Self-tapping screw with sawtooth threads

A self-tapping screw and sawtooth thread technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of screw breakage, delayed breakage, and high driving torque requirements, so as to improve work efficiency and increase cutting function , The effect of improving the connection force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

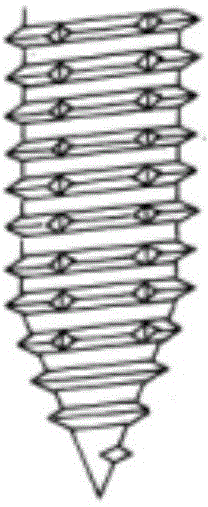

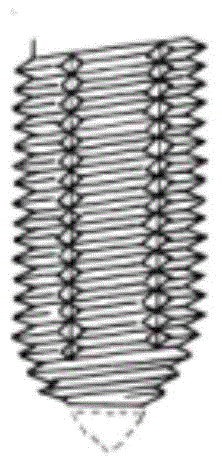

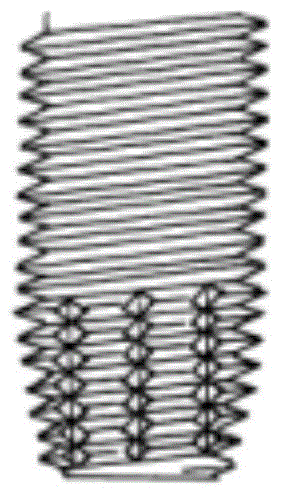

[0024] Such as Figure 1-5 As shown, the thread is provided with sawtooth 3, and the tooth shape includes full sawtooth, upper half sawtooth, lower half sawtooth, oblique sawtooth, and straight sawtooth of the thread.

[0025] image 3 , 4 , 5 is a self-tapping screw with sawtooth threads of the present invention, the threaded area 2 of the screw rod 1 is extended to reduce the outer diameter, and the end of the screw rod is a transitional threaded area, which is to reduce the outer diameter and extend the frustum or conical shape , the thread in the transition thread area is provided with at least 2-4 turns of thread or all threads are serrated threads. There are 5, 7, and 9 teeth on each turn of the thread in the transitional thread area, and the teeth are oblique or straight, and the thread tail can have two forms: flat tail or pointed tail.

[0026] The thread in the transitional thread zone will have 5 to 9 turns, which is the most common. The thread in the transition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com