Belt-tensioning device

A tensioning device, belt technology, applied in transmission, belt/chain/gear, transportation and packaging, etc., can solve problems such as stress of large parts, achieve long working life, compensate for pretension loss, and simple parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

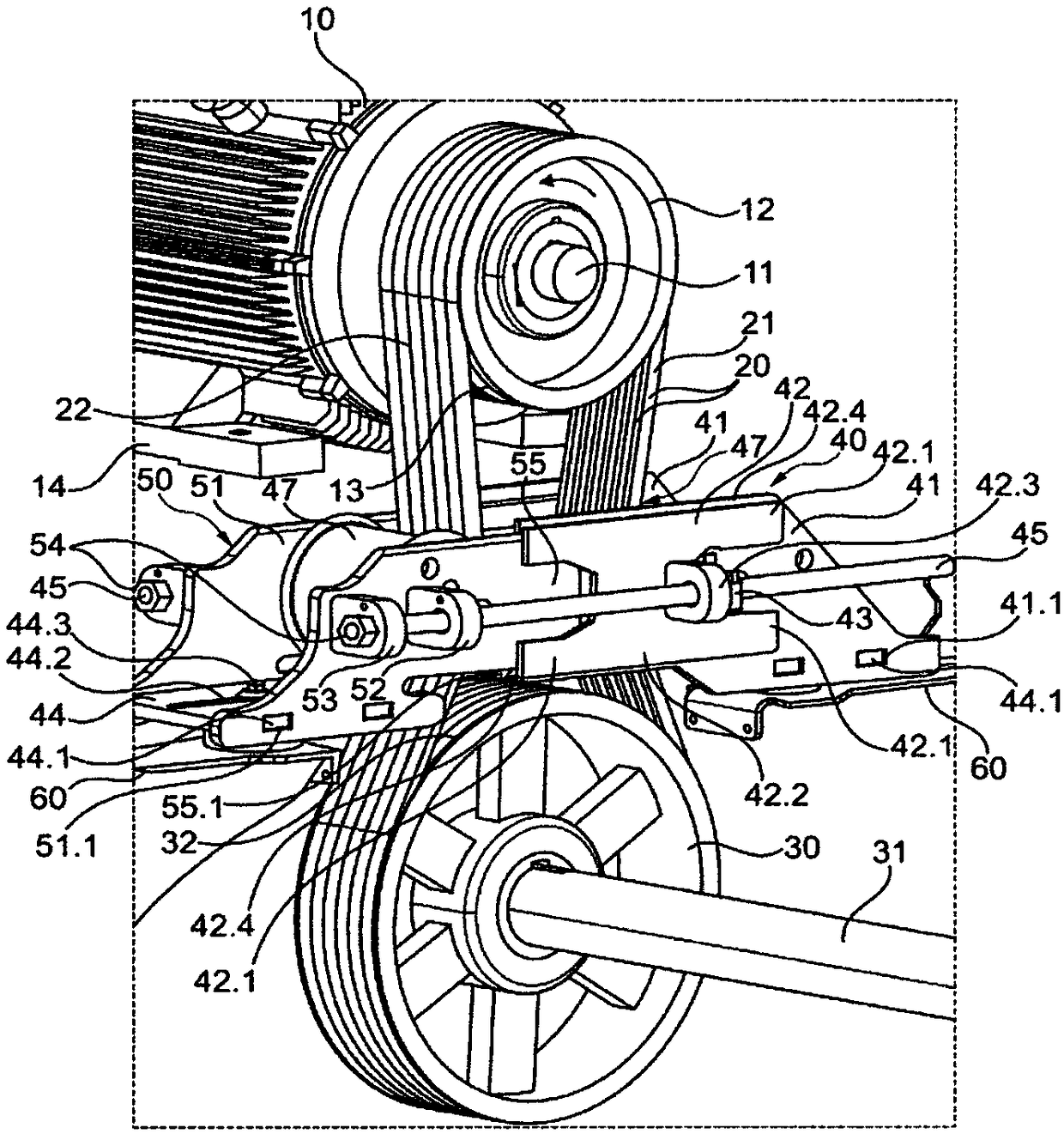

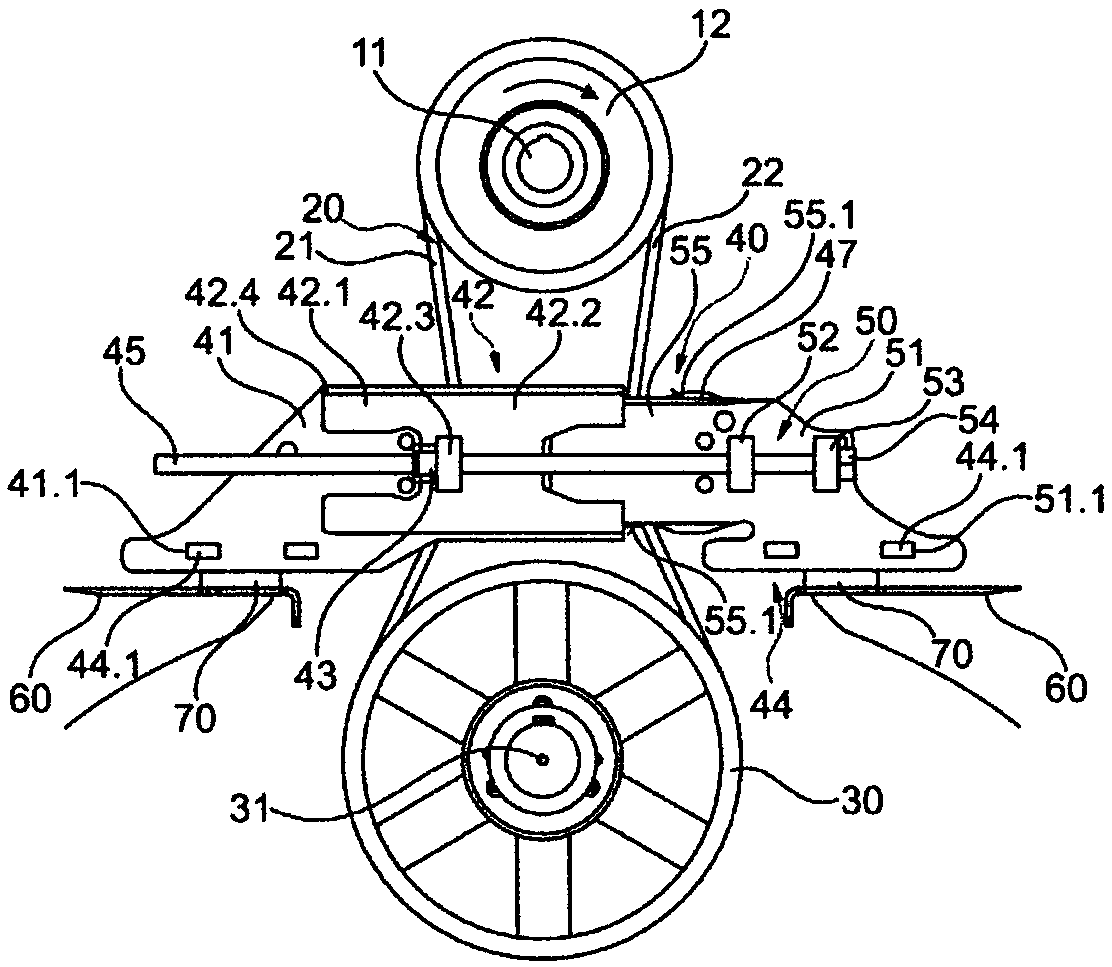

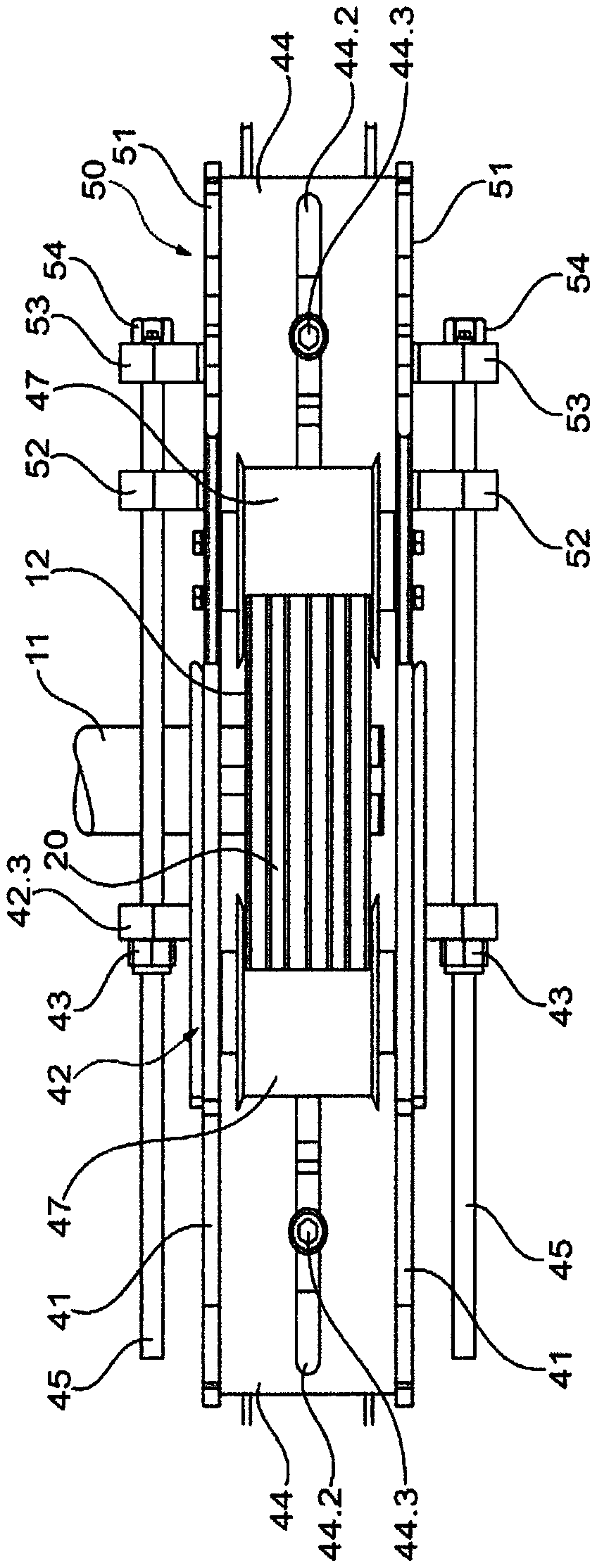

[0024] figure 1 A belt tensioner suitable for a rock crusher, in particular a cone crusher, is shown. In this case, a drive 10 in the present case as an electric motor is used. The electric motor is usually powered by a generator, which in turn is driven by the rock crusher's internal combustion engine. Alternatively, a direct drive via a switchable clutch is also conceivable. A pulley 12 is fastened in a non-rotatable manner to a transmission shaft 11 of the drive device 10 . The belt tensioner also includes a second pulley 30 coupled to the drive shaft 31 in a rotationally fixed manner. The drive shaft 31 leads to the crushing assembly of the rock crusher. The two pulleys 12 and 30 are coupled to each other by a drive belt 20 . In the present case, a plurality of individual drive belts 20 wound around the two pulleys 12 and 30 respectively are used. A belt tensioner is arranged between the two pulleys 12 and 30 . The belt tensioner here comprises two tension rollers 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com