Automatic focusing optical lens module

An optical lens and auto-focus technology, applied in optics, optical components, installation, etc., can solve the problems of non-commercial value utilization, increase manufacturing processing, and precision processing of related components, achieve high industrial utilization value, and improve driving torque , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention are described below with reference to the accompanying drawings, so that those skilled in the art can easily understand the technical features and effects of the present invention.

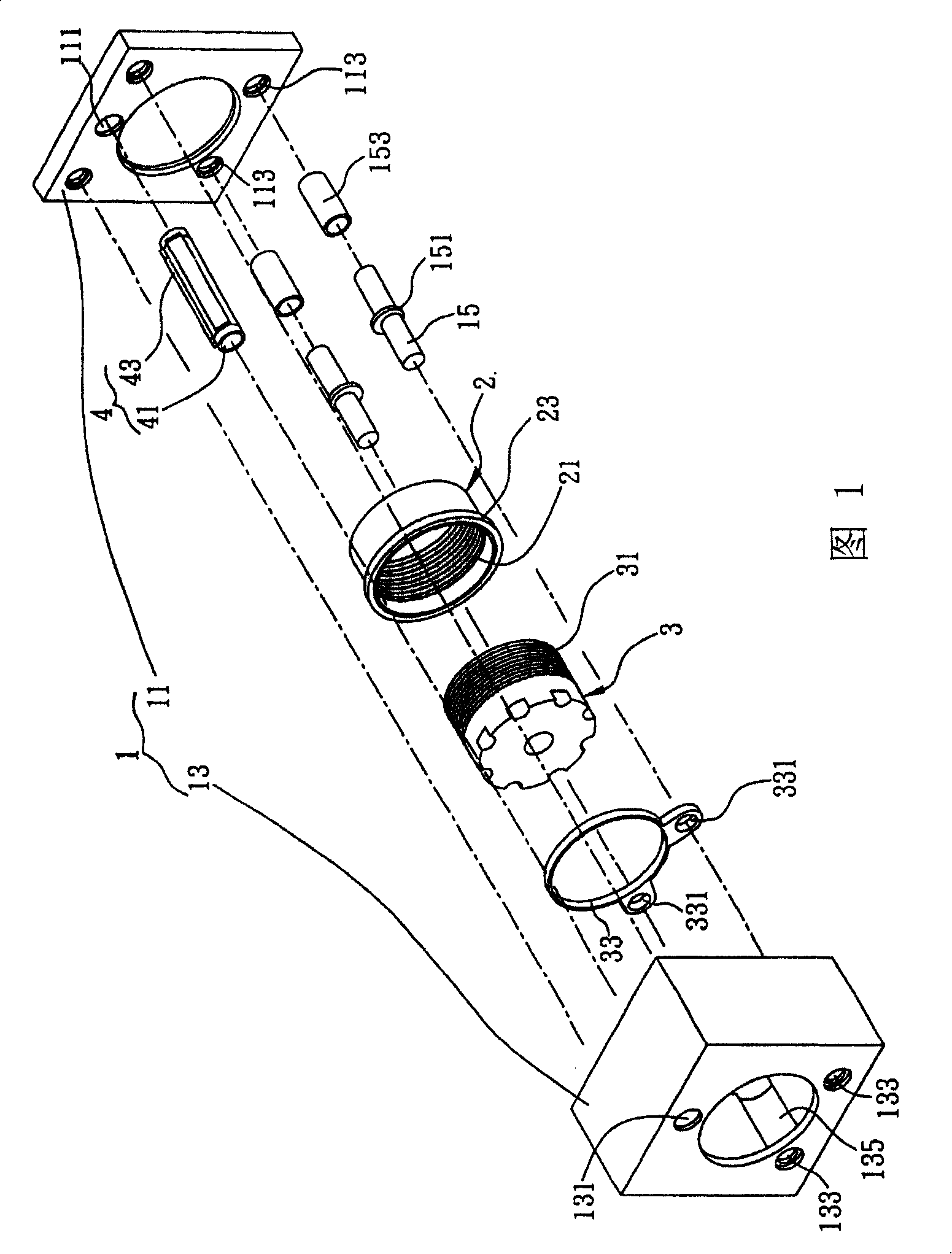

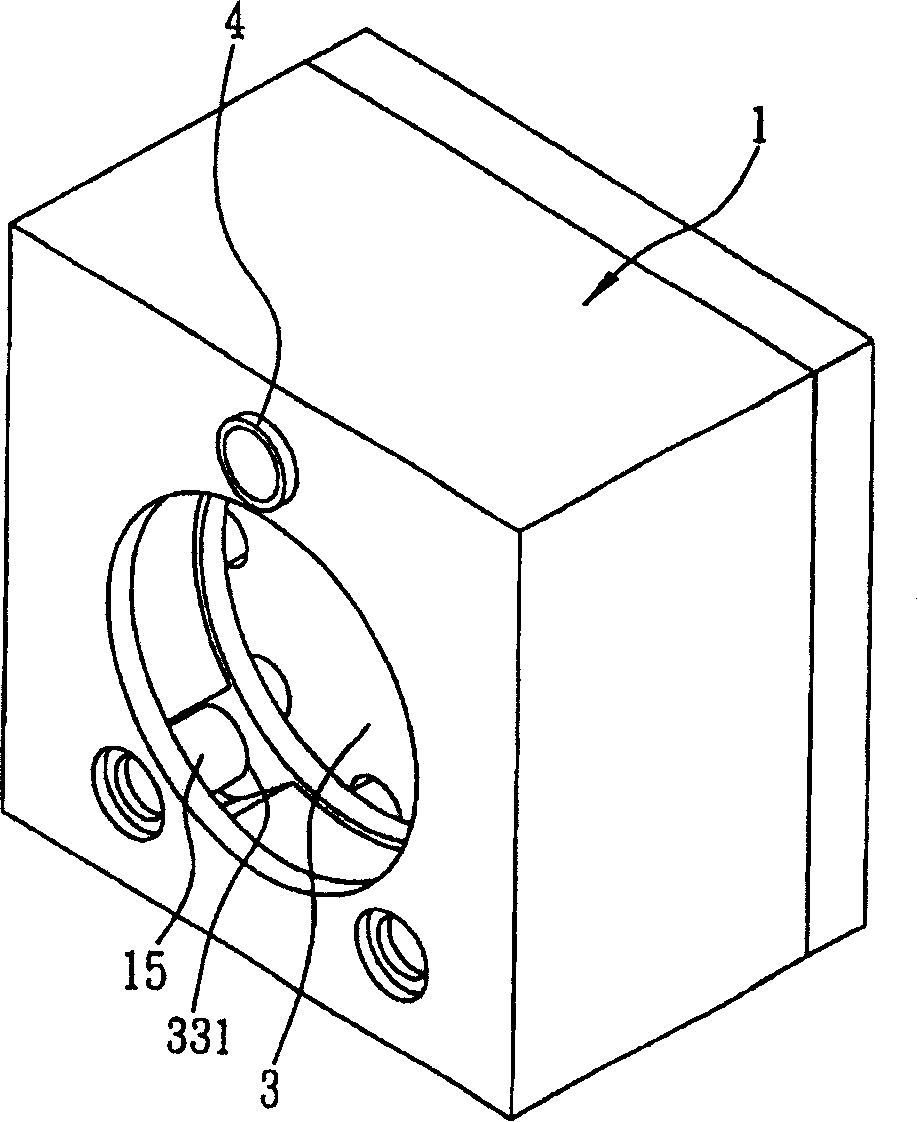

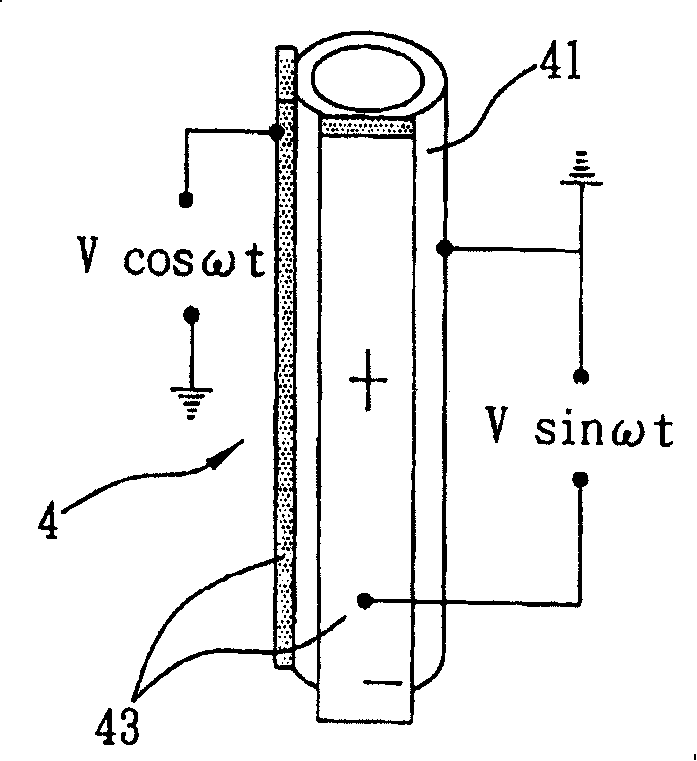

[0028] Figure 1 and figure 2 As shown, the present invention provides an auto-focus optical lens module, which includes a seat body 1 with an accommodation space, a sleeve 2 rotatably positioned in the accommodation space 1, a lens 3 screwed to the sleeve 2, and a piezoelectric component 4 fixed in the base body 1 for contacting and driving the rotation of the sleeve 2, the base body 1 and the lens 3 are respectively provided with a first guide part 15 and a second guide part for corresponding sliding positioning 331, so that the lens 3 can be converted and driven to focus by driving the sleeve 2 to rotate, so that the autofocus optical lens module with simple components improves the driving force and overcomes the shortcomings of complex co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com