Improved single-track pneumatic drill carriage device

A drilling rig and crawler technology, which is applied in the field of improved single-track pneumatic drilling rigs, can solve problems affecting the normal operation of electric drilling rigs or hydraulic drilling rigs, double-track drilling rigs cannot pass smoothly, and complex and harsh environments. Kinetic energy conversion efficiency, superior performance, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, no longer described in detail here.

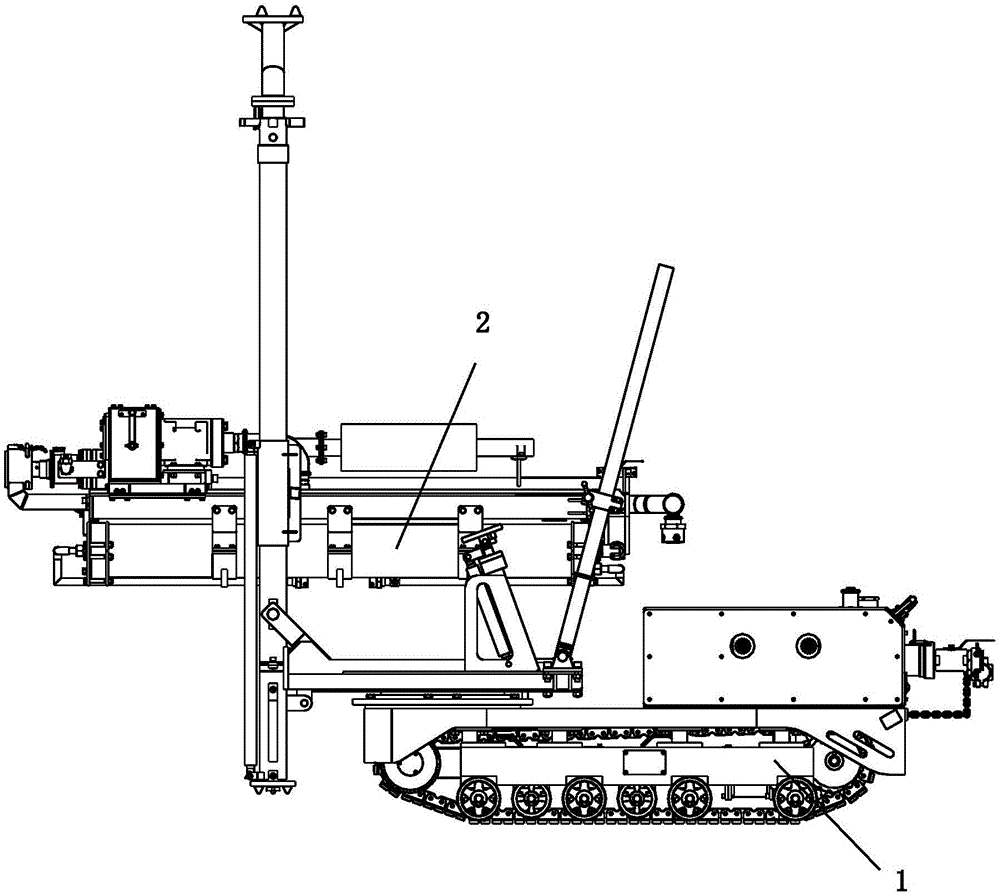

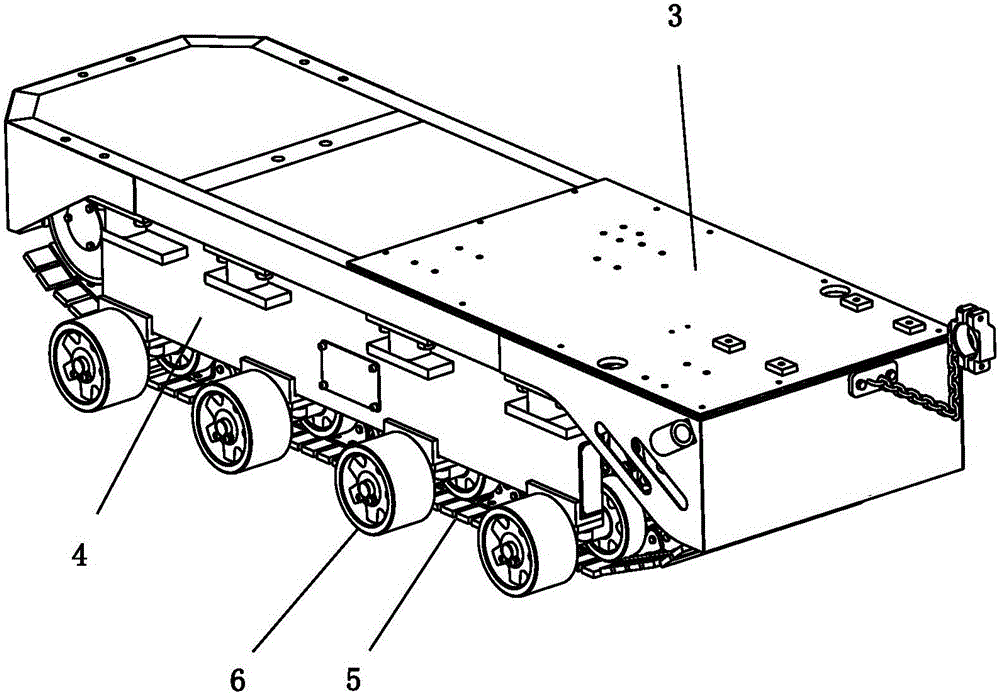

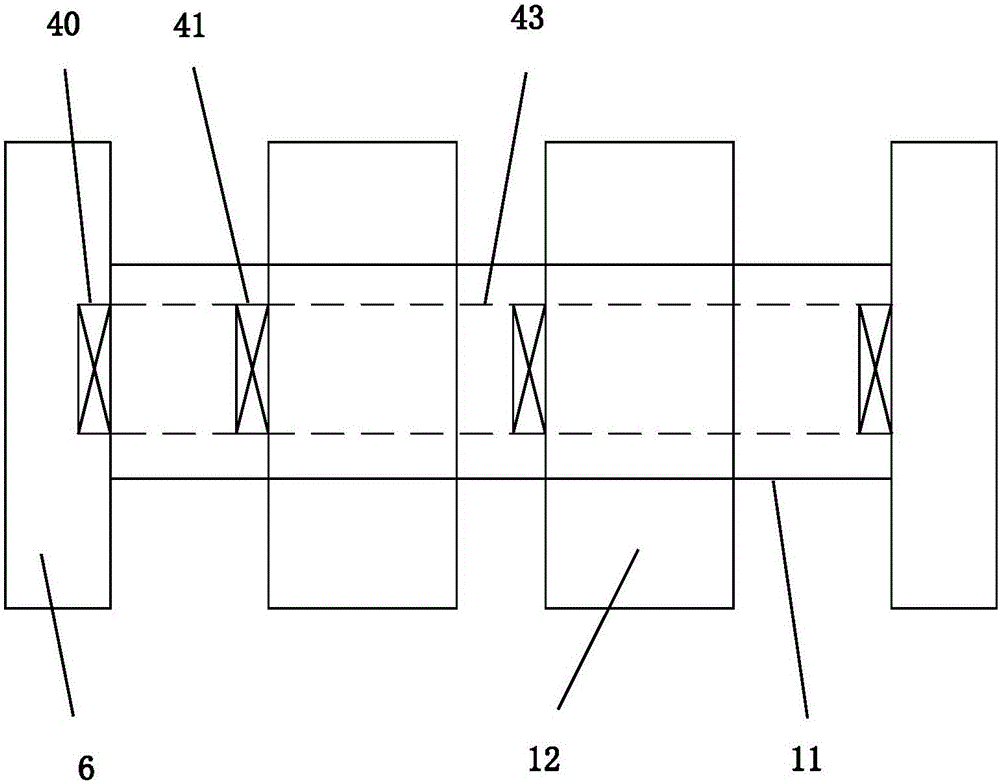

[0026] refer to Figure 1-10 , a specific embodiment of the present invention includes a drilling truck chassis 1, a drilling actuator 2 is arranged on the drilling truck chassis 1, and the drilling truck chassis 1 includes a vehicle frame 3, and a crawler frame 4 is arranged on the vehicle frame 3, and the outer side of the crawler frame 4 The crawler belt 5 is sleeved, and the inner side of the crawler belt 5 is provided with a supporting wheel 6; the drilling actuator 2 includes a guide rail 7, and a rotary mechanism 8 is arranged on the guide rail 7, and the guide rail 7 is fixed on the propulsion cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com