Improved optical fiber turbine flowmeter

An improved technology of a turbine flowmeter, which is applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, volume/mass flow generated by mechanical effects, etc. It can solve the problems of anti-pollution on the end face of the fiber optic probe, and improve the range ratio and measurement sensitivity, solving pollution prevention problems, and improving the effect of driving torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

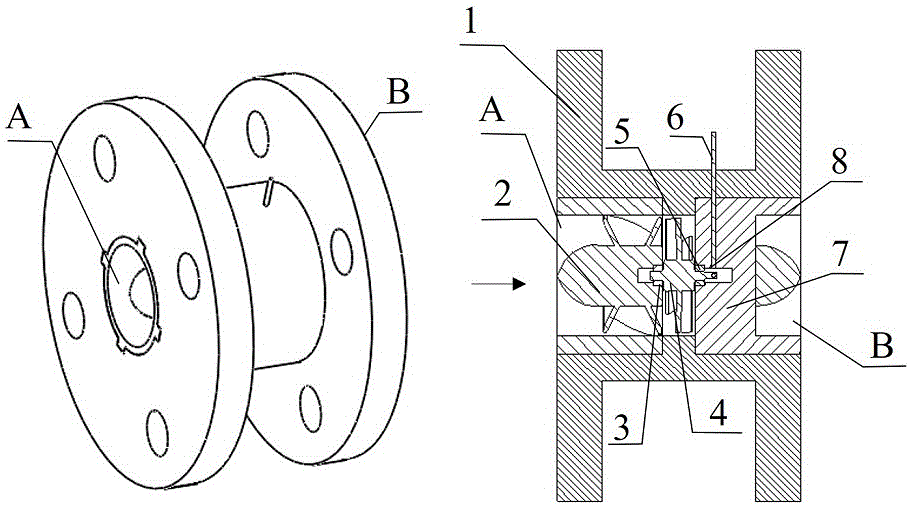

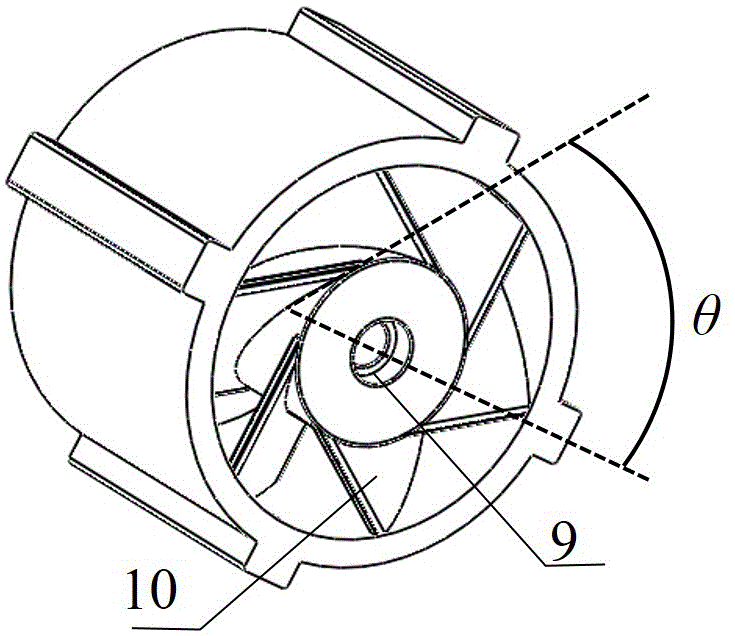

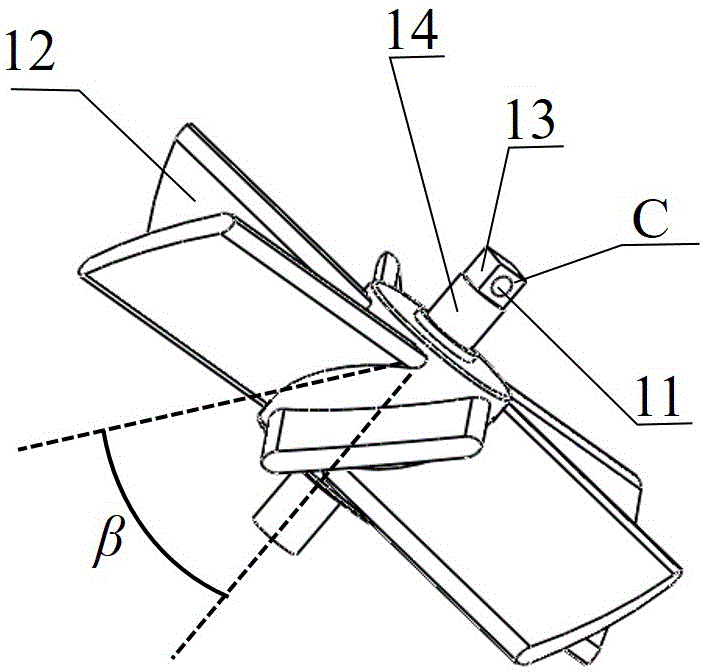

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific structure, principle and optimization process of the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an improved fiber optic turbine flowmeter includes a casing 1, a front guide element 2 placed in the casing 1, a front bearing 3, a rotating turbine 4, a rear bearing 5, an optical fiber 6, and a rear flow guide element 7. The front guide element 2 guides the fluid so that the fluid can act vertically on the rotating turbine blades 12 so that the rotating turbine 4 can obtain the maximum driving torque. The rear guide element 7 acts as a rectifier, reducing the impact of the rotating fluid passing through the rotating turbine 4 on the devices installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com