Walking piezoelectric rotary motor

A rotating motor and walking technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of low miniaturization, insufficient driving force, poor stability, etc. problems, to achieve the effect of low difficulty in miniaturization, compact structure, and large torsional displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

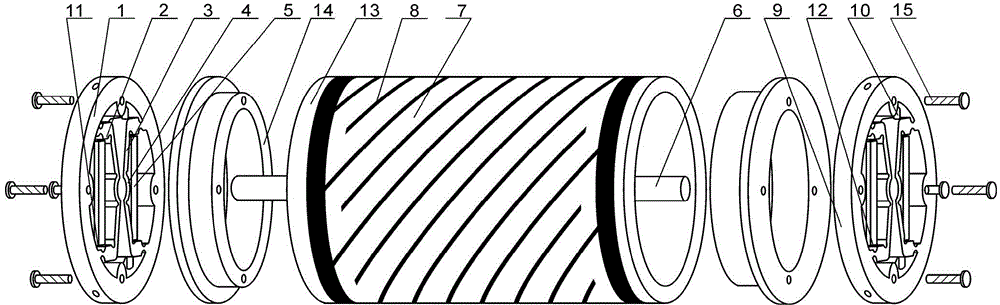

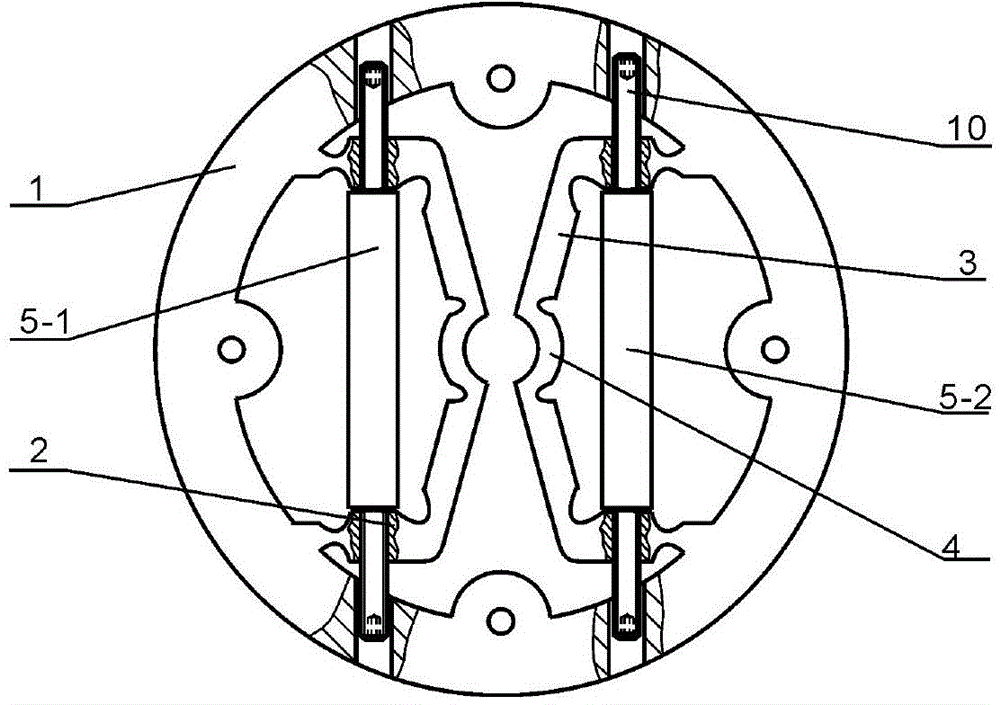

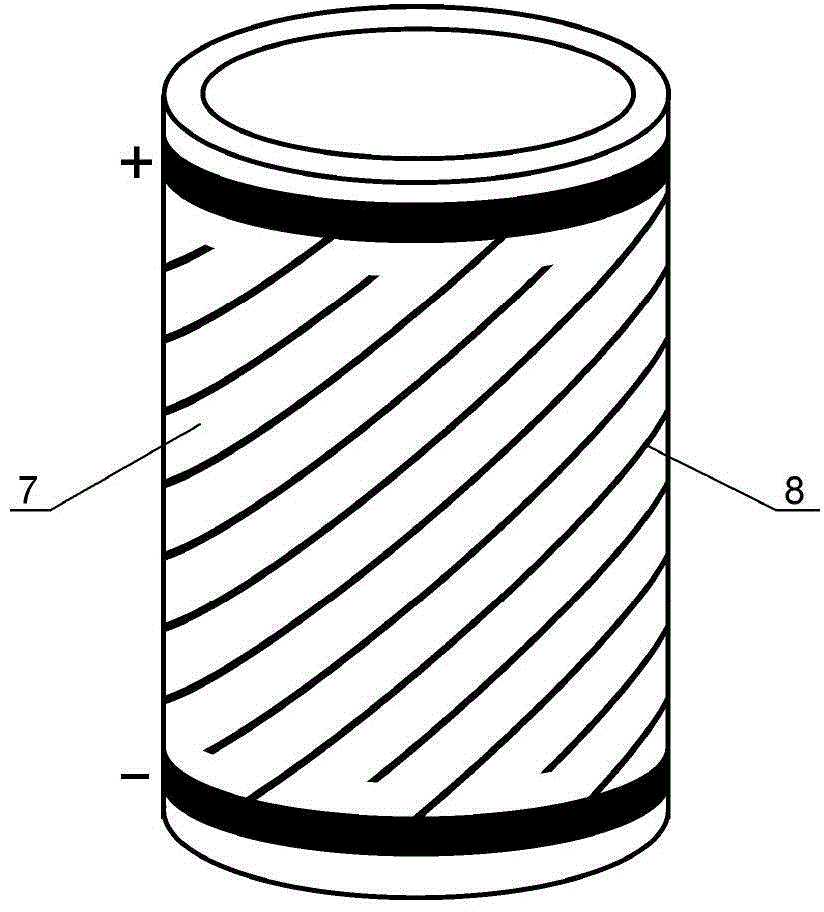

[0034] In this embodiment, the piezoelectric stack 5 is stretched and deformed under voltage driving, and the bearing ring 4 is driven to realize small movements such as clamping and loosening. By controlling the clamping and loosening timing of the piezoelectric stack 5 and the piezoelectric torsion driver 13 The timing of the torsional movement realizes the stepping movement of the rotary axis. Such as figure 1 and figure 2 As shown, the sleeve 14 is bonded to the piezoelectric torsion driver 13 through epoxy glue or AB glue, and the piezoelectric clamp bearing drive module 11 and the piezoelectric clamp bearing drive module 12 are connected to the sleeve 14 through screws 15, Therefore, the piezoelectric torsion driver 13 , the piezoelectric clamp bearing drive module 11 and the piezoelectric clamp bearing drive module 12 are closely connected. If the middle part of the piezoelectric torsion driver 13 is fixed, the stepping of the rotating shaft 6 is realized by controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com