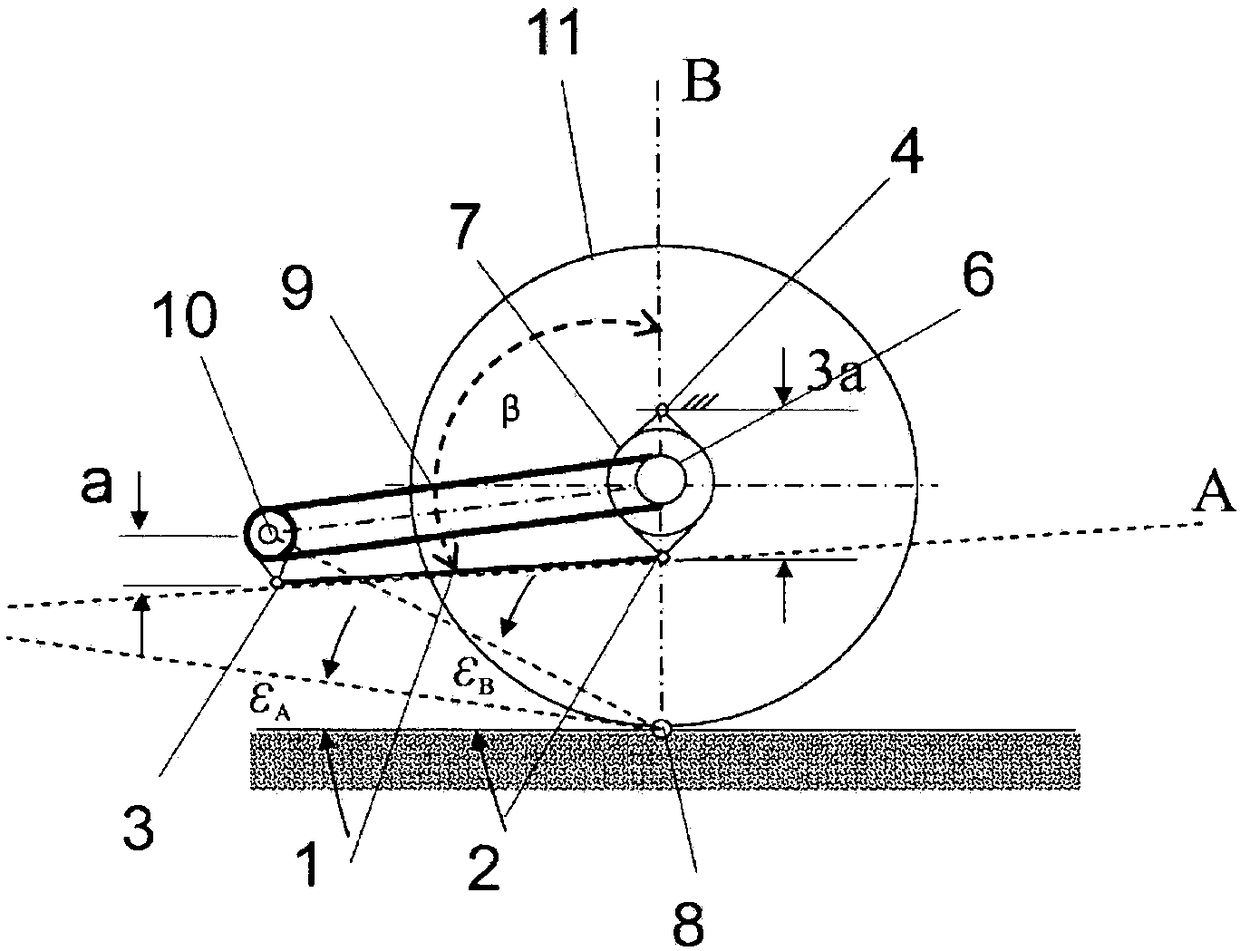

Rotary piston engine

InactiveCN101622454BFirmly connectedEasy to driveOscillating piston pumpsInternal combustion piston enginesRotational axisEngineering

The invention relates to a planetary rotation machine comprising at least one ring channel (1) which is curved along an at least partial arc and contains a piston (2) that can be moved in a fluid generating a movement, said piston being coupled to a rotary body coaxially arranged by means of a lever (5) by the rotational axis thereof. A stable structure able to transmit high torques is obtained by guiding the lever (5) through a gap created in the wall of the ring channel (1) in the direction of displacement of the piston (2), in the radial direction away from the piston (2) in a sealed manner.

Owner:海因茨·劳巴彻

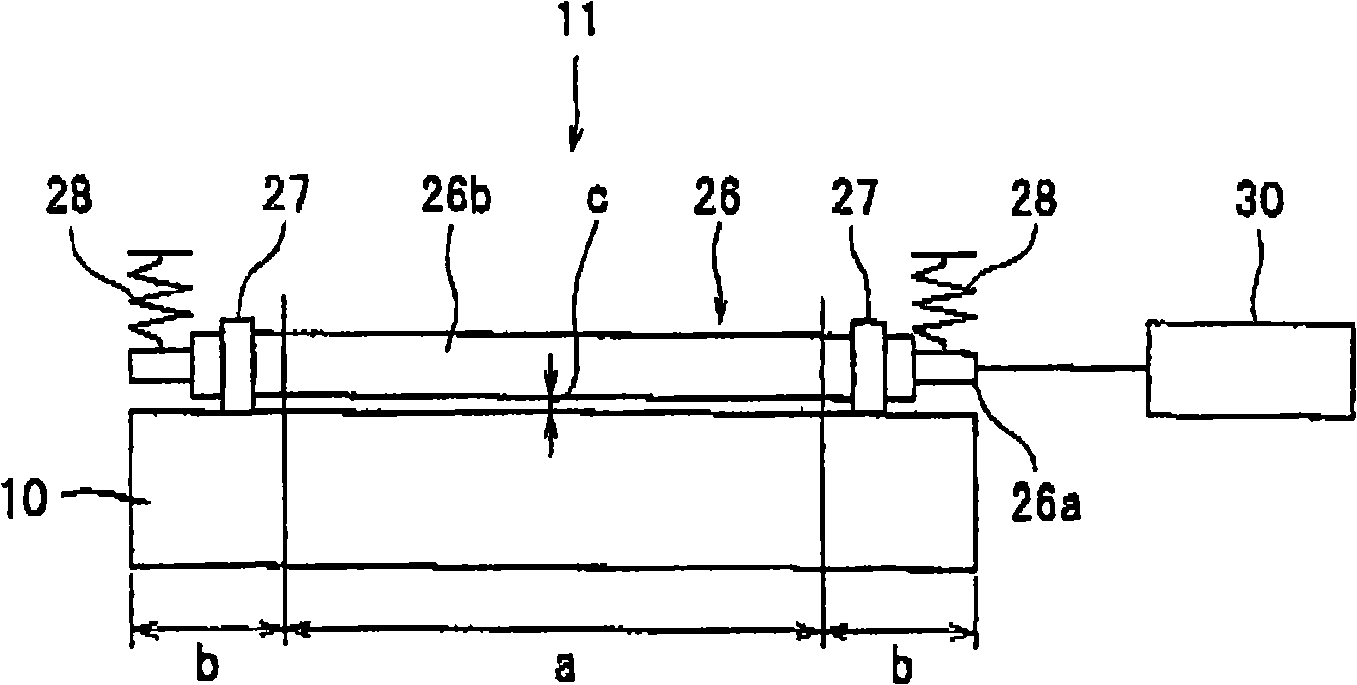

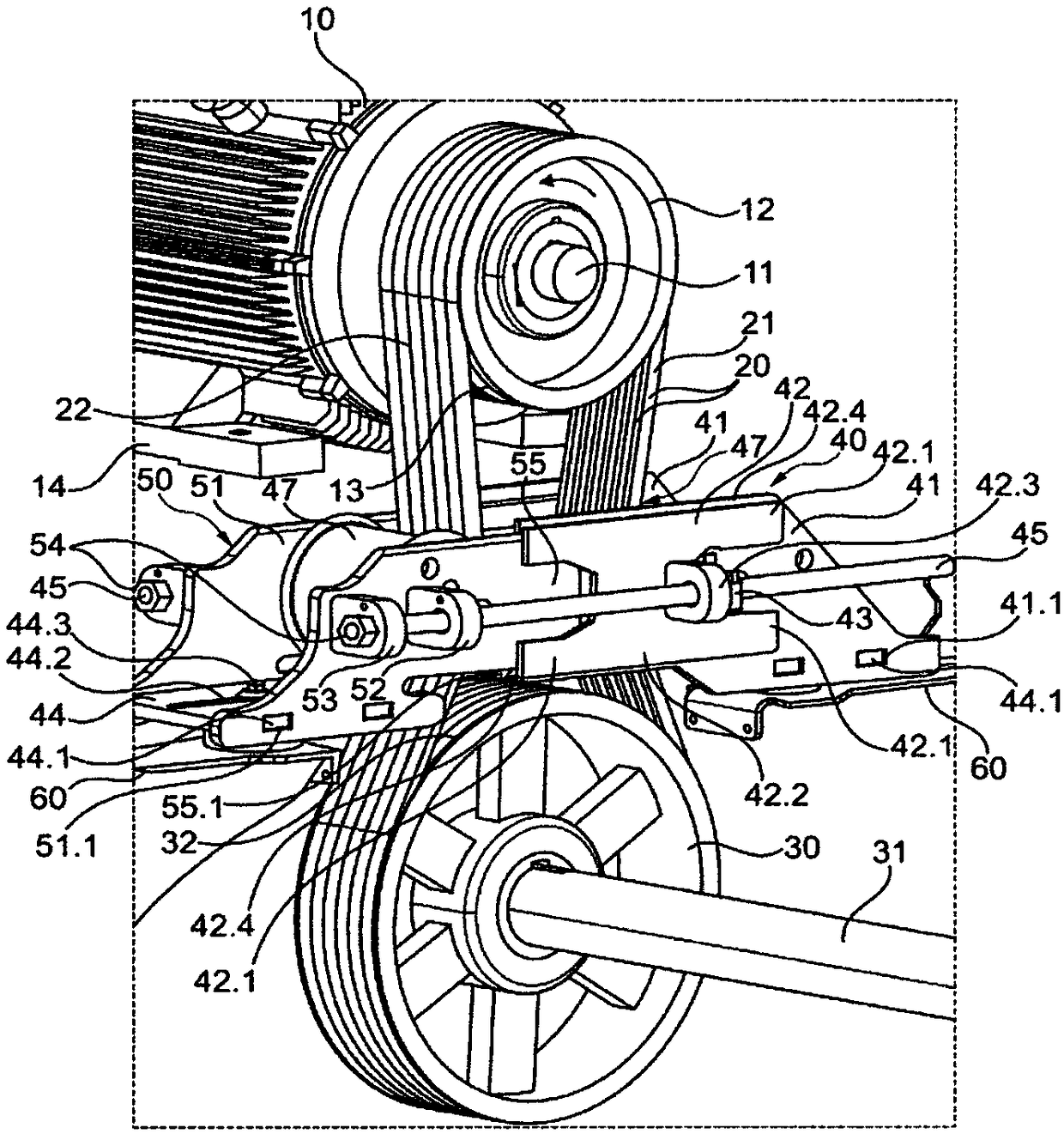

Belt-tensioning device

ActiveCN108884915AExtend working lifeCompensation for pretension lossGearingSupporting framesLinear motionEngineering

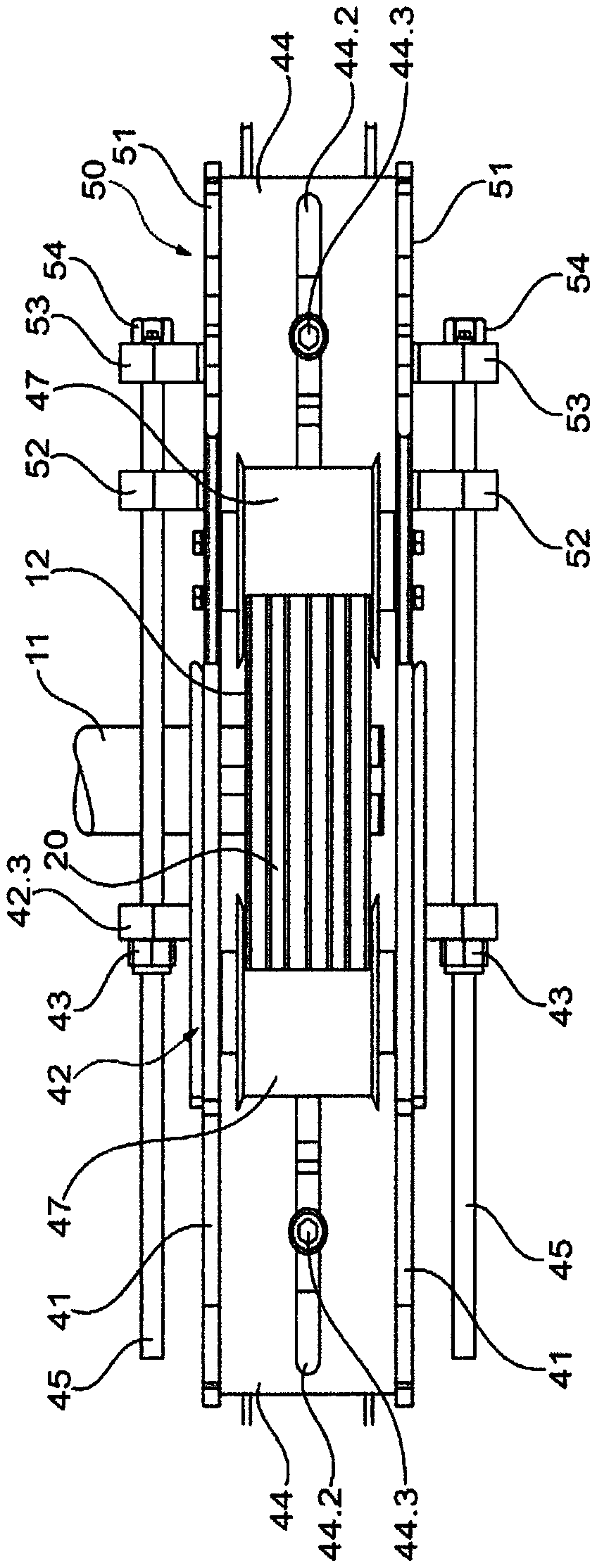

The invention relates to a belt tensioning device for a crusher or a screening machine for tensioning at least one circulating drive belt (20) which is deflected about a belt pulley (12) of a drive (10) and has a load strand (21) and an empty strand (22). The drive (10) can be driven with a crushing assembly, a screening unit, a generator, or the like of the crusher by means of the drive belt (20). The vibrational stress acting on the machine chassis can be significantly reduced in that the belt tensioning device has two tensioning rollers (47), each of which is rotatably mounted on a holder (41, 51) of a tensioning part (40, 50). One tensioning roller (47) is paired with the empty strand (22) and the other is paired with the load strand (21). Additionally, the two tensioning parts (40, 50) can be adjusted relative to each other between an open position and a tensioning position, in which the tensioning parts are held against each other at least opposite the tensioning direction, in particular the tensioning parts can be blocked against each other, and the complete closed system can be freely moved linearly using actuators (44.2) according to the load situation.

Owner:KLEEMANN

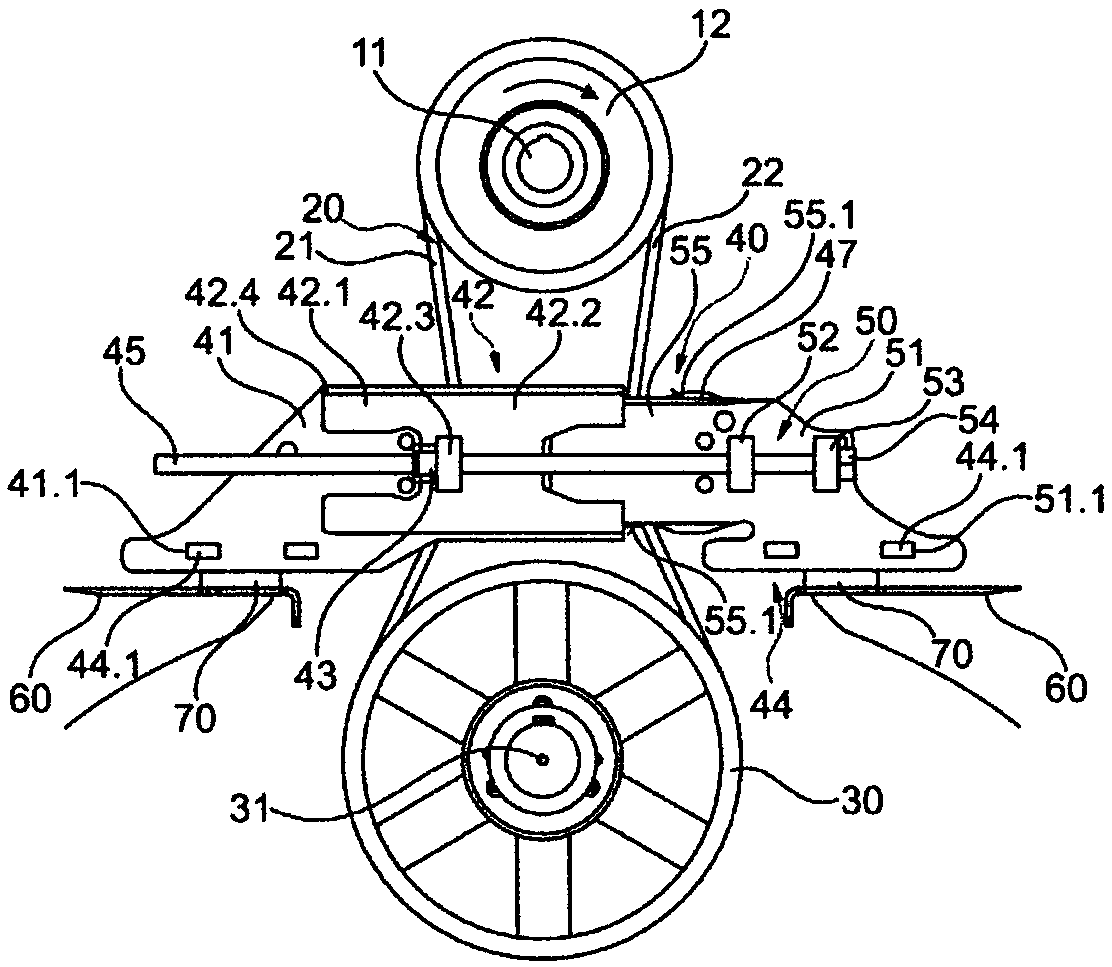

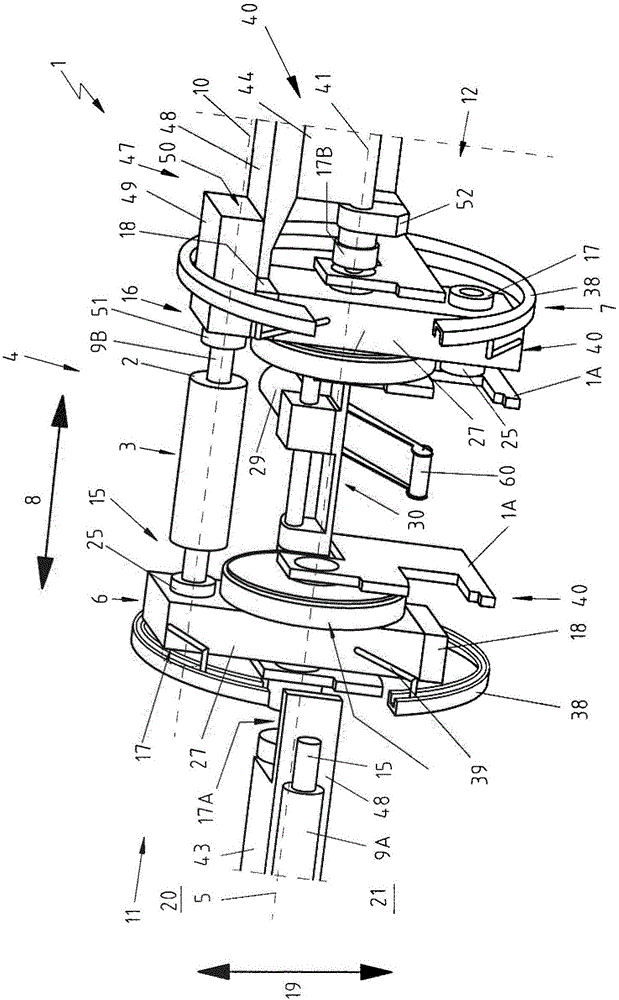

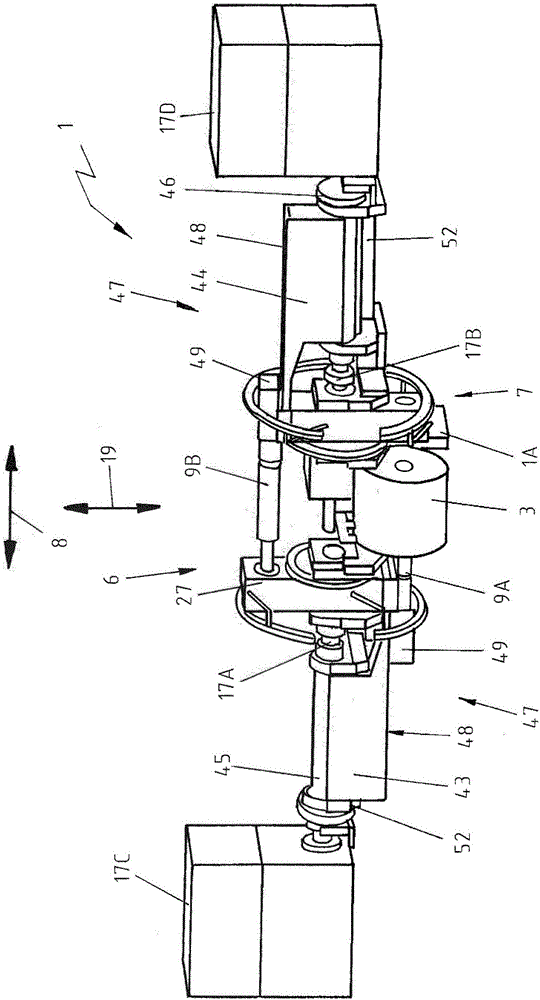

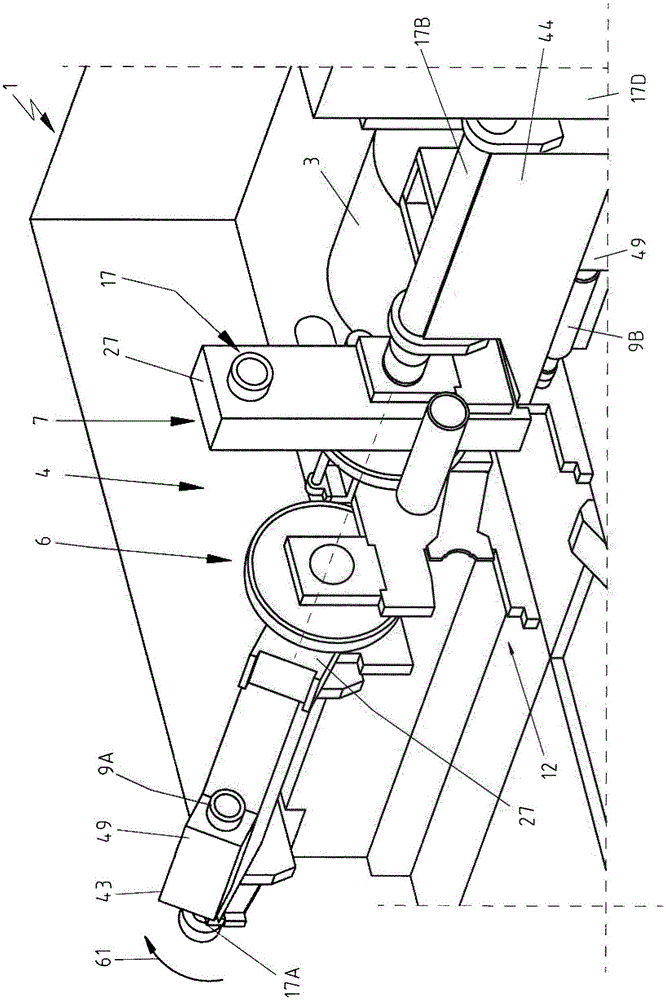

Device and method for winding a strip material

The invention relates to a device (1) for winding a strip material (2) into a coil (3), comprising a rotor winder (4), which comprises two rotor lateral parts (6, 7) that can be rotated about a common rotor axis (5), which rotor lateral parts are spaced apart from each other in the axial direction (8) of the rotor axis (5) in such a way that rotationally driven winder mandrels (9) can be retained between the rotor lateral parts, wherein the device (1) comprises, outside of the rotor winder (4), two rocker parts (43, 44) that can be rocked independently of each other, which are supported in such a way that the two rocker parts can be pivoted in relation to the two rotor lateral parts (6, 7), wherein each of the rocker parts (43, 44) comprises an axial displacement apparatus (47), by means of which the winder mandrel (9A, 9B) retained on the rocker part (43, 44) can be displaced in the axial direction (8).

Owner:SMS GRP GMBH

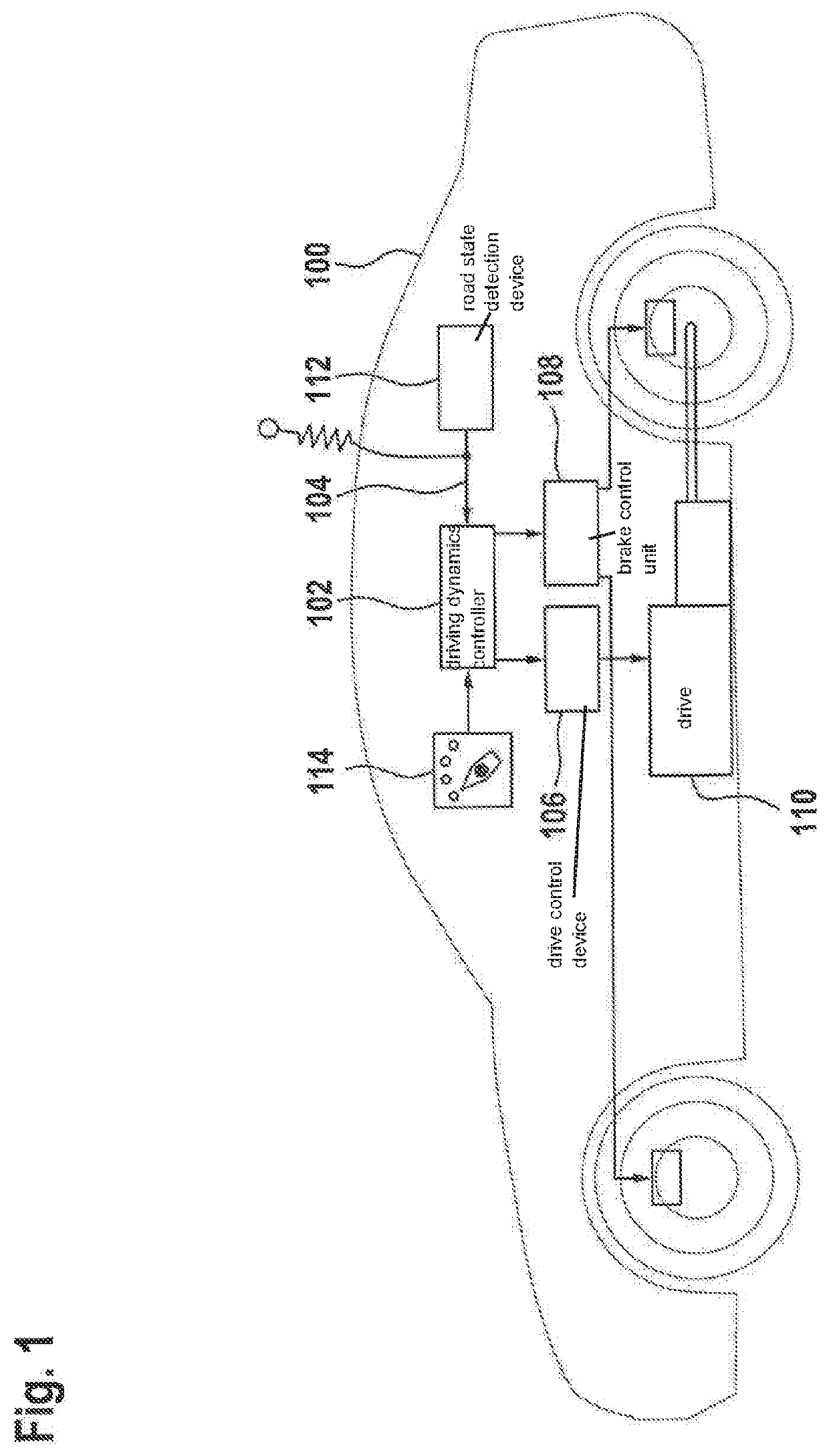

Method for Influencing Driving Dynamics of a Vehicle, and Driving Dynamics Controller

ActiveUS20200114903A1Increase drive torqueAvoid lostExternal condition input parametersControl engineeringComputer science

Owner:ROBERT BOSCH GMBH

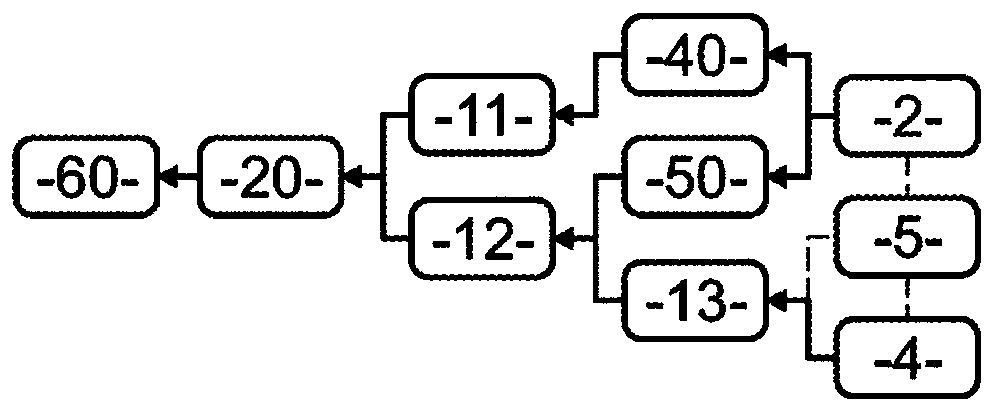

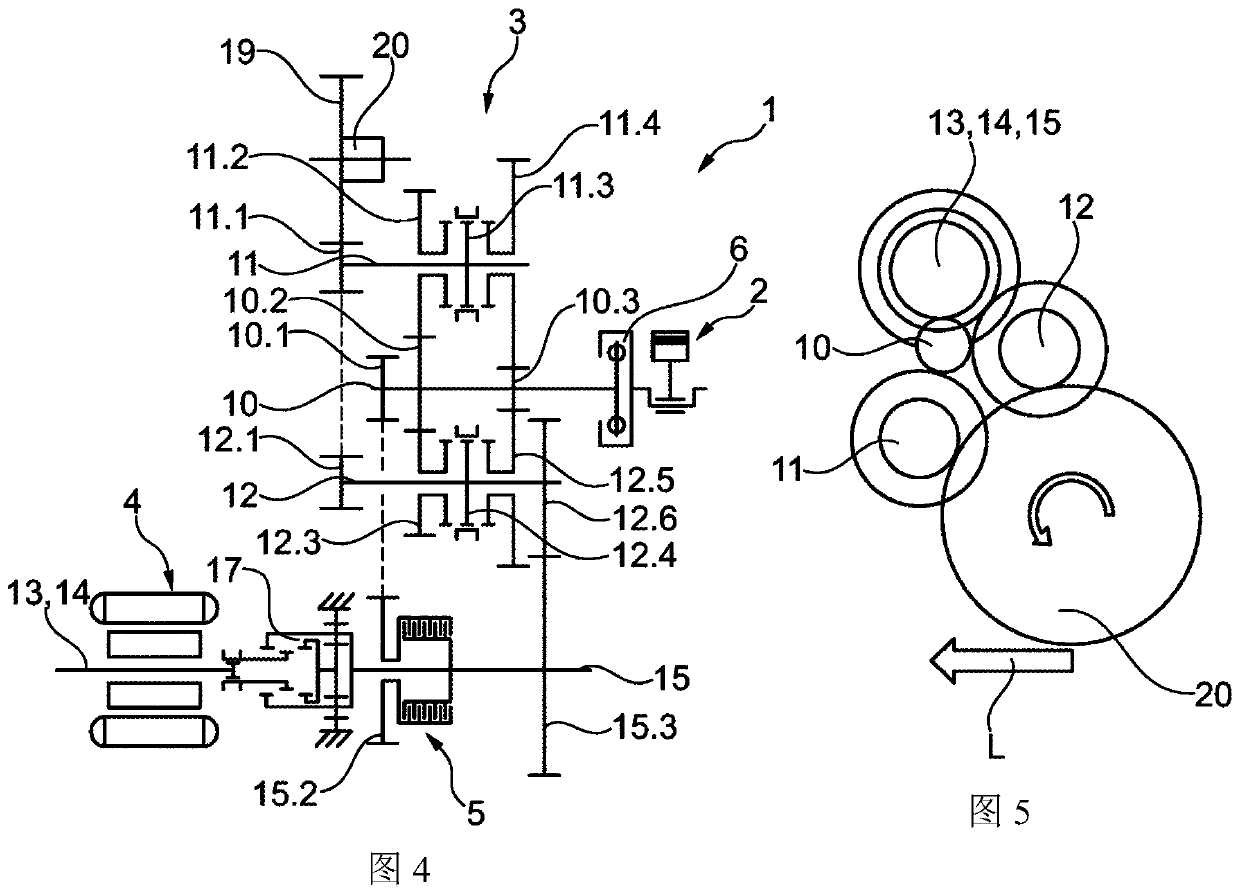

Drive train for a motor vehicle, and method for operating a drive train

The invention relates to a drive train for a motor vehicle, having an internal combustion engine (2), having an automated change-speed transmission (3), having an electric machine (4) with a switchable separating clutch (5) for selectively making a power flow possible between the electric machine (4) and the internal combustion engine (2), and having a differential gear mechanism (20), wherein theinternal combustion engine (2) has an output shaft (2.1) which is coupled without a separating clutch to a first transmission input shaft (10) of the automated change-speed transmission (3), whereinthe automated change-speed transmission (3) has a first transmission output shaft (11) and a second transmission output shaft (12) which are operatively connected to a differential drive gear (19) ofthe differential gear mechanism (20), wherein the separating clutch (5) is arranged coaxially with respect to a clutch shaft (15) which is connected to the separating clutch (5) and is arranged spacedapart in parallel from the first transmission input shaft (10), wherein the clutch shaft (15) is arranged spaced apart in parallel from the first transmission output shaft (11) and the second transmission output shaft (12).

Owner:SCHAEFFLER ENG

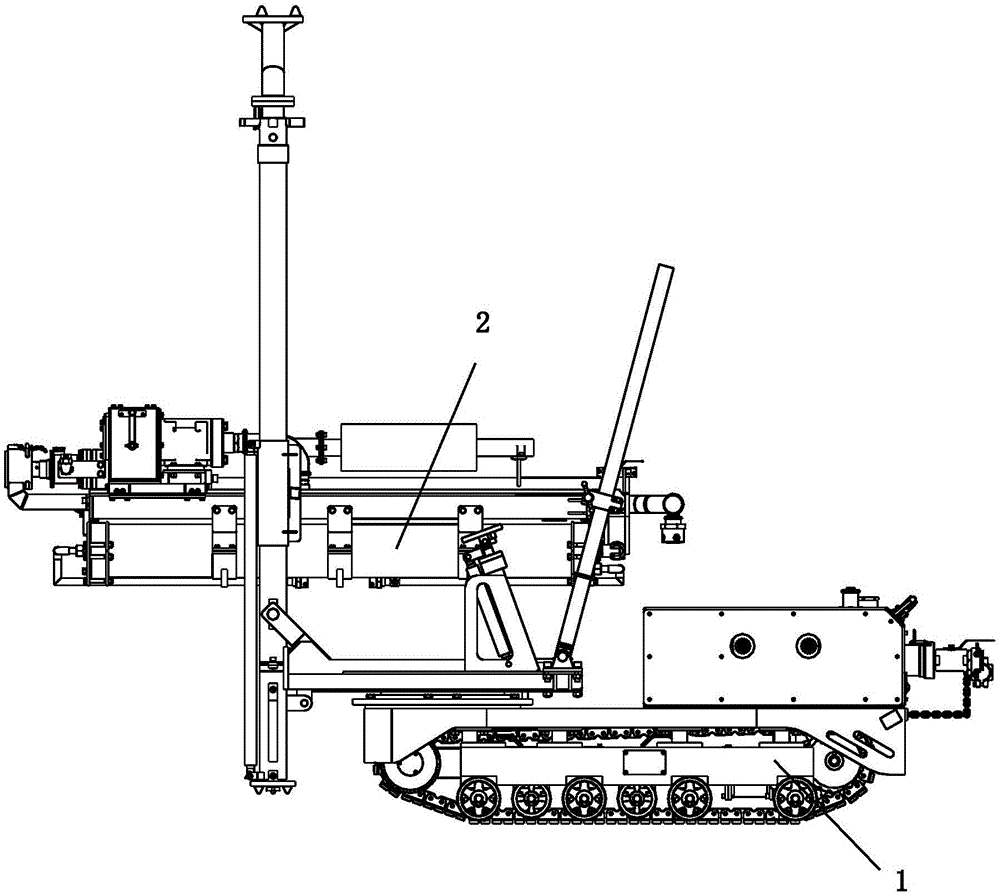

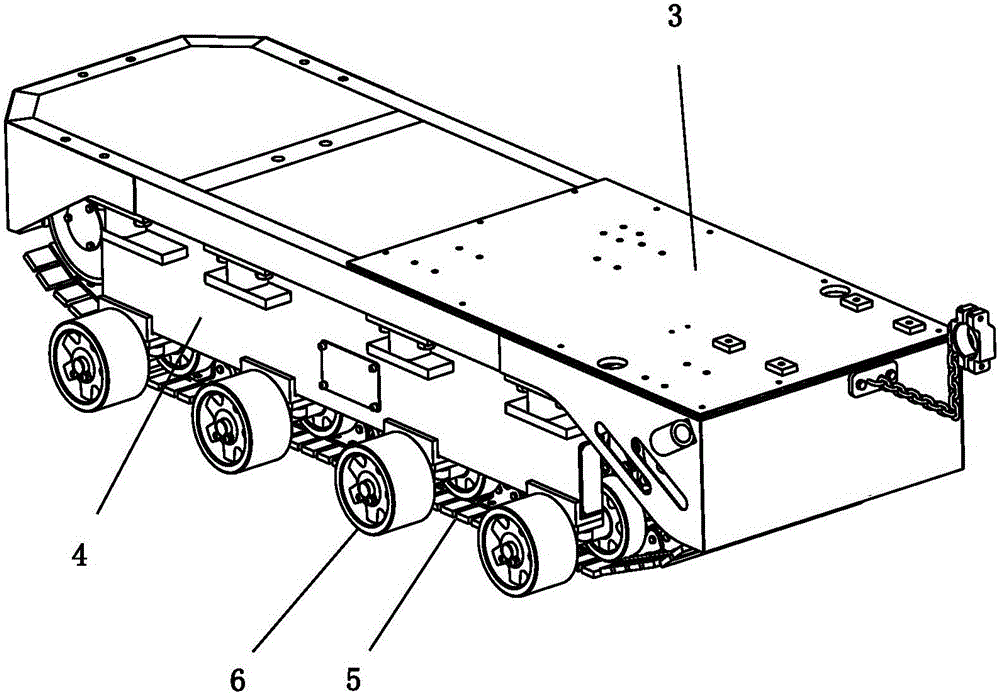

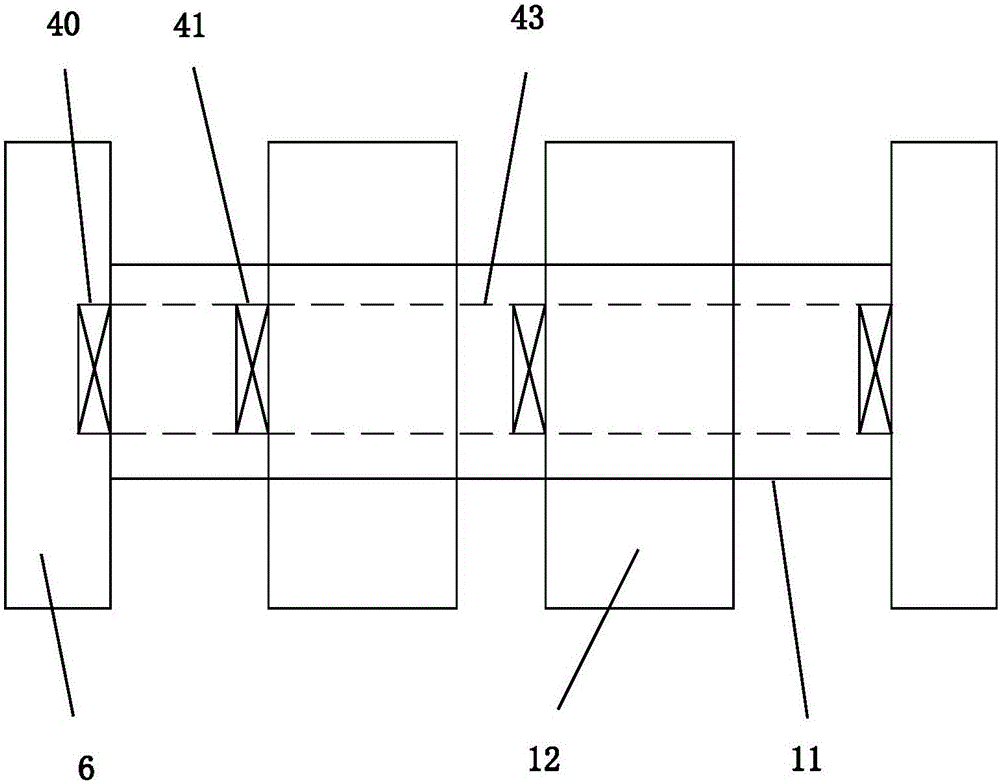

Improved single-track pneumatic drill carriage device

ActiveCN106005069ANarrow widthImprove performancePropulsion partsEndless track vehiclesEngineeringDrill

The invention discloses an improved single-track pneumatic drill carriage device. The improved single-track pneumatic drill carriage device comprises a drill carriage chassis. A drilling actuating mechanism is arranged on the drill carriage chassis. The drill carriage chassis comprises a frame, a track frame is arranged on the frame and sleeved with the track, and thrust wheels are arranged on the inner side of the track; the drilling actuating mechanism comprises a guide rail, a rotary mechanism is arranged on the guide rail, the guide rail is fixed to a boosting air cylinder, and a silencer is arranged at the exhaust end of the rotary mechanism. The defects in the prior art can be overcome, and the improved single-track pneumatic drill carriage device is suitable for operation in a narrow roadway.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com