Drive for a conveyor, in particular a baggage conveyor at an airport facility

A driving device and conveyor technology, which is applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of large extrusion force, wear, and increased deflection radius of the transmission belt, and achieve the advantages of avoiding wear, low price, and simplified drive unit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

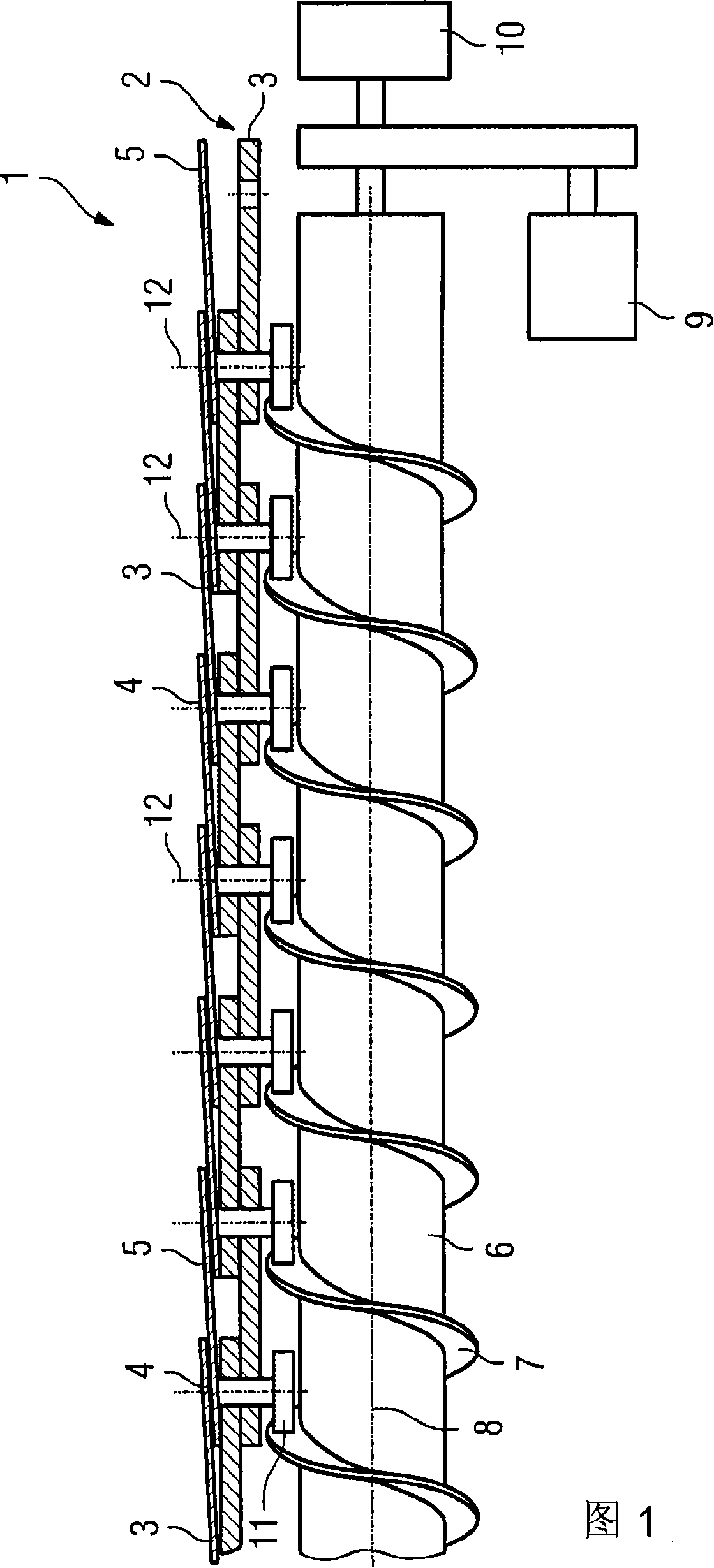

[0018] The drive of the baggage conveyor is designated overall with 1 . Designated overall at 2 is a traction chain consisting of individual chain links 3 which are connected to each other by means of joint bolts 4 . The swing bolt 4 allows the deflection of the drag chain in a horizontal plane, ie perpendicular to the plane shown. Plate-shaped brackets, shown schematically at 5 , are attached to the traction chain 2 , which overlap each other and provide a scale-like support surface for aircraft luggage (not shown) lying flat thereon.

[0019] The vertically oriented swing bolt 4 extends downwards and serves as a support for a driver which is designed as a roller 6 and is mounted coaxially for rotation about the longitudinal axis 12 of the swing bolt 4 . Arranged below the traction chain 2 is a helically toothed worm 6 according to the invention, the longitudinal axis 8 of which extends parallel to the direction of movement of the traction chain 2 . The worm is designed as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com