Device and method for winding a strip material

A strip and equipment technology, applied in the field of equipment and methods for coiling strip materials, can solve the problems of expensive, structural limitations, etc., and achieve the effects of simple structure, good force and moment, and high strip tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

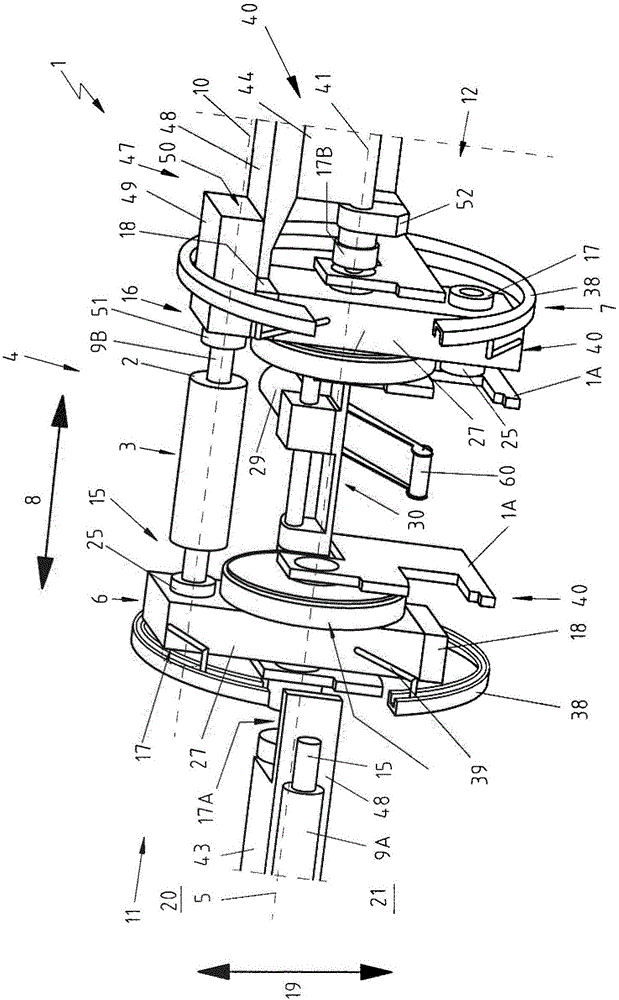

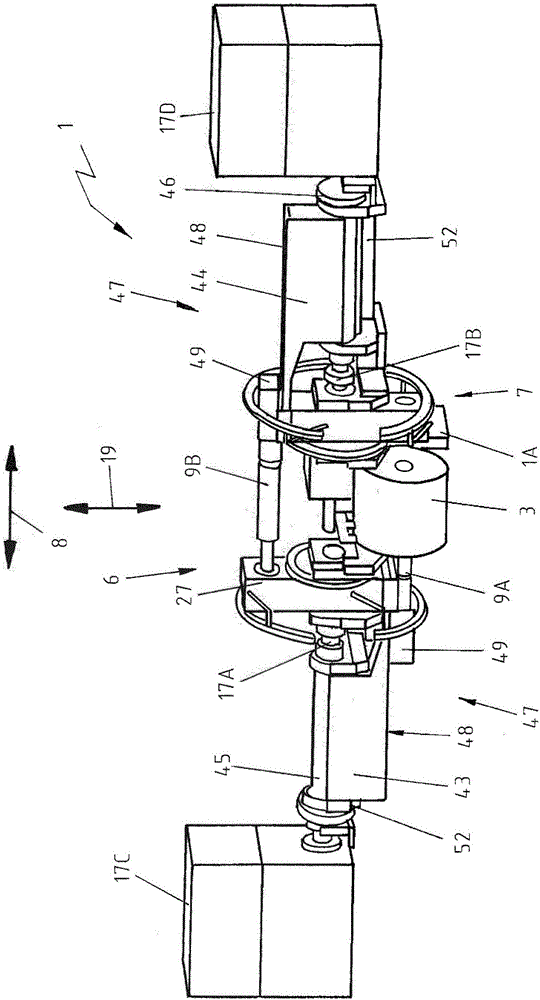

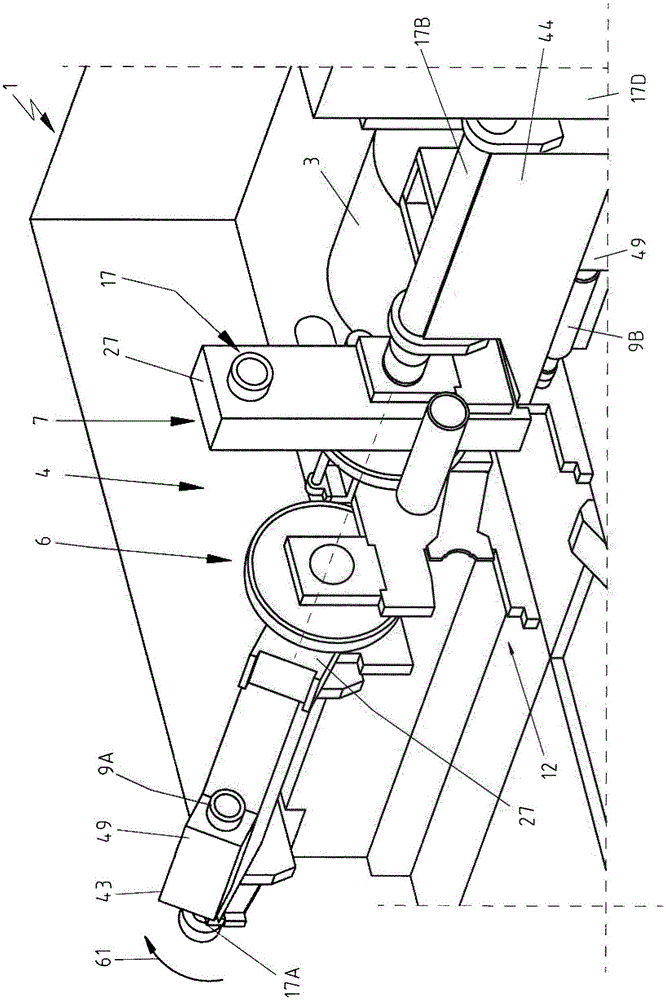

[0101] exist Figure 1 to Figure 14 A first embodiment of a device 1 for coiling a strip material 2 into a coil 3 according to the invention and its working principle are shown and described by way of example in figure 1 and figure 2 The illustration in , mainly explains the structural configuration of the device 1 in relation to the first functional relationship. Followed by Figure 3 to Figure 14 The schematic diagram of again elaborates the feasible method flow.

[0102] exist Figure 1 to Figure 14 The apparatus 1 for coiling a strip material 2 into a coil 3 shown in FIG. 2 has a rotor coiler 4 comprising two rotor side parts 6 and 7 rotatable about a common rotor axis 5 .

[0103] The rotor coiler 4 is mounted rotatably in a frame 1A of the device 1 , wherein the device 1 is fixed by means of the frame 1A on a base not shown here.

[0104] The two rotor-side parts 6 and 7 are arranged axially spaced apart from one another in the axial direction 8 of the rotor axis 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com