Rotary piston engine

一种旋转活塞、发动机的技术,应用在内燃活塞发动机、燃烧发动机、机器/发动机等方向,能够解决不涉及、产生燃料混合物导出废气、难运动过程精确控制等问题,达到增大泵功率、提高驱动力矩的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

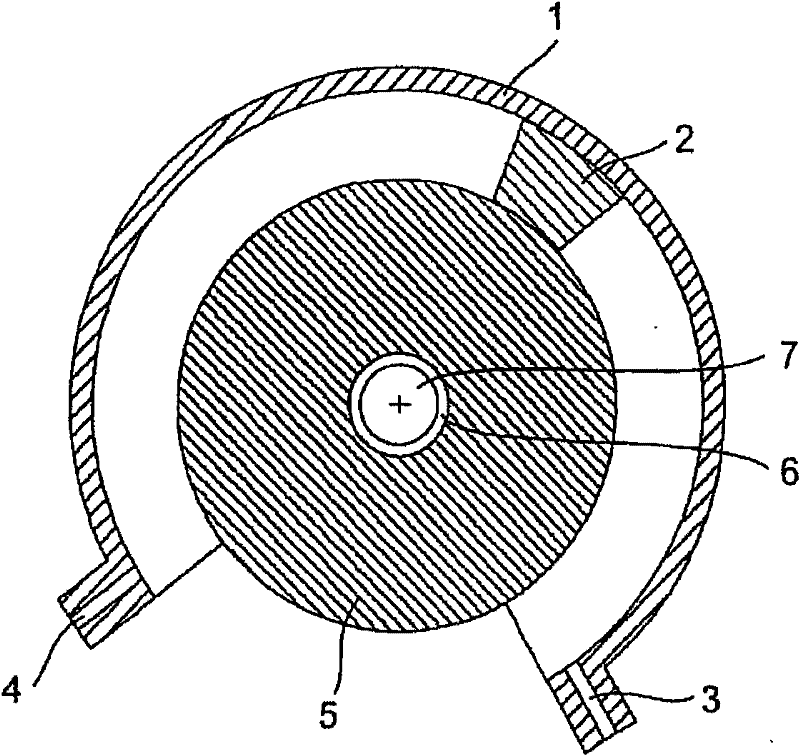

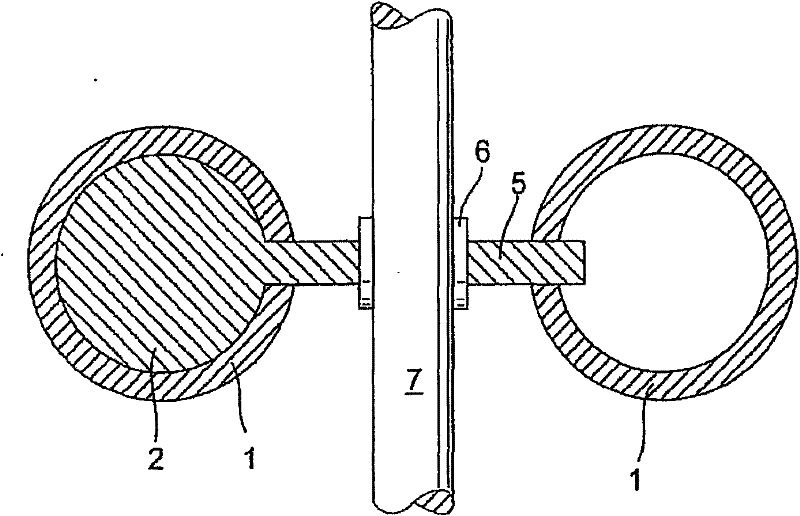

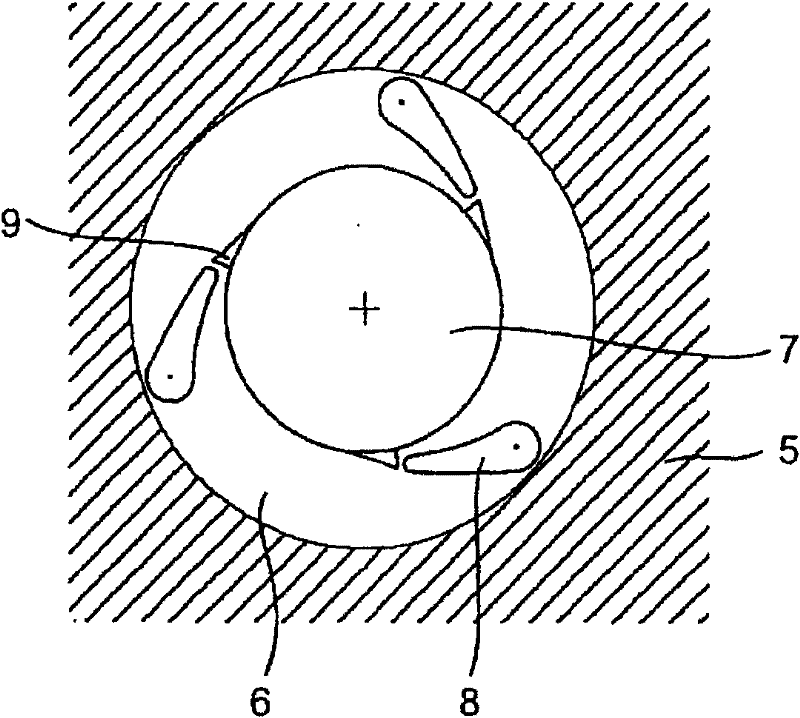

[0039] figure 1 A schematic illustration of a section through a rotary piston engine perpendicular to a rotating body in the form of an axis 7 is shown. The piston 2 is guided in an annular channel 1 extending along a subcircle at an angle greater than 180° (for example a circular cylinder) and the movement of the piston is guided through the sleeve by means of a lever 5, for example designed as a circular disc 6 is transferred to axis 7.

[0040] The piston 2 is moved, for example, as a drive element by pumping in a preferably incompressible fluid via the corresponding fluid connection 3 or 4 or by discharging the fluid via the other fluid connection 4 or 3 . On the shaft 7 is provided a sleeve 6 for connection between the lever 5 and the shaft 7, which can be designed in various forms, for example, for transmitting torque to the shaft 7 in one direction and idling in the other direction or with to transmit torque in both directions. Considerable angular ranges (for examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com