High-power density electric vehicle motor

A high power density, electric vehicle technology, applied in electric vehicles, motors, electric components, etc., can solve the problems of not too high motor winding efficiency, reduced stator winding efficiency, complex winding shape, etc., to achieve compact structure and strong bearing capacity. , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

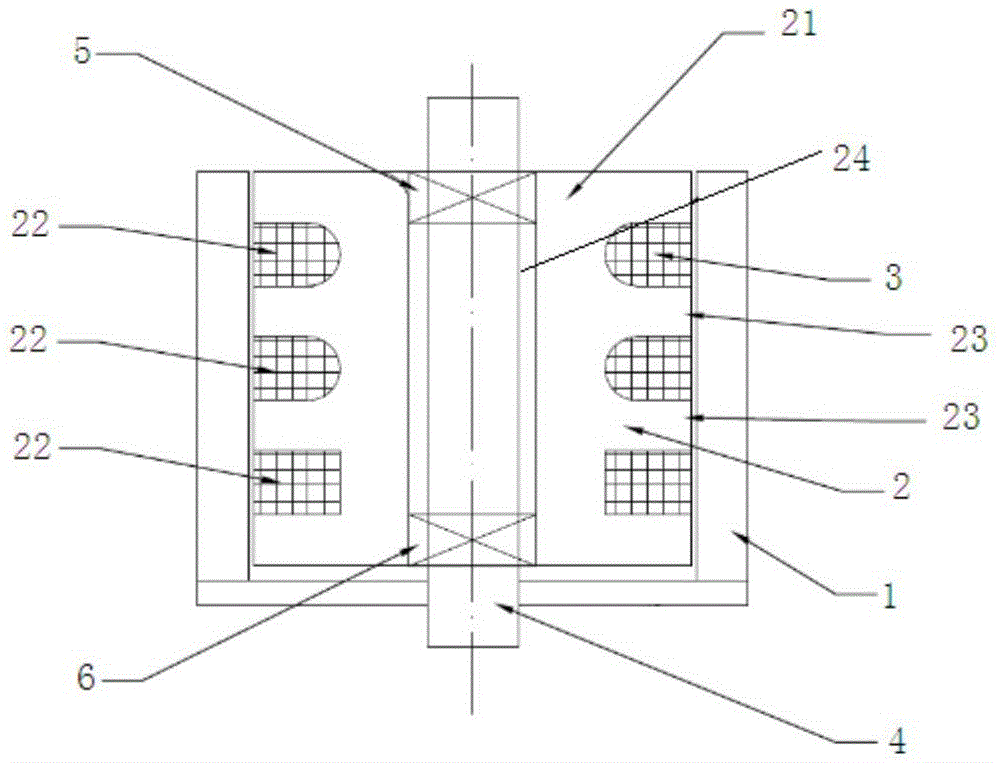

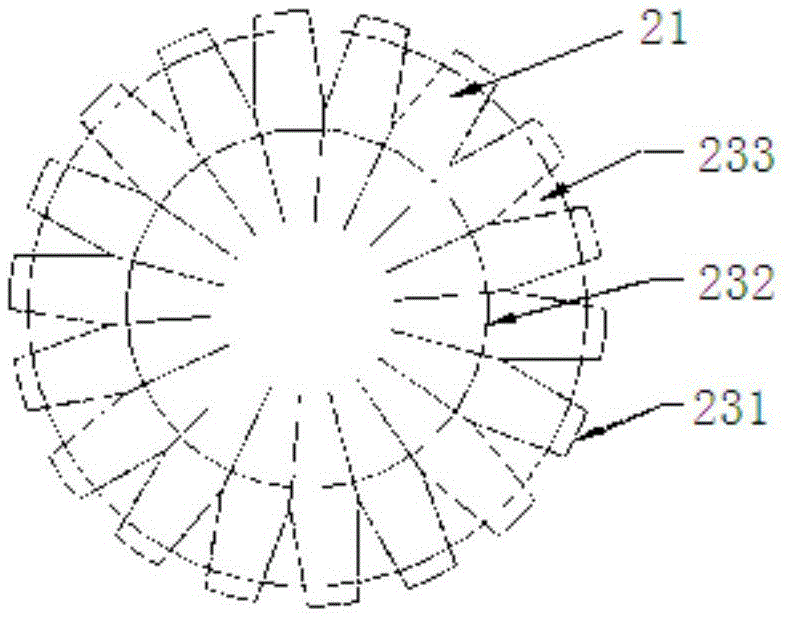

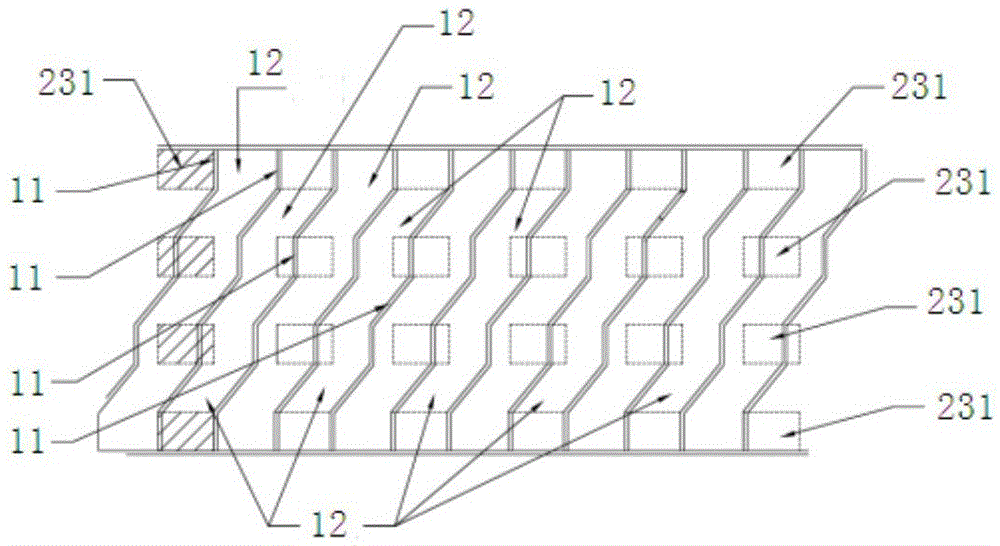

[0021] The present invention will be described in detail below in conjunction with accompanying drawing: Figures 1 to 3 As shown, the present invention is composed of a rotor 1 and a stator 2. The stator 2 is located in the rotor 1, and the circumferential area 21 of the stator 2 is provided with several stator slots 22 equally distributed up and down. The stator slots 22 An annular coil 3 is arranged inside; the area between the adjacent stator slots 22 is the magnetically permeable area 23, the magnetically permeable area 23 is composed of a magnetic pole 231, a winding slot bottom 232 and an annular winding 233, and the space between the magnetic pole 231 and the magnetic pole 231 It is distributed in a straight line to reduce the process difficulty of the stator magnetic circuit. The stator can adopt a winding structure of high magnetic permeability material, such as a relatively economical winding structure of single-oriented silicon steel sheet, which can reach a saturat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com