Dual-motor driving device of electric automobile

A dual-motor drive, electric vehicle technology, applied to electric vehicles, electromechanical devices, power devices, etc., can solve problems such as insufficient power and large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

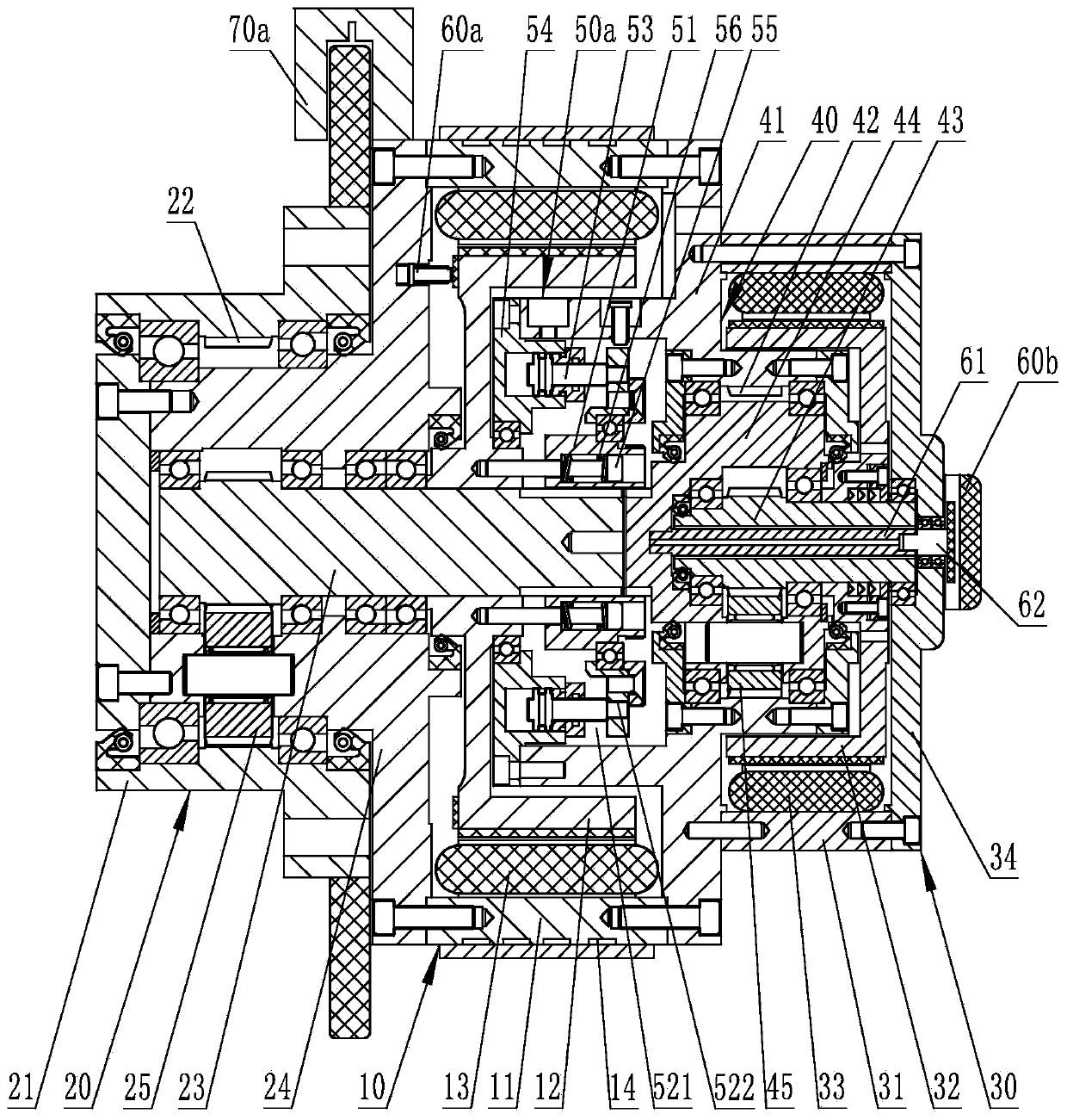

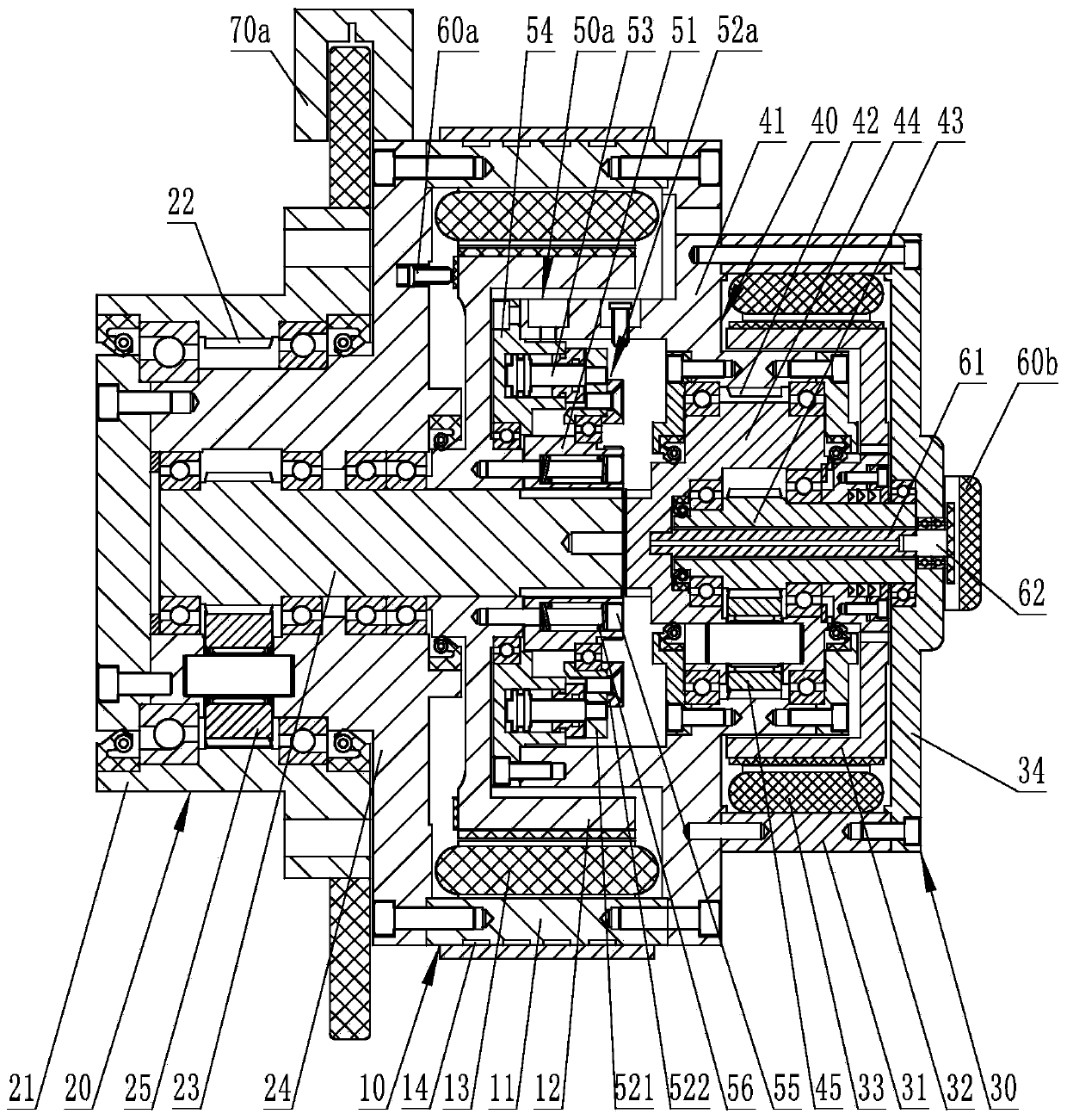

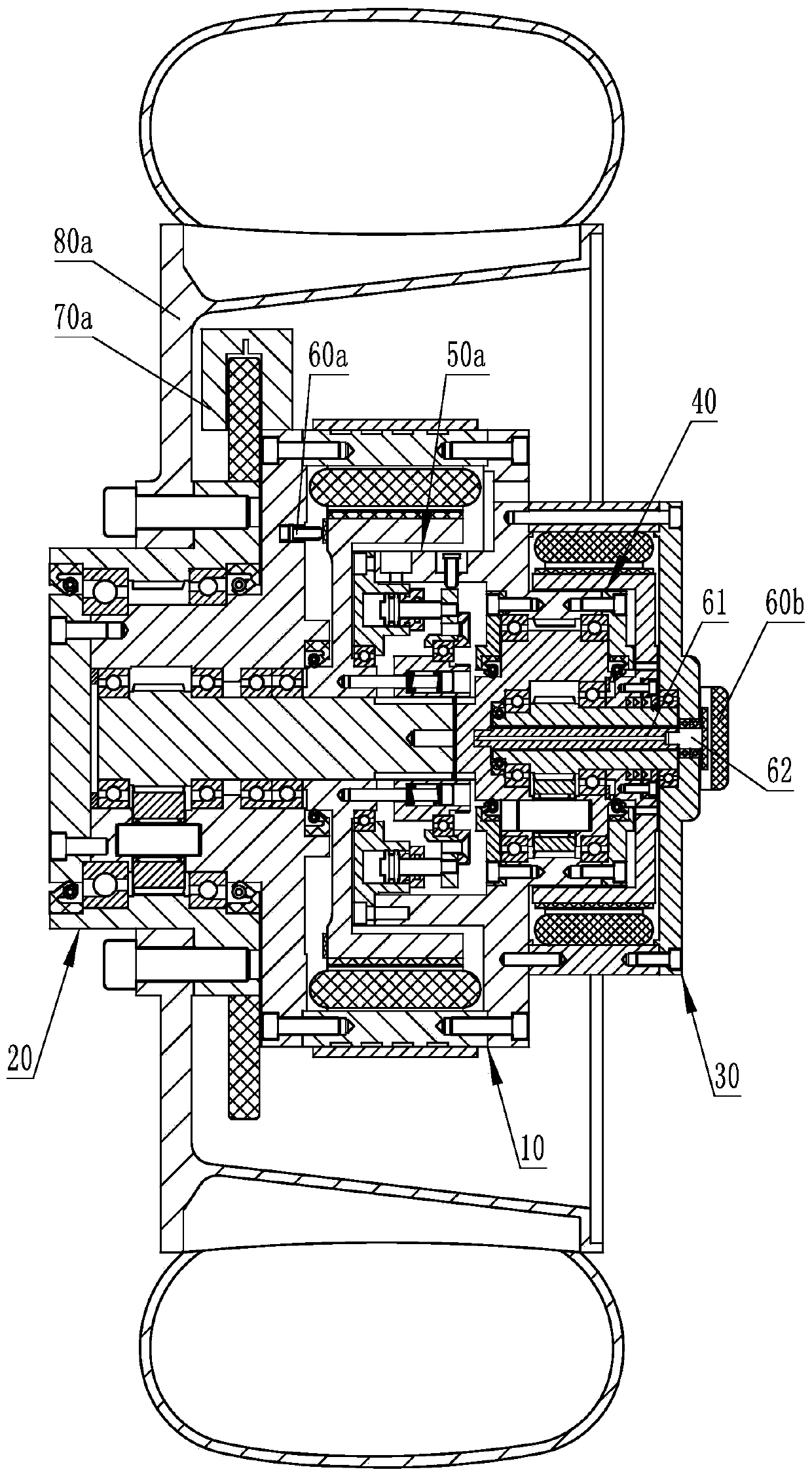

[0036] Depend on figure 1 , figure 2 and image 3 It can be seen that the dual-motor driving device for electric vehicles includes a first inner rotor motor 10, a first planetary reduction mechanism 20 arranged at one end of the first inner rotor motor 10, a second inner rotor mechanism 20 arranged at the other end of the first inner rotor motor 10, The rotor motor 30, and the second planetary reduction mechanism 40 arranged between the second inner rotor motor 30 and the first inner rotor motor 10;

[0037] The first inner rotor motor 10 includes a first stator 11, a first rotor 12 set together with the first stator 11, and a first coil magnet winding arranged between the first stator 11 and the first rotor 12. 13;

[0038] The first planetary reduction mechanism 20 includes a first sun gear shaft 23, a first sun gear arranged on the first sun gear shaft 23, and a first planetary gear fixedly connected to the first stator 11 and rotatably mounted on the first sun gear sha...

no. 2 example

[0052] Depend on Figure 4 It can be seen that this embodiment is basically the same as the first embodiment, the differences are:

[0053] The clutch mechanism is a hydraulic clutch 50c, the connection plate 52b of the hydraulic clutch 50c is an integral structure, and is installed together with the inner gear sleeve 51 through bearings, and the hydraulic clutch 50c is used to drive the connection plate 52b and the inner gear sleeve 51 to perform axial rotation. A plurality of moving oil cylinders 53 are arranged between the connecting plate 52b and the second housing 41. Usually, a second housing installation hole is respectively provided on the second housing 41 corresponding to each oil cylinder 53, and the corresponding oil cylinders 53 are fixed on the second housing. Two shell installation holes.

no. 3 example

[0055] Depend on Figure 5 and Figure 6 It can be seen that this embodiment is basically the same as the first embodiment, the differences are:

[0056] The clutch mechanism is an electromagnetic clutch 90. The electromagnetic clutch 90 includes a clutch housing 91, a driven plate 92, and a driving plate 93. The driving plate 93 is fixedly connected to the first sun gear shaft 23, and the driven plate 92 is connected to the second planetary wheel carrier 44. Fixedly connected, the driving plate 93 and the driven plate 92 are relatively rotatable anti-torque connections, and a slip ring 94 is provided on the second housing 41 to supply power to the coil of the electromagnetic clutch 90. The structure and principle of the electromagnetic clutch are those of ordinary skill in the art. Well-known, do not repeat them here.

[0057] During work, the rotation parameter of the first sun gear shaft 23 (referred to as the rotational speed of the first sun gear shaft 23 in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com